Hydraulic double moving stretcher oil cylinder

A stretching machine and oil cylinder technology, which is applied in the field of hydraulic oil cylinders, can solve the problems of time-consuming disassembly and assembly, difficulty in precise adjustment, and increasing the height and size of the whole machine.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

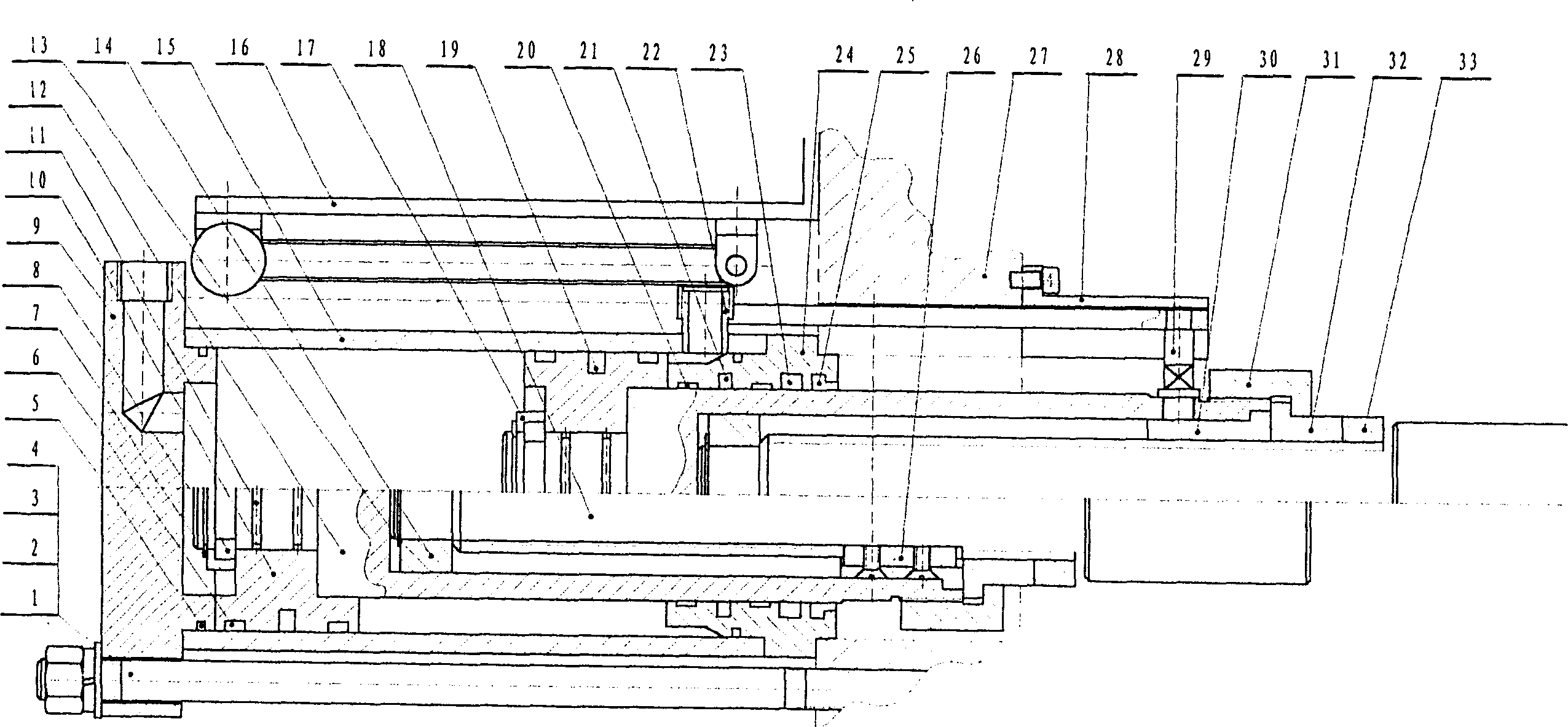

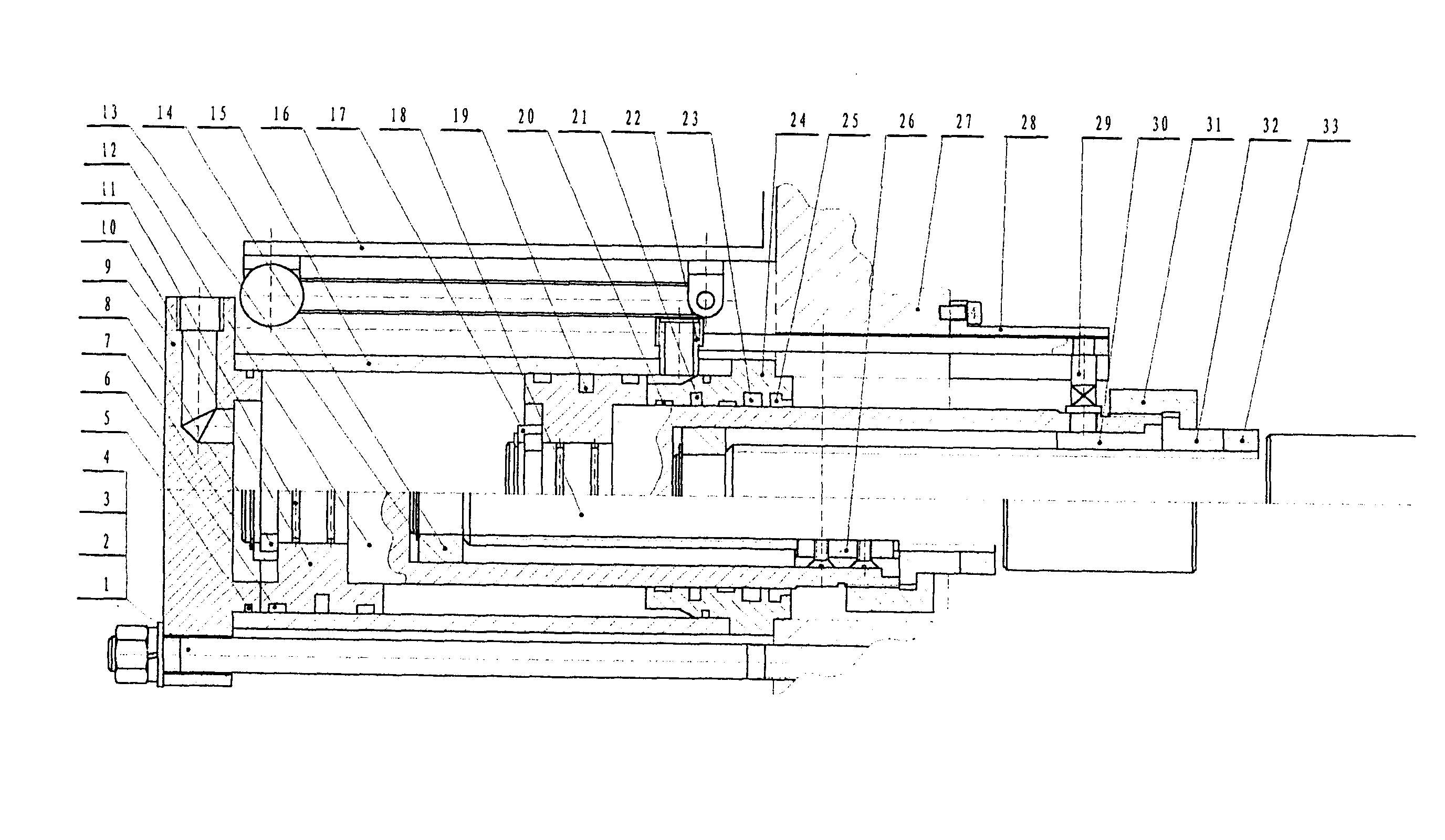

[0008] The structure of the oil cylinder on the hydraulic double-action stretching machine of this embodiment is as follows: figure 1 Shown, mainly by cylinder block 15, oil cylinder end cover 9, guide end cover 24, piston 10, piston rod 12 and center screw rod 18 form.

[0009] The upper and lower two ends of the cylinder block 15 are respectively connected with the guide end cover 24 and the oil cylinder end cover 8 with the stud bolt 4, the flat washer 2, the spring washer 3 and the nut 1. The oil cylinder end cover 9 is shaped on the upper oil delivery hole, and the cylinder body 15 is shaped on the lower oil delivery hole where the oil pipe joint 22 is installed. Piston 10 is housed in cylinder body 15 middle parts. The guide ring 6 and the combined seal 19 for the hole are inlaid on the piston 10, the O-ring seal 5 is inlaid on the shaft end where the piston rod 12 is connected with the piston 10, and the piston 10 is fixedly connected by the snap ring 8 and the shaft c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com