Patents

Literature

51results about How to "Strong load capacity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Steam-bubble-driven micro pump conducting heating through induction

ActiveCN103967740AStrong load capacityRealize flow outputPositive displacement pump componentsPumpsDrug deliveryMagnet

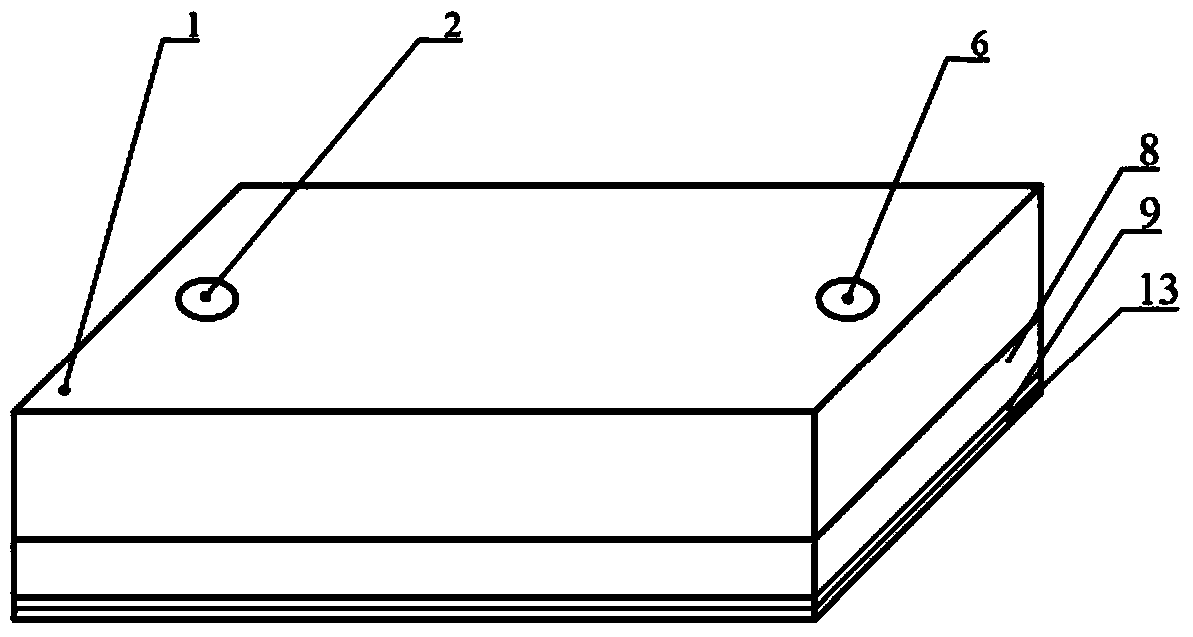

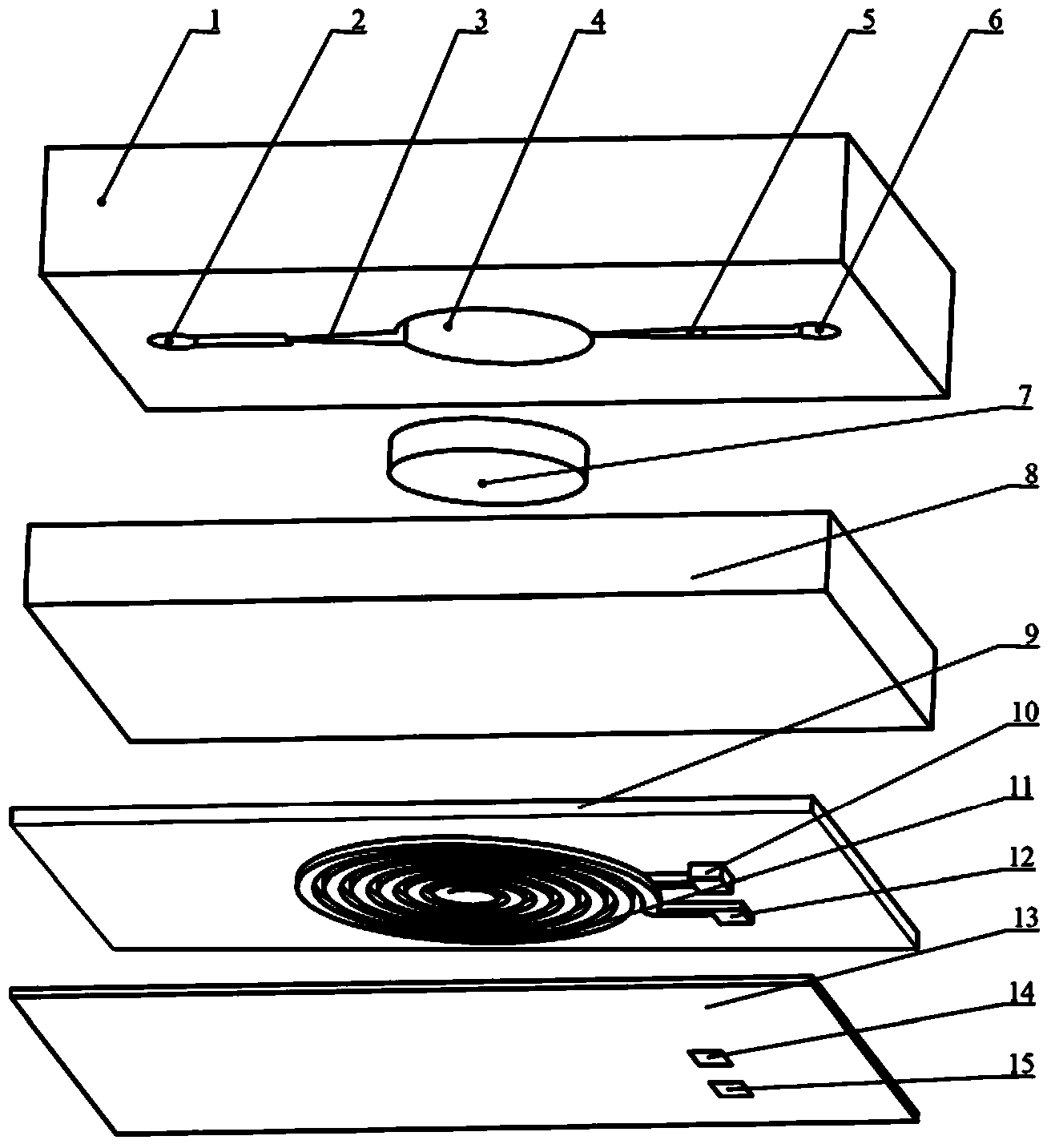

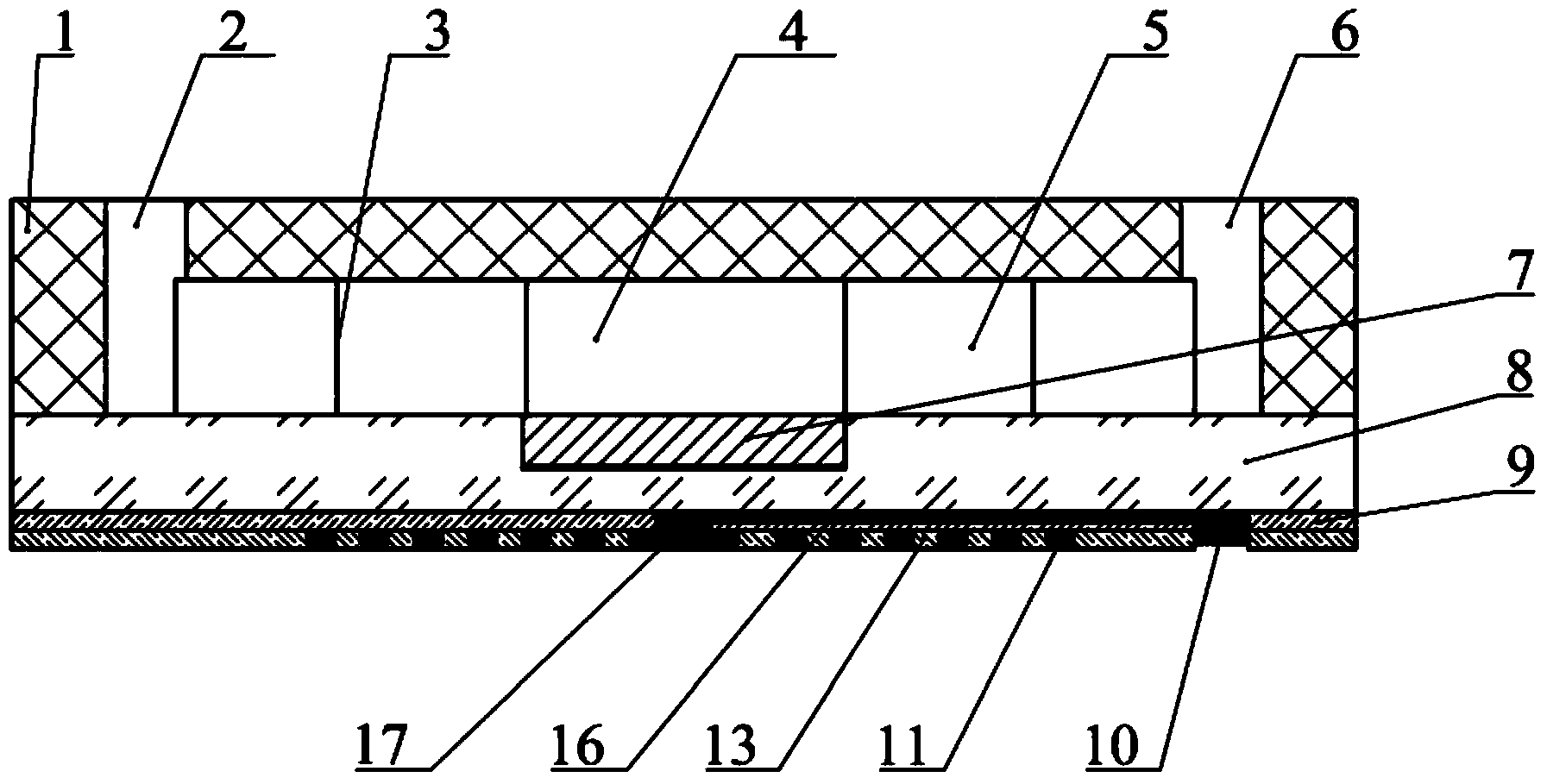

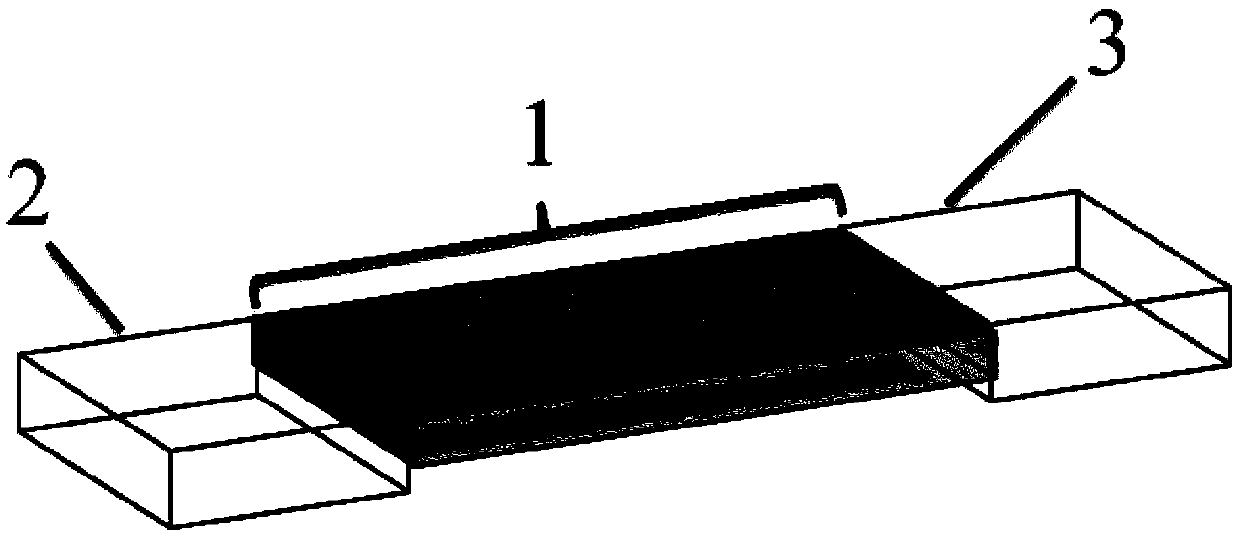

The invention discloses a steam-bubble-driven micro pump conducting heating through induction, and belongs to the field of micro-flow control systems. A pump body is composed of a micro-flow-control upper chip (1), a heating disk (7), a glass base (8) and a magnet exciting coil (11). The micro-flow-control upper chip (1) structurally comprises a liquid inlet (2), a micro flow channel I (3), a micro cavity (4), a micro flow channel II (5) and a liquid outlet (6). According to the micro pump, liquid in the micro cavity (4) is heated through induction eddy currents to enable the liquid to be partially vaporized to generate steam bubbles, the micro pump is driven through pressure pulses generated at the moment when the steam bubbles expand to become large, and the function of pumping a micro amount of liquid can be realized. No movable components exist in the micro pump, so that pollution sources and mechanical faults are reduced, meanwhile, the micro pump has the advantages of being high in flow and controllable, and the micro pump has wide application prospects in various fields such as disease diagnosing, medicine conveying, fuel feeding and environment detection.

Owner:湖州南浔双程建设发展有限公司

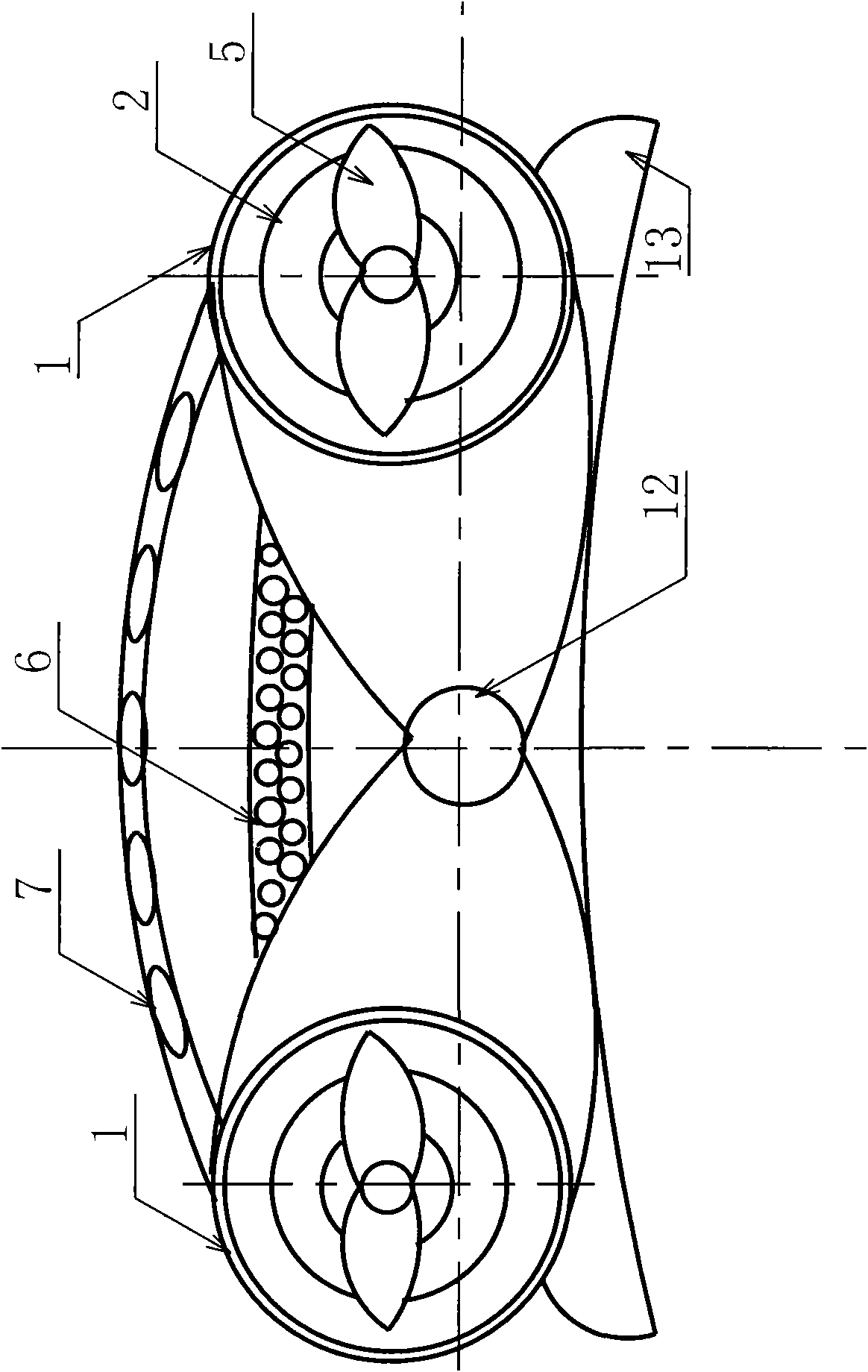

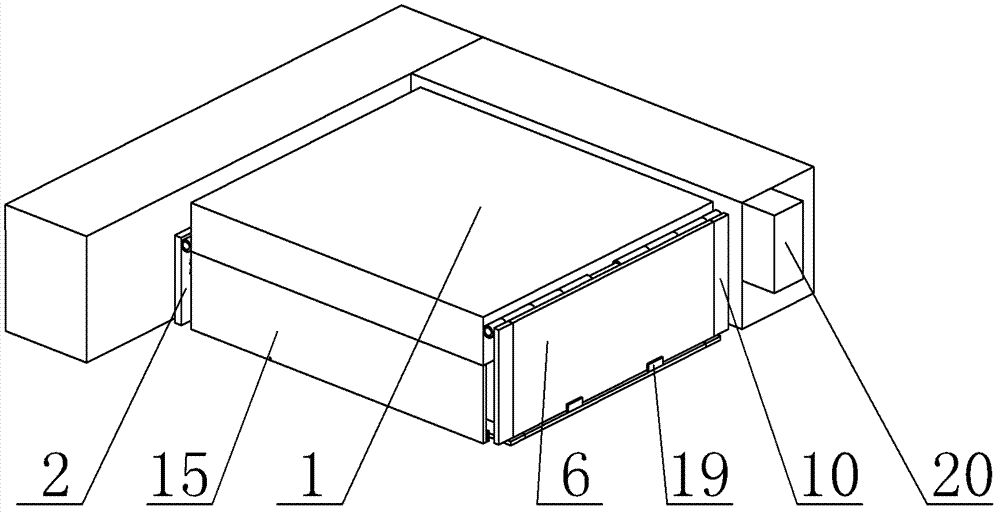

Bionic soft robot

PendingCN109533066ARich varietyEasy to makeProgramme-controlled manipulatorVehiclesRough surfaceEngineering

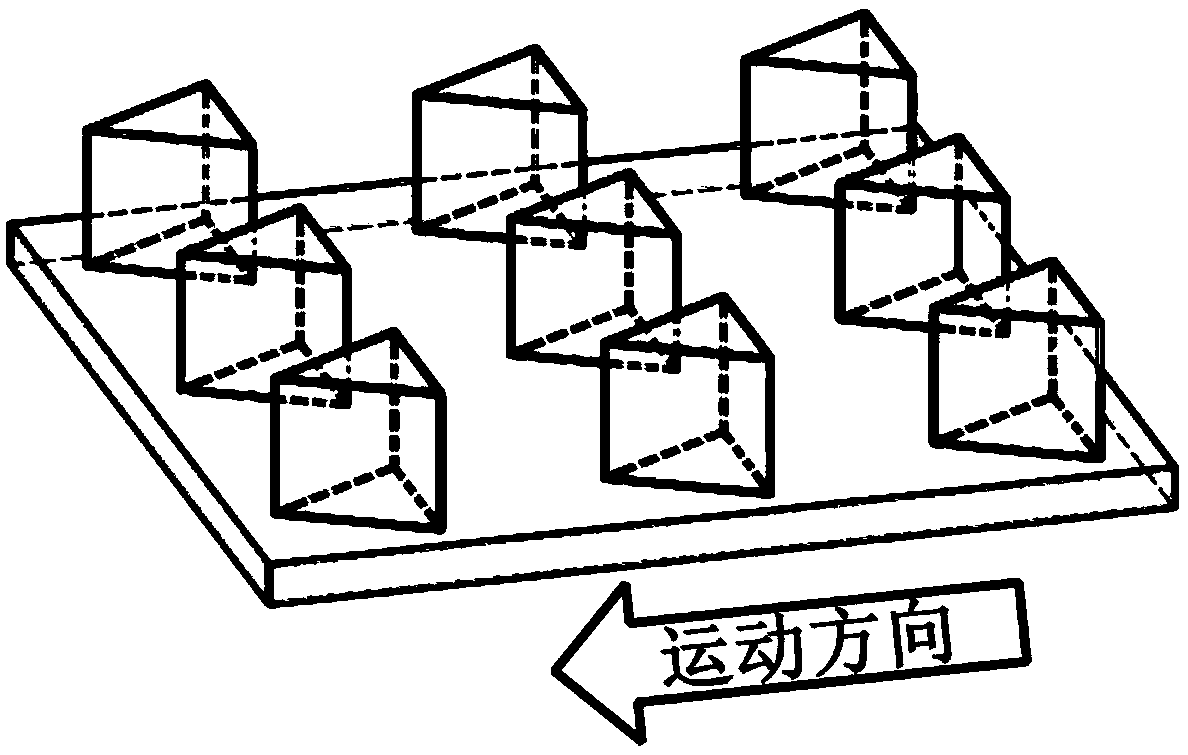

The invention discloses a bionic soft robot. The bionic soft robot comprises a trunk, a forefoot, a hind foot and an energy supply module, wherein the front and rear ends of the trunk are connected with the forefoot and the hind foot respectively, and the trunk maintains suspended; the lower surface of the forefoot and the lower surface of the hind foot have asymmetric structures with consistent orientation, the tail ends of the asymmetric structures are in contact with a base as a walking surface, so that the friction force generated by the forefoot and the hind foot in the front and rear directions is unequal when the forefoot and the hind foot are in contact with the base as the walking surface. The trunk is a deformation body capable of undergoing reversible telescopic deformation, andthe energy supply module provides energy for the reversible telescopic deformation process of the trunk. The bionic soft robot has the advantages that the structure is simple, the sources of the driving energy is abundant, the movement is stable, the bionic soft robot can move in narrow closed space, has very strong environmental adaptation and load capacity and can move on smooth or rough surfaces, dry or wet surfaces, upslopes or downslopes, high or low temperature surfaces.

Owner:WUHAN UNIV

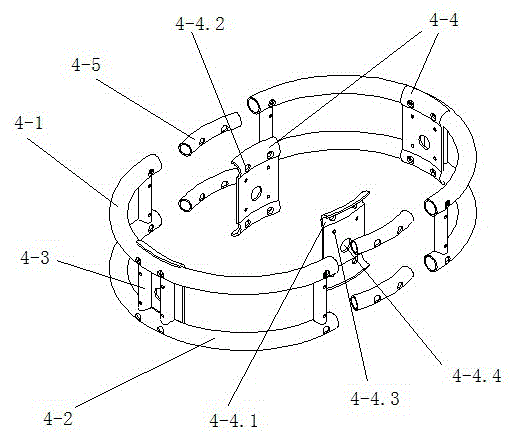

Climbing robot

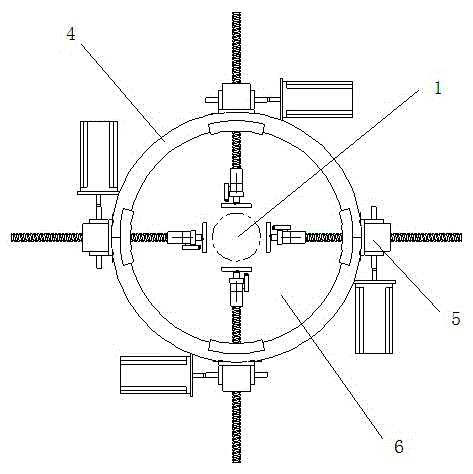

The invention discloses a climbing robot. The climbing robot comprises two vertically-arranged climbing units and a plurality of lifting mechanisms arranged between the two climbing units. The lifting mechanisms drive the two climbing units to move along a climbed object in an alternated manner, and therefore the climbing of the climbing robot is achieved. The climbing robot further comprises an inclined supporting rod for enabling the pitching angle of a supporting face of a support to be adjusted. According to the climbing robot, the high bearing capability is achieved through the design of the annular climbing units, persons and equipment can be carried to climb trees, and researchers can study the growing state of the trees conveniently.

Owner:RES INST OF FORESTRY NEW TECH CHINESE ACAD OF FORESTRY

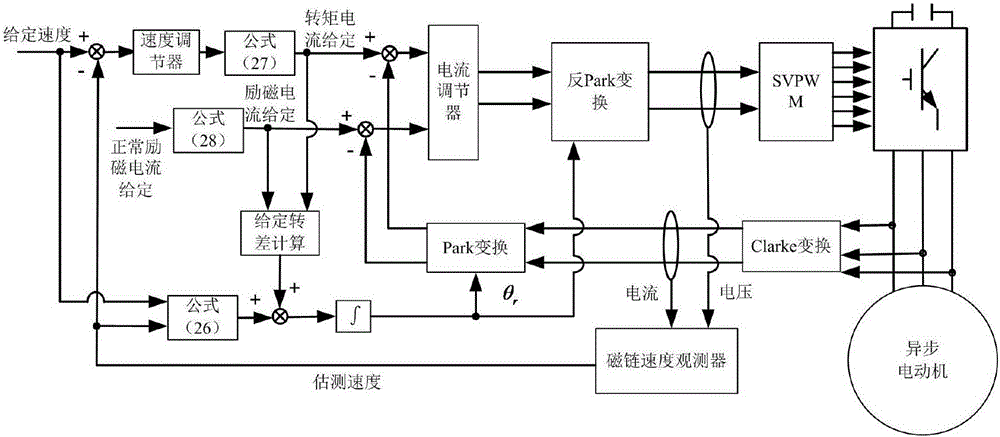

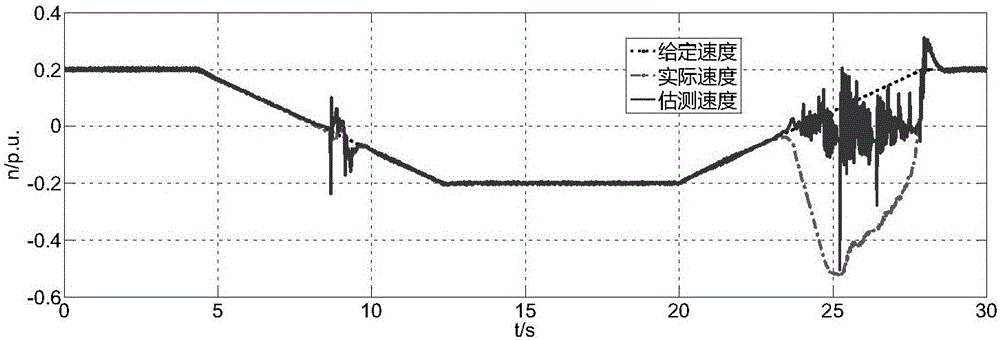

Low-frequency processing method of asynchronous motor speed sensorless vector control system

ActiveCN106549620AStrong load capacityAvoid running out of controlElectronic commutation motor controlElectric motor controlControl modeControl vector

The invention discloses a low-frequency processing method of an asynchronous motor speed sensorless vector control system. The method comprises the following steps: performing certain time delay according to a relation of size between motor real-time given speed corresponding angle frequency and switching frequency, and carrying out switching between a vector control mode and an I / f control mode, wherein the switching frequency comprises a switching frequency relatively large value and a switching frequency relatively small value; if the motor real-time given speed corresponding angle frequency is greater than the switching frequency relatively large value, switching the vector mode into the vector control mode; if the motor real-time given speed corresponding angle frequency is not greater than the switching frequency relatively small value, switching the control mode into the I / f control mode, wherein, in the I / f control mode, the motor real-time given speed corresponding angle frequency is used for replacing estimated speed corresponding angle frequency as system operation synchronous frequency, and meanwhile a current loop adopts closed-loop control. Through the adoption of the method, the operation out-of-control state, caused by speed estimation inaccuracy in a low-frequency stage, of the speed sensorless vector control system can be effectively avoided.

