Low-temperature deep cooling bearing

A low-temperature cryogenic, ball bearing technology, used in ball bearings, bearing components, shafts and bearings, etc., can solve the problem that bearings are not suitable for high-speed refrigerator equipment, etc., and achieve long service life, strong load capacity, and improved service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

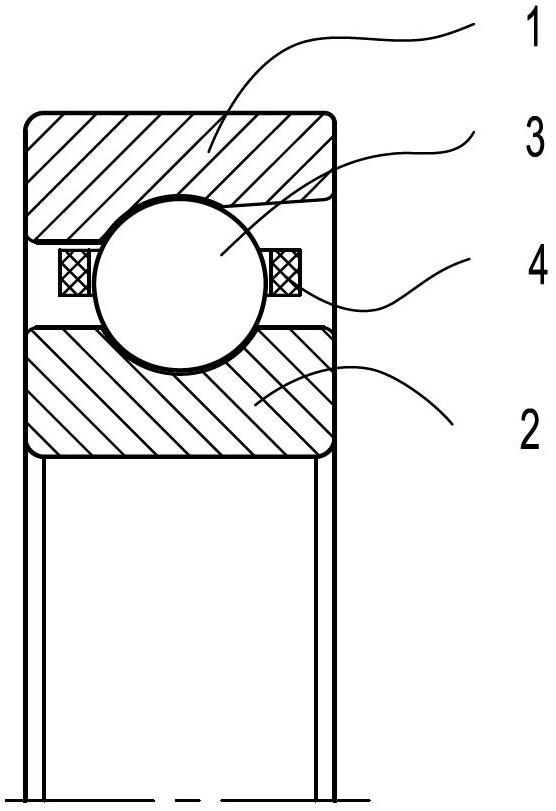

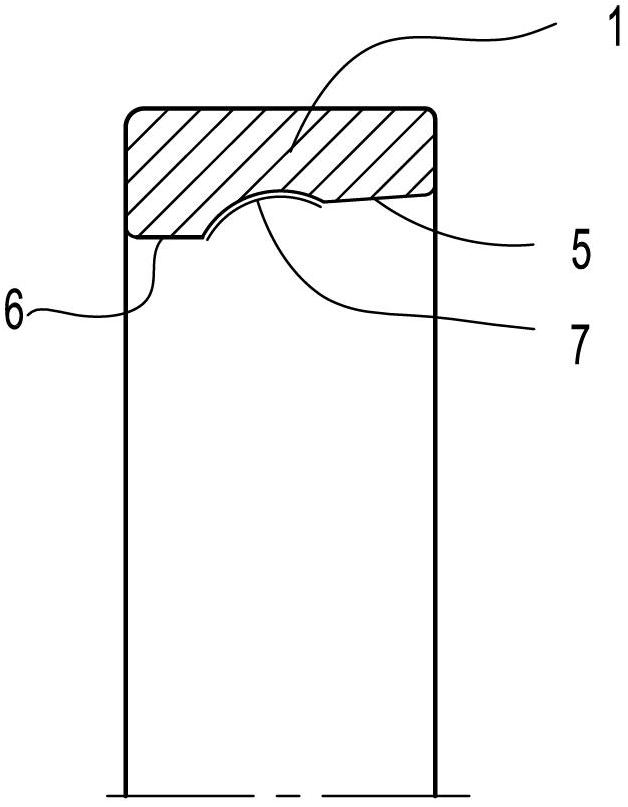

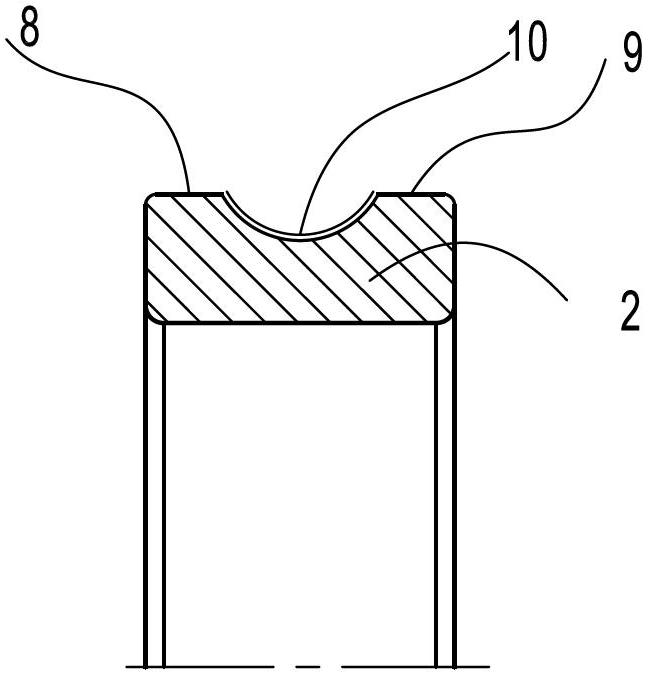

[0016] Figure 1~Figure 4 , including outer ring 1, inner ring 2, rolling element 3, cage 4, ball lock 5, rib 6, raceway 7, rib 8, rib 9, raceway 10, cylindrical surface 11, lock Ball hole 12, lock ball mouth 13 etc.

[0017] Such as figure 1 As shown, the present invention is a low-temperature cryogenic ball bearing for high-speed freezing equipment, especially for liquid nitrogen pumps therein, including an outer ring 1 , an inner ring 2 , rolling elements 3 and a cage 4 .

[0018] The outer ring 1 and the inner ring 2 are made of stainless steel, preferably 9Cr18 stainless steel, which can prevent the bearing from rusting in a low-temperature and cryogenic environment. The raceway 7 of the outer ring 1 and the raceway 10 of the inner ring 2 are super-finished and treated with tungsten disulfide surface, so that the bearing has a self-l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com