Stator core unit, stator, motor and wind generator unit

A technology for wind turbines and stator cores, which is applied in wind turbine combinations, wind turbines, wind energy power generation, etc., can solve the problems of long heat transfer path, large thermal resistance, and poor cooling effect of end windings, so as to improve cooling efficiency, The effect of reducing costs and reducing consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] Embodiments of the present invention will be described hereinafter with reference to the accompanying drawings, in which the same or similar reference numerals refer to the same or similar features. The following detailed description and accompanying drawings serve to illustrate by way of example the principles of the invention, and other features, objects and advantages of the invention will become apparent. It should be understood that the present invention is not limited to the preferred embodiments described, but that the scope of the present invention is defined by the claims.

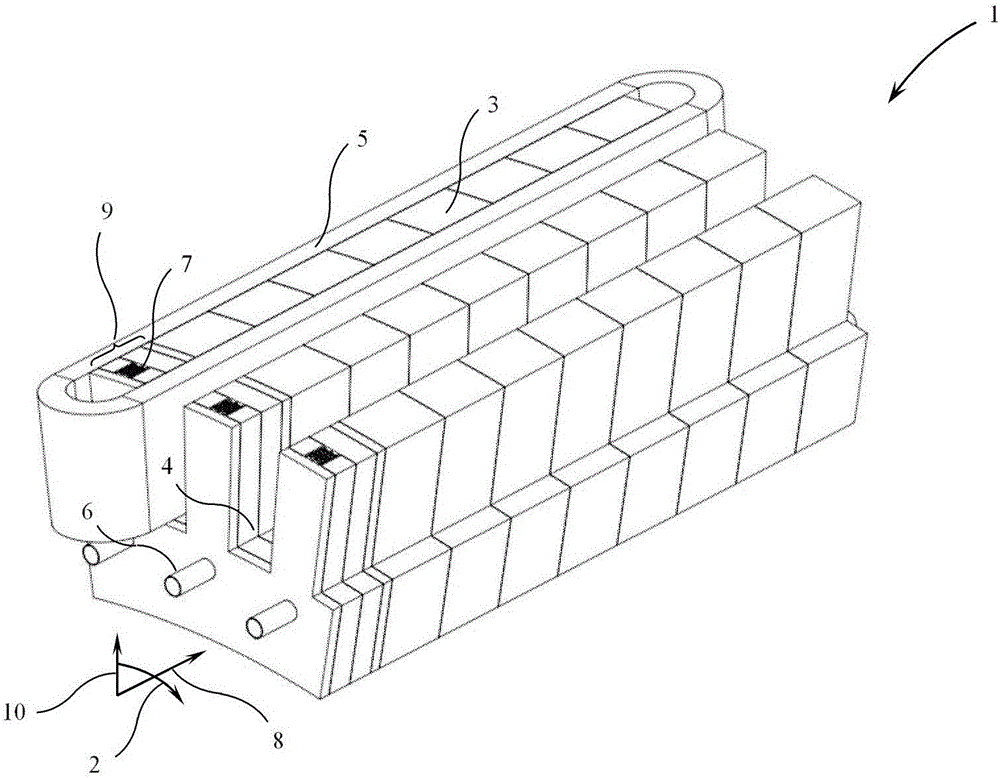

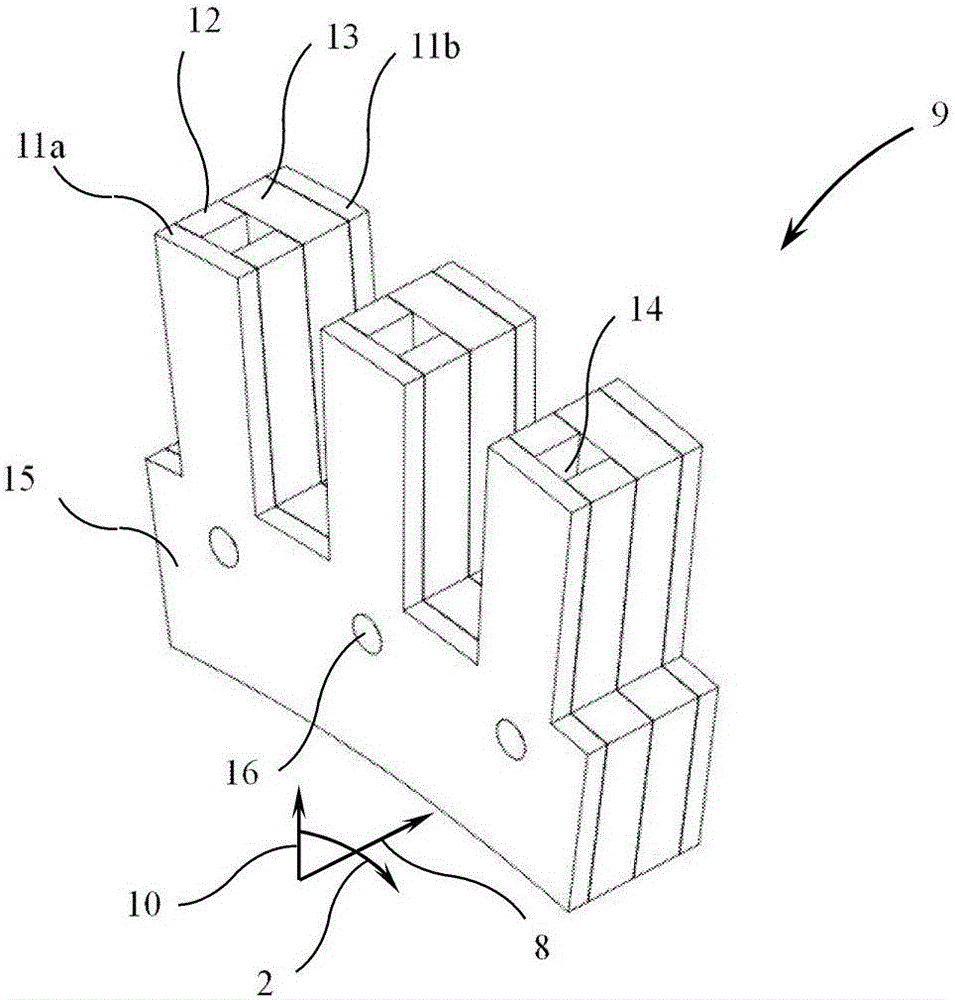

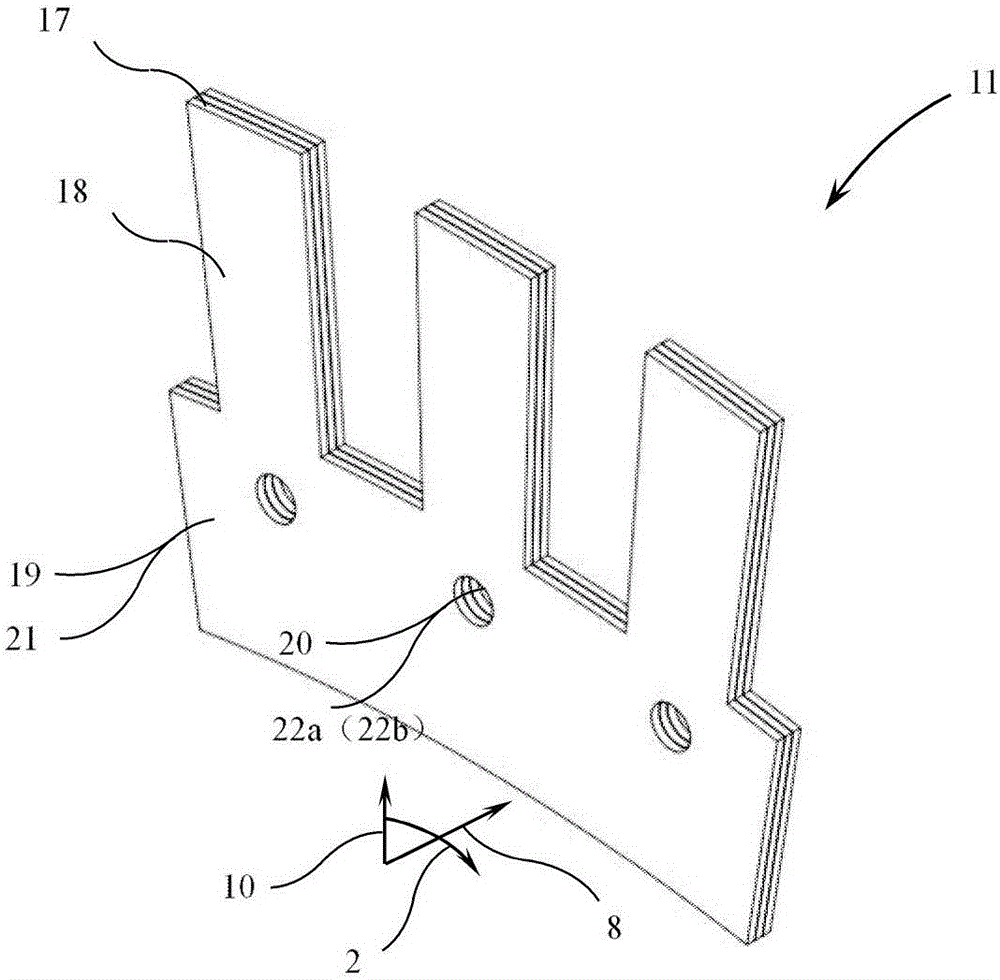

[0058] figure 1 A schematic diagram of a stator 1 for an electric machine, in particular a wind turbine, is shown. For the convenience of description, in the drawings, the circumferential direction 2 is the rotation direction of the motor, the axial direction 8 is the direction of the rotation axis of the motor, and the corresponding radial direction 10 is the direction perpendicular to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com