Owner:WISDRI WUHAN AUTOMATION

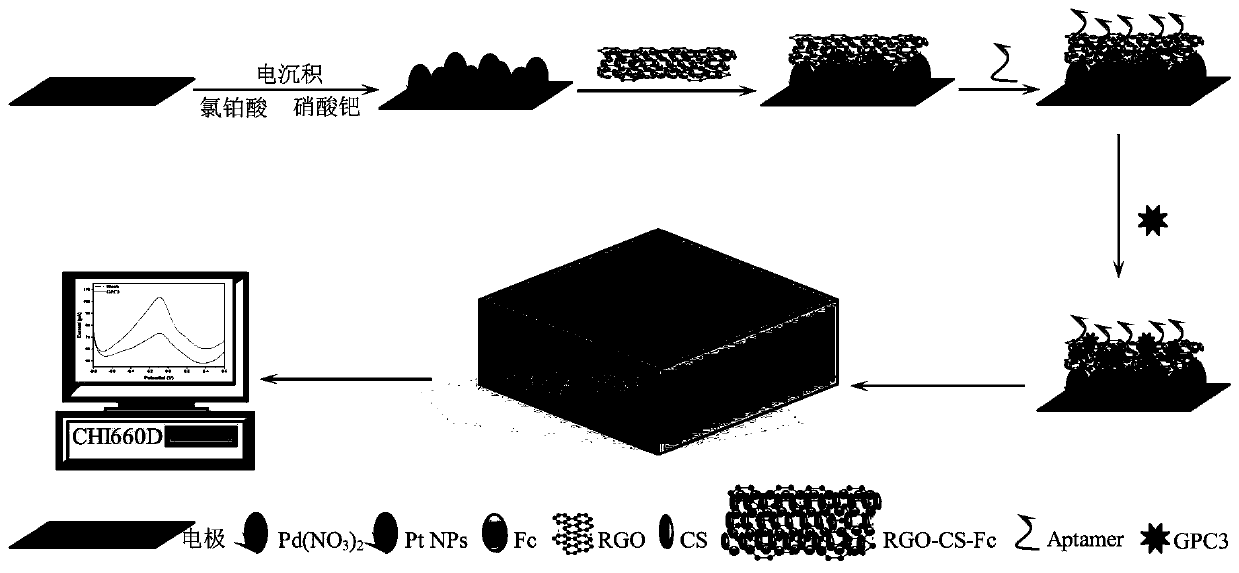

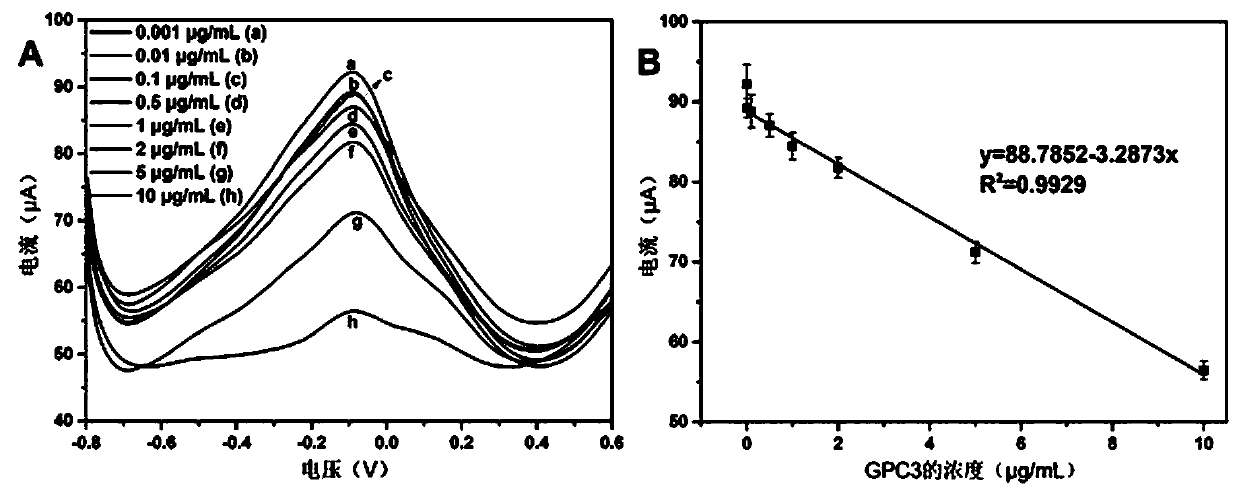

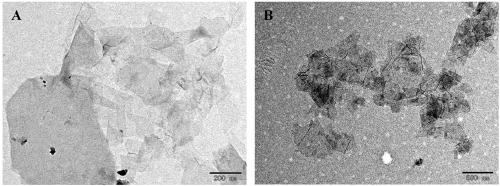

Method for detecting GPC3 based on RGO-CS-Fc/Pt-Pd NPs nano composite material

ActiveCN111413385AEnhanced transfer effectAmplified current signalMaterial electrochemical variablesAptamerNano composites

A liver cancer marker phosphatidylinositol proteoglycan 3 (Glypican-3, GPC3) is used as a research object, a GPC3 aptamer is used as a recognition probe, on the basis of good electron transfer effectand excellent loading capacity of a reductive graphene oxide-chitosan-ferrocene / nano platinum and palladium (Pt-Pd NPs / RGO-CS-Fc) composite material, the GPC3 aptamer can specifically recognize and becombined with GPC3 protein, and a novel aptamer sensor capable of performing specific recognition and quantitative analysis on the GPC3 protein is constructed and used for detecting the content of GPC3 in serum. The method is simple to operate, time-saving, low in cost and relatively low in detection limit.

Owner:GUILIN UNIV OF ELECTRONIC TECH

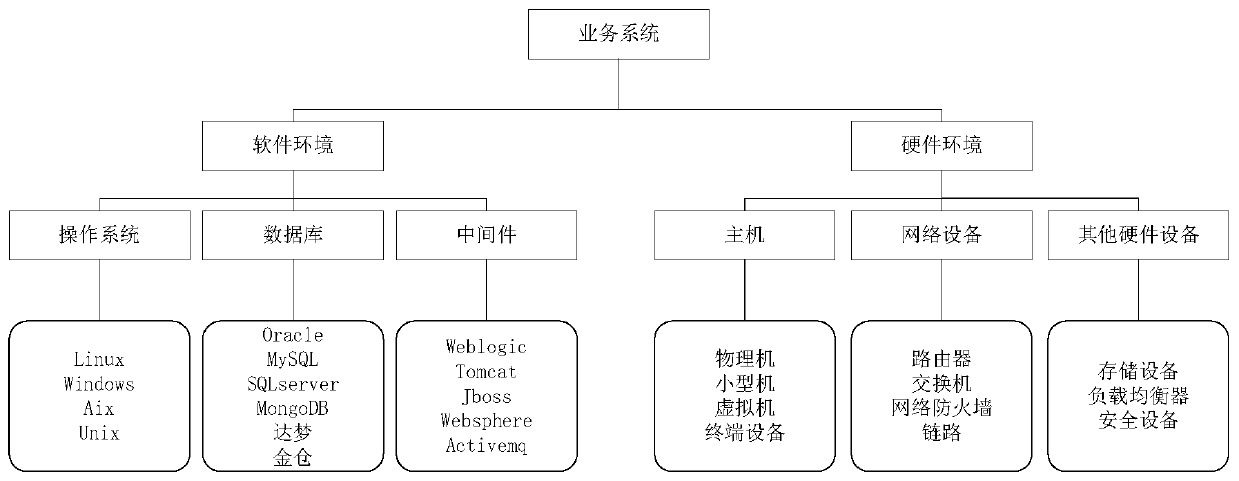

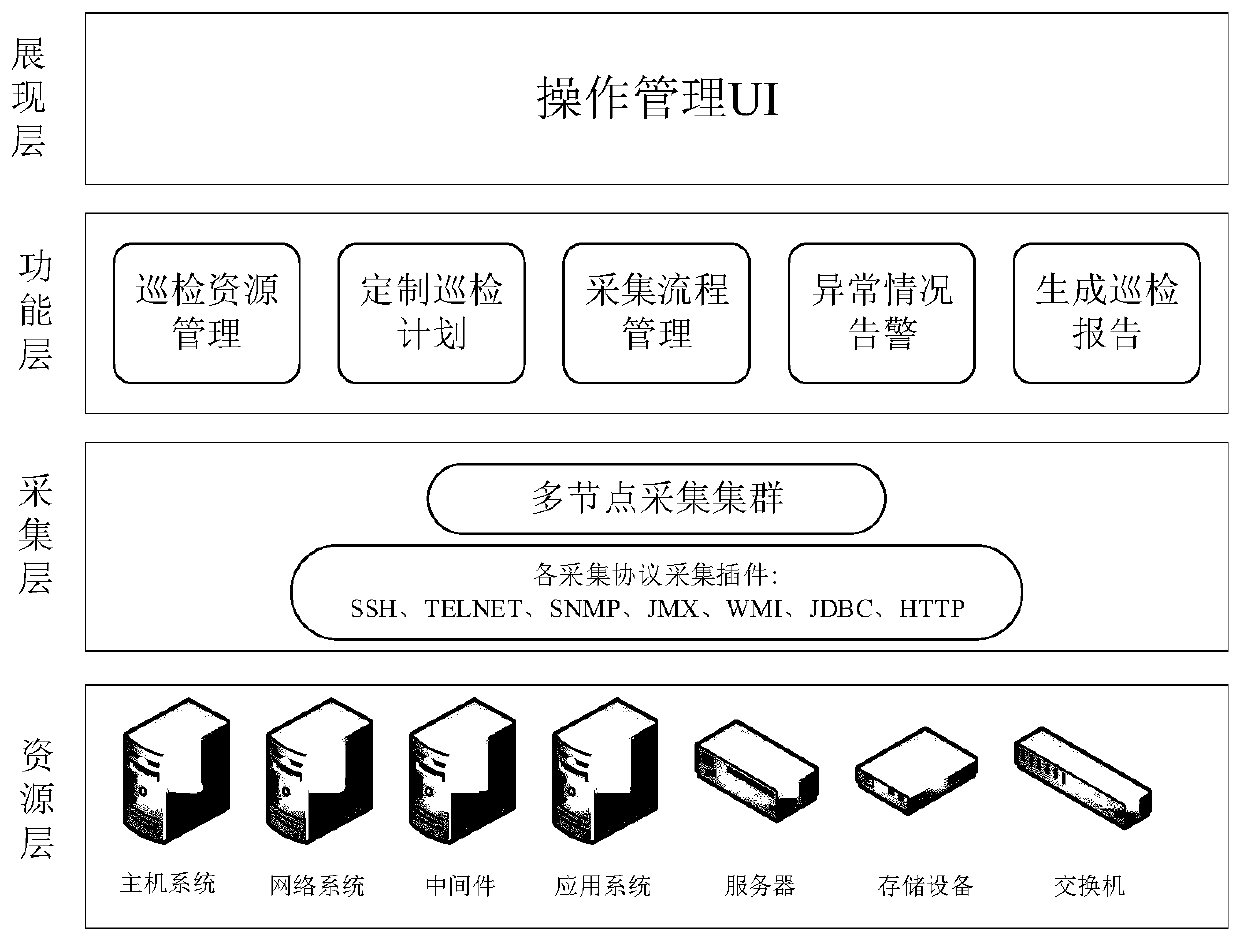

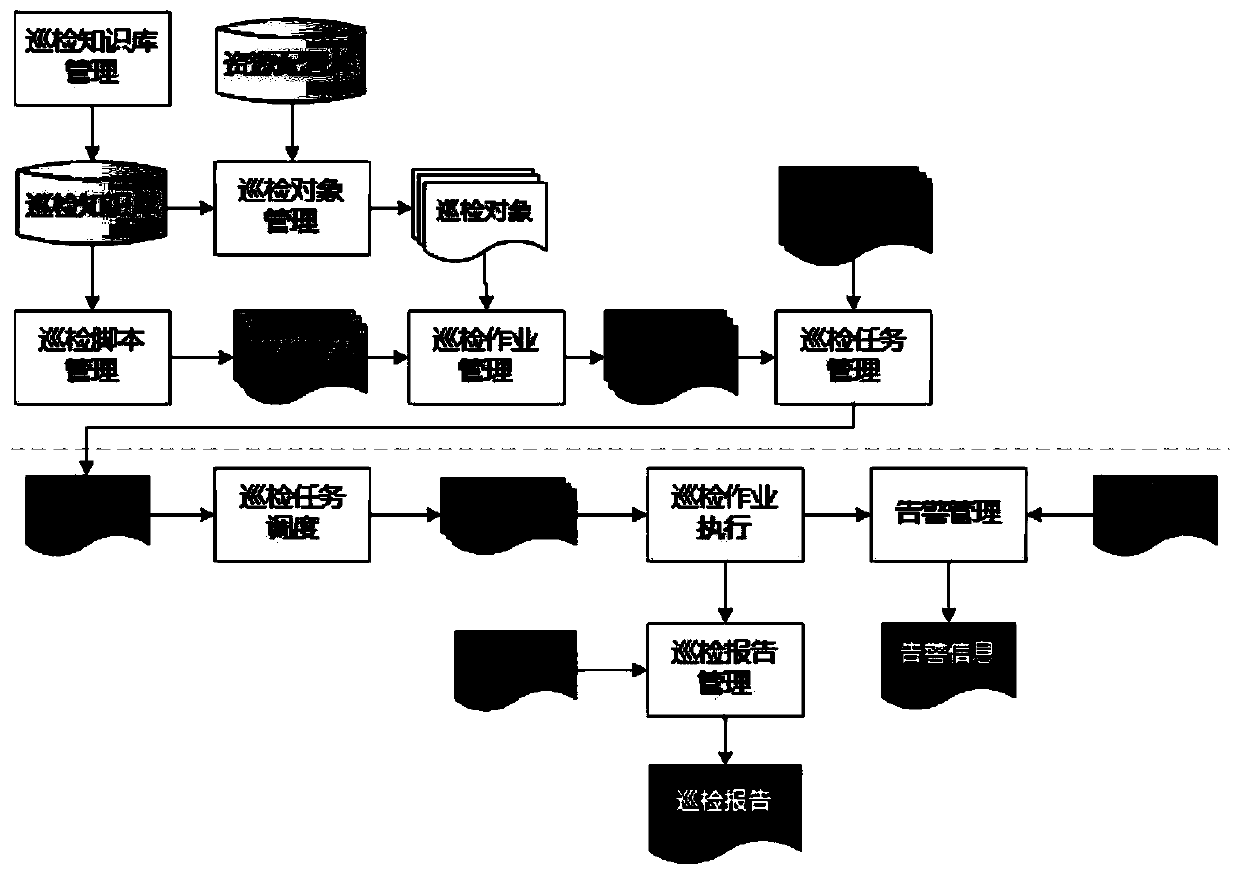

Automatic operation and maintenance system based on acquisition cluster

ActiveCN109857613AStrong load capacityEnsure reliabilityHardware monitoringSystems managementDependability

The invention discloses an automatic operation and maintenance system based on an acquisition cluster. The automatic operation and maintenance system is divided into a display layer, a function layer,an acquisition layer and a resource layer from top to bottom. The display layer is used for issuing an operation instruction to the functional layer. The functional layer calls various acquisition nodes to complete automatic configuration, daily inspection and fault inspection on software and hardware resources of the resource layer, the acquisition layer configures a multi-node acquisition cluster, acquires data of the resource layer and feeds back an acquisition result to the functional layer, and the resource layer is all software and hardware resources managed by the automatic operation and maintenance system. According to the automatic operation and maintenance system, customized configuration and inspection tasks are formed according to different configuration and inspection scenes,and automatic collection and automatic analysis of index parameters and automatic generation of inspection reports are achieved. According to the invention, the good load capacity for a large numberof acquisition tasks is ensured by means of the coordinated work among a plurality of acquisition nodes, so that the reliability and the high efficiency of the acquisition process are ensured.

