Main transmission mechanism of all-electric servo numerical control turret punch press

A numerically controlled turret punch press and electric servo technology, applied in the direction of punching machines, presses, manufacturing tools, etc., can solve the problems of rotor and stator air gap changes, poor stability, and large internal force of the mechanism, etc., to achieve small structure size, The effect of stable dynamic performance and easy high-speed processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific preferred embodiments.

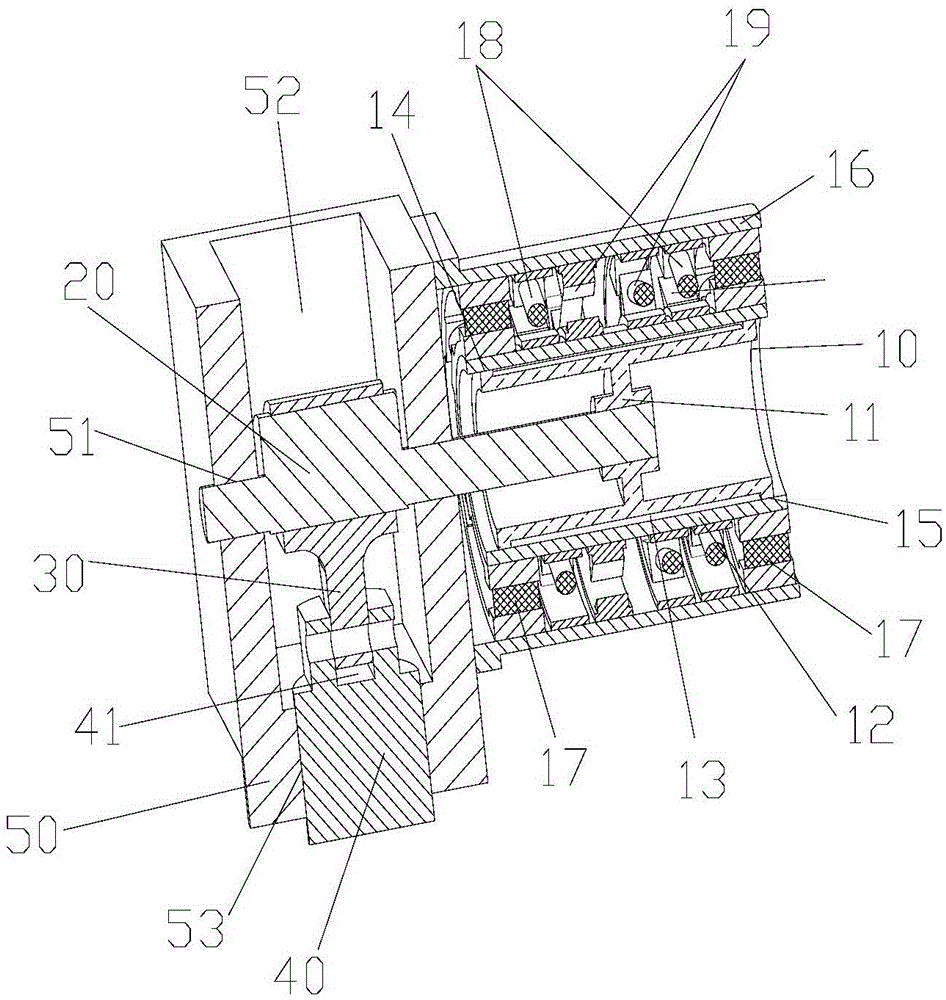

[0064] The all-electric servo numerical control turret punch press in the present invention includes a frame 50 and a fixed frame 16 .

[0065] The fixed mount 16 is preferably cylindrical, on one side of the fixed mount 16, such as figure 1 As shown, a connecting flange is preferably provided on its left end surface, and the fixed frame 16 is fixedly connected to the frame 50 through the connecting flange.

[0066] The center of frame 50 is preferably provided with vertical through hole 52, and the center bottom of frame 50 is provided with the guide hole 53 that communicates with vertical through hole 52; Hinge hole 51 .

