Vertical supporting device driven through servo electric cylinder

A technology of servo electric cylinder and vertical support, which is applied in the field of mechanical processing fixtures, can solve the problems of poor rigidity, large size, and inability to use, and achieve the effect of good rigidity, good orientation and rigidity, and compact axial size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

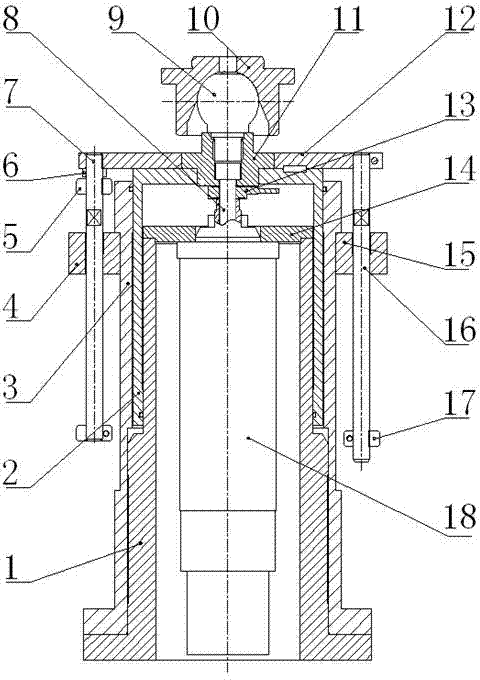

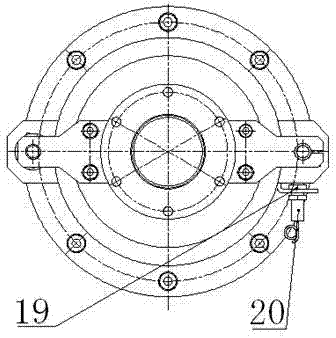

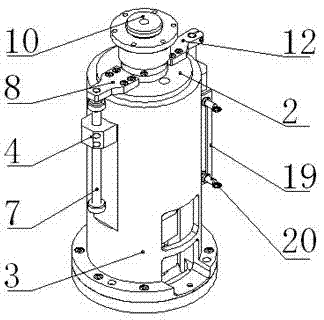

[0017] The embodiment of the present invention mainly includes inner and outer guide seats (1, 3), sliding sleeve (2), servo electric cylinder (18) and anti-rotation device, and the inner and outer guide seats (1, 3) are inner and outer Set it up and secure it with screws at the bottom. The sliding sleeve (2) is located between the inner and outer guide seats (1, 3), and can slide up and down therebetween.

[0018] The cylinder body of the servo electric cylinder (18) is set in the inner guide seat (1), and is fixed on the inner guide seat (1) through the end plate (14); the sliding sleeve (2) and the servo electric cylinder (18) The cylinder rod (8) is connected, and can slide up and down under the promotion of the cylinder rod (8). A load cell (13) and an anti-rotation device are connected in series on the cylinder rod (8), and the rod end of the cylinder rod (8) is provided with a ball joint floating support assembly composed of a ball head (9) and a ball socket (10).

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com