Owner:NARI INFORMATION & COMM TECH

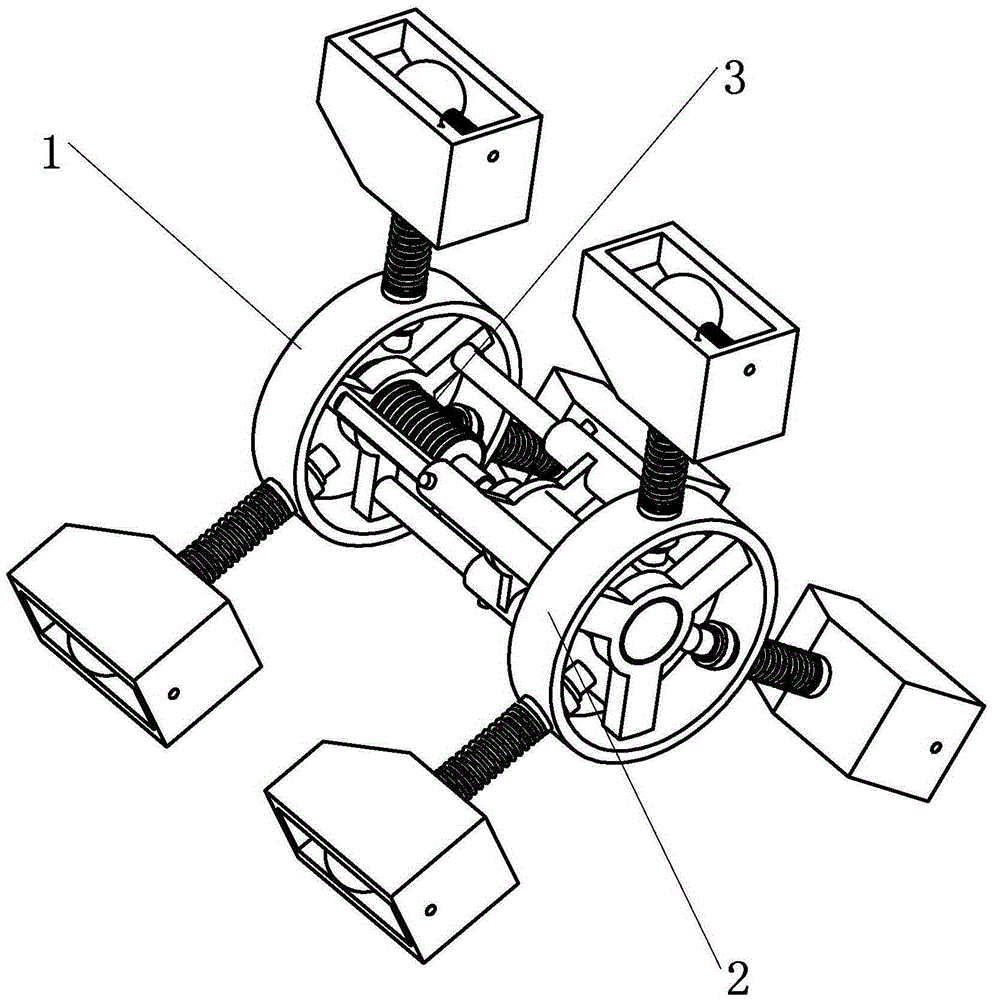

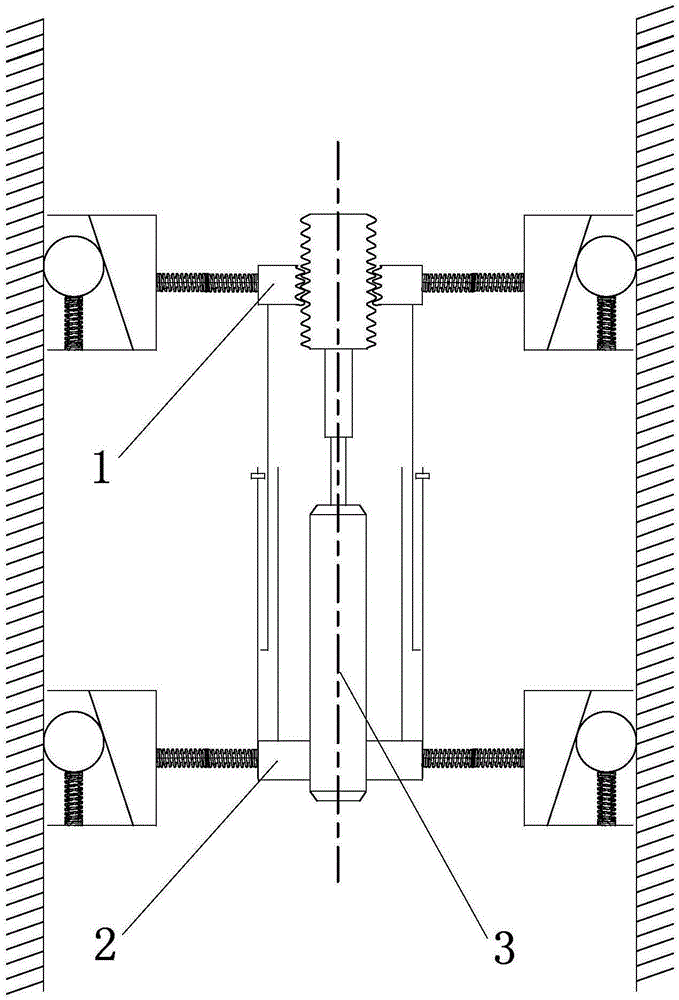

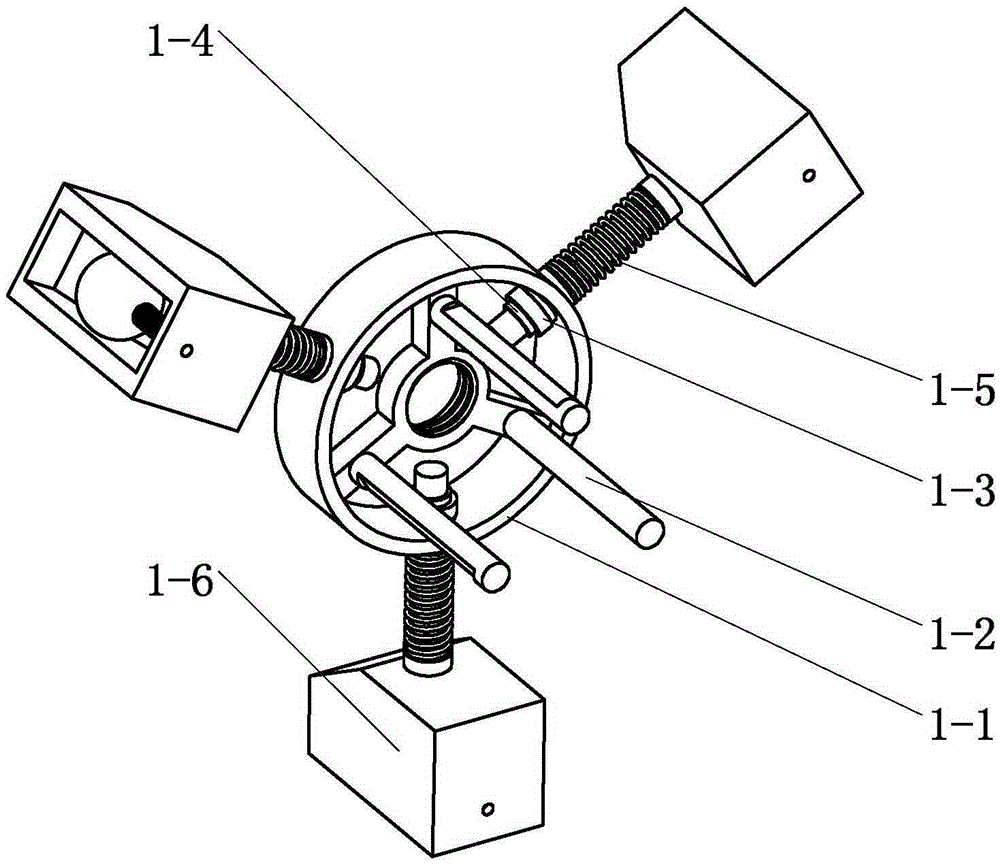

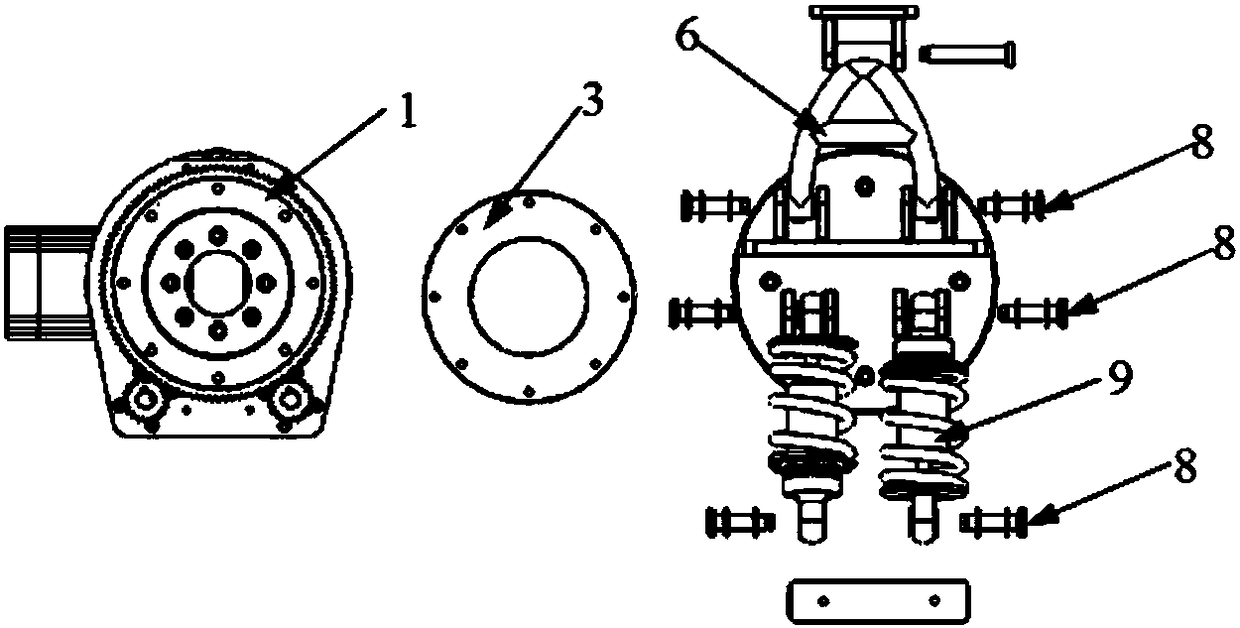

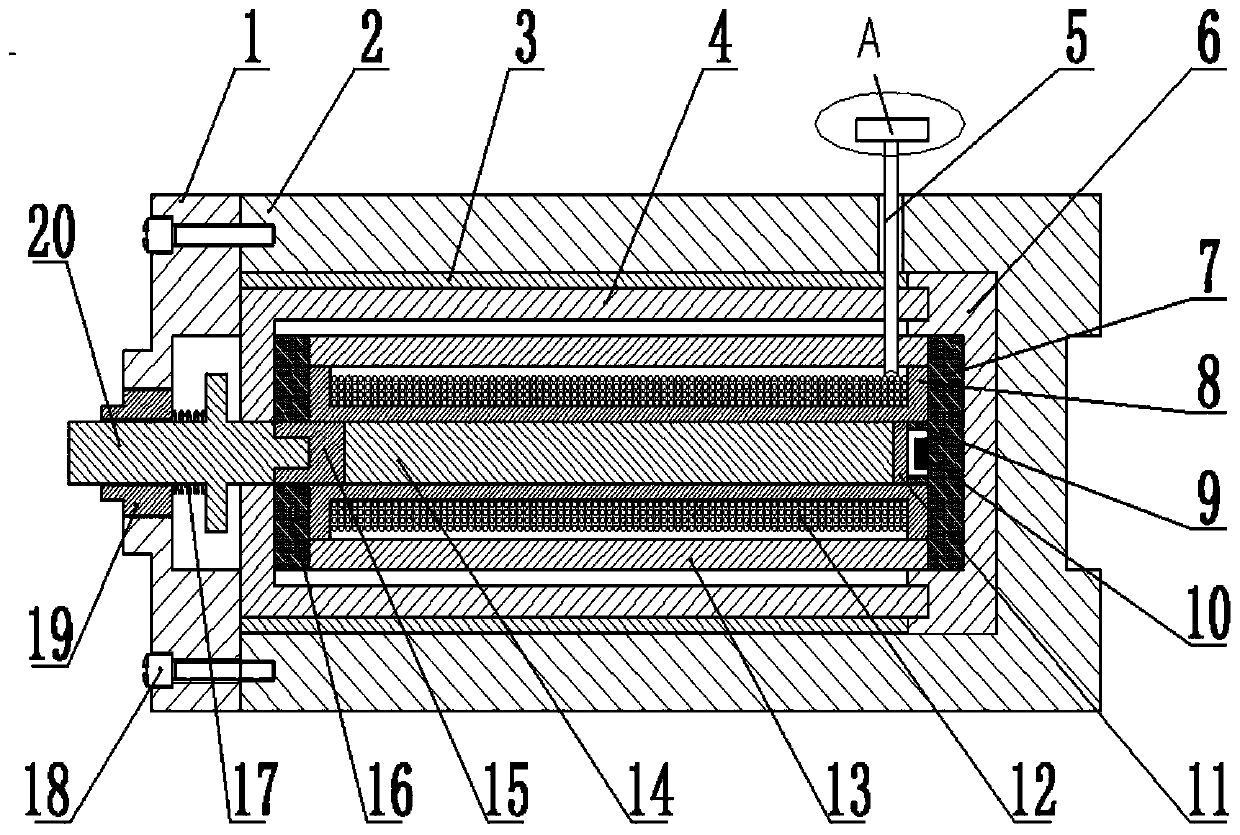

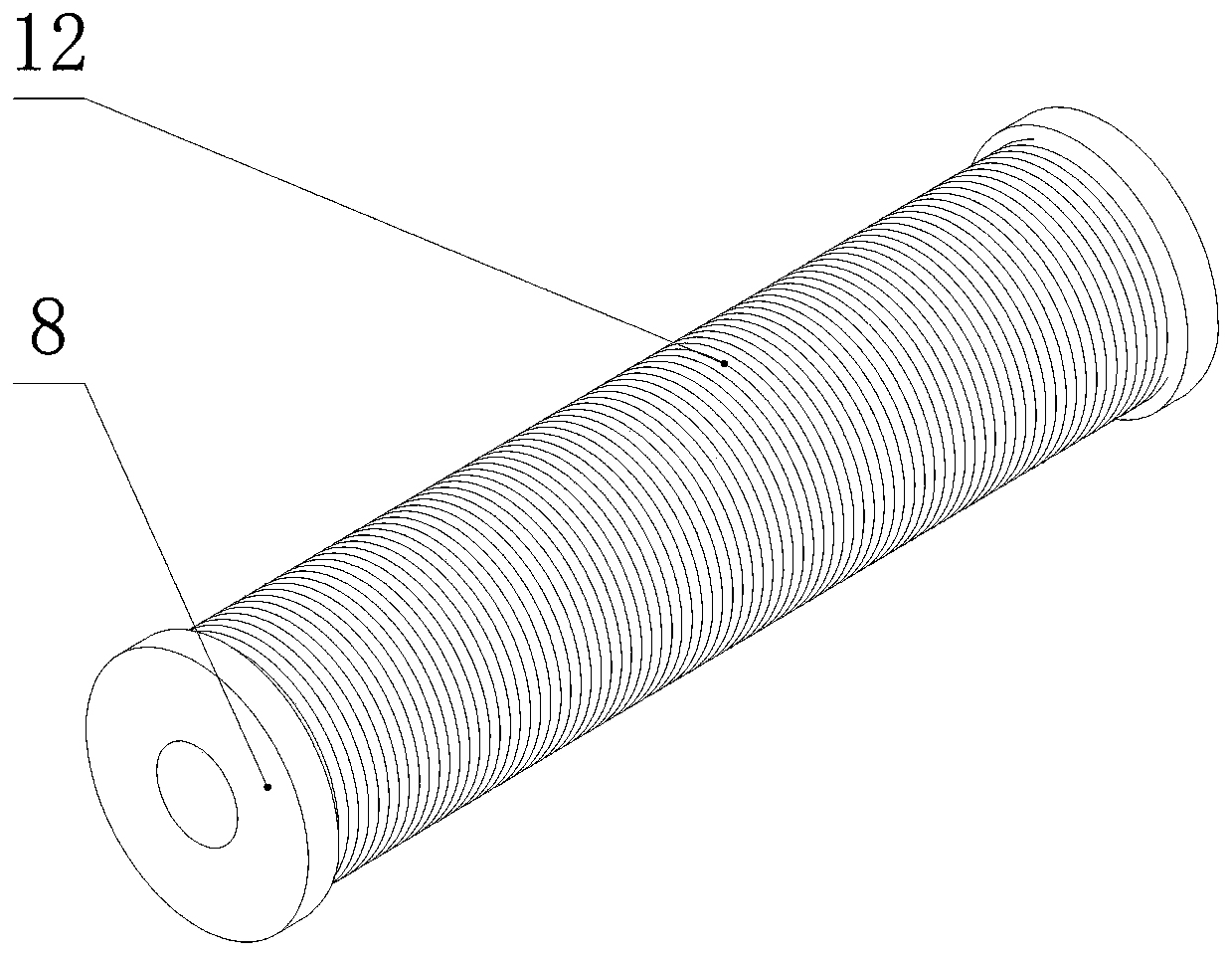

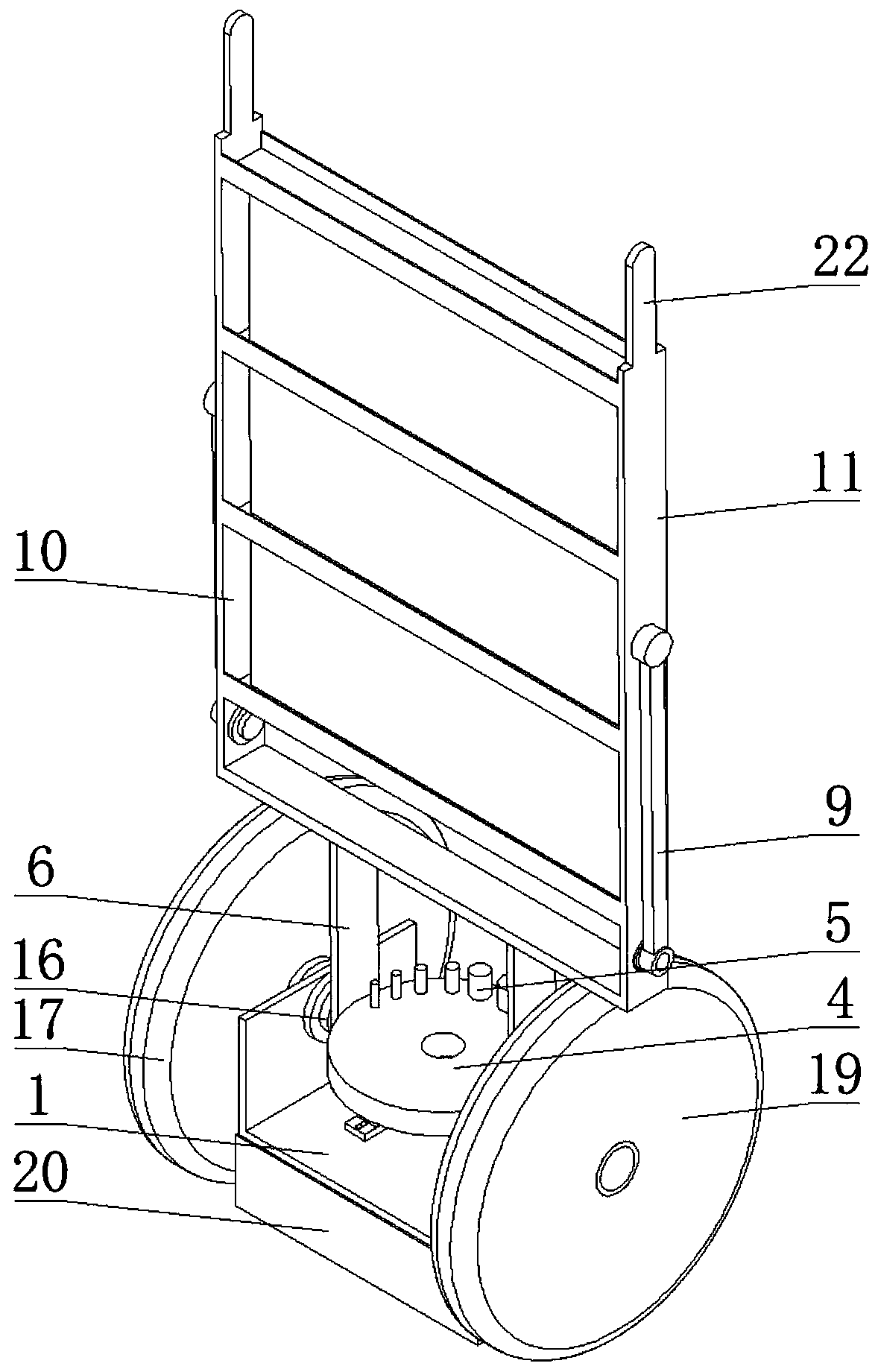

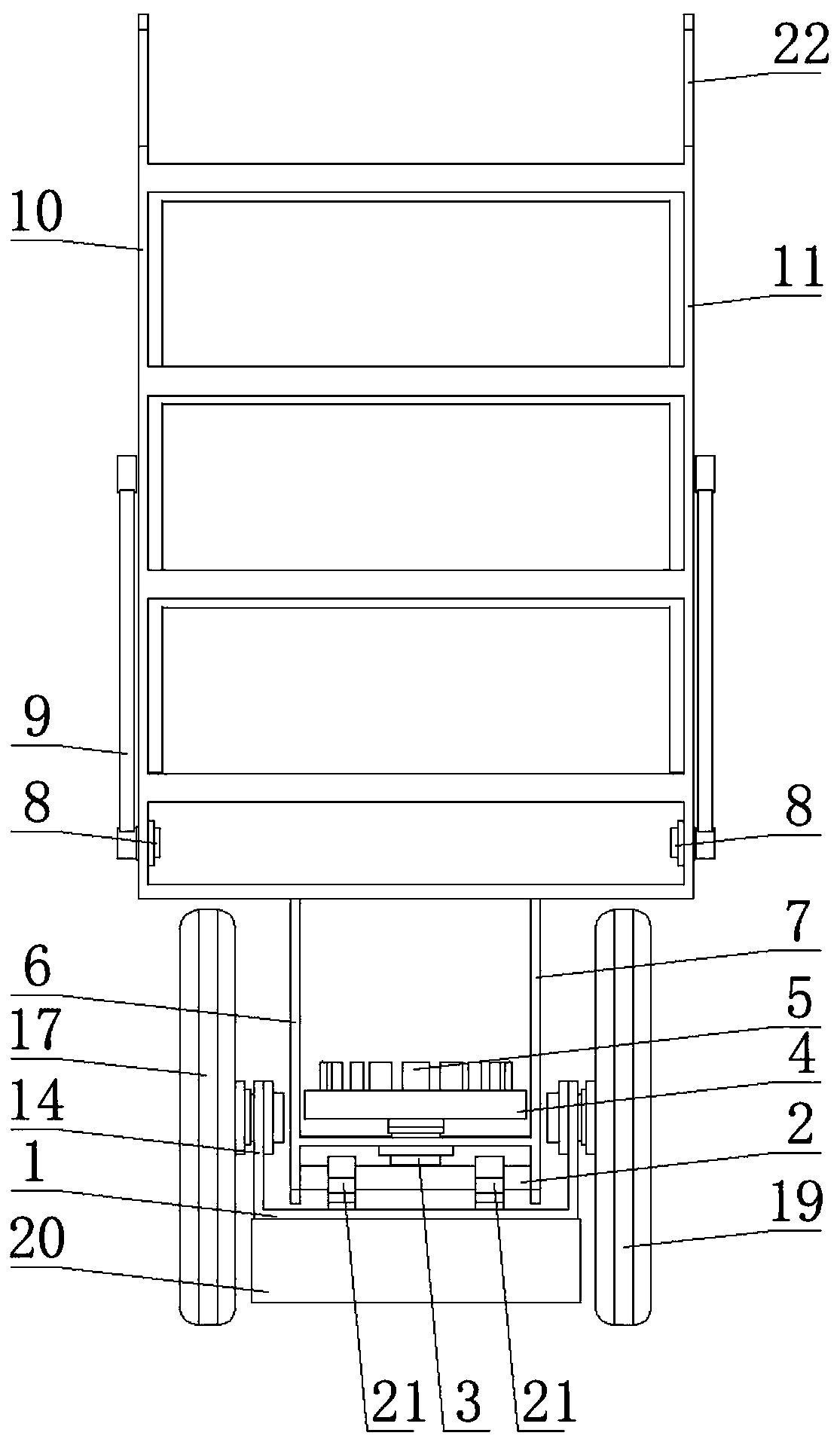

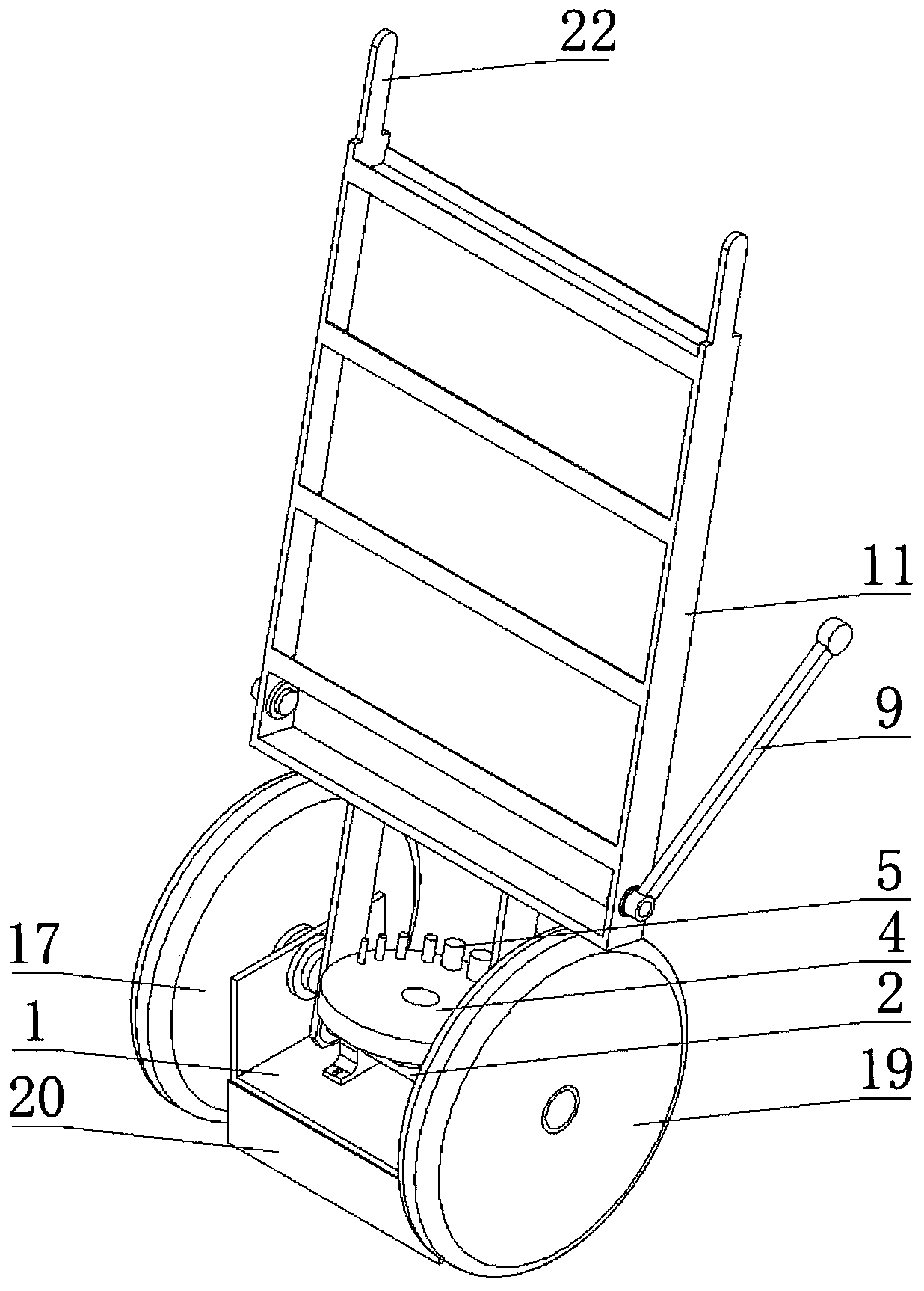

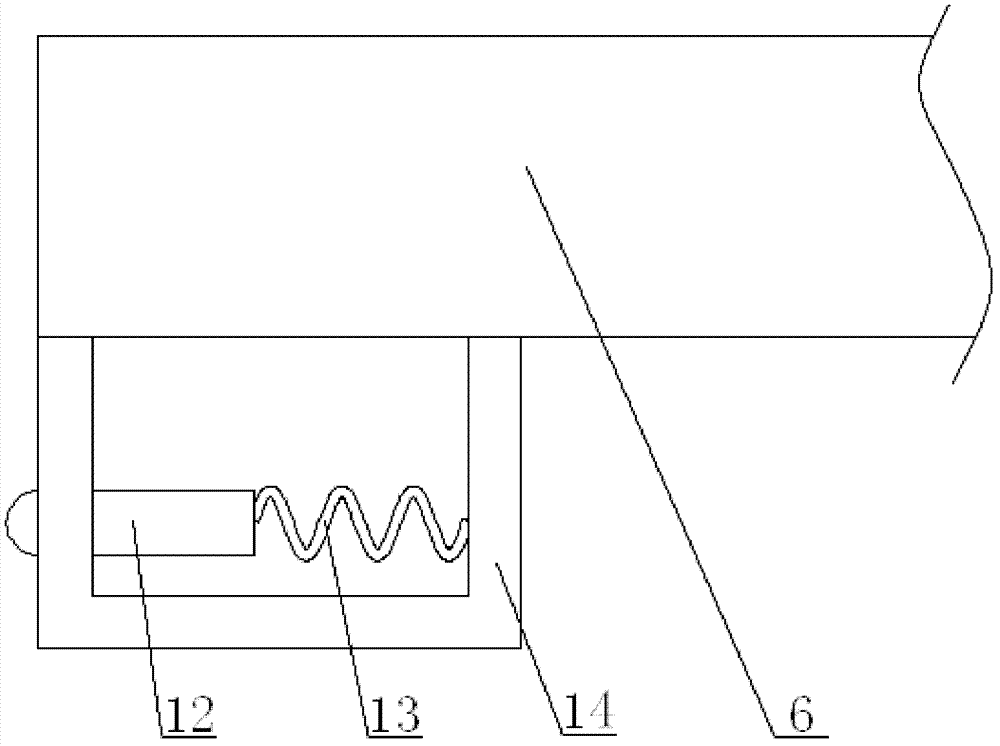

Telescopic self-lock type intra-pipe movable robot

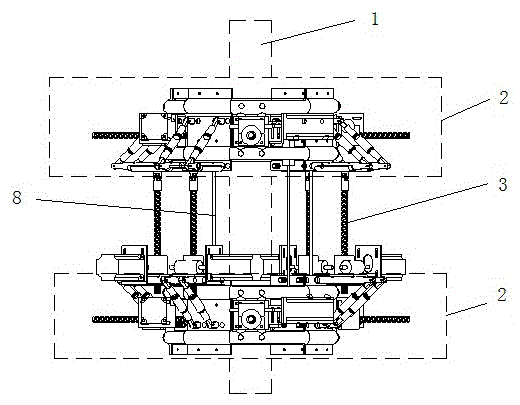

The invention discloses a telescopic self-lock type intra-pipe movable robot. An existing pipeline robot is low in loading capacity and poor in stability, and an operation device under a high-resistance condition still has serious defects. A front cart body assembly of the telescopic self-lock type intra-pipe movable robot is provided with a front self-lock mechanism assembly. A rear cart body assembly is provided with a rear self-lock mechanism assembly. A moving pair is formed by the front cart body assembly and the rear cart body assembly through guide rods and guide sleeves. A threaded shaft of a driving assembly is in spiral transmission with a front cart body. Rotation of a driving motor is converted into movement of the front cart body assembly and movement of the rear cart body assembly so that the intra-pipe robot can be driven. According to the telescopic self-lock type intra-pipe movable robot, it is guaranteed that the robot is in full contact with the inner wall of a pipeline through the front self-lock mechanism assembly and the rear self-lock mechanism assembly, and the stability and loading capacity of the robot inside the pipeline are effectively improved; it is guaranteed that pressing force exists all the time between the self-lock mechanism assemblies and the inner wall of the pipeline through pressure springs, and the movement stability of the robot inside the pipeline is guaranteed; in addition, the spiral pair formed by the front cart body assembly and the rear cart body assembly has a self-lock function, and therefore the robot can be stopped and locked in any position.

Owner:ZHEJIANG SCI-TECH UNIV

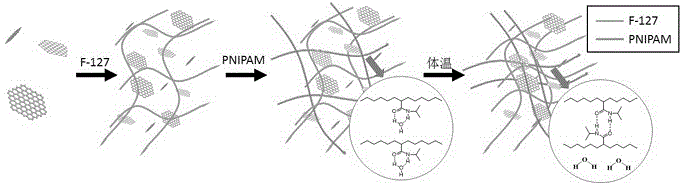

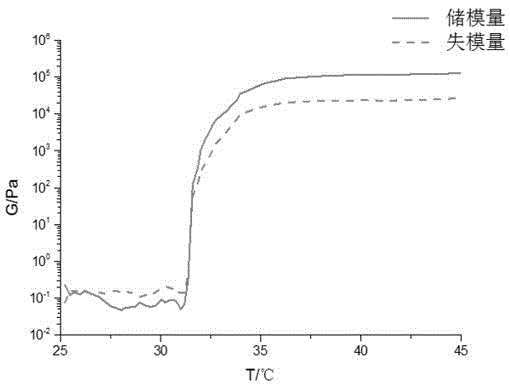

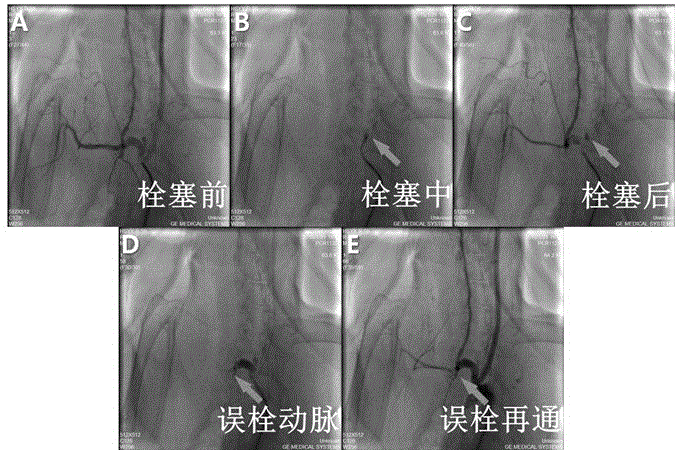

Thermo-sensitive type interpenetrating polymer network hydrogel material and preparation method and application thereof

InactiveCN105462142AStrong load capacityGood biocompatibilitySurgical adhesivesX-ray constrast preparationsX-rayTreatment field

The invention aims at preparing a hydrogel material which has thermo-sensibility, is organically and inorganically hybrid and is of a three-dimensional interpenetrating polymer network structure, by means of good mechanical properties and biocompatibility of the material, the requirements that a clinical injection embolizing agent is good in mechanical property, complete embolization can be achieved, X-ray absorbing capacity is high, an operation is easy to operate are satisfied, and application of the material to the clinical embolism treatment field is achieved.