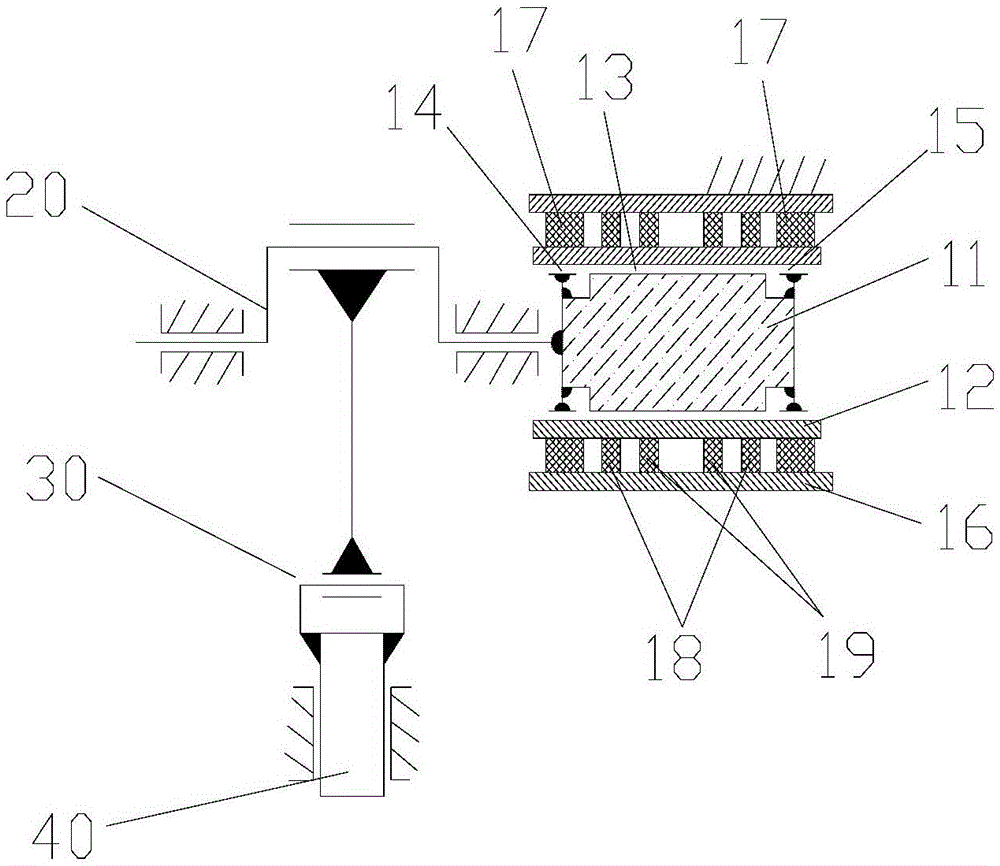

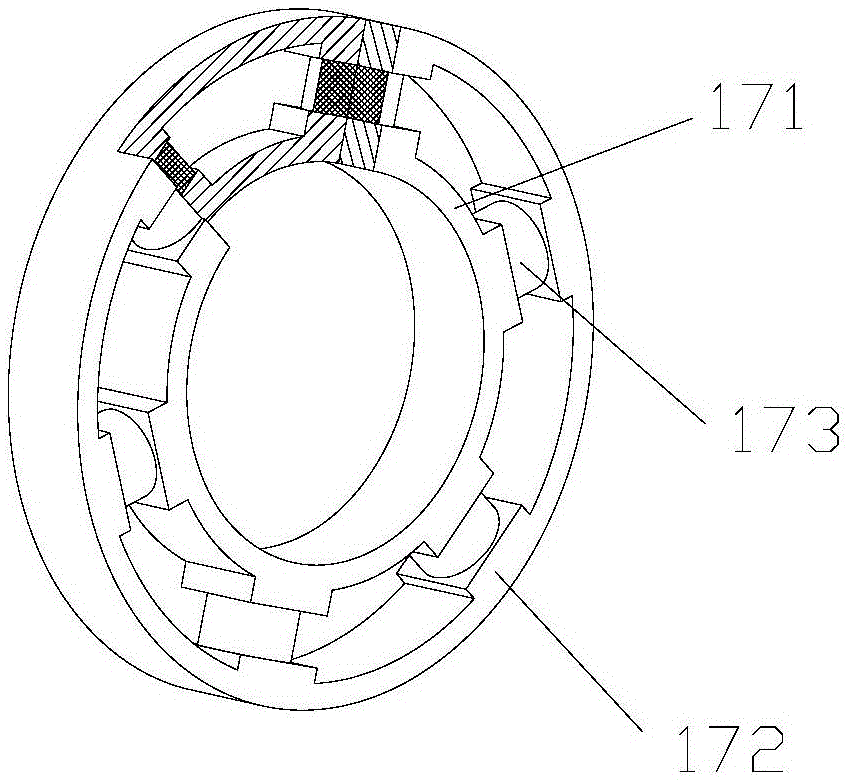

[0067] like figure 1 and figure 2 As shown, a main transmission mechanism of an all-electric servo numerical control turret punch press includes a servo motor 10, a crankshaft 20, a connecting rod 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com