Fluid bearing device and its manufacturing method

A technology of fluid bearings and bearing sleeves, applied in bearings, bearing components, shafts and bearings, etc., can solve problems such as dimensional tolerances, deterioration of rotation accuracy, and difficult positioning, and achieve the effects of excellent load capacity, easy assembly, and easy precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0072] Next, embodiments of the hydrodynamic bearing device and its manufacturing method according to the present invention will be described based on the drawings. In addition, the "up and down" directions described below merely represent the up and down directions in each figure for convenience, and therefore do not limit the installation direction and usage of the fluid bearing device.

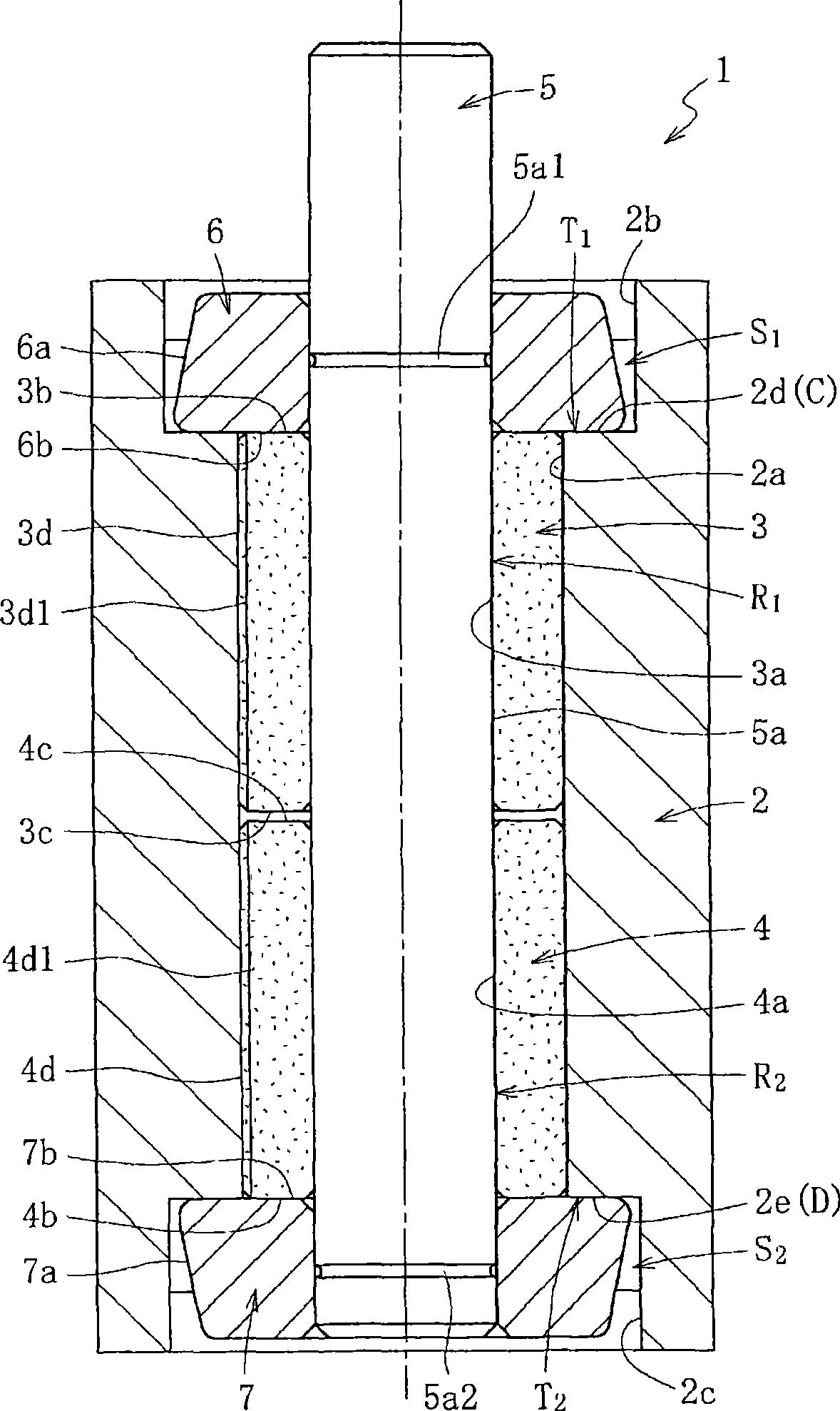

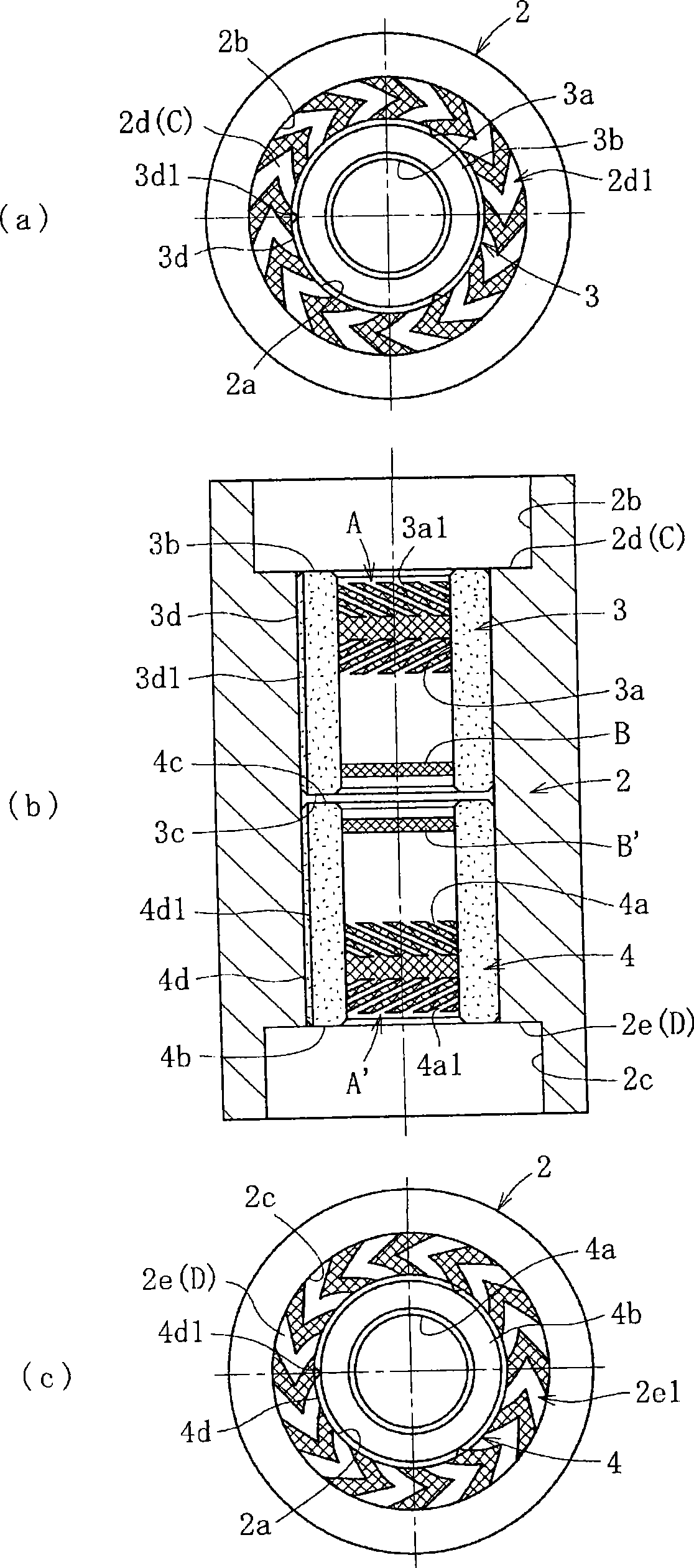

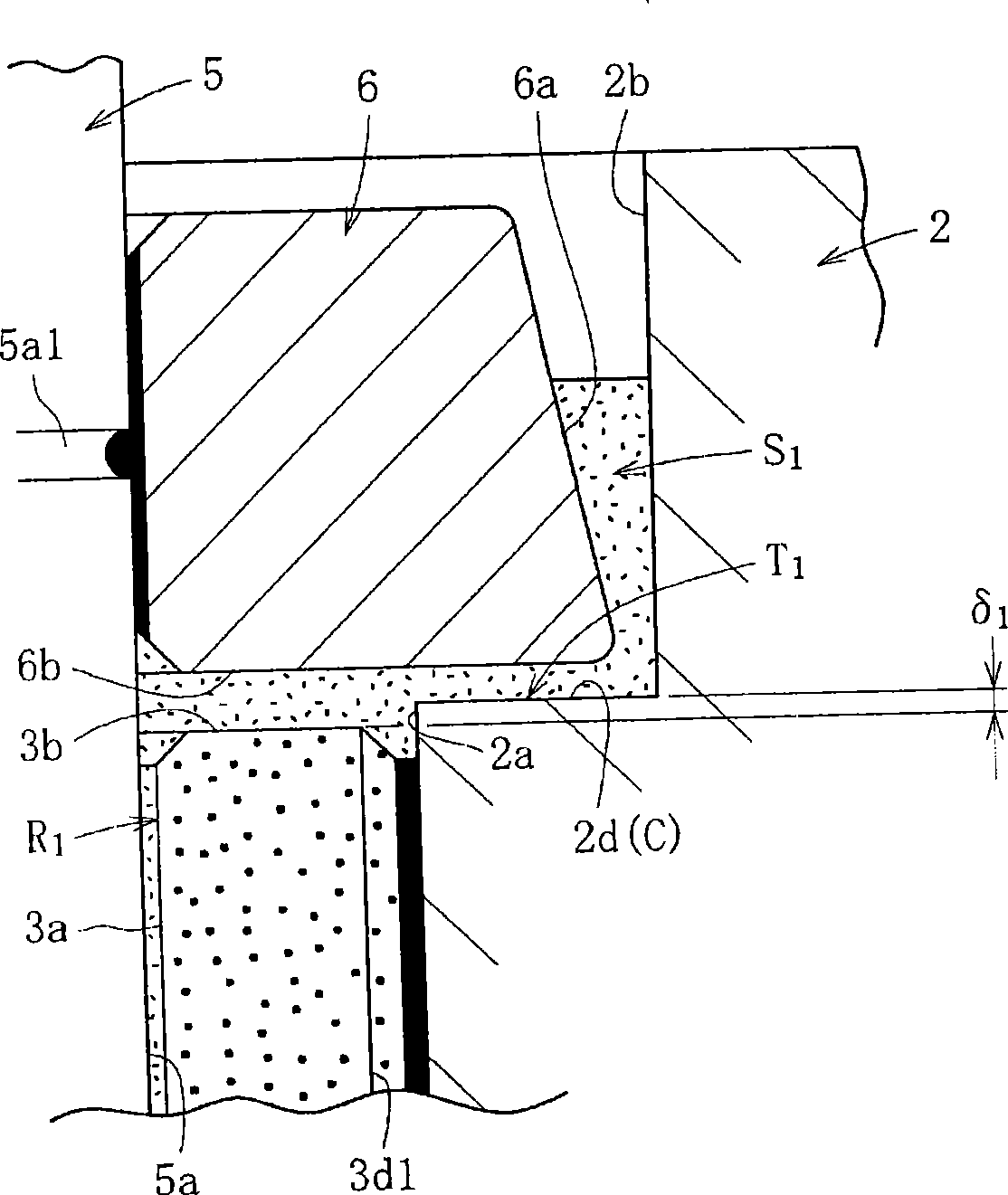

[0073] figure 1 The fluid bearing device 1 of the first embodiment is shown. This fluid bearing device 1 is incorporated into, for example, a spindle motor for HDD and used. This fluid bearing device 1 has the following structural components: a housing 2; a plurality of, here two, bearing sleeves (the first bearing sleeve 3 and the second bearing sleeve 4) fixed to the housing 2; inserting the two bearing sleeves 3, shaft member 5 on the inner periphery of shaft member 4; and seal members 6 and 7 as protrusions protruding from the outer diameter side of shaft member 5 .

[0074] The det...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com