Owner:FUDAN UNIV +1

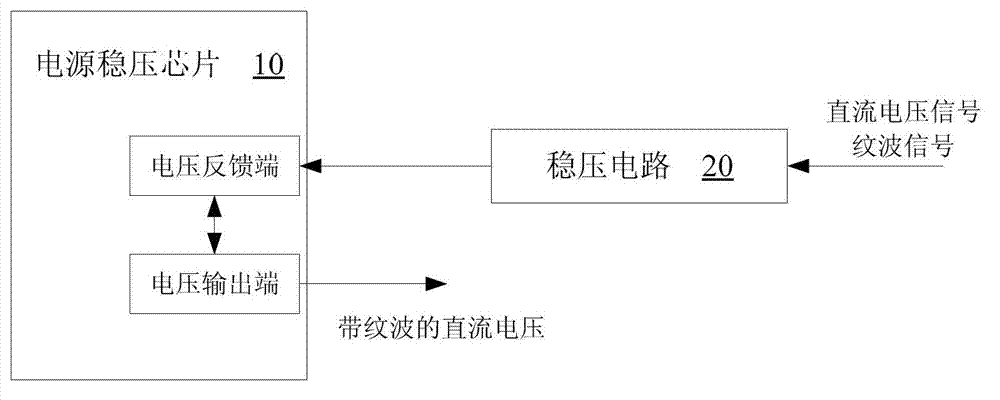

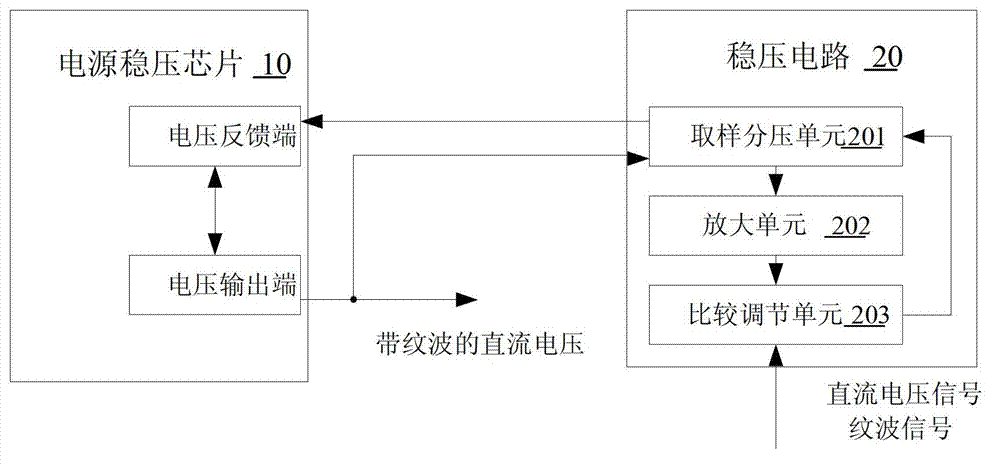

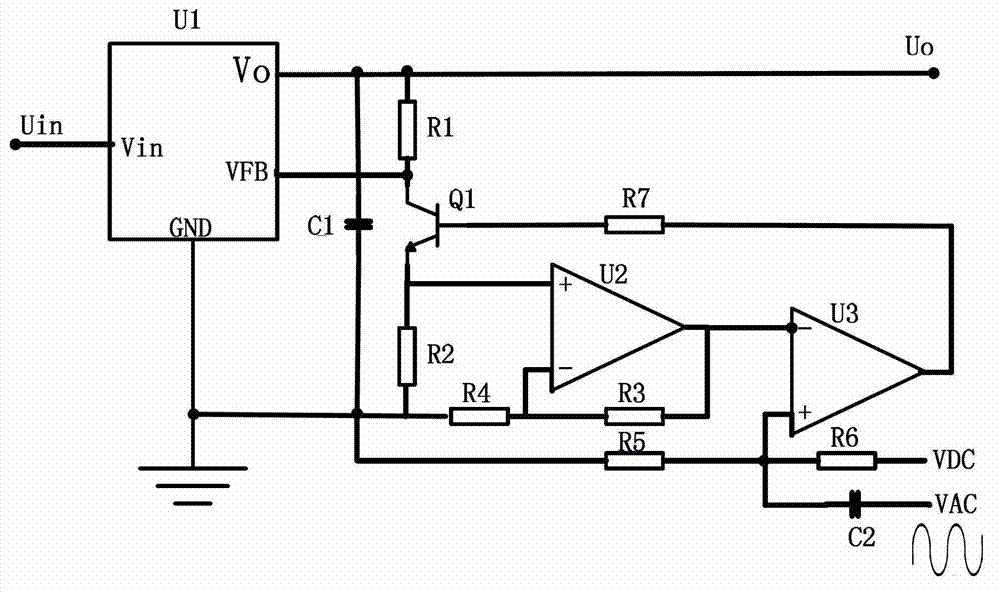

Ripple power supply device and method for providing direct-current voltage with ripples

ActiveCN102882366AStrong load capacitySimplify circuit designDc-dc conversionElectric variable regulationElectrical and Electronics engineeringDc voltage

The invention belongs to the technical field of power supply circuits, and discloses a ripple power supply device and a method for providing a direct-current voltage with ripples. The ripple power supply device comprises a voltage stabilizing chip of a power supply and a voltage stabilizing circuit, wherein a control voltage is applied to a control voltage input end of the voltage stabilizing circuit, so that the output voltage of the voltage stabilizing chip of the power supply can be adjusted; and when the control voltage consists of direct-current voltage signals and ripple signals, both of the ripple signals and the direct-current voltage signals are transmitted to a voltage feedback end of the voltage stabilizing chip of the power supply by the voltage stabilizing circuit, so that the direct-current voltage with the ripple can be acquired at the voltage output end of the voltage stabilizing chip of the power supply. According to the ripple power supply device and the method for providing the direct-current voltage with the ripples, the direct-current voltage overlapped with the ripple voltage can be acquired at the voltage output end when the ripple signals and the direct-current voltage signals are both applied to the voltage feedback end due to the characteristic that the output voltage of the voltage stabilizing chip of the power supply is controlled by the voltage feedback end; the output voltage has relatively high loading capacity; and the overlapped ripple voltage can be controlled in frequency and amplitude, thereby meeting different test requirements.

Owner:HYTERA COMM CORP

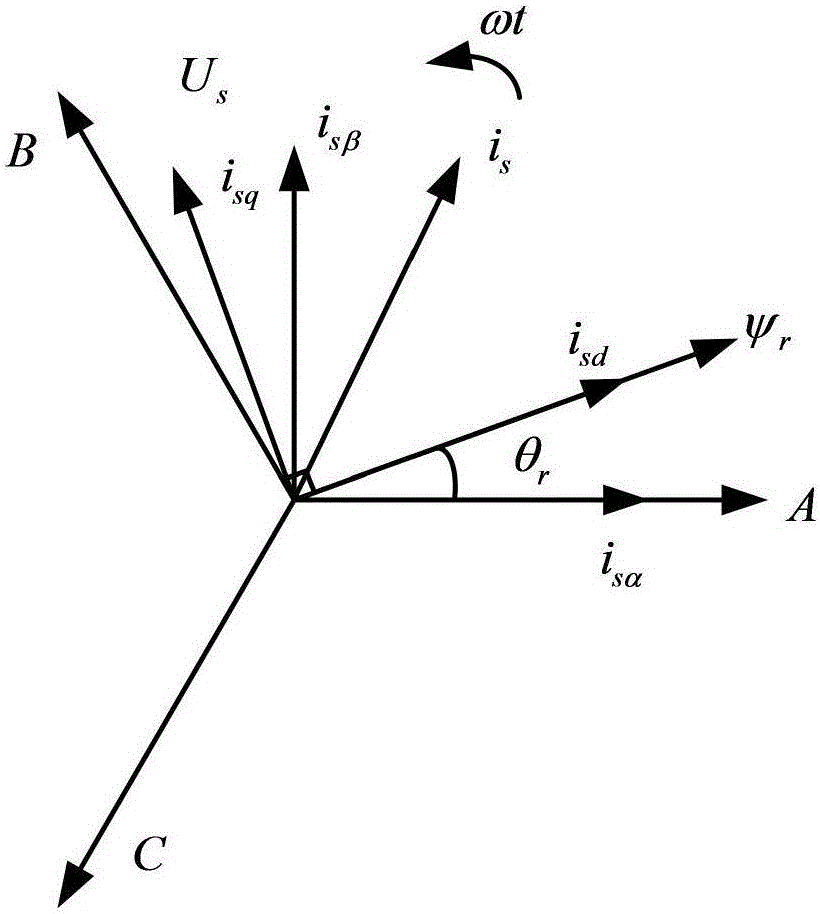

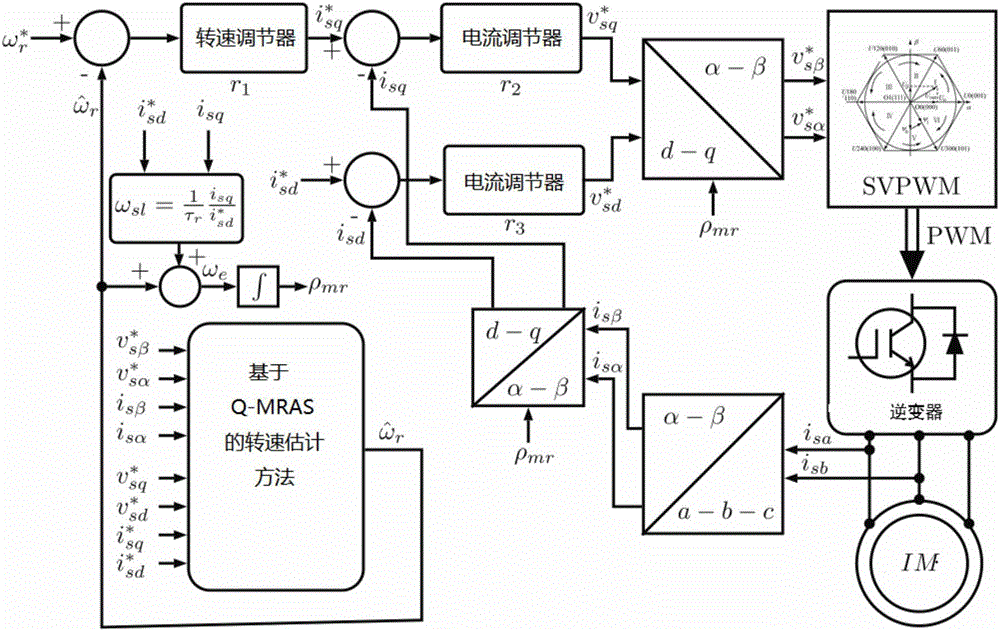

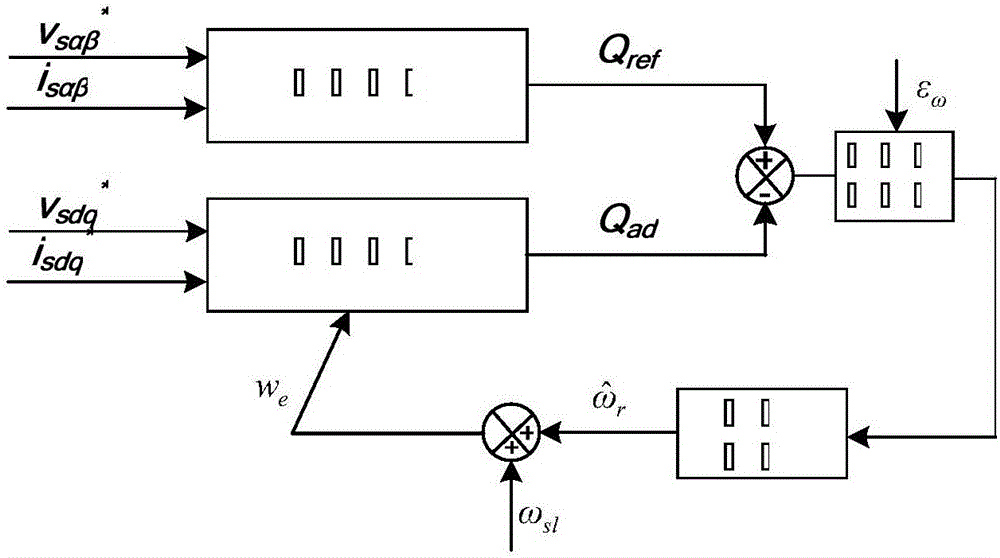

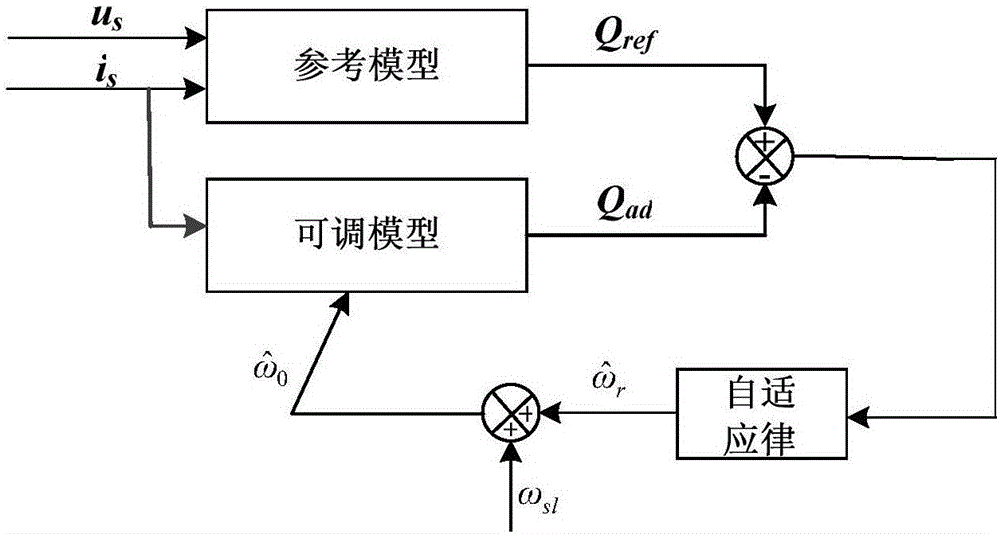

Asynchronous motor speed sensorless control method based on improved Q-MRAS

InactiveCN107181438AGood dynamic performanceStrong load capacityElectronic commutation motor controlVector control systemsStatorVoltage

The invention provides an asynchronous motor speed sensorless control method based on an improved Q-MRAS. The method includes the steps of rotational speed control: obtaining a given value of a stator current q-axis component, calculating a rotational speed difference frequency, and obtaining a rotational speed difference angular speed and a flux linkage phase of a motor; coordinate transformation: obtaining a stator current under dq-axis by coordinate transformation; current control: obtaining a given value of a stator voltage dq-axis component, modulating space vectors, and performing space vector modulation according to the stator voltage given value to output a drive pulse; and a speed sensorless method: obtaining an estimated motor rotational speed through an appropriately designed reference model and adjustable model based on a Q-MRAS structure. The beneficial effects of the method of the invention are that a rotational speed identification system based on the improved Q-MRAS well fits to the actual rotational speed no matter under a starting process, a state switching process or a low speed condition, the dynamic tracking performance is high, meanwhile the problem of high dependency of a traditional Q-MRAS method on motor parameters is solved, and the identification accuracy and loading capacity are high.

Owner:HARBIN INST OF TECH SHENZHEN GRADUATE SCHOOL

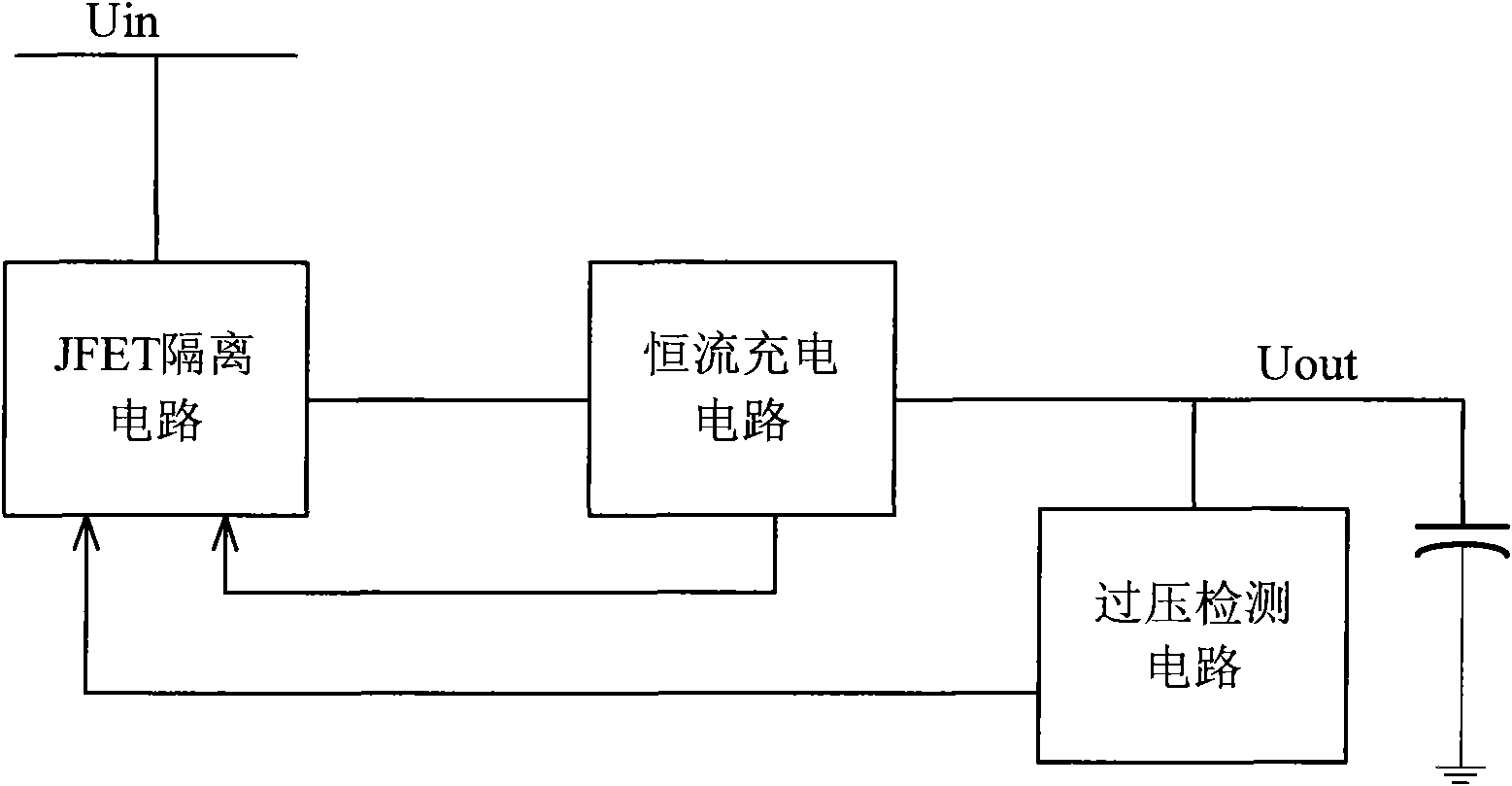

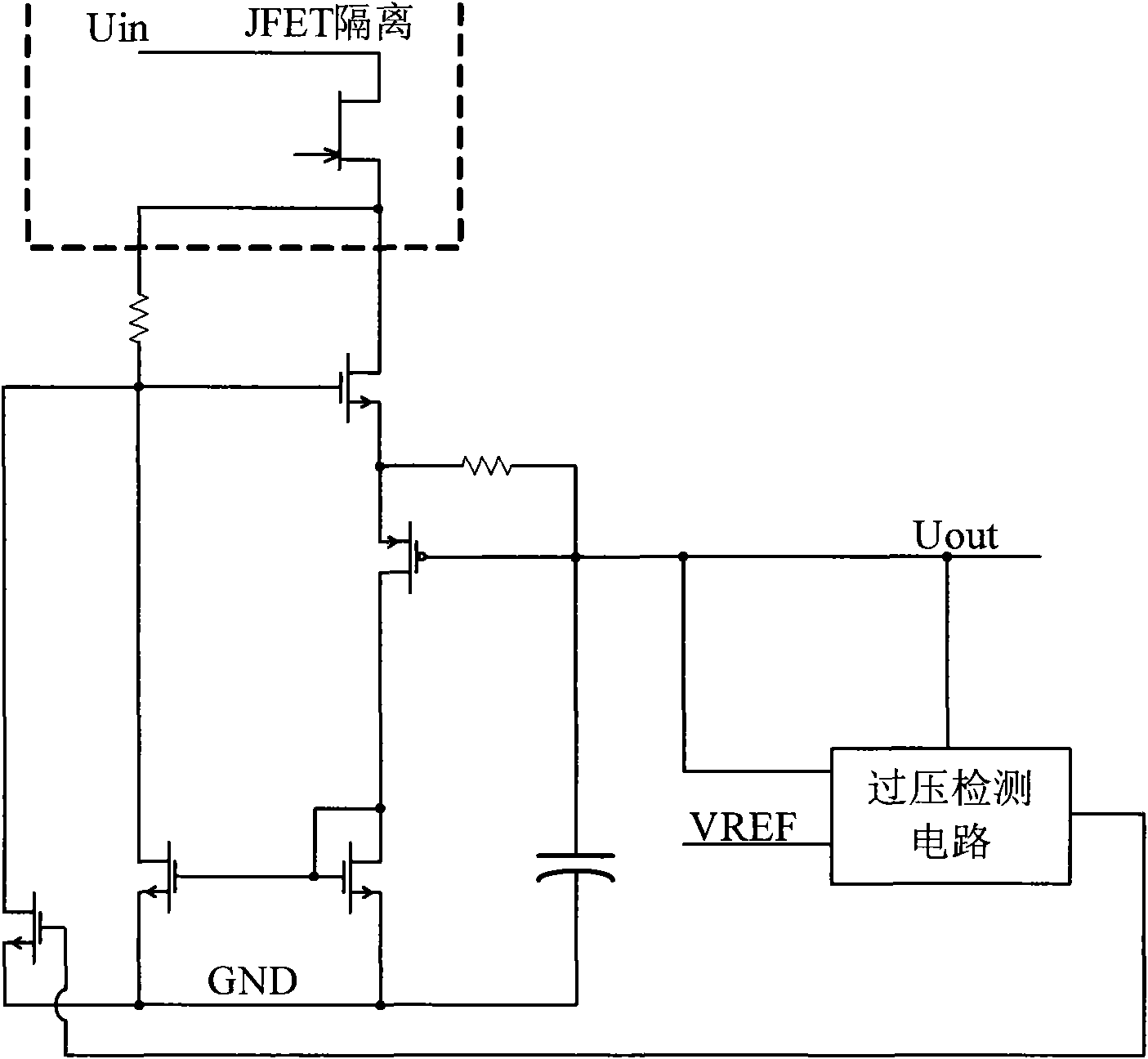

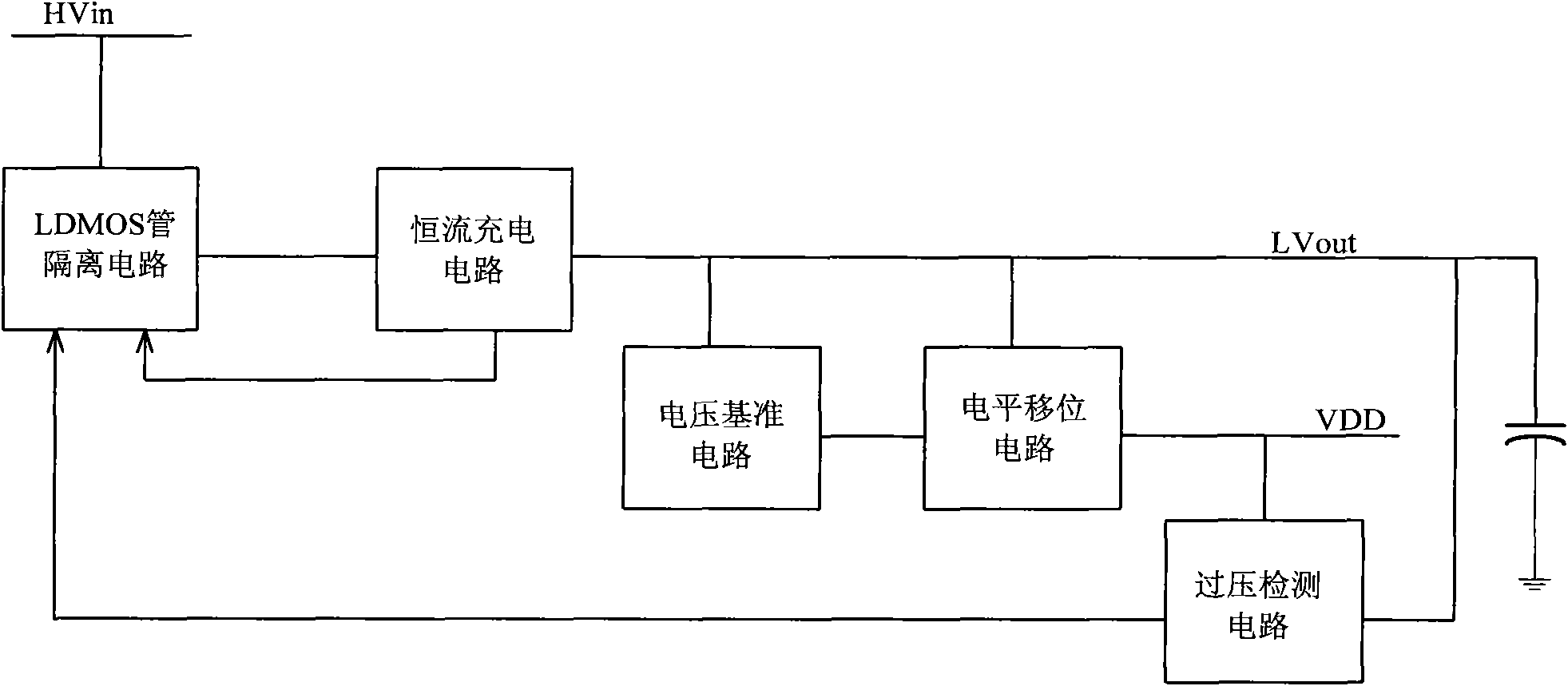

Internal power supply circuit started with high voltage and constant current

ActiveCN101901019AGood temperature characteristicsStrong load capacityElectric variable regulationCurrent limitingPower circuits

The invention discloses an internal power supply circuit started with high voltage and constant current, which is used for generating stable internal power supply voltage and comprises a high voltage resistant LDMOS tube isolation circuit, a constant current charging circuit, a voltage reference circuit and a level shifting circuit, wherein the high voltage resistant LDMOS tube isolation circuit comprises a current limiting resistor R1 and a N-channel high voltage resistant LDMOS tube MN1, wherein the high voltage resistant LDMOS tube MN1 is used as an adjusting tube, and the input end is connected with a power supply pin HVin and simultaneously receives the signals of overvoltage control circuits in the constant current charging circuit and the level shifting circuit, thereby ensuring the normal starting of the circuit and the stability of the output voltage. In the invention, a high-voltage LDMOS tube is used for carrying out high-voltage isolation, so that the circuit has higher breakdown voltage, larger safe operation area and lower on-resistance.

