Universal hinge-type expansion joint

A technology of universal hinges and expansion joints, which is applied to expansion compensation devices for pipelines, pipes/pipe joints/fittings, adjustable connections, etc., which can solve the problem of long product length, no significant improvement, and difficult application of assembly space, etc. problem, to achieve the effect of axial length reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

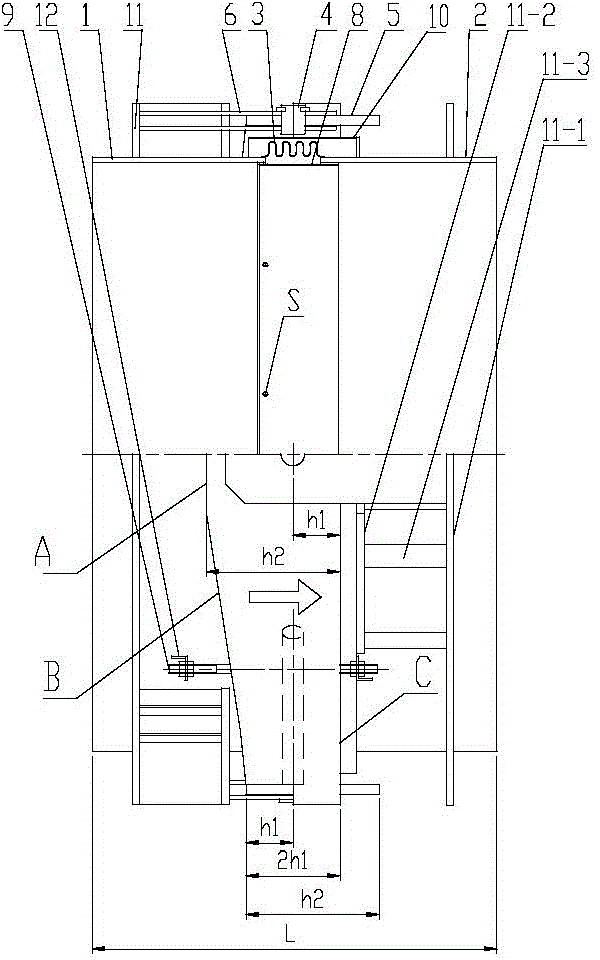

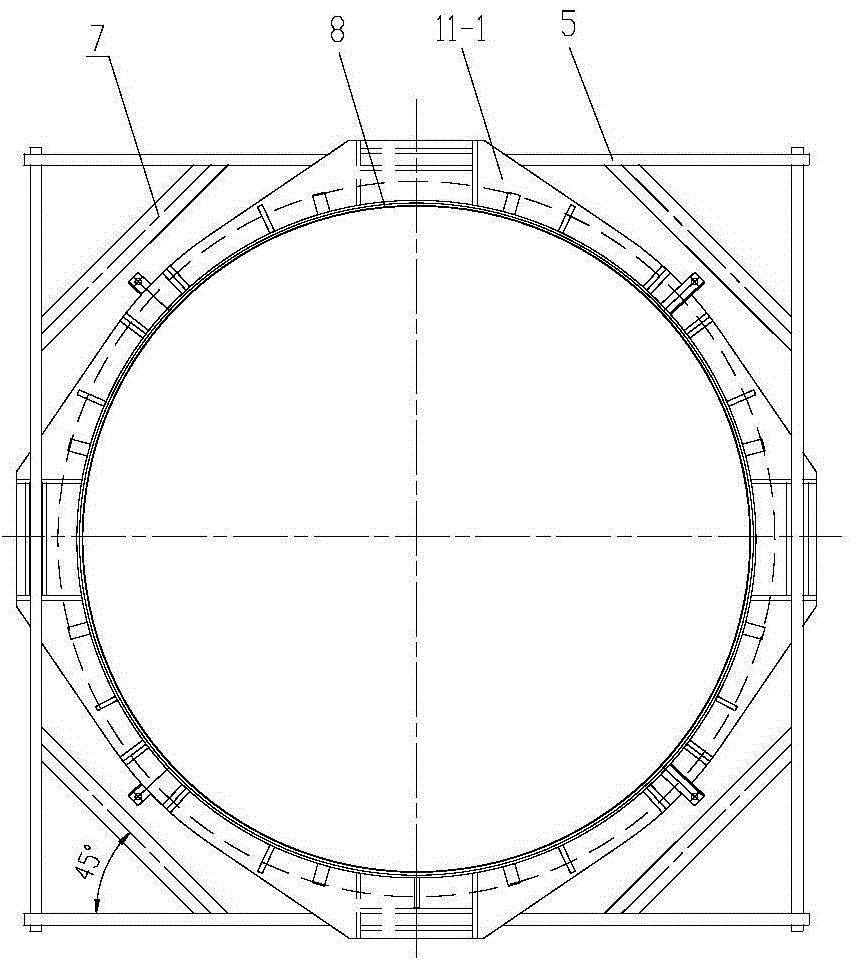

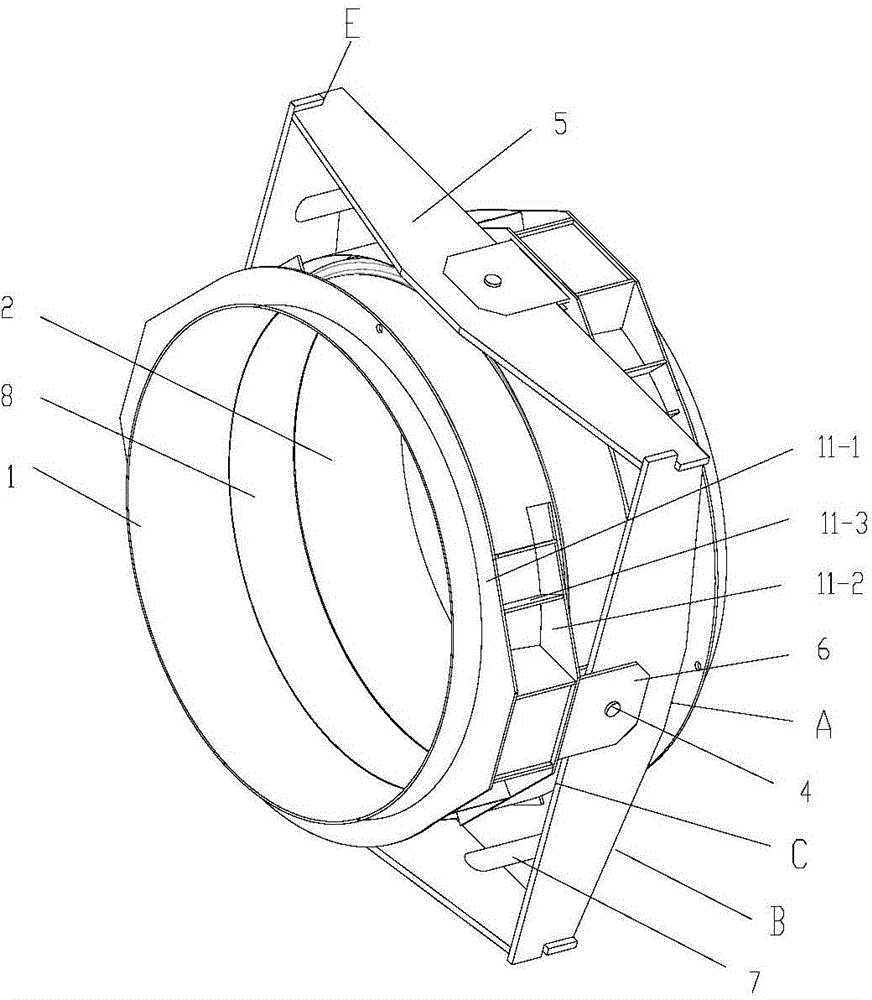

[0023] The universal hinge type expansion joint of this embodiment is such as figure 1 , figure 2 with image 3 As shown, it includes a first connecting pipe 1 and a second connecting pipe 2 that are butted through a corrugated pipe 3 and a rectangular (square) universal ring 5. The first connecting pipe 1 is fixedly inserted into the guide tube 8 of the second connecting tube 2, and the fixed end of the guide tube 8 has hydrophobic holes S distributed at intervals. The first connecting pipe 1 and the second connecting pipe 2 respectively have a pair of hinge seats 11 extending radially from the outer circle. Specifically, the hinge seat 11 is composed of a ring plate 11-1 surrounding the outer circle, a radially erected saddle plate 11-2 adjacent to the installation position of the rectangular universal ring 5, and spaced apart between the ring plates 11-1 and 11-1. The reinforcement ribs 11-3 between the saddle-shaped plates 11-2 are formed by welding, wherein the middle par...

Embodiment 2

[0031] The universal hinge type expansion joint of this embodiment is such as Image 6 As shown, the basic structure is the same as the first embodiment. Wherein, the first connecting pipe 1 and the second connecting pipe 2 communicating with each other are relatively inserted through the inner-lined guide tube 8. The guide tube 8 is fixed to the first connecting tube 1, and the fixed ends are provided with circumferentially spaced hydrophobic holes S. The first connecting pipe 1 and the second connecting pipe 2 are connected by a corrugated pipe 3. The outer circles of the two connecting pipes each extend a pair of hinge seats 11 staggered by 180 degrees. The hinge seats 11 are composed of a ring plate 11-1 and a saddle. It is composed of a shaped plate 11-2 and a rib 11-3. The rectangular universal ring 5 is welded by four polygonal plates. Each polygonal plate includes a long straight side C, a short straight side A, a hypotenuse B, and two ends E. The center of the length d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com