Patents

Literature

96results about How to "With self-lubricating function" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

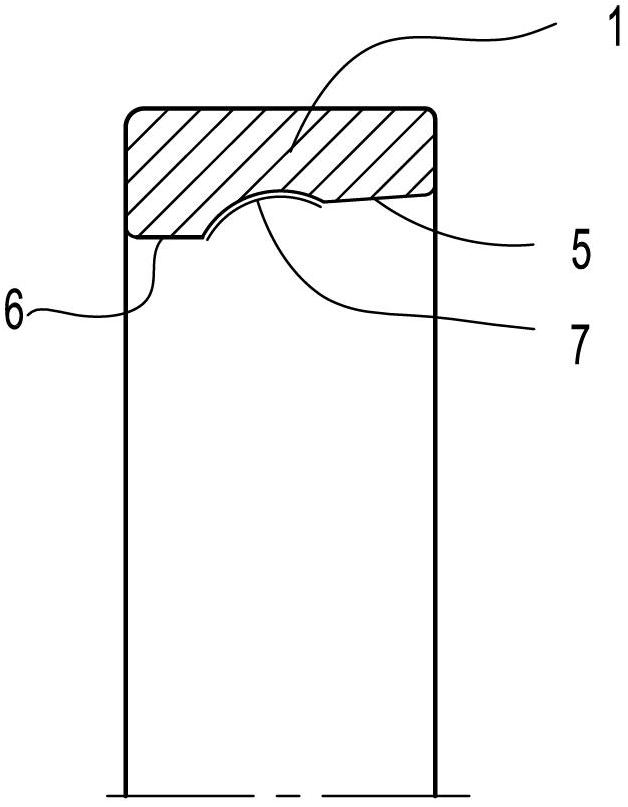

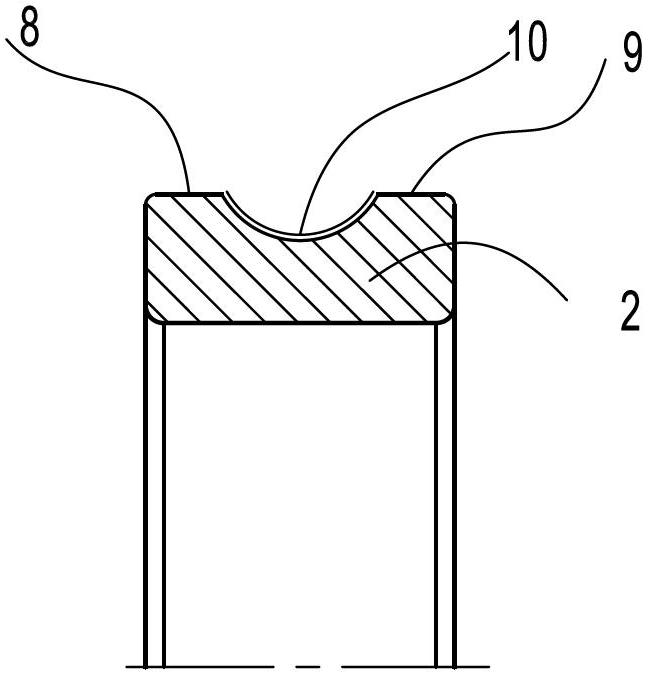

Diamond polishing paste in high purity, and preparation method

InactiveCN101050339AImprove polishing efficiencyModerate viscosityOther chemical processesCoupling light guidesDispersion stabilityOptical fiber connector

This invention relates to a method for preparing polishing paste containing high-purity nanoscale diamond for precision polishing of the small inner pores of ceramic ferrule used in optical fiber connector. The polishing paste is prepared from: diamond micropowder 0.05-5 wt.%, wetting agent 0.01-25 wt.%, surfactant 0.1-5 wt.%, dispersion stabilizer 0.1-50 wt.%, pH regulator 0.1-1 wt.%, and glycerol 14-99.64 wt.%. The purity of the diamond micropowder is greater than or equal to 99.9%, and the particle sizes are 100-200 nm. The polishing paste is amphipathic, and has such advantages as high polishing speed, high dispersion stability, and appropriate viscosity. The polishing paste can effectively prevent the generation of small inner pores on the surface of polished ceramic ferrule.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

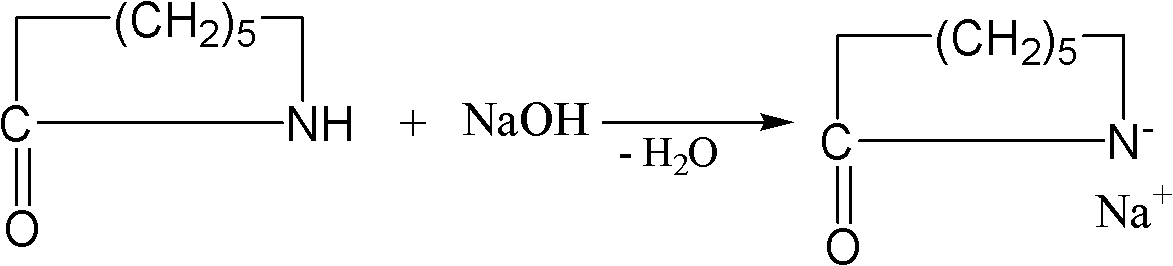

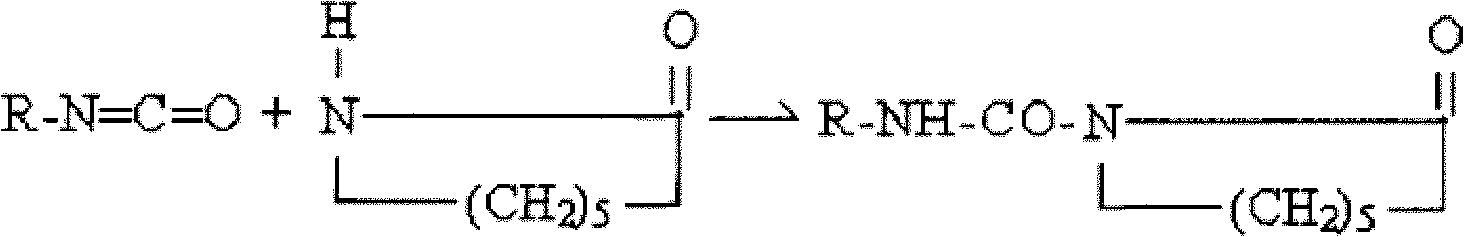

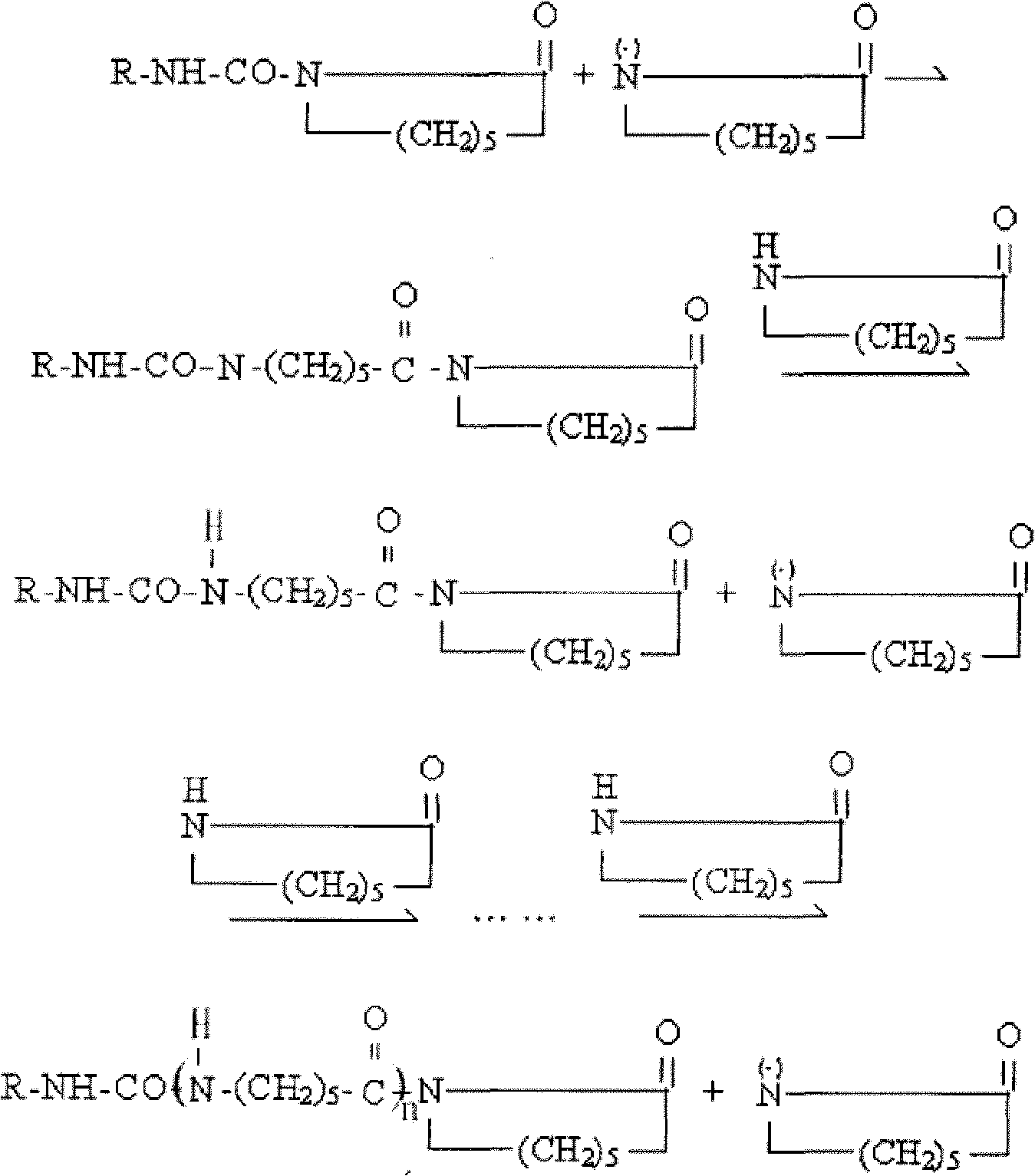

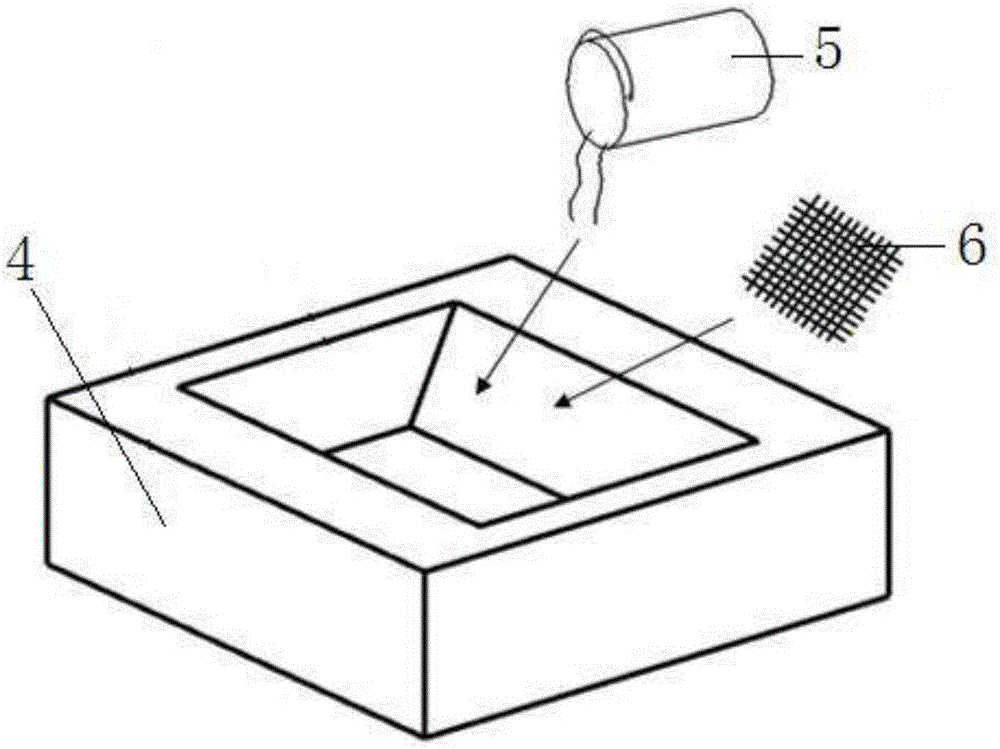

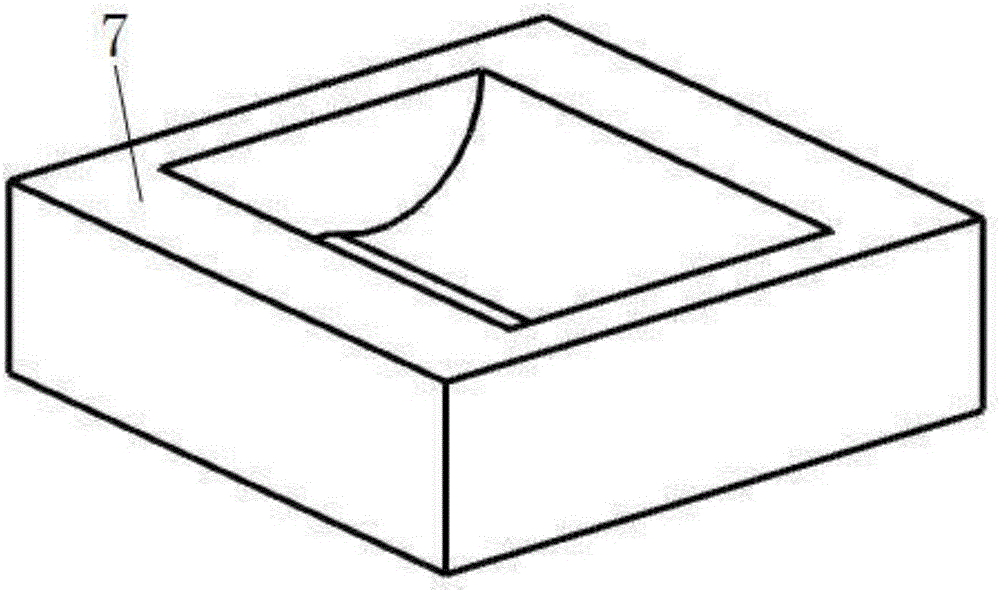

Preparation method of self-lubricating and high-strength pouring nylon

InactiveCN102153743AHas a coefficient of frictionReduce coefficient of frictionPigment treatment with organosilicon compoundsPolymer scienceToluene

The invention relates to a preparation method of a self-lubricating and high-strength pouring nylon, comprising the following steps of: (1) stirring and heating a caprolactam monomer, surface-modified nano TiO2 and nano graphite powder subjected to alkaline treatment, and vacuumizing simultaneously, continuously stirring a caprolactam fused mass mixture to obtain a caprolactam fused mass containing a nano composite material; (2) adding a sodium hydroxide solid to the caprolactam fused mass, raising temperature and continuously stirring to obtain an alkaline caprolactam fused mass mixture; (3)restoring the pressure of a reaction kettle to the atmospheric pressure, adding IPDI (Isophorone Diisocyanate) or TDI (Toluene Diisocynate) to the reaction kettle, uniformly stirring to obtain a caprolactam nylon prepolymer; and (4) flowing or pressurizing the prepolymer and injecting to a mold cavity, closing a mold, then continuously warming, then naturally cooling to room temperature to obtaina formed self-lubricating and high-strength pouring nylon part. The preparation method of the self-lubricating and high-strength pouring nylon has the advantages of simple process device and apparatus, simple process route, simple formation and control and unlimited part size and shape.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