Owner:昌芯(西安)集成电路科技有限责任公司 +1

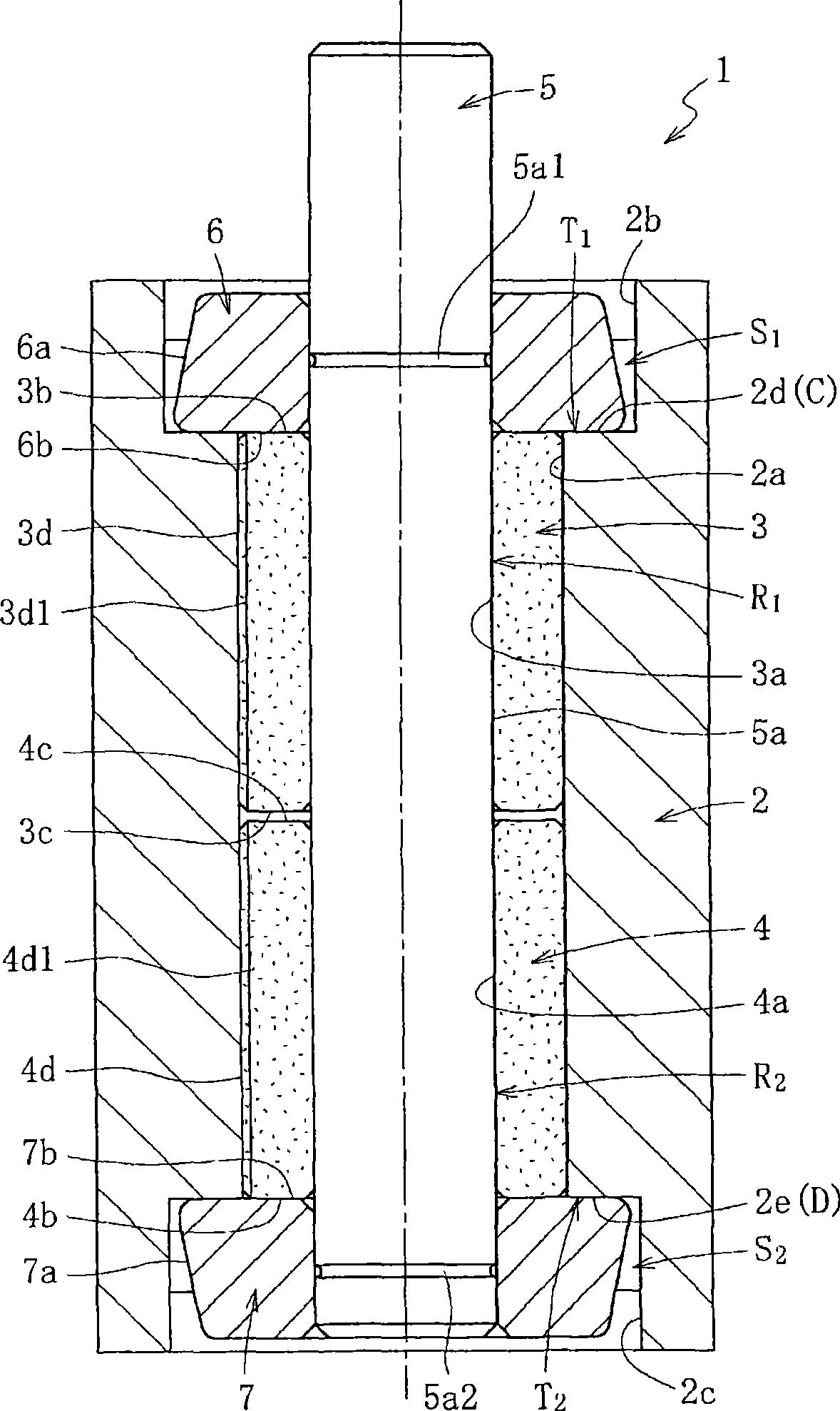

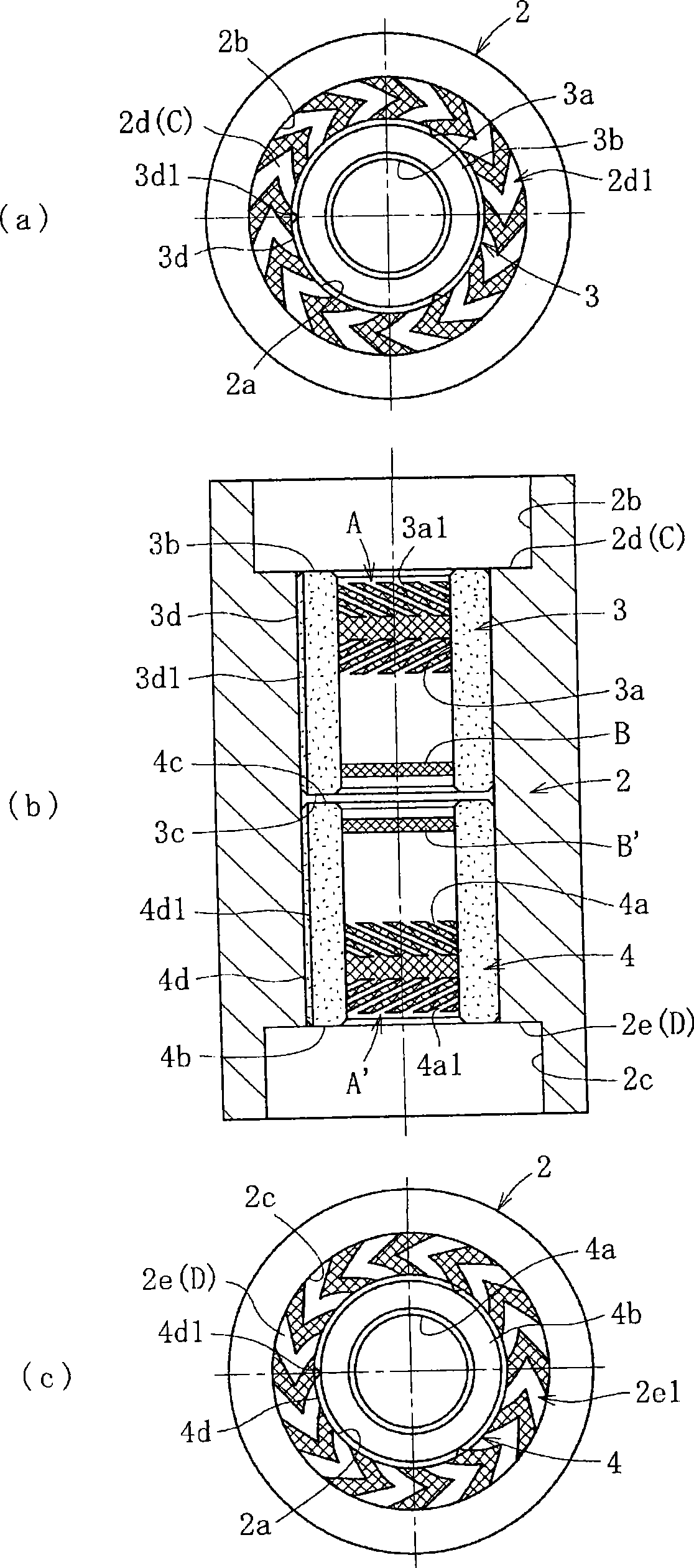

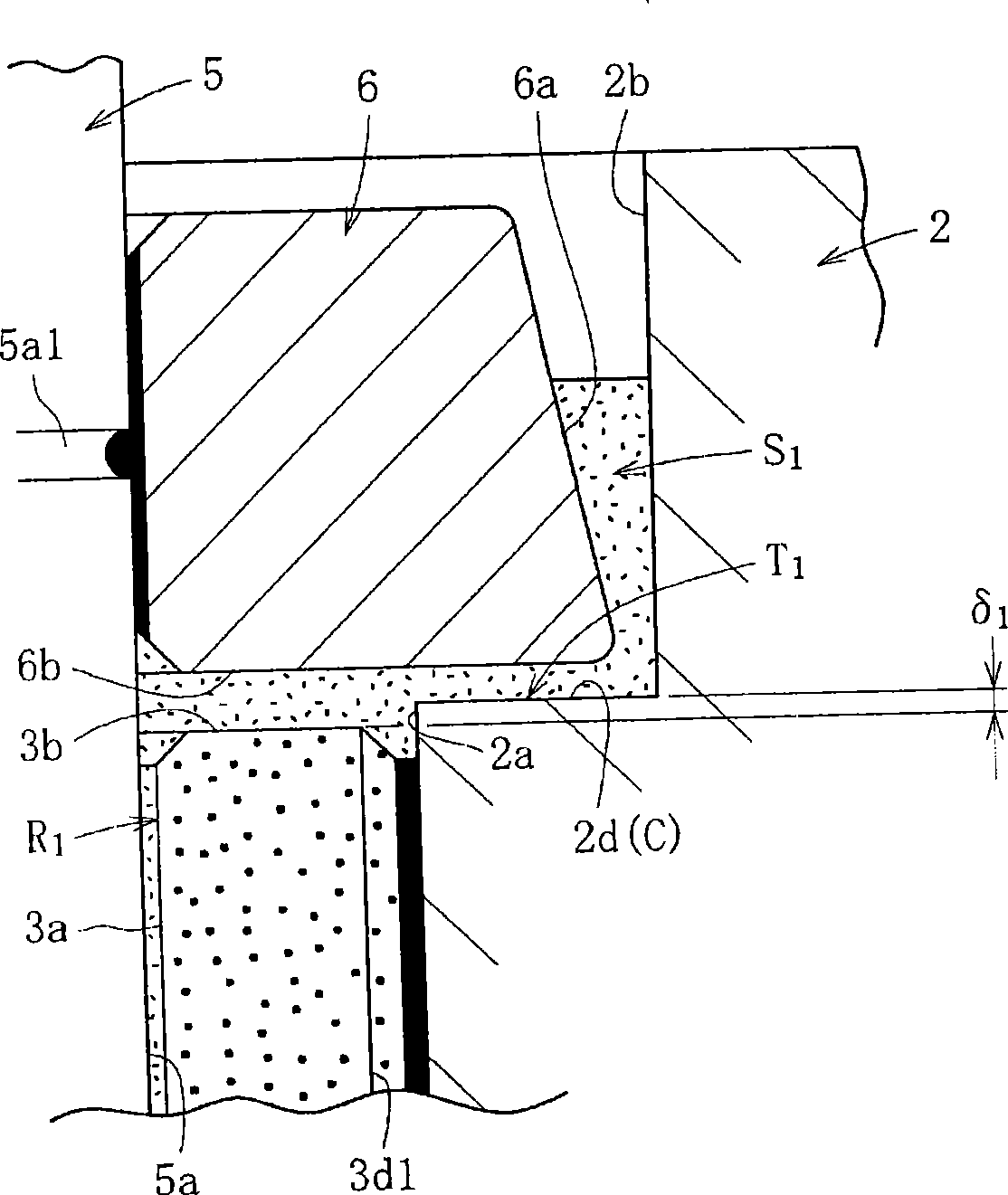

Fluid bearing device and its manufacturing method

InactiveCN101438068AEasy to assembleStrong load capacitySliding contact bearingsBearing unit rigid supportThrust bearingStructural engineering

To provide a fluid bearing device in which a bearing sleeve can be easily assembled to a housing and which has excellent moment rigidity. [MEANS FOR SOLVING THE PROBLEMS] This fluid bearing device (1) comprises radial bearing parts (R1, R2) and thrust bearing parts (T1, T2). Thrust bearing surfaces (C, D) are provided on the first and second step surfaces (2d, 2e) of the housing (2) respectively. The thrust bearing parts (T1, T2) are formed between the thrust bearing surfaces (C, D) and the end surfaces (6b, 7b) of seal members (6, 7) projecting to the outer diameter side of a shaft member (5).

Owner:NTN CORP

Preparation method of paving asphalt modified at normal temperature

ActiveCN102190898ASimple processShorten the production cycleBuilding insulationsRoom temperatureRoad surface

The invention provides a preparation method of paving asphalt modified at a normal temperature. The invention belongs to the preparation field of pavement materials and comprises the following steps of cracking, low pressure separation, diluent preparation, high-molecular resin modifier preparation, modification and blending. The preparation method adopts improved technical processes, thus a process of heating matrix asphalt is avoided and purposes of short production period, low production cost and environmental protection are realized.

Owner:SICHUAN GUOXING POLYMER RESIN CO LTD

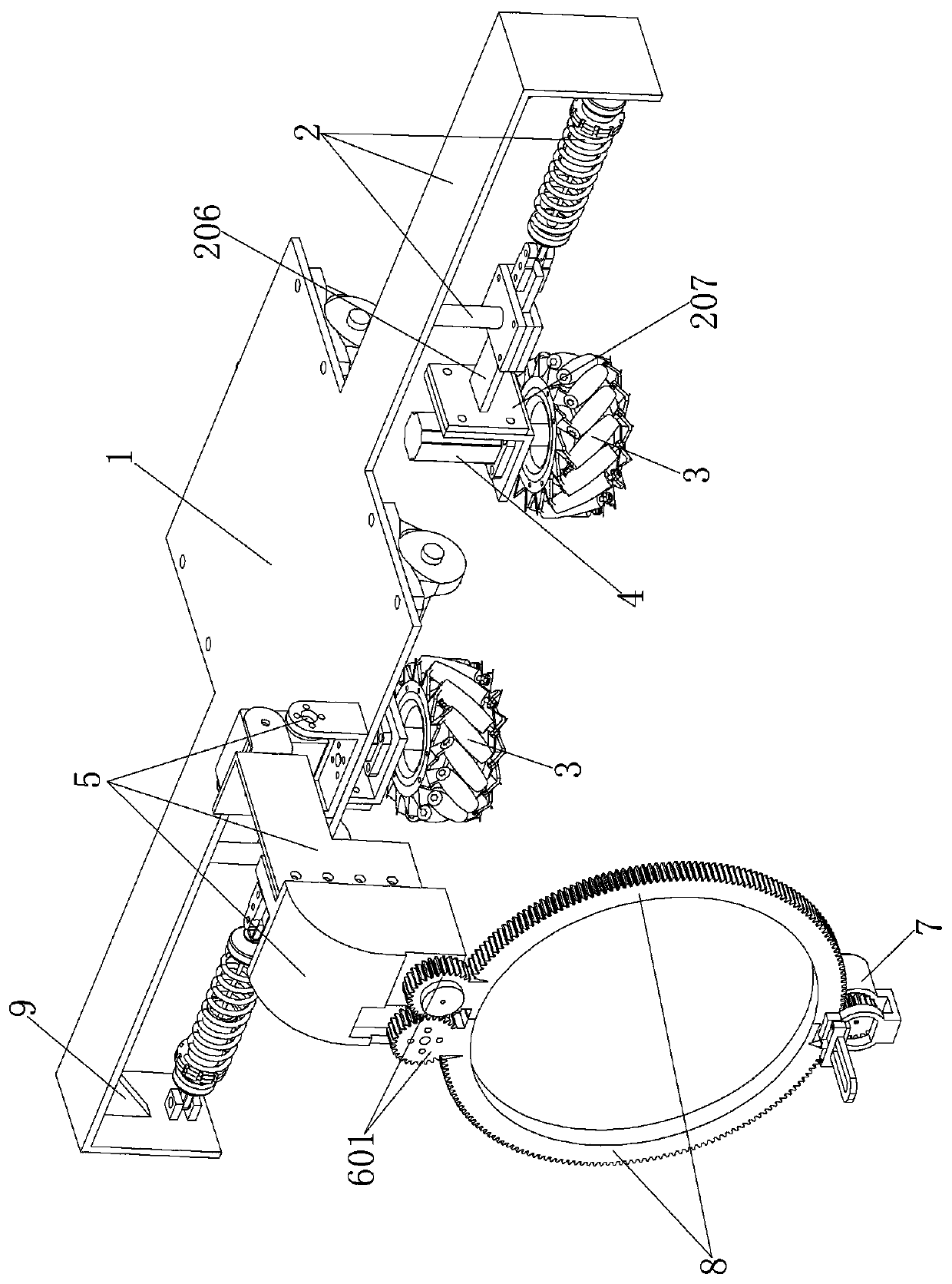

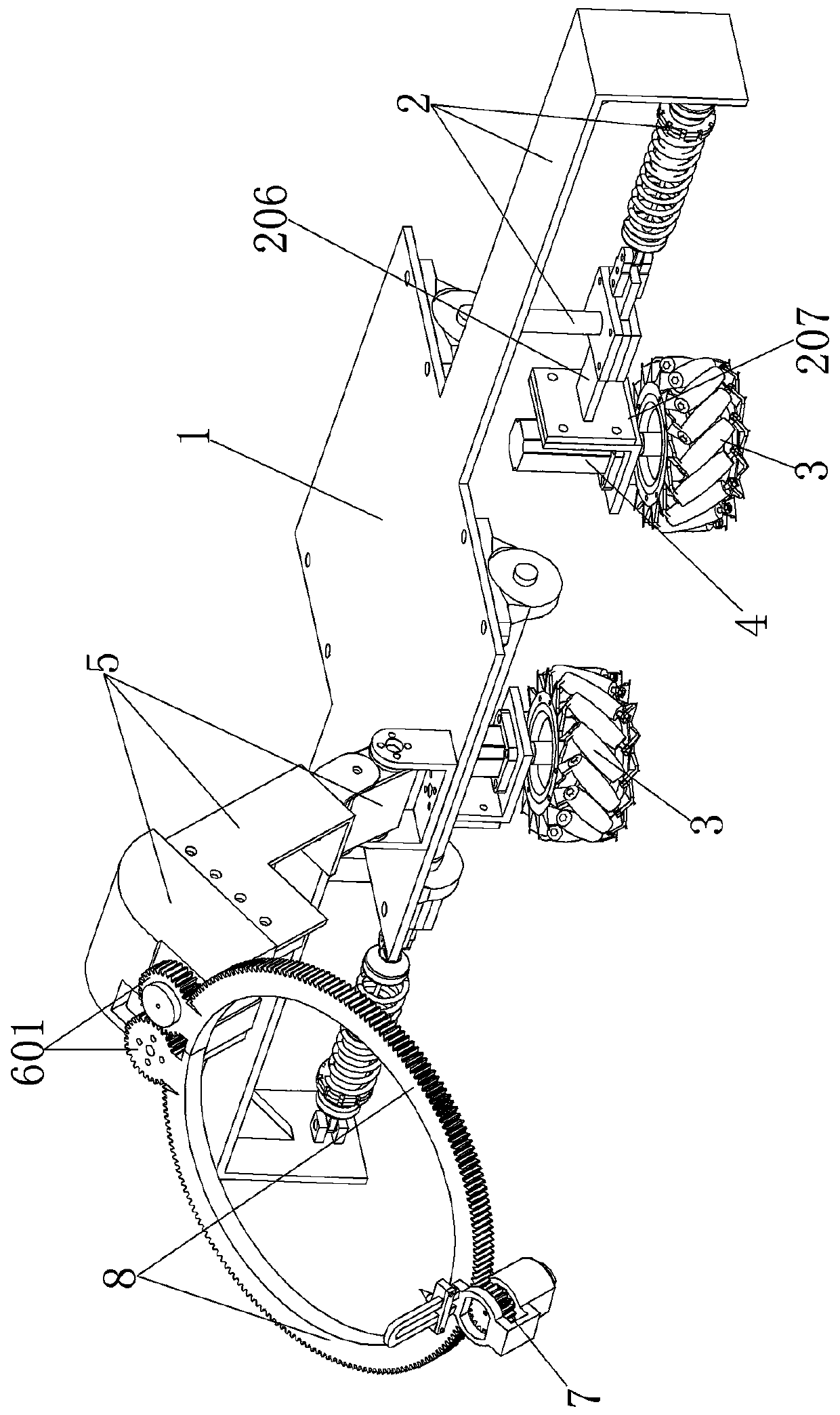

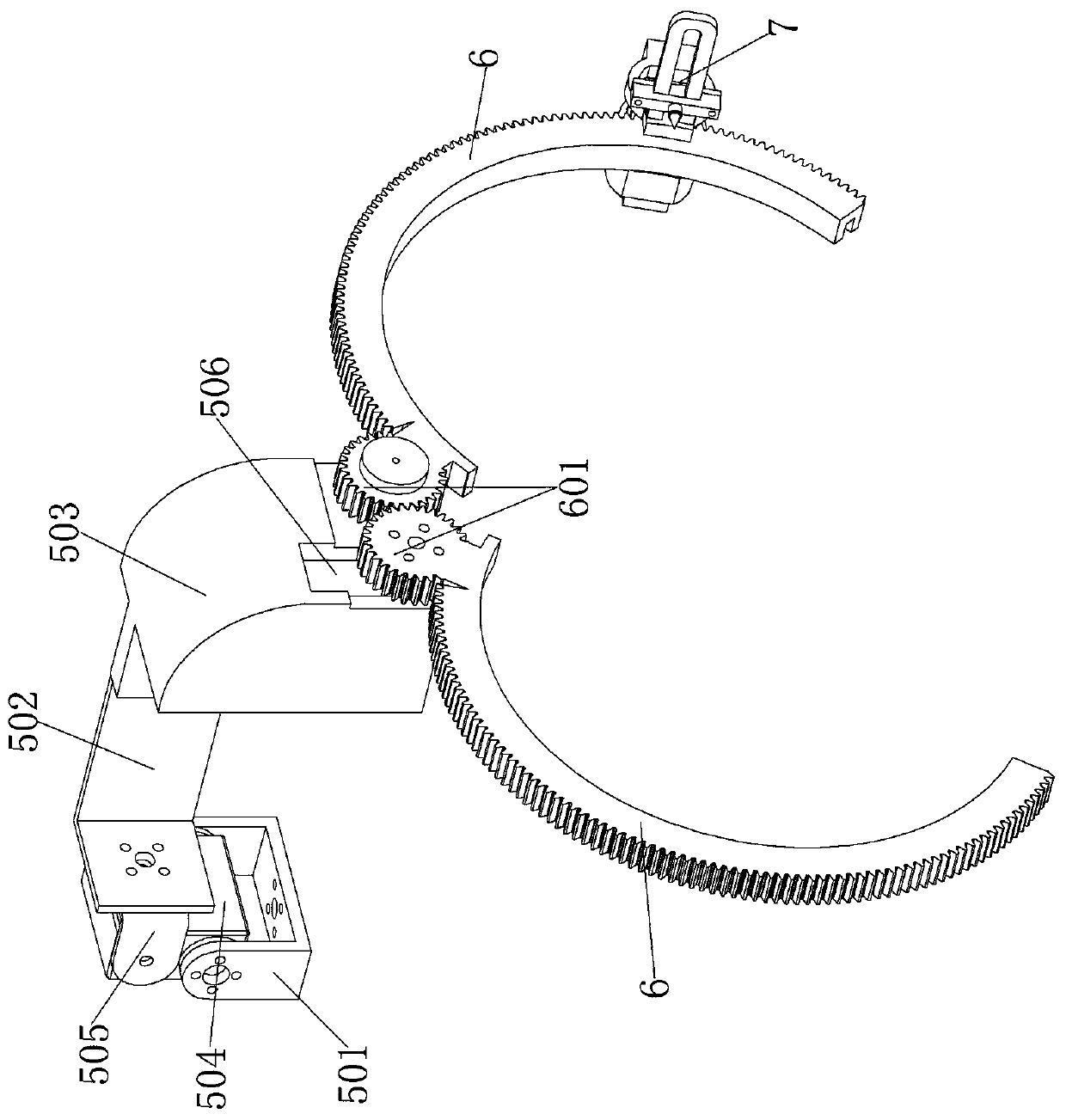

Pipeline crawling welding robot

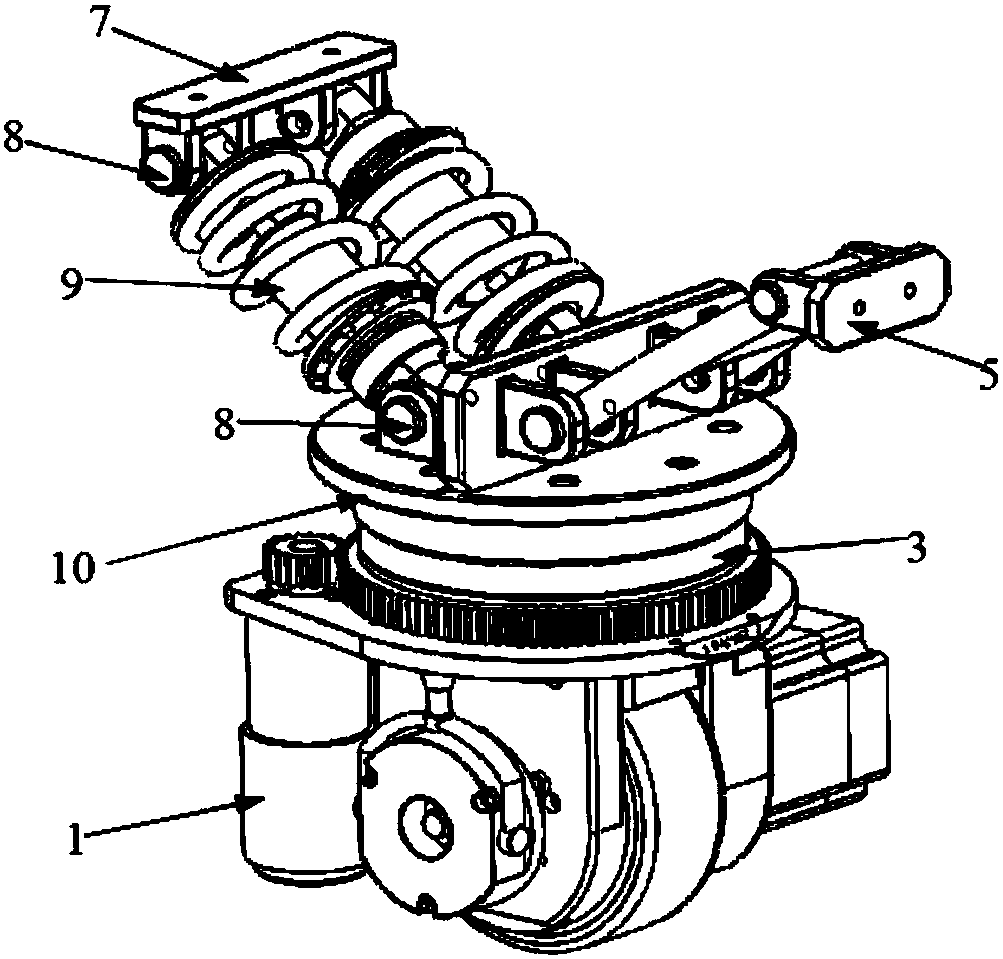

PendingCN109967833AStrong load capacityRunning balanceArc welding apparatusTubular articlesMecanum wheelEngineering

The invention relates to a pipeline crawling welding robot. The pipeline crawling welding robot includes a traveling mechanism and a welding mechanism, wherein the traveling mechanism adopts a suspension structure with Mecanum wheels, the two symmetrical Mecanum wheels are installed on the end parts of an extensible rod of the inner end of a suspension spring, and are provided with an independentmotor for driving, and thus the two Mecanum wheels can bestride on a pipeline to move back and forth under pressure of the suspension spring; the welding mechanism is fixed to the front end of the traveling mechanism and can be raised and recycled to the upper end of the traveling mechanism without affecting crawling of the robot; and when the welding mechanism descends, two semicircular gear rings can be enclosed to the circumference of the pipeline, and a moving welding machine is controlled to rotate to weld a joint of the pipeline. The welding robot can crawl and turn a corner on the pipeline, meanwhile, the all-direction welding task of the pipeline can be completed, and welding of the pipeline by human in the field can be replaced; and at the same time, the pipeline crawling weldingrobot has the advantages of being high in welding quality, high in welding precision, high in efficiency, and low in cost, and is beneficial to promoting the market.

Owner:ZHENGZHOU UNIVERSITY OF LIGHT INDUSTRY

Cleaning dishcloth easy to remove oil and making method thereof

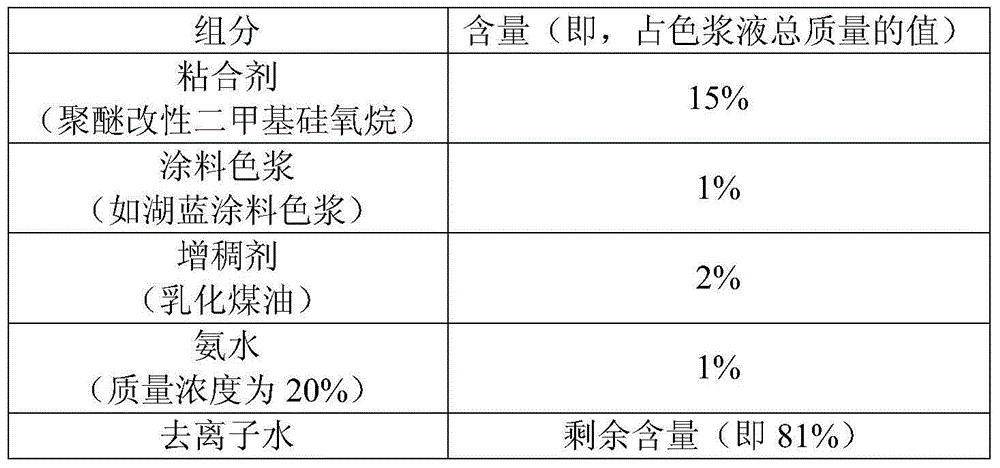

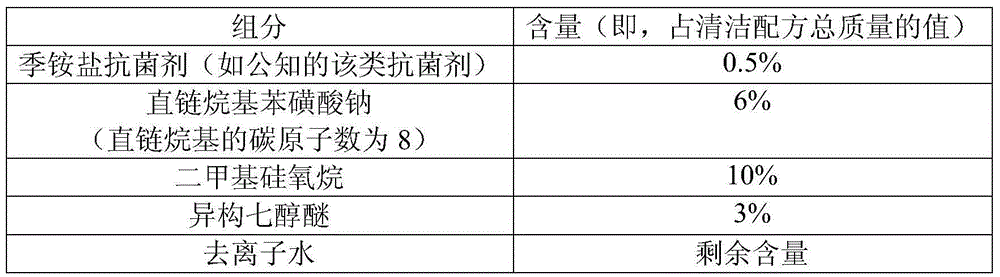

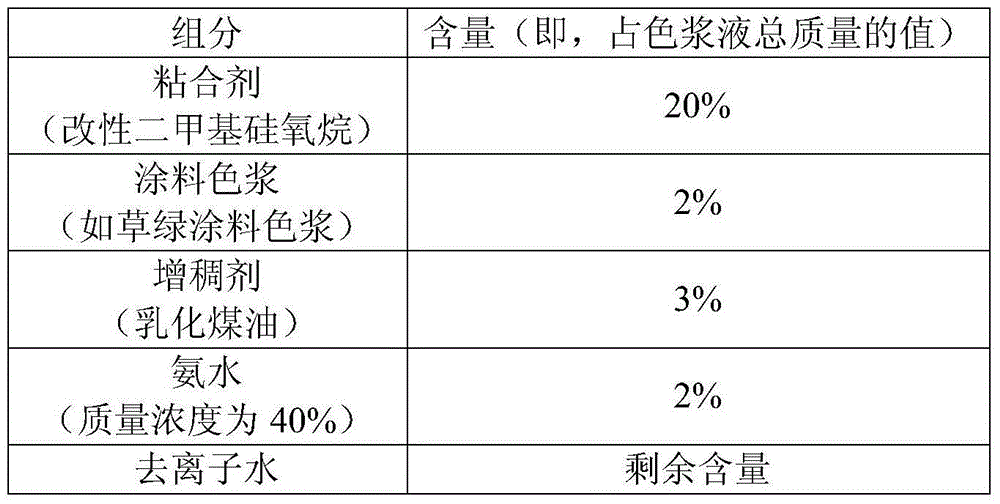

InactiveCN105982630AStrong load capacityQuick and automatic separationOrganic detergent compounding agentsNon-ionic surface-active compoundsChemistryEther

The invention discloses cleaning dishcloth easy to remove oil and a making method thereof. The dishcloth comprises base cloth which is added with a composition for cleaning. The composition comprises quaternary ammonium salt antibacterial agent, sodium n-alkyl benzene sulfonate, dimethyl siloxane, isomeric alcohol ether-7 and water. The making method includes a method A or a method B, wherein, a step (2) and a step (3) in the method A are omitted in the method B, and the method A includes the steps of (1) preparation of cleaning formula stock solution, (2) dyeing, (3) drying, (4) shaping and (5) drying. The dishcloth has functions of absorbing water and oil without being stained with oil, after the dishcloth wipes oil, fast and automatic separation of oil and cloth can be realized by cleaning the dishcloth directly with clear water, and then the cleaning dishcloth recover as new can be obtained; the dishcloth can be reused or used repeatedly.

Owner:上海研蓁化工科技有限公司

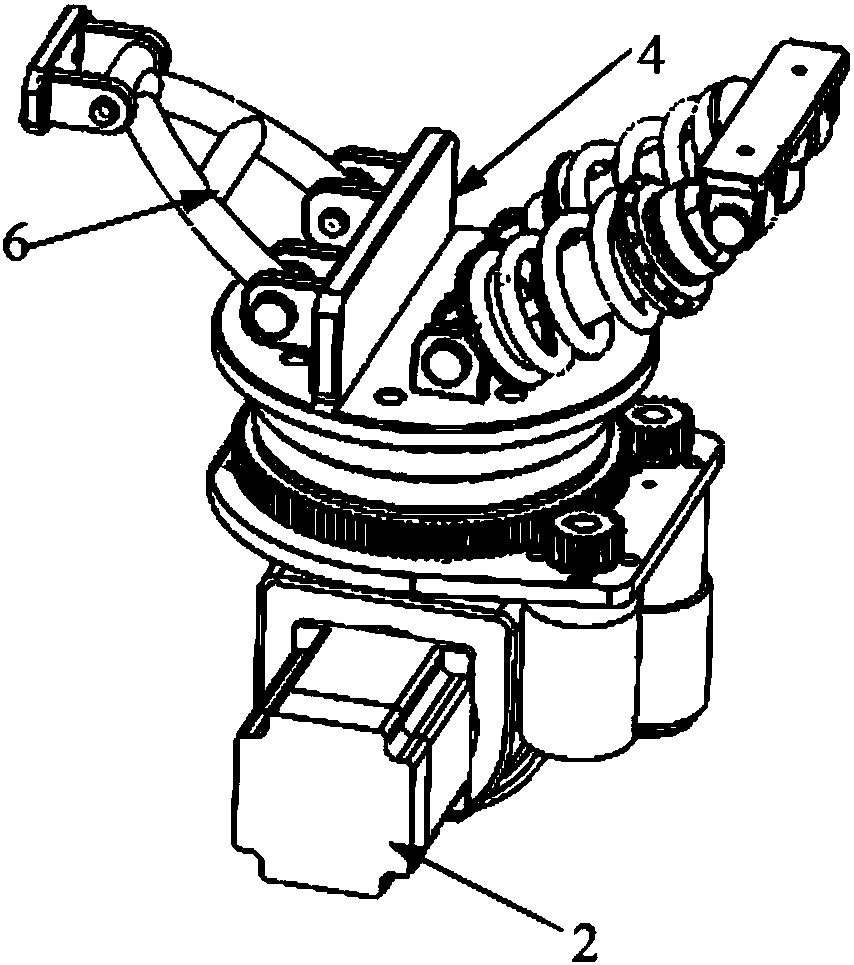

Steering wheel independent suspension system

InactiveCN108081895AImprove obstacle performanceEasy to adjustResilient suspensionsSteering wheelHigh load

The invention discloses a steering wheel independent suspension system comprising a steering wheel mechanism, a main mounting frame, a damping damper, and a connecting arm; the main mounting frame isarranged on the steering mechanism for being connected with a car body; lower ends of the damping damper and the connecting arm are both connected with the main mounting frame in a hinged mode; and upper ends of the damping damper and the connecting arm are both connected with the car body in a hinged mode. The steering wheel independent suspension system is reasonable in structural design, the ability of obstacle climbing ability and dynamic regulation ability of the steering wheel can be improved, high load capacity of a steering wheel AGV and flexible athletic ability are furthest played, the system is stable and reliable, the vibration is small, the service life of the steering wheel is prolonged, and the use cost is reduced.

Owner:WUHU HIT ROBOT TECH RES INST

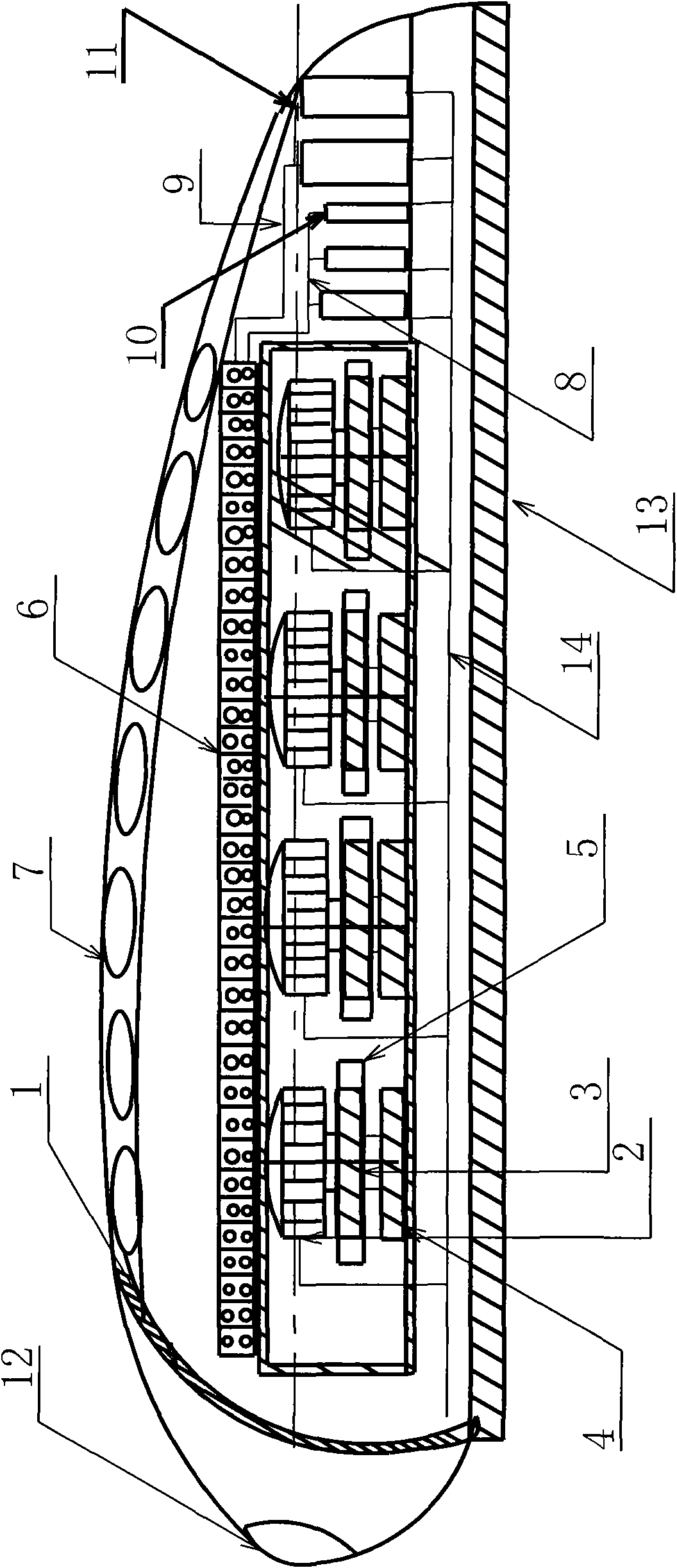

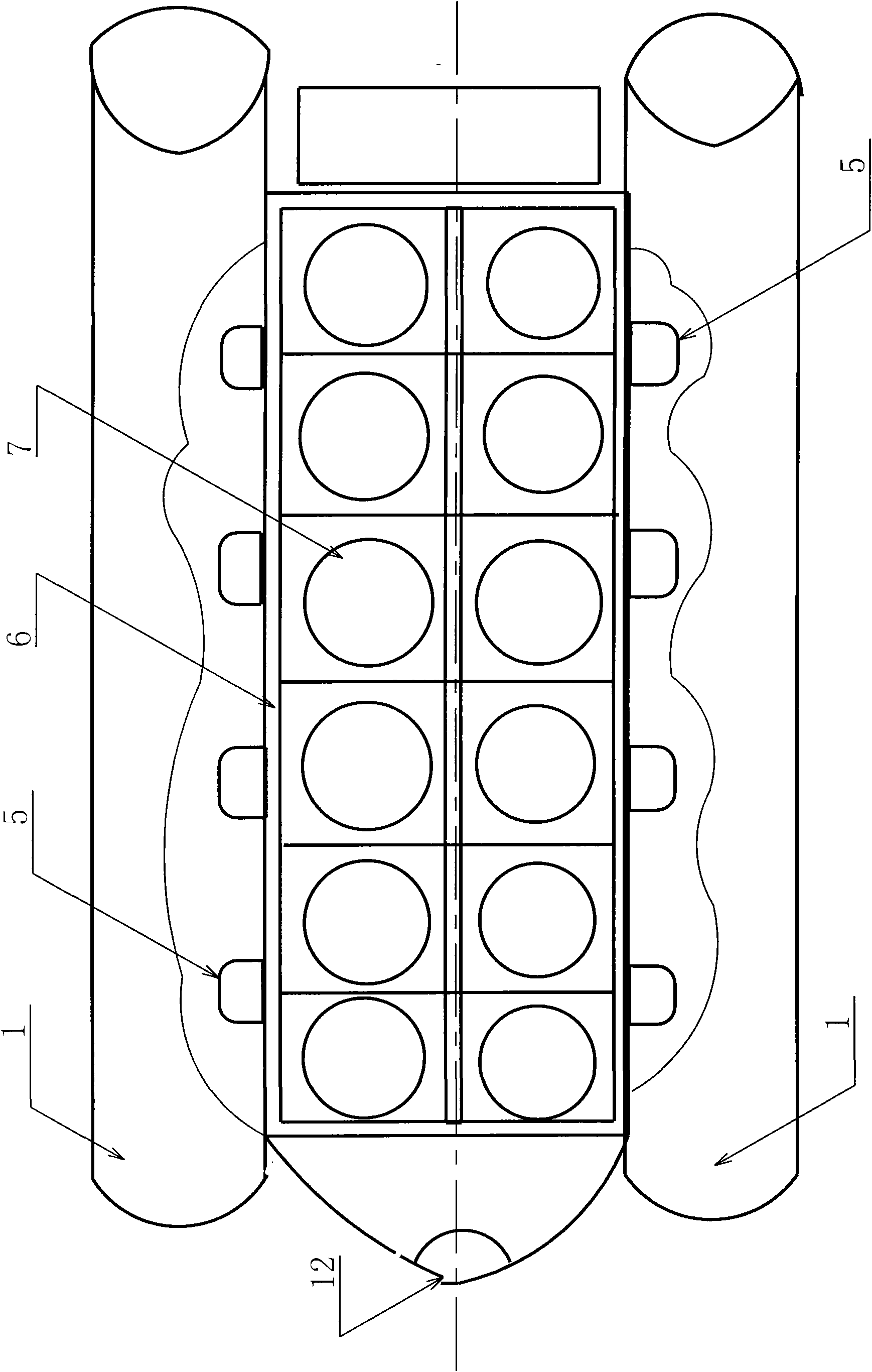

Vehicle mobile-type four-to-one generating set of wind, light, magnet and heat

InactiveCN101624013AStrong battery lifeStrong load capacityAuxillary drivesWind motor combinationsFiber optic sensorAutomotive engineering

The invention discloses a vehicle mobile-type four-to-one generating set of wind, light, magnet and heat, belonging to main classes of power generation, power transformation or power distribution of H02 power according to international classification, in particular the technical field of configuring vehicles by using the four-to-one generating set of wind, light, magnet and heat to prepare a pure electric automobile. A wind tunnel (1) is connected by a stand (13), a generator (2) is arranged in the wind tunnel, the wind tunnel is sequentially connected with an photo-thermal collector (6) and a Fresnel light collector (7), an optical fiber sensor (8) in the photo-thermal collector is connected in series with a photoelectric converter (10) and a heat pipe serial-connection thermoelectric converter (11), the generated electricity flows into a cable (14), and a flow distribution head (12) is arranged in the front of the device, and the stand (13) and the wind tunnel (1) are connected to the vehicle body to form an integral structure. The technical scheme shows that the wind, the light, the magnet and the heat which can be utilized currently in the nature are utilized to carry out energy conversion to provide a clean energy used as a power source of an automotive vehicle, thereby achieving a pure electric automobile with self power generation, strong cruising capacity, strong load capacity, no environment pollution and real clean energy.

Owner:赵大庆

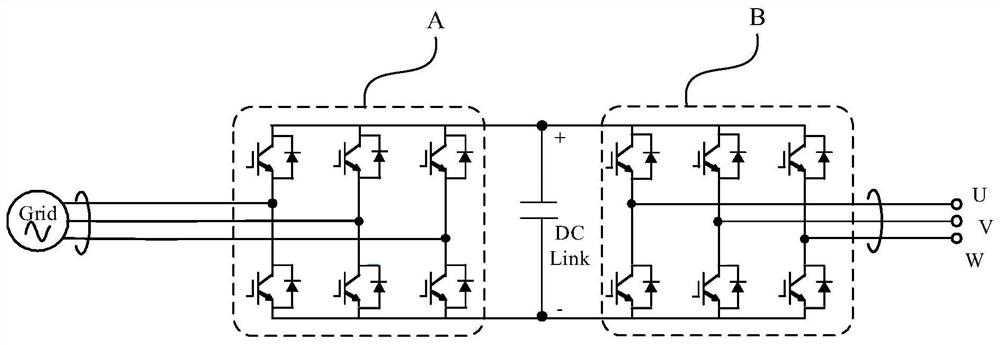

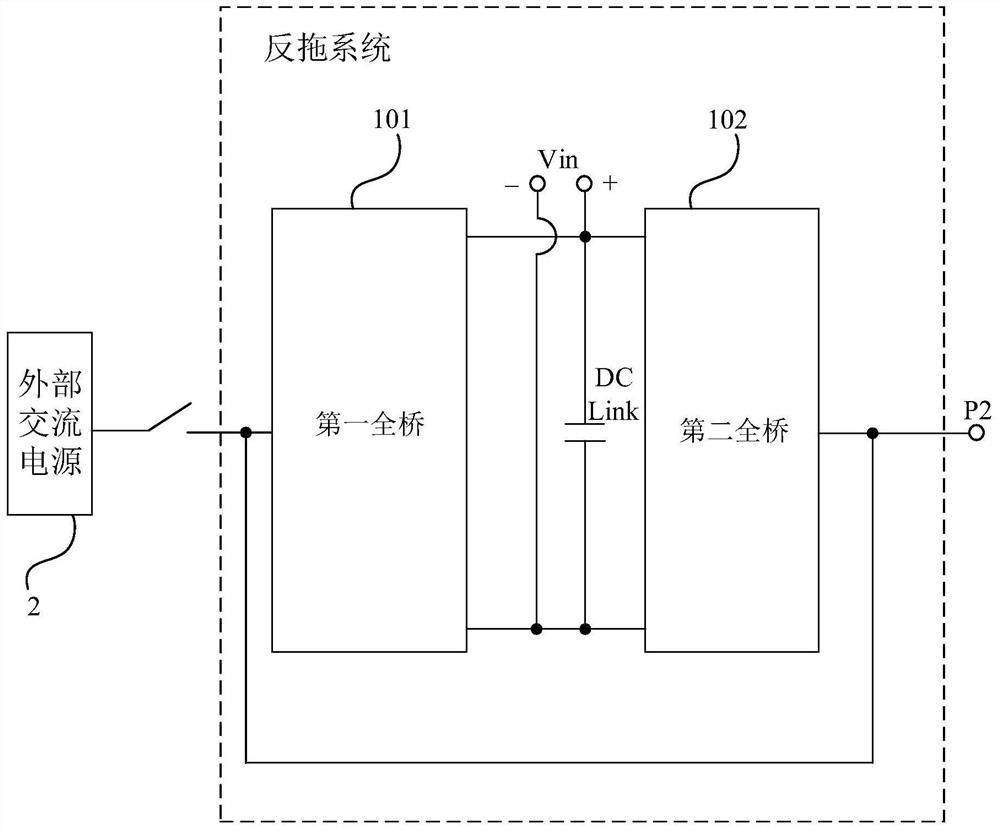

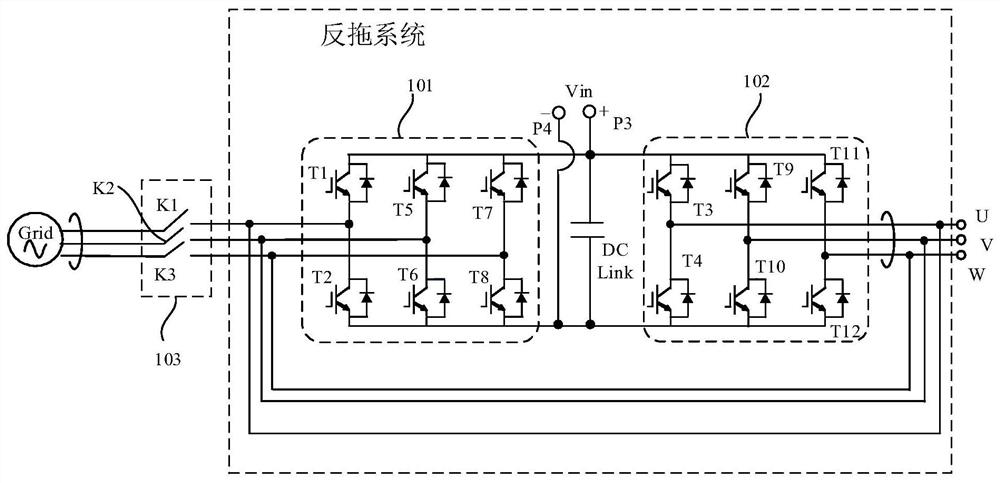

Reverse towing system and wind generating set

ActiveCN111669061AStrong load capacityStable output performanceAc-dc conversionSingle network parallel feeding arrangementsWind power generatorTowing

The invention discloses a reverse towing system and a wind generating set. The reverse towing system comprises a converter, wherein the converter comprises a first full bridge, a second full bridge and a direct current bus; the first full bridge and the second full bridge are connected back to back through a direct-current bus; the alternating current port of the first full bridge is disconnectedwith an external alternating current power supply; the alternating current port of the first full bridge is electrically connected with the alternating current port of the second full bridge; the direct-current bus is used for being electrically connected with an external direct-current power supply; and the alternating current port of the second full bridge is used as an output end of the reversetowing system. The reverse towing system provided by the invention has relatively strong loading capacity and can provide stable output performance.

Owner:ZHEJIANG UNIV +1

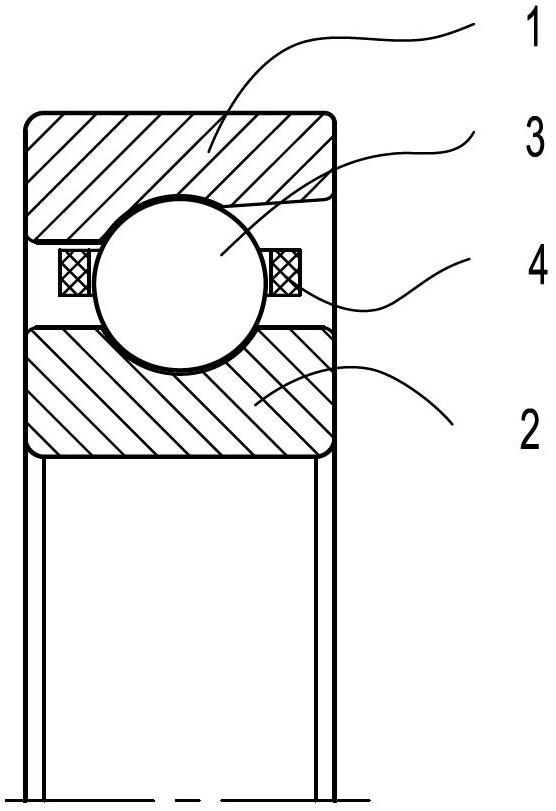

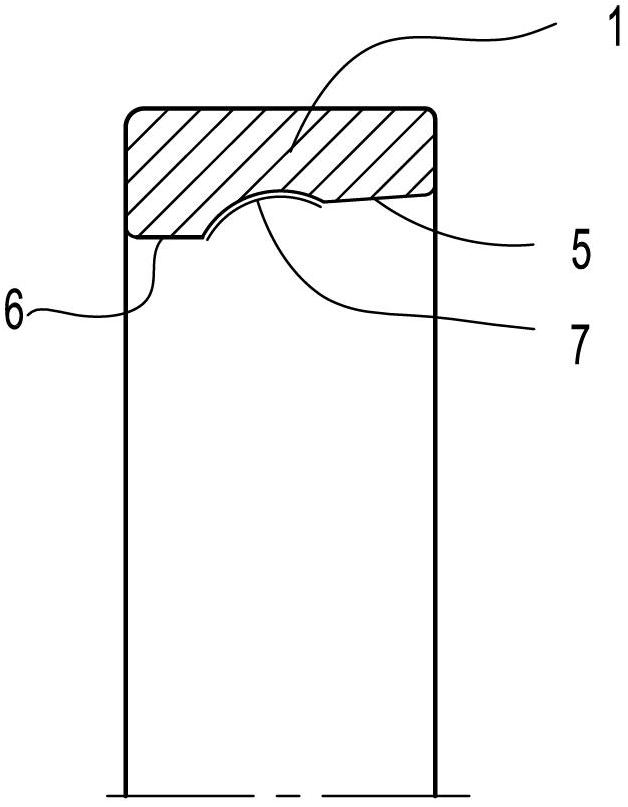

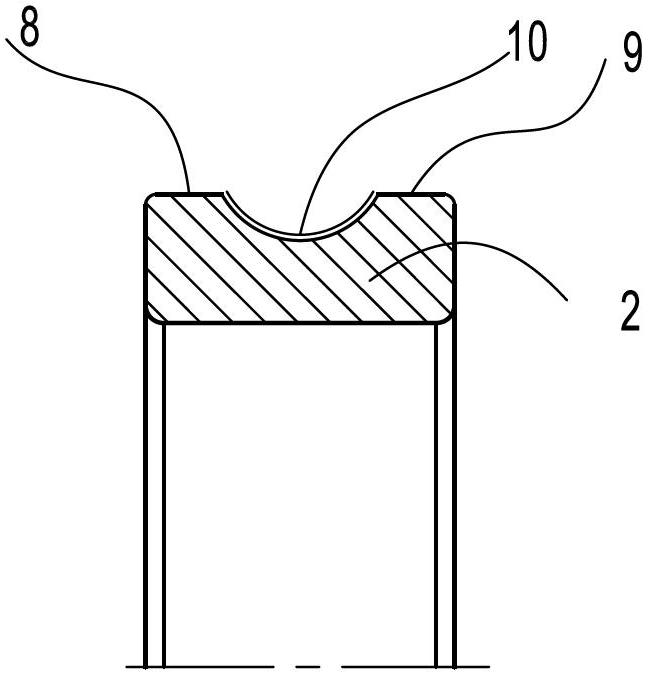

Low-temperature deep cooling bearing

ActiveCN102678740AExtended service lifeStrong load capacityBall bearingsBearing componentsPolyether ether ketoneTungsten disulfide

The invention relates to high-speed refrigeration equipment, in particular to a low-temperature deep cooling bearing which is applied to a liquid nitrogen pump. The low-temperature deep cooling bearing comprises an outer ring, an inner ring, a rolling body and a retainer; the outer ring and the inner ring adopt stainless steel materials; a rolling path of the outer ring and a rolling path of the inner ring are both sequentially subjected to superfinishing and tungsten disulfide surface treatment; the rolling body is a ceramic ball; and the retainer adopts a PEEK (polyether-ether-ketone) material. According to the low-temperature deep cooling bearing, the outer ring and the inner ring adopt the stainless steel materials, the rolling body adopts the ceramic ball, and the retainer adopts the PEEK material, so that the bearing can meet requirements on shape change and rust prevention under deep cooling condition; and the rolling paths of the inner and outer rings are sequentially subjected to the superfinishing and the tungsten disulfide surface treatment, so that the bearing has self-lubricating function, and the service life of the bearing under low temperature condition can be prolonged.