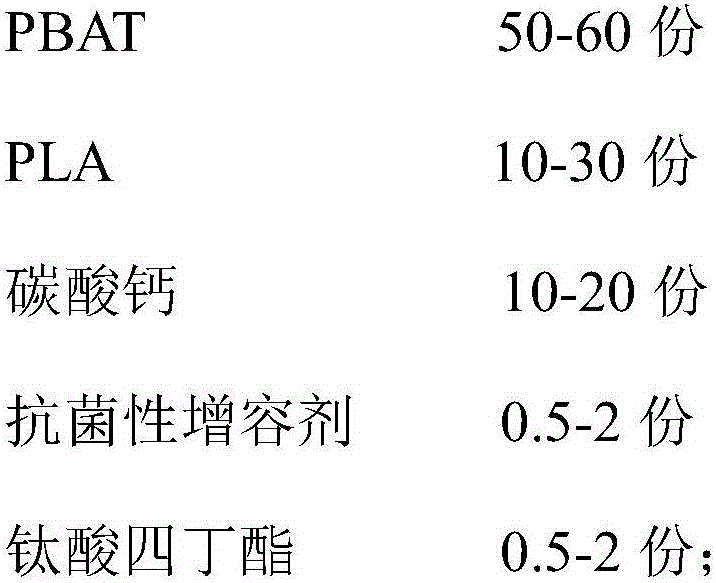

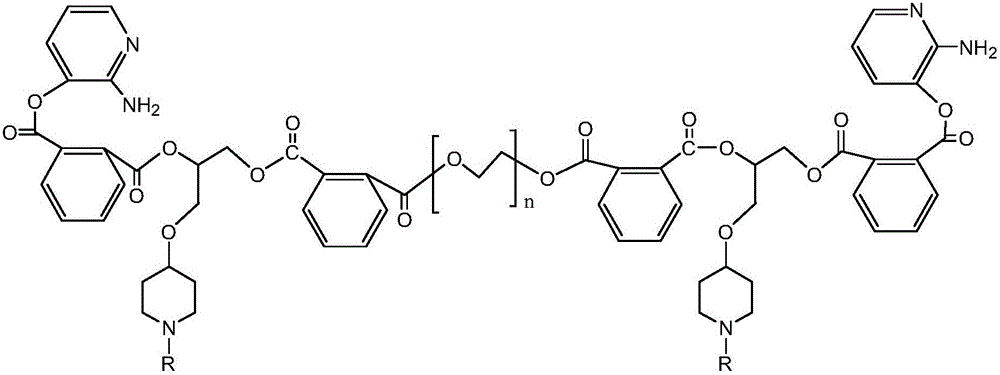

Controllable-degradation PBAT/PLA (poly(butyleneadipate-co-terephthalate)/polylactic acid) composite film and preparation method thereof

The invention relates to the technical field of PBAT / PLA (poly(butyleneadipate-co-terephthalate) / polylactic acid) blend compatibilization, particularly a controllable-degradation PBAT / PLA composite film. The controllable-degradation PBAT / PLA composite film comprises the following components in parts by weight: 50-60 parts of PBAT, 10-30 parts of PLA, 10-20 parts of calcium carbonate, 0.5-2 parts of antibacterial compatibilizer and 0.5-2 parts of tetrabutyl titanate. The mass ratio of the PLA to the calcium carbonate is (1-3):1. The PLA / calcium carbonate proportion is strictly controlled and restricted within the range of (1-3):1; and the PLA / calcium carbonate proportion can be regulated to control the degradation start time of the PBAT / PLA composite film at 60-90 days and control the complete degradation time at 120-150 days.

Owner:常州绿之源高分子材料有限公司

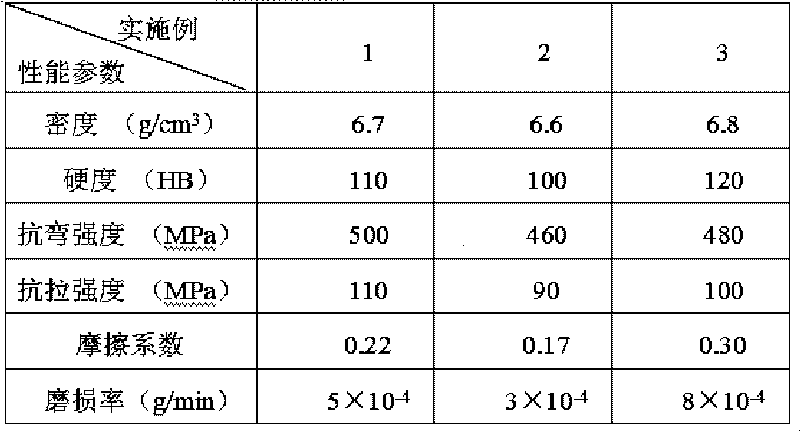

Nickel-based bearing retainer material and preparation method thereof

ActiveCN101709412AGuaranteed normal operationWith self-lubricating functionShaftsBearing componentsMolybdenum disulfideMetallic Nickel

The invention discloses a nickel-based bearing retainer material and a preparation method thereof. The retainer material is prepared by the following components in percentage by weight: 65 to 70 percent of nickel, 5 to 12 percent of chromium, 2 to 8 percent of silver, and 16 to 22 percent of molybdenum disulfide. The preparation method comprises the processes of mixing, forming and sintering, and comprises the following steps: firstly, accurately weighing nickel powder, chromium powder, silver powder and molybdenum disulfide powder in percentage by weight, and uniformly mixing the powder; then, pressing and shaping the mixed powder to form a blank; and sintering the blank in vacuum to obtain the bearing retainer material. A bearing retainer made of the bearing retainer material of the invention has self-lubricating function and can ensure the normal operation of a bearing when the bearing is at the high temperature of 400 DEG C in the high-vacuum environment of 10-4 to 10-6 Pa.

Owner:LUOYANG BEARING RES INST CO LTD

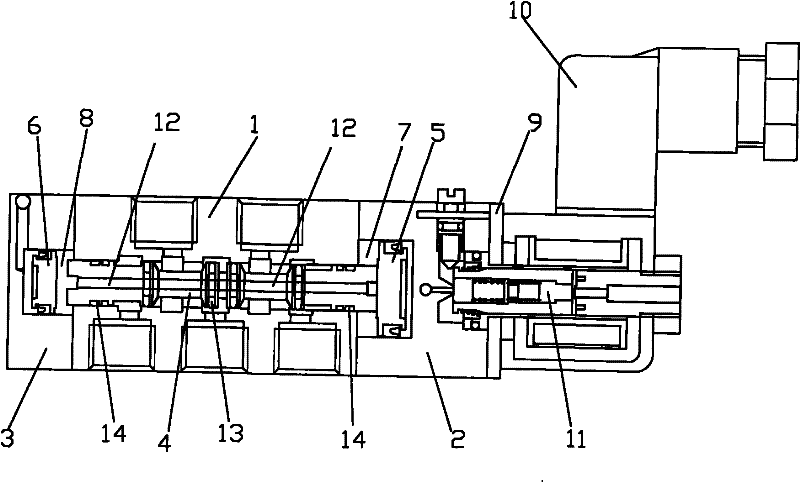

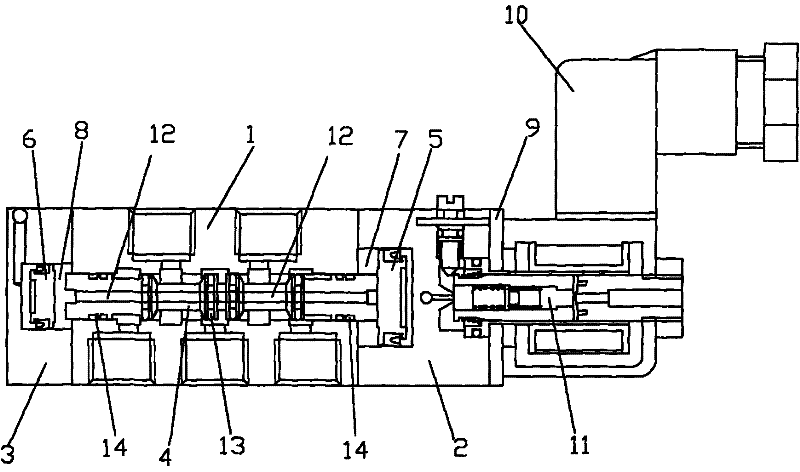

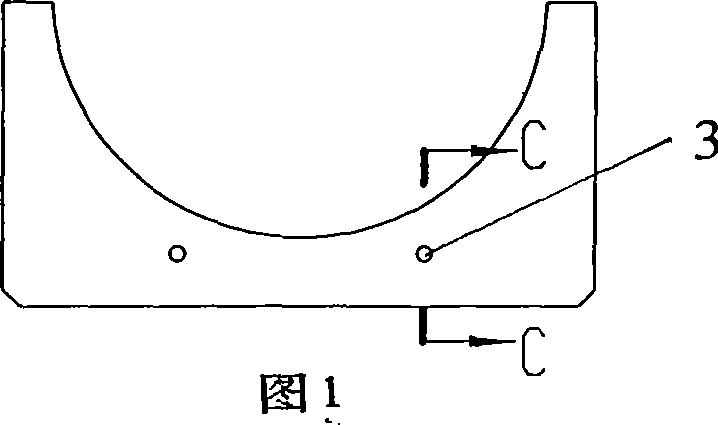

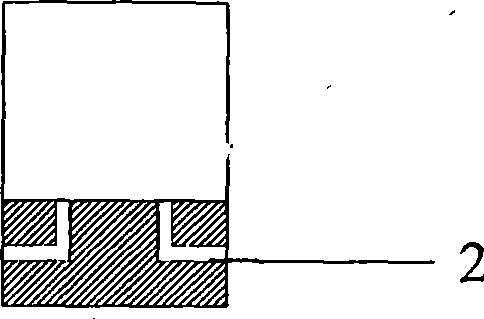

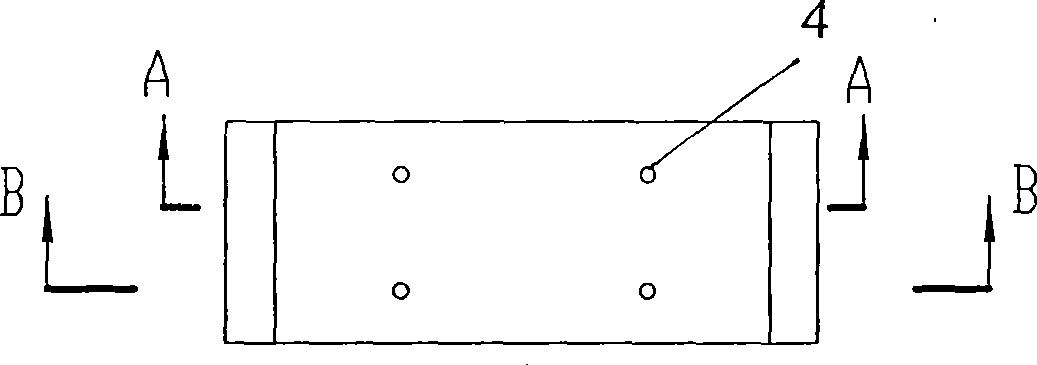

An electronically controlled reversing valve

InactiveCN102261492AExtended service lifeImprove the stability of useOperating means/releasing devices for valvesMultiple way valvesEngineeringElectric control

The invention discloses an electric control reversing valve, which comprises a valve body, front and rear covers at both ends of the valve body, a sliding valve rod is arranged in the valve body, a large piston and a small piston are respectively arranged at the two ends of the sliding valve rod, and the front and rear covers are There are large and small piston chambers corresponding to the large and small pistons, and a gland and a coil assembly are arranged in turn at the front cover end. The coil assembly is provided with a sleeve assembly that opens and closes the air path and moves the piston. The sliding valve A hollow groove is arranged in the rod, and the two ends of the hollow groove communicate with the large and small piston chambers respectively. The reversing valve has the characteristics of long life, good stability, miniaturization, low power consumption and the like.

Owner:ZHAOQING ZHICHENG PNEUMATIC

Integral composite material self-lubricating plain bearing and method for the production thereof

InactiveCN101363474ASmall sizeImprove carrying capacityMetal rolling stand detailsBearing coolingFiberCompression molding

The invention provides a one-piece composite material self lubricating sliding bearing and a manufacturing method thereof; the bearing is made of reinforced fibrous resin composite material, and a bearing pedestal and a bearing bush are of integral structure formed by one step; wherein the included angle between the arranging direction of over 50% of fibers in the bearing and the radial direction of the bearing is less than 30 degrees, and a cooling water channel is arranged in the bearing. The manufacturing method includes the following steps: firstly preparing impregnated fibrous resin, then making the impregnated fibrous resin into a fiber laminated body, placing the fiber laminated body into a die and producing the bearing by compression molding. The method has high production efficiency and the produced bearing has precise size, high carrying capacity, strong wearing resistance, self lubricating function and high reliability when running in high-temperature and damp environment and can withstand the impact of periodical alternating load of a rolling mill. The bearing is mainly applied to a rolling mill used for rolling seamless steel pipes.

Owner:攀钢集团成都钢铁有限责任公司 +1

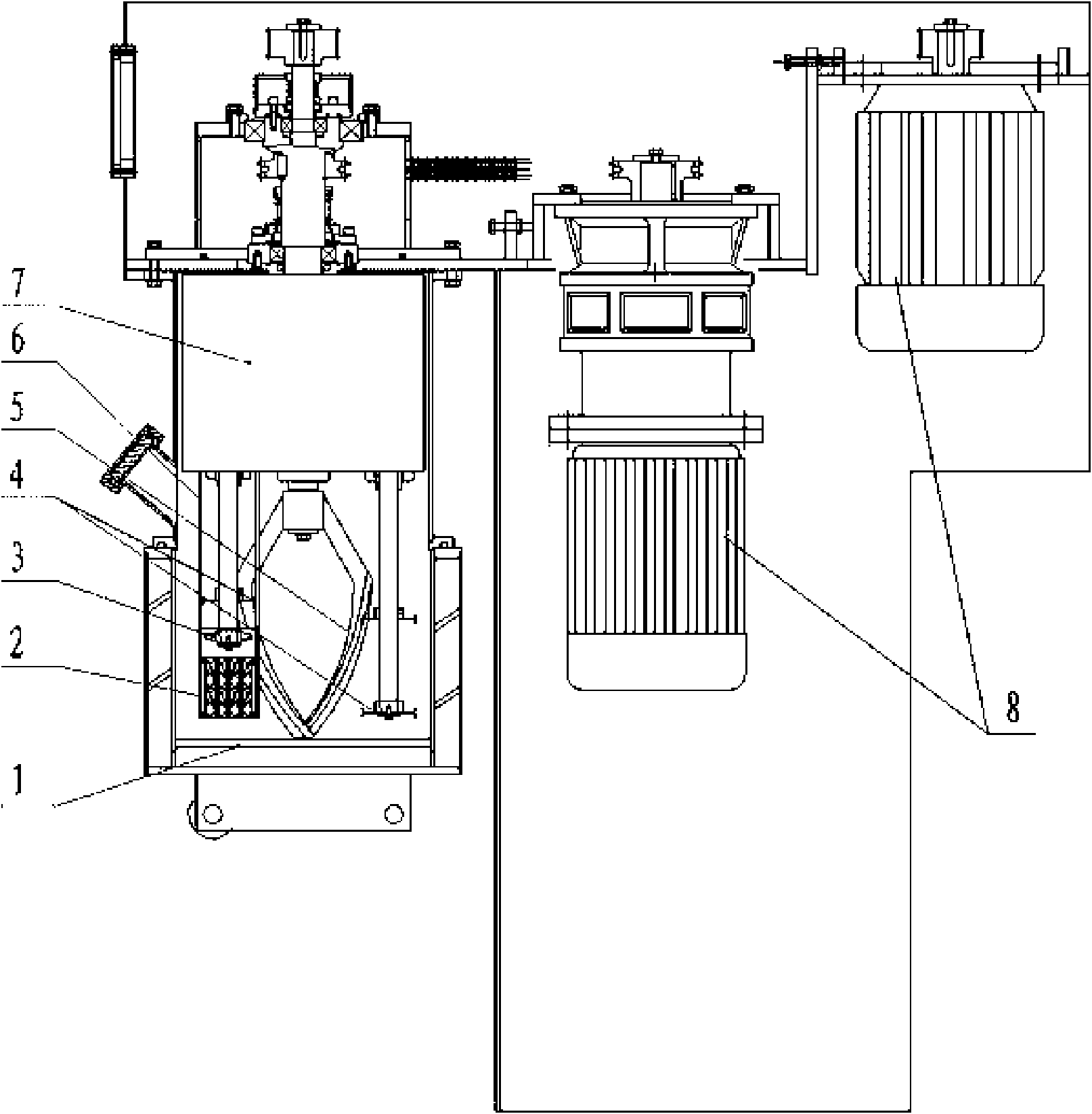

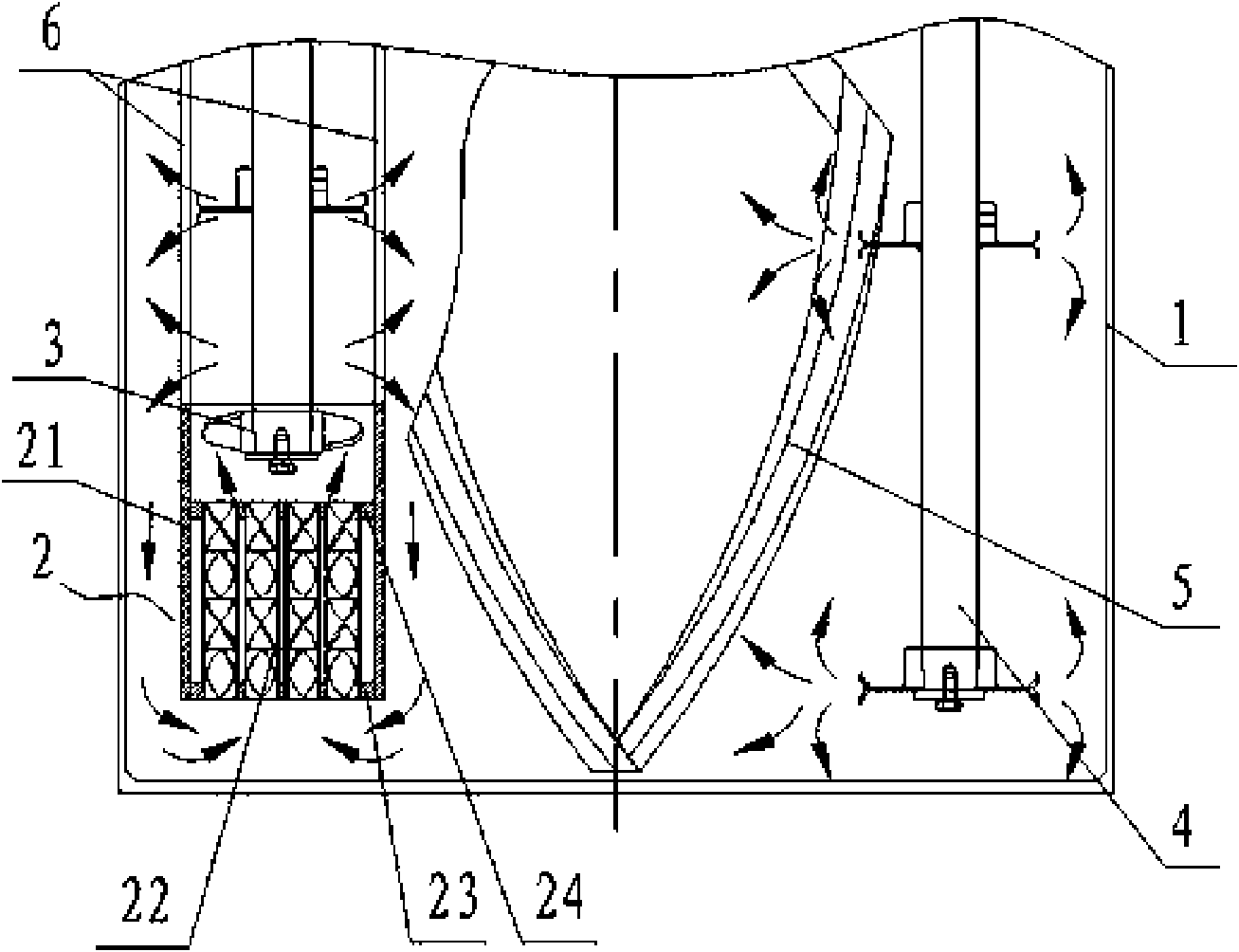

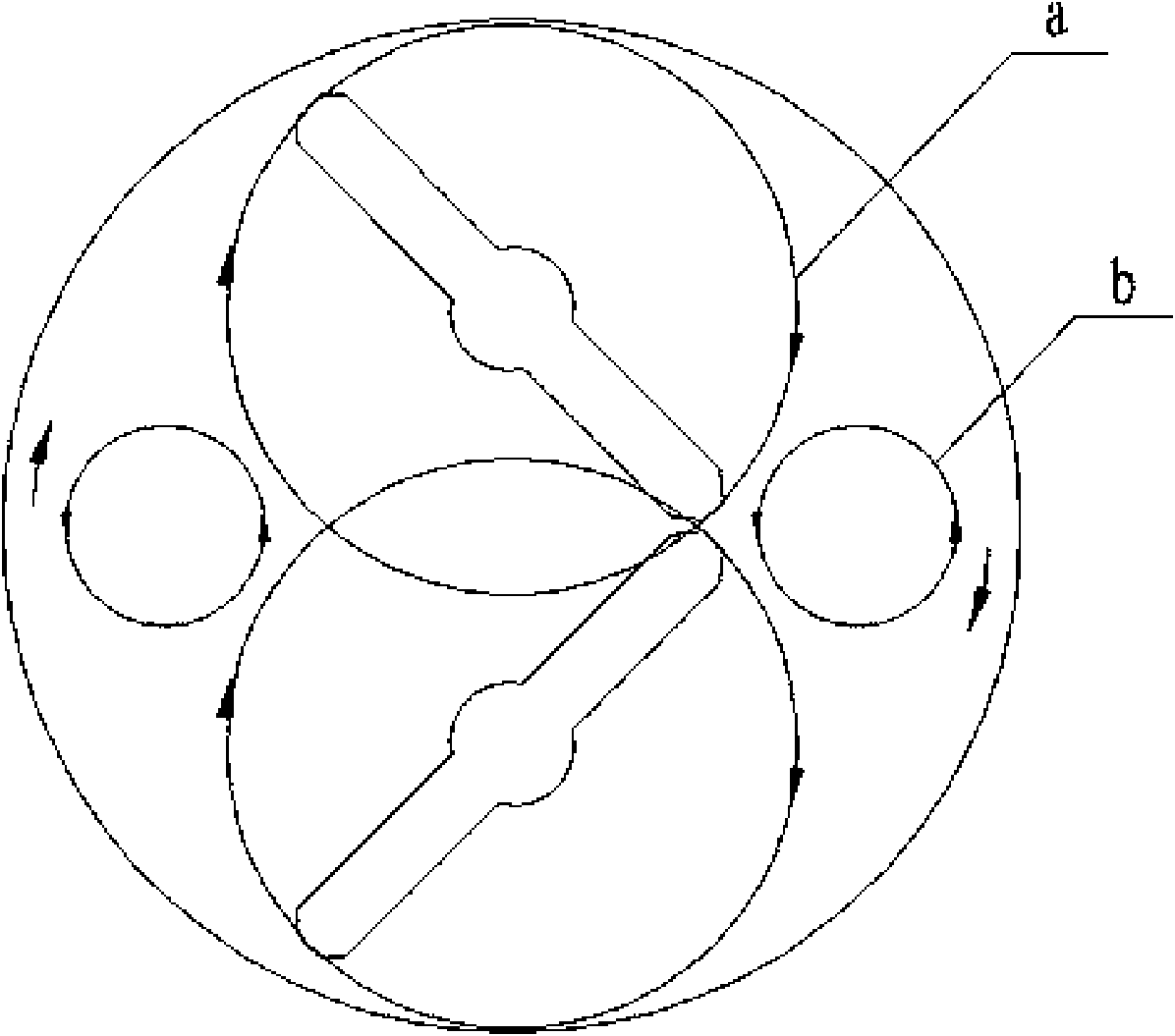

Epicyclic dynamic and static vacuum mixer

InactiveCN101927135AImprove mixing efficiencyImprove the mixing effectRotary stirring mixersChemical industryLow speed

The invention relates to mixing equipment for chemical industry, in particular relating to an epicyclic dynamic and static vacuum mixer, which comprises a power plant, an epicyclic train assembly, a mixing tank, a transmission shaft, high-speed dispersion assemblies and low-speed mixing assemblies, wherein the high-speed dispersion assemblies and the low-speed mixing assemblies are driven by the power plane via the transmission shaft and the epicyclic train assemblies; the epicyclic train component comprises an epicyclic train, an epicyclic box and an epicyclic shield; the lower part of at least one group of the high-speed dispersion assembly is provided with a static mixer set; the bottom end of the high-speed dispersion assembly is provided with a propelled paddle; the static mixer set is connected with the epicyclic box by a connection plate; each group of the static mixer set is composed of a hollow cylinder and n-numbered static mixers arranged inside the cylinder in parallel, wherein n is any integer in the range of 1-40; and the propelled paddle is arranged in the hollow cylinder. The invention integrates the advantages of the epicyclic dispersion vacuum mixer and the static mixer in the processing of mixing the materials, thereby greatly improving the mixing efficiency and having the low cost; and the epicyclic train has the self-lubricating function.

Owner:LIUZHOU HUT CHEM MACHINERY

Diameter-enlarging cone and manufacturing process thereof

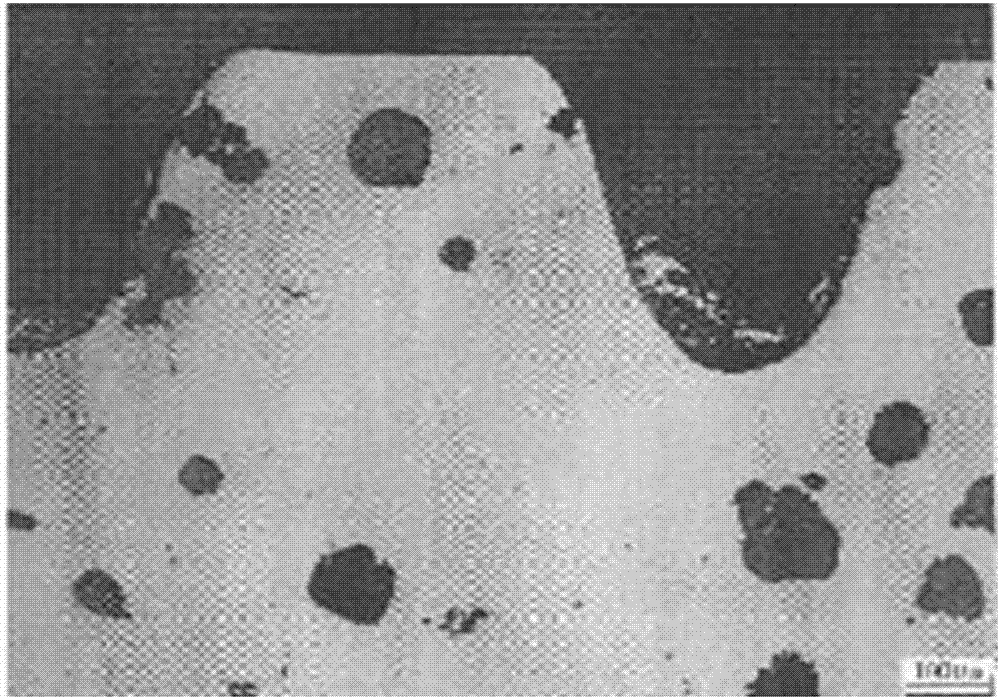