Owner:WUXI NO 2 BEARING

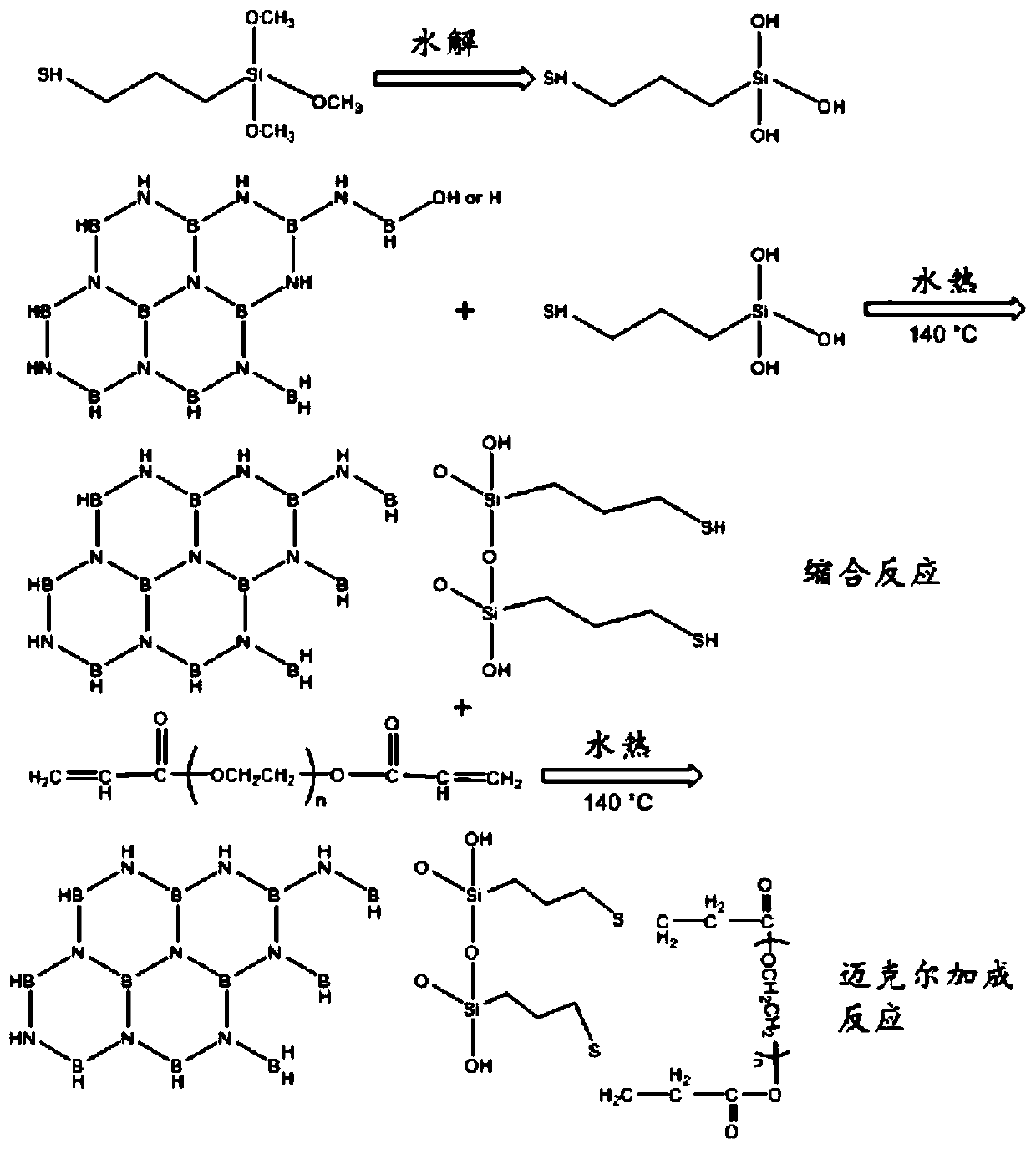

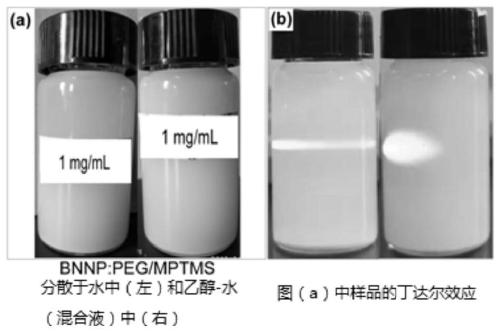

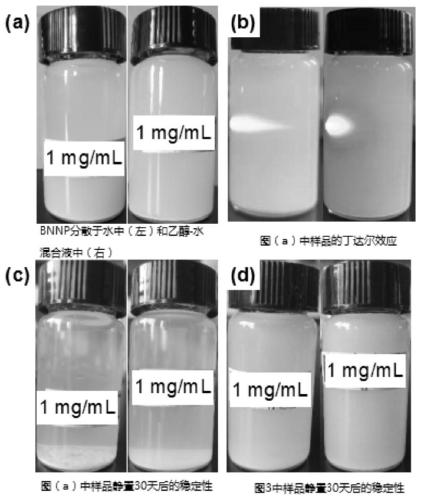

Nano pesticide preparation based on boron nitride nanosheet grafted hydrophilic macromolecules and preparation method thereof

ActiveCN111406740AStrong load capacityObvious nano confinement effectBiocideAnimal repellantsPesticideAddition reaction

The invention provides a nano pesticide preparation based on boron nitride nanosheet grafted hydrophilic macromolecules and a preparation method thereof, and belongs to the technical field of nano pesticide preparations. Biocompatible hydrophilic macromolecules and mercaptosilane are grafted to the surface of the hexagonal boron nitride nanosheet through condensation and Michael addition reaction;the interaction between the raw materials promotes the hexagonal boron nitride powder to form rich orderly arranged thin-layer-shaped nano channels, and the nano-pesticide carrier has a nano-constraint effect on hydrophobic pesticide loading and delivery. Besides, through the synergistic combination of hydrophobic-hydrophobic interaction, [pi]-[pi] accumulation and electrostatic interaction, theelectrostatic interaction is enhanced; the nano pesticide carrier has higher drug loading capacity and remarkable pH response controlled release behavior, improves the wetting and affinity of pesticide leaf surfaces, has the capability of effectively shielding ultraviolet radiation, and can be used as an environment-friendly and stable water-based nano pesticide carrier.

Owner:ZHONGKAI UNIV OF AGRI & ENG

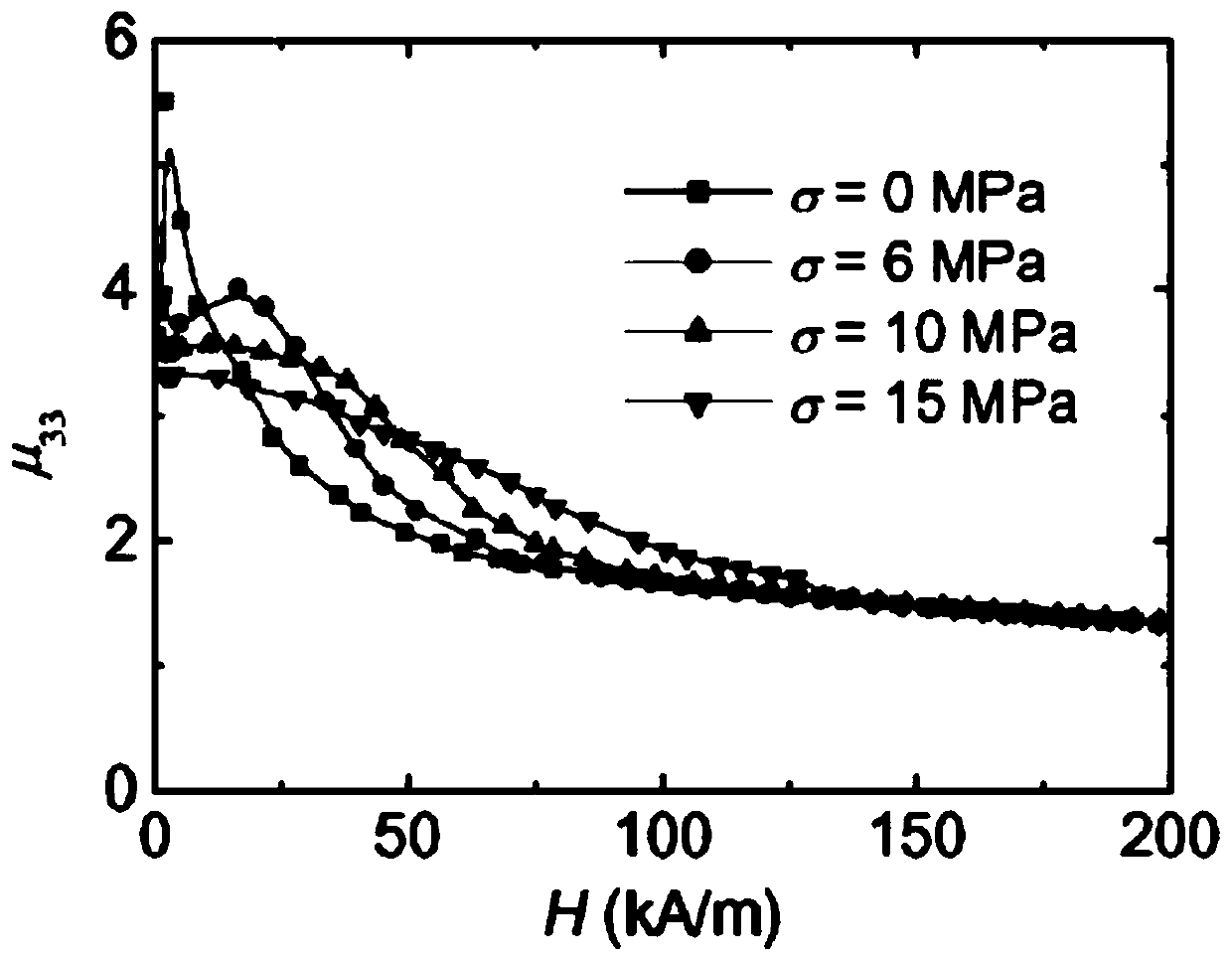

Pressure sensor based on giant magnetostrictive inverse effects

PendingCN110196123AStrong load capacityHigh precisionForce measurement by measuring magnetic property varationEngineeringSensor field

The invention discloses a pressure sensor based on giant magnetostrictive inverse effects, which belongs to the field of sensors. The pressure sensor based on giant magnetostrictive inverse effects isstructurally characterized in that the whole structure is an axisymmetric cylindrical structure, a shell is internally provided with a jacket, a magnetic isolation cylinder and a magnetic isolation end cover are adjacently arranged inside, the center of the magnetic isolation cylinder is provided with a through hole, the inner right side of the magnetic isolation cylinder is provided with an upper magnetizer, the left side of the magnetic isolation end cover is provided with a lower magnetizer, a coil frame is used for winding a bias coil, a giant magnetostrictive rod is arranged inside the coil frame, the right side of the giant magnetostrictive rod is provided with a magnetic conductive gasket, the right side of the magnetic conductive gasket is provided with a magnetic isolation steelring, a hall sensor is attached and fixed inside, the left side of the giant magnetostrictive rod is provided with a magnetic conductive block, an ejection rod passes through the through hole, a pre-tightening spring and a pre-tightening bolt respectively, a slight gap is left between, the magnetic conductive block, the upper magnetizer, a cylindrical yoke and the lower magnetizer form a closed magnetic circuit, the pre-tightening bolt and the end cover are fixedly connected through thread, the end cover and the shell are fixedly connected through an internal slot screw, and the internal structure is protected. The structure is compact, firm and reliable.

Owner:ANHUI UNIV OF SCI & TECH

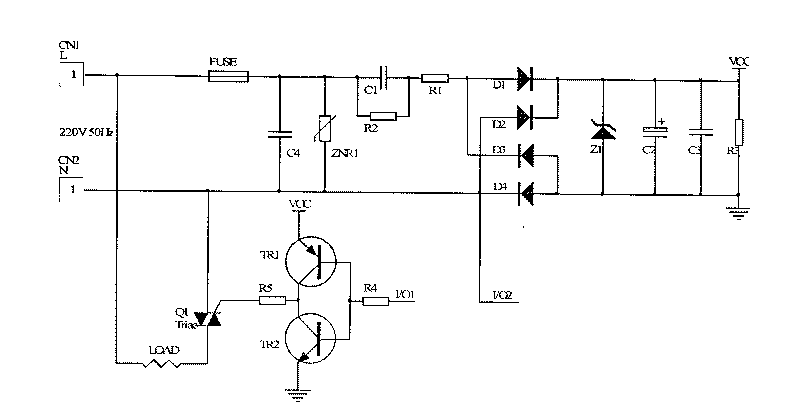

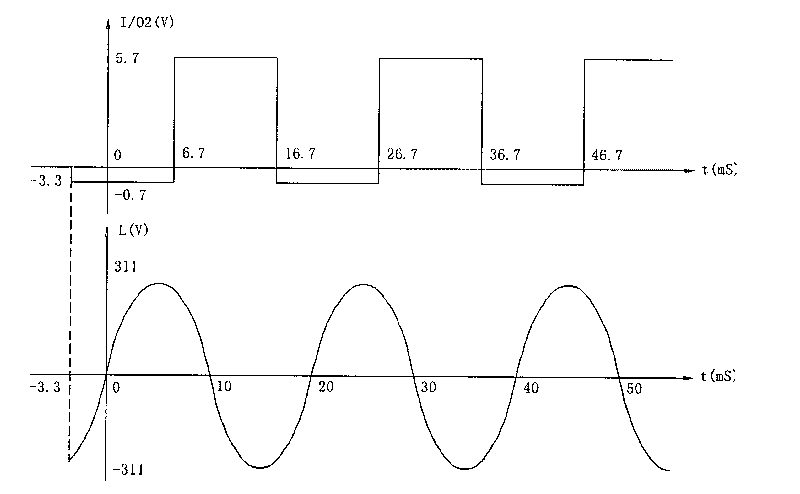

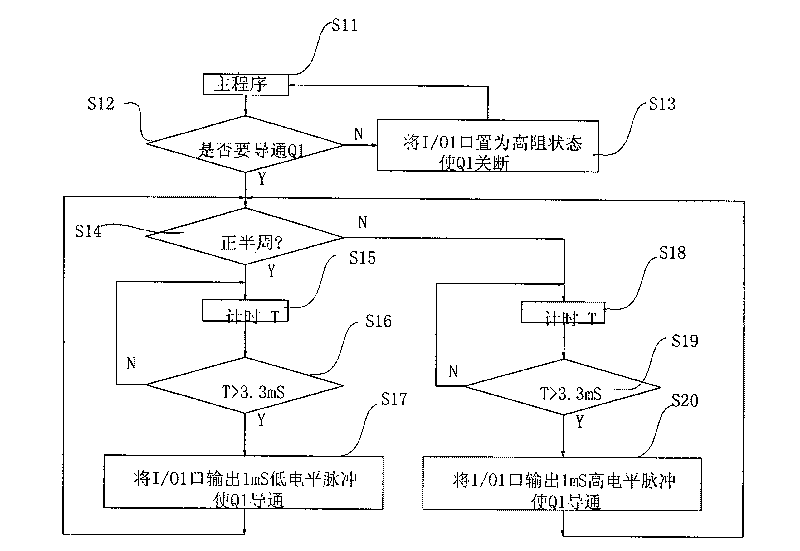

Silicon controlled drive circuit, device and control method thereof

InactiveCN101729050AStrong load capacityFew parametersElectronic switchingAc-ac conversionZero crossingLoad capacity

The invention relates to a silicon controlled drive circuit, which comprises a drive unit, a silicon controlled thyristor which is controlled by the drive unit, a control unit for providing a drive signal for the drive unit, and a DC power supply for providing power for the control unit. The DC power supply is obtained in a mode that an alternating current is subjected to resistance-capacitance voltage reduction and full-wave rectification to acquire a DC voltage. A pin of the control unit is directly connected to an alternating current input end of a full-wave rectifier for acquiring a zero-crossing detection signal of the alternating current. The invention also relates to a silicon controlled drive device and a drive method. The silicon controlled drive circuit, the silicon controlled drive device and the control method thereof have the following advantages that: under the condition of the power supply subjected to resistance-capacitance voltage reduction, due to the adoption of the full-wave rectification, the silicon controlled drive circuit and the silicon controlled drive device have stronger load capacity due to the adoption of the resistance-capacitance voltage reduction with the same parameters, the parameters of resistance-capacitance voltage reducing device can be reduced, and the energy is saved; at the same time, as the zero-crossing detection circuit is simpler, the silicon controlled drive circuit and the silicon controlled drive device have lower cost.

Owner:SHENZHEN H&T INTELLIGENT CONTROL

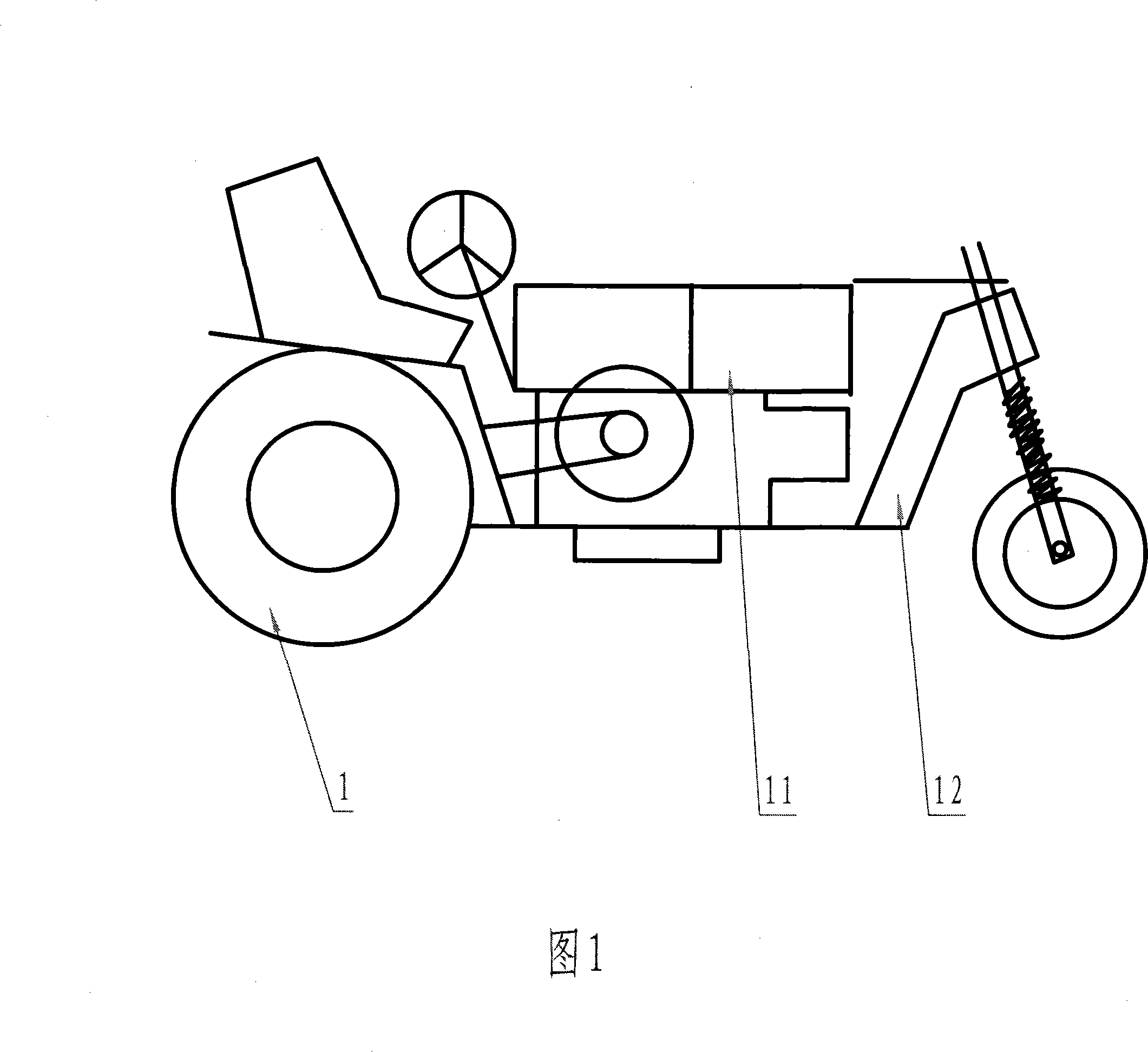

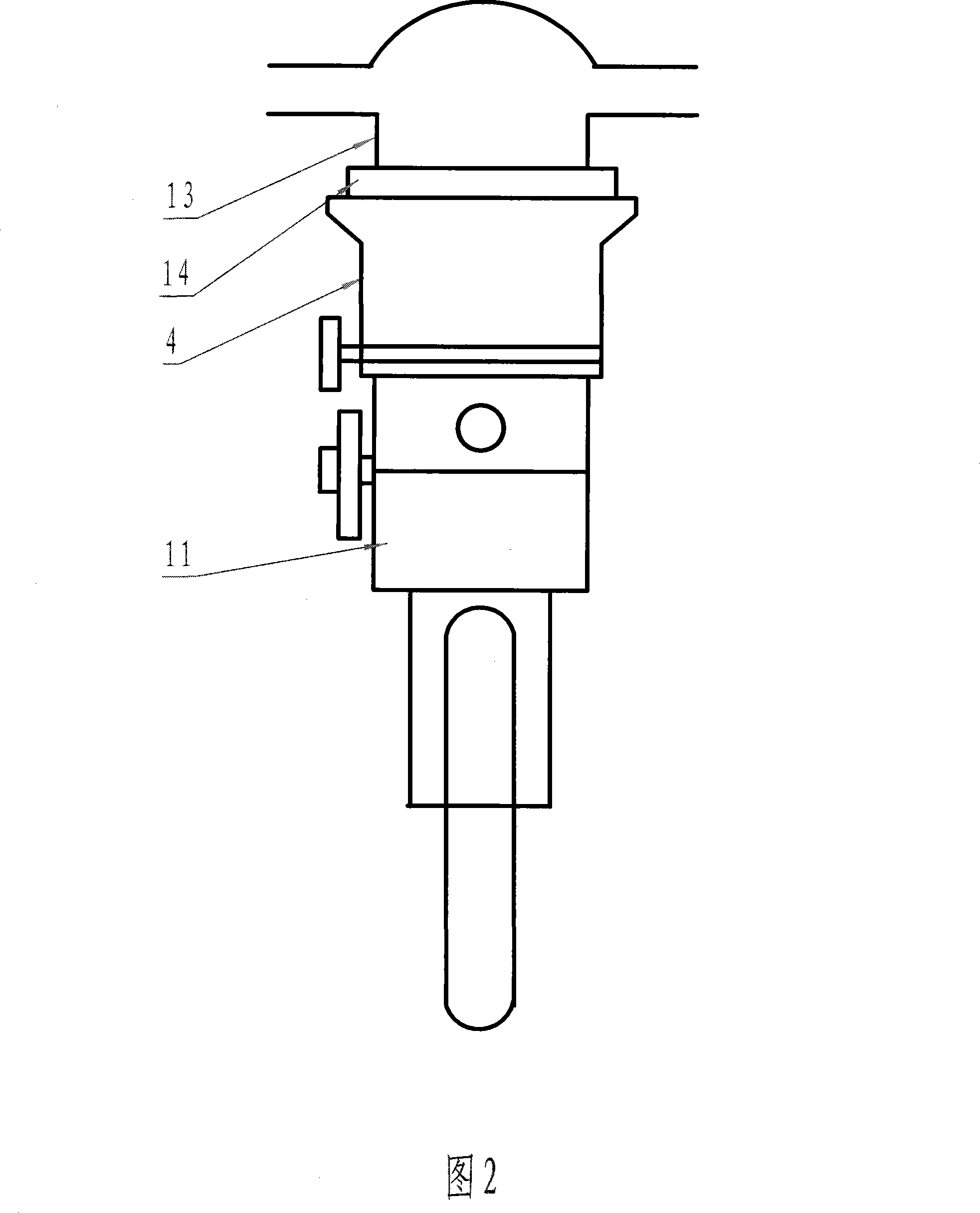

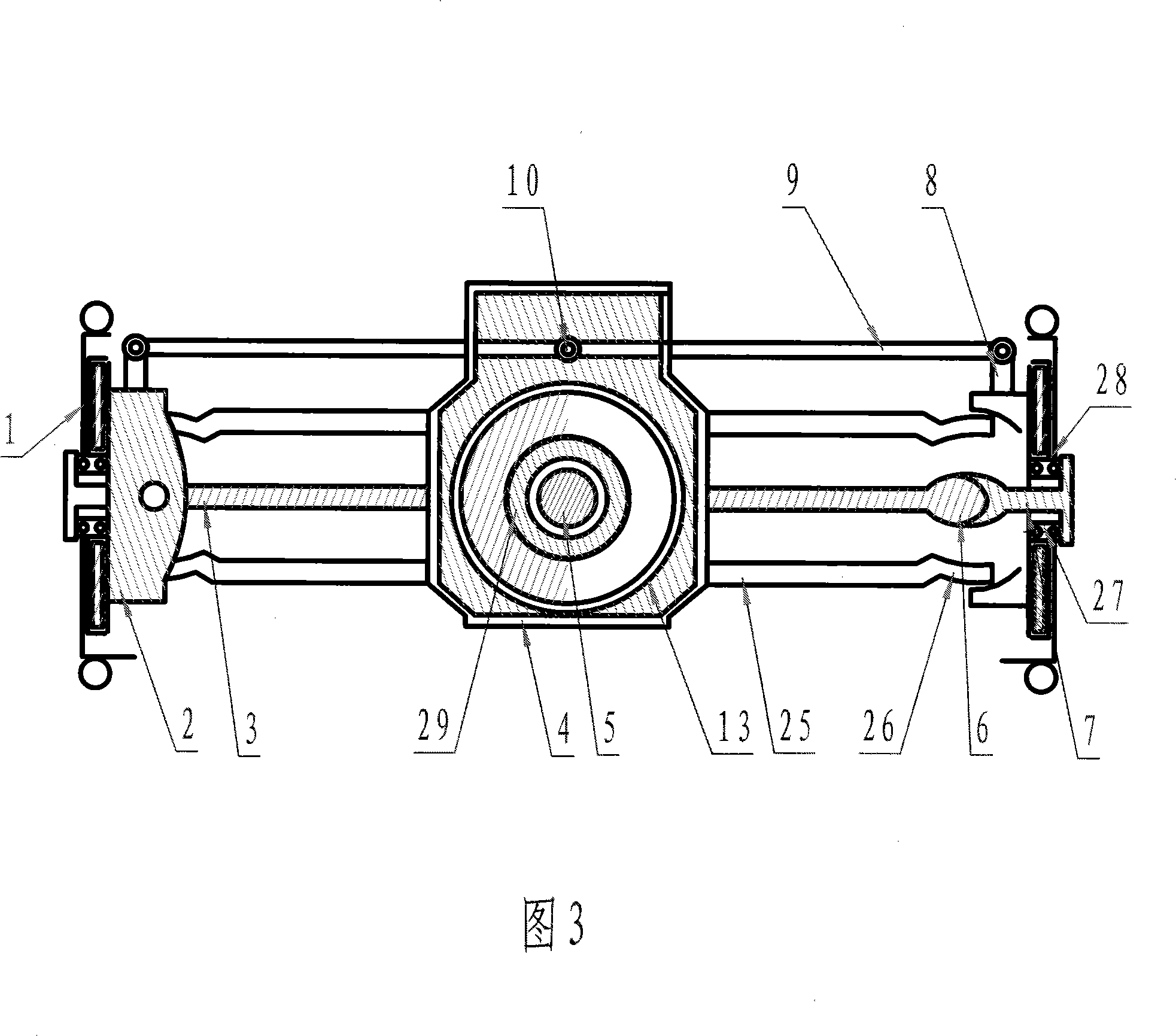

Self-balancing tractor

The invention relates to a self-balancing tractor belonging to the agricultural machinery field, which is characterized in that the internal half-shaft tubes of the left and right two ends of a main reducer shell of a balance drive axle are respectively connected in sequence with a spherical bearing, a knuckle shell, a brake disc, a neck journal link of knuckle, a neck journal of knuckle and a drive wheel link. The rear end of the central transmission shaft tube on a gearbox is nested with the main reducer shell. The angular wheel on the counter shaft of the gearbox of a transmission mechanism is meshed with an angular wheel of the central transmission shaft. The other end of the central transmission shaft is connected to the main reducer. The gearbox is provided with a high-low difference balance mechanism, a regulating switch and a lead weight link. The motor is respectively meshed with a transmission gear, a worm, a worm gear, the 60 degree gear ring arranged on the joint of a small gear, the gearbox and the main reducer shell. With the invention, the vehicle body can maintain the state of balance and the phenomenon of tilting and overturning are not easy to occur. Thus the driver can be in safe operation. The operation is simple with reliable performance, low costs, large carrying capacity, strong traction and a wide range of use.

Owner:柴俊兵

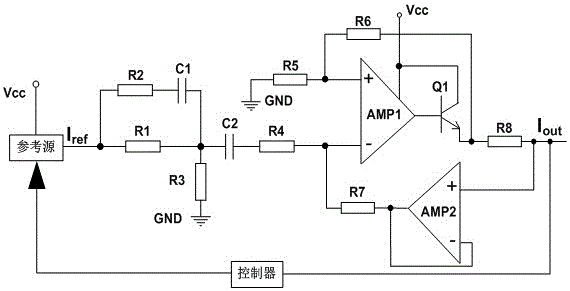

A low-power-consumption radar constant current source

InactiveCN106226743AStrong load capacityReduce power consumptionWave based measurement systemsElectric variable regulationConstant current sourceCapacitance

The invention discloses a low-power-consumption radar constant current source comprising a reference source; a second resistor is connected in series with a first capacitor and then connected in parallel with a first resistor; a first end of the parallel connection is connected with a reference source output end; a second end of the parallel connection is grounded through a third resistor, connected with a reverse input end of a first operational amplifier and connected to an output end of a second operational amplifier through a seventh resistor; a non-inverting input end of the first operational amplifier is grounded through a fifth resistor and connected to an emitter of a transistor through a sixth resistor; a base of the transistor is connected to an output end of the first operational amplifier; a collector of the transistor is connected to a power supply end of the first operational amplifier; the emitter of the transistor is connected to a non-inverting end of the second operational amplifier; a connection common end is regarded as a constant current source output end; an inverting input end of the second operational amplifier is connected between the seventh resistor and the output end of the second operational amplifier; and the controller is connected between the constant current source output end and the reference source. The low-power-consumption radar constant current source of the invention realizes strong loading capability, lower power-consumption and a stable constant current source output.

Owner:HEFEI JIARUILIN ELECTRONICS TECH

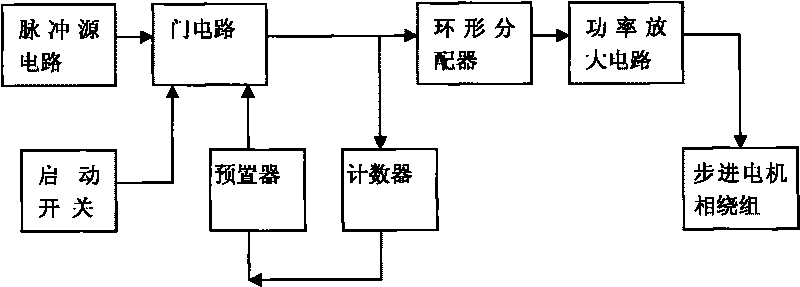

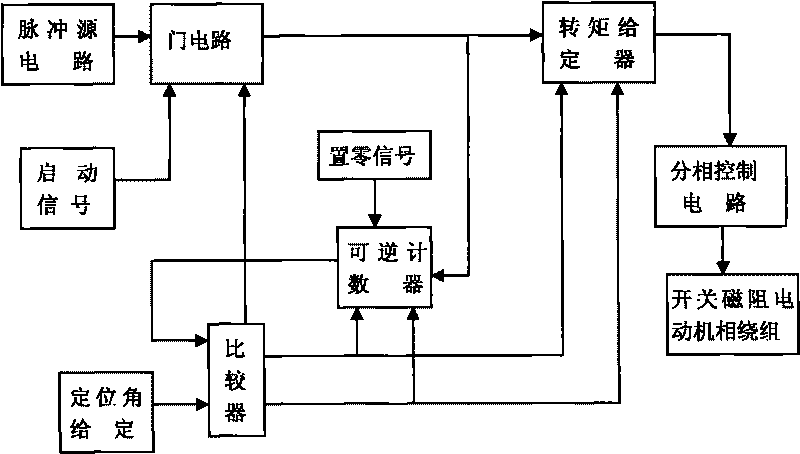

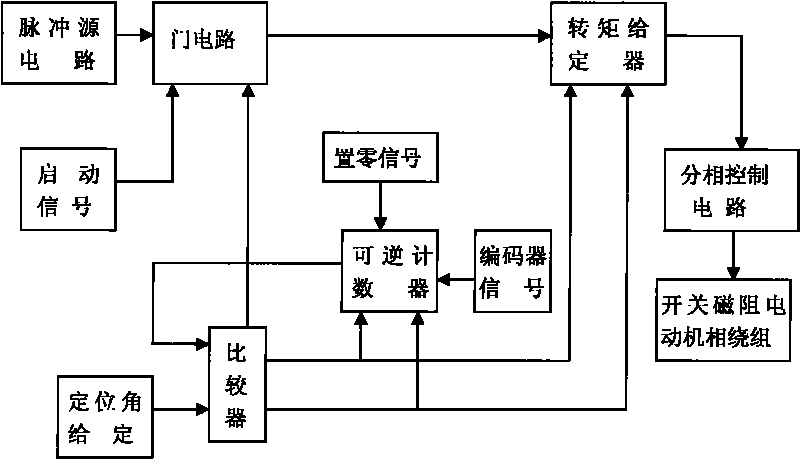

Switched reluctance motor positioning control system

InactiveCN101764552AHigh precisionStrong load capacitySingle motor speed/torque controlDynamo-electric converter controlLoad capacityPosition control system

The invention discloses a switched reluctance motor positioning control system. The system comprises a switched reluctance motor and a controller, wherein the switched reluctance motor is a motor that a rotor can be positioned at an arbitrary set angle; the controller consists of a pulse generating circuit, a gate circuit, a torque setter, a reversible counter and a comparer; a pulse source generates a pulse sequence representing a certain angle interval, and transmits the pulse sequence to the torque setter through the gate circuit; the gate circuit is controlled by output of an activating signal and the comparer; the comparer is controlled by orientation angle setting and the output of the reversible counter; the reversible counter is controlled by the output of the comparer and a zero setting signal; the torque setter is controlled by the output of the comparer; and output of the torque setter and the switched reluctance motor are winded. Positioning control has an open loop mode and a closed loop mode. The system can control a stepping motor to accurately step an arbitrary angle through a mode that two adjacent phases are electrified at the same time, and has high accuracy and strong load capacity.

Owner:BEIJING CHINA TEX MECHANICAL & ELECTRICAL ENG

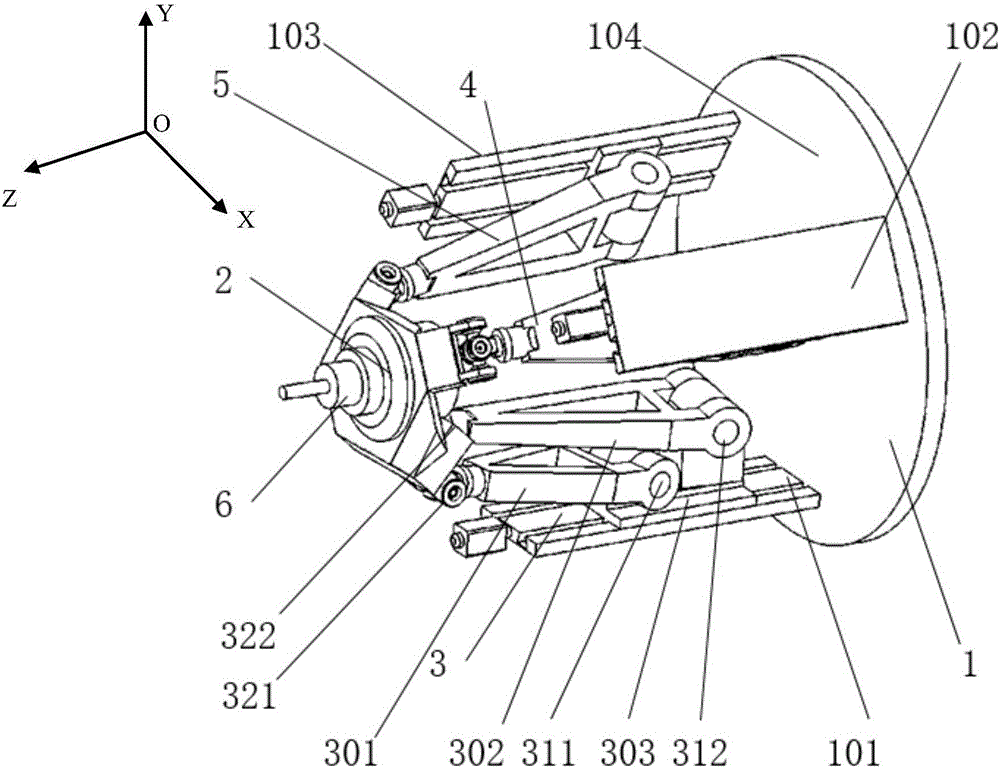

Three-freedom-degree parallel spindle head mechanism suitable for horizontal machining

InactiveCN106623993AIncrease stiffnessStrong load capacityLarge fixed membersLoad capacityMachine tool

The invention provides a three-freedom-degree parallel spindle head mechanism suitable for horizontal machining and belongs to the field of machine manufacturing. The three-freedom-degree parallel spindle head mechanism comprises a movable platform, a fixed platform, a first branch, a second branch and a third branch, wherein a spindle is installed on the movable platform, and the first branch, the second branch and the third branch are connected between the movable platform and the fixed platform and are uniformly distributed in space. The first branch is installed at the bottom and comprises a sliding block and guide rail mechanism, a first connecting rod and a second connecting rod, and the two ends of each connecting rod are connected with a sliding block and the movable platform through a hooke joint and a ball pair correspondingly. The second branch comprises a sliding block and guide rail mechanism and a third connecting rod, and the two ends of the third connecting rod are connected with a sliding block and the movable platform through a revolving pair and a ball pair correspondingly. The third branch and the second branch are the same in structure. The horizontal three-freedom-degree parallel spindle head mechanism has the characteristics of being high in stiffness and load capacity, small in moving component mass, isotropic in dynamic performance and the like; and the first branch is provided with the dual connecting rods, thus, the influence of gravity on the horizontal mechanism can be weakened, and high-speed high-precision machining of a machine tool is achieved.

Owner:CHANGCHUN UNIV OF SCI & TECH

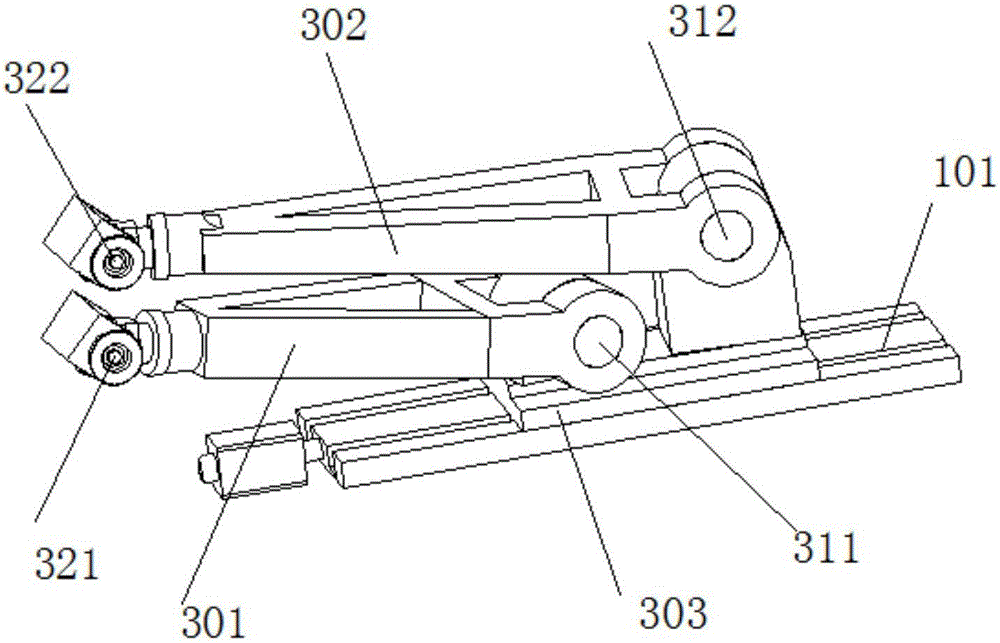

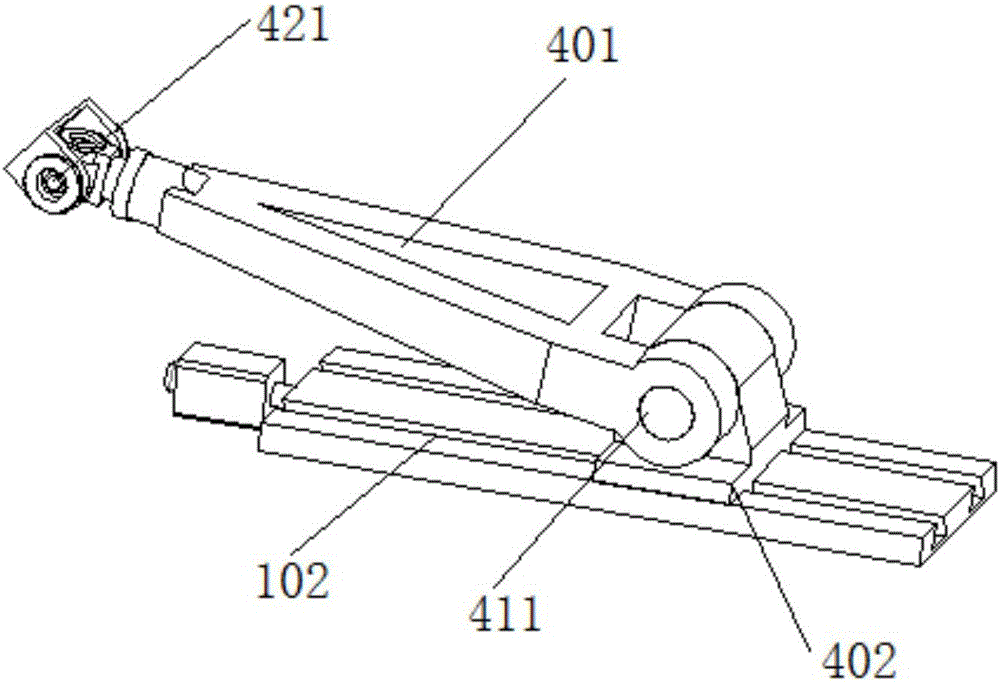

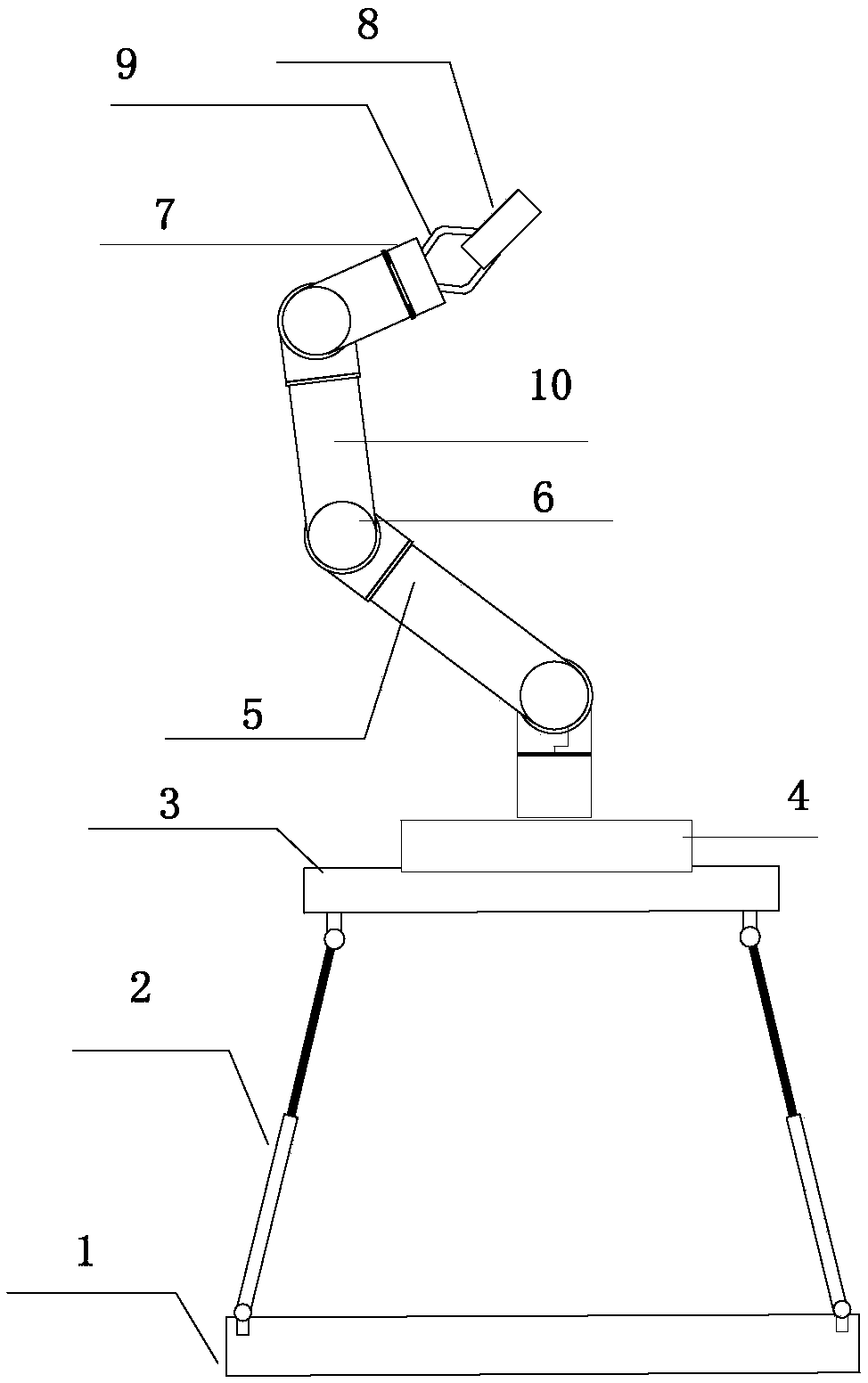

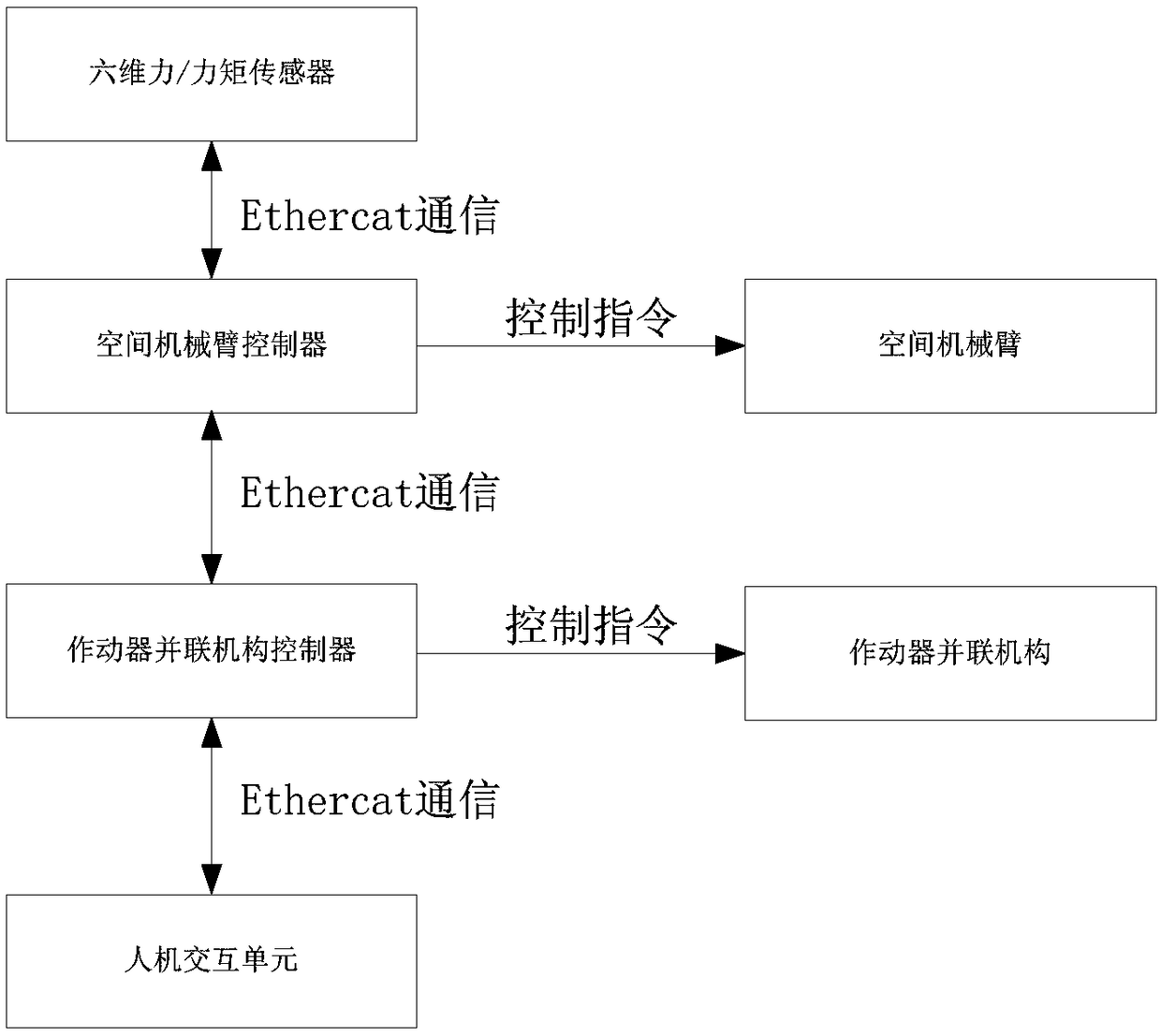

All-dimension ground physical verification system and method for space manipulator load changing situation

ActiveCN109500814AStrong load capacityWide adaptabilityProgramme-controlled manipulatorManipulatorControl algorithm

The invention discloses an all-dimension ground physical verification system and method for a space manipulator load changing situation and belongs to the technical field of space robot ground test verification. By designing the all-dimensional ground verification technology of a load changing space manipulator, the pose changing situation of a pedestal in the space robot load changing process ina three-dimensional space can be simulated, the feasibility and the validity of a control algorithm under the space robot load changing situation are verified, and the problem that an existing groundtesting system cannot simulate the pose change under the space manipulator load changing situation in the three-dimensional space is solved.

Owner:BEIJING RES INST OF PRECISE MECHATRONICS CONTROLS +1

Multifunctional all-terrain transportation robot

PendingCN111284582AGood passabilityStrong load capacityElectric propulsion mountingVehiclesAutomotive engineeringTransportation technology

The invention provides a multifunctional all-terrain transportation robot, and belongs to the technical field of transportation. The problem that an existing transportation robot is poor in obstacle crossing capacity is solved. The multifunctional all-terrain transportation robot comprises a chassis and wheel assemblies, a tilting shaft horizontally extending in the left-right direction is arranged on the chassis, a goods shelf capable of swinging around the central axis of the tilting shaft is arranged on the tilting shaft, a gravity center adjusting assembly used for changing the tilting angle of the goods shelf is arranged on the goods shelf, and an auxiliary assembly used for supporting the goods shelf and realizing auxiliary obstacle crossing during obstacle crossing is further arranged on the goods shelf. The robot has the advantages of being high in obstacle crossing capacity, wide in application range and the like.

Owner:行星算力(深圳)科技有限公司

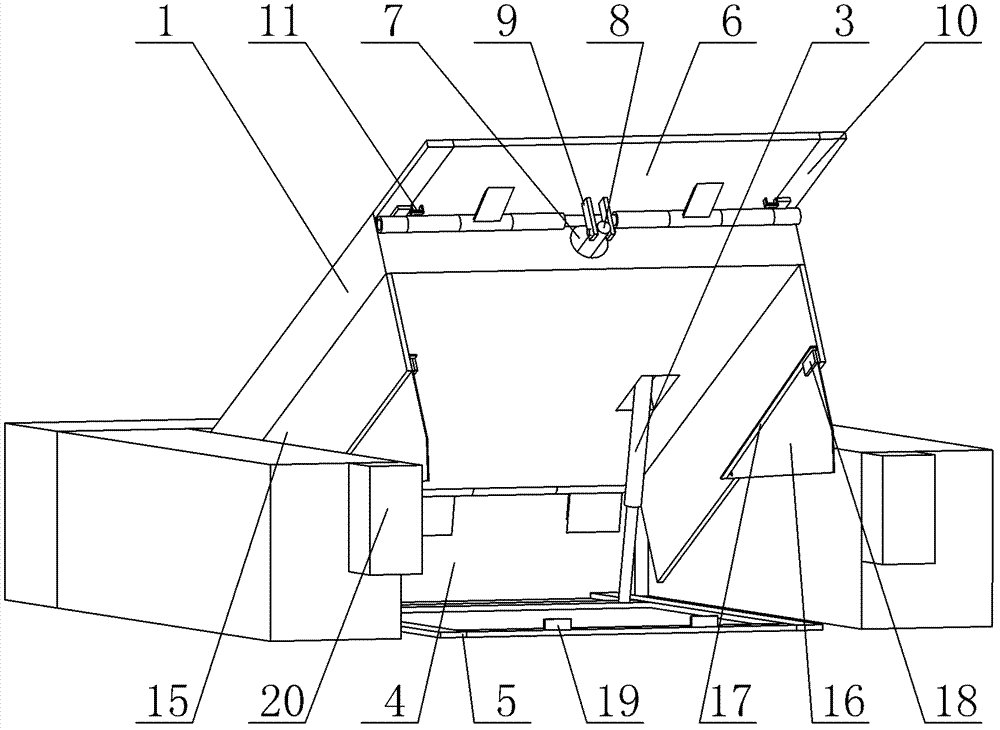

Lifting platform

The invention discloses a lifting platform which comprises a bearing platform (1), a bearing platform support (2) and a lifting jack (3). The bearing platform support (2) comprises a rear wall (4) and a bottom frame (5), the bearing platform (1) is arranged above the bearing platform support (2) and rotatably connected with the rear wall (4), one end of the lifting jack (3) is rotatably connected with the bottom frame (5), and the other end of the lifting jack (3) is rotatably connected with the bearing platform (1). By utilizing the bearing platform to form a transition cant between a compartment and a base platform, the former problem of two-section-type cargo transportation is solved, and working efficiency is improved; by utilizing the jack and a piston as a driving mode, the lifting platform is high in bearing capacity, quite convenient to control and high in reliability; and by arranging a lapping plate and an auxiliary lapping plate, the lifting platform can adjust the width of the lapping plate according to the size of the compartment and is high in adaptability. In addition, the lifting platform has the advantages of high protection capability, compact structure and the like.

Owner:沈兴财

High-strength bamboo plywood

InactiveCN107053368AHigh economic valueStrong load capacitySynthetic resin layered productsCane mechanical workingCarbon fibersNylon fiber

The invention discloses high-strength bamboo plywood. The high-strength bamboo plywood is formed in the manner that carbon fiber cloth is used as a core layer, bamboo skin curtains and bamboo filament curtains mixed with nylon fiber in a woven manner are alternately stacked and bonded, and hot pressing is conducted, and a production technology of the high-strength bamboo plywood is provided. Phenolic resin glue mixed with micron sized silica aerogel is used as a sizing agent, so that the defects that the phenolic resin glue is large in fragility, poor in creep resistance and the like are relieved. The manufactured bamboo plywood is better than bamboo plywood produced by the adoption of a traditional technology in the aspects of loading capacity, deformation resistance, heat resistance and the like, and the economic value of the bamboo plywood is effectively improved.

Owner:ANHUI SHUCHENG HUAZHU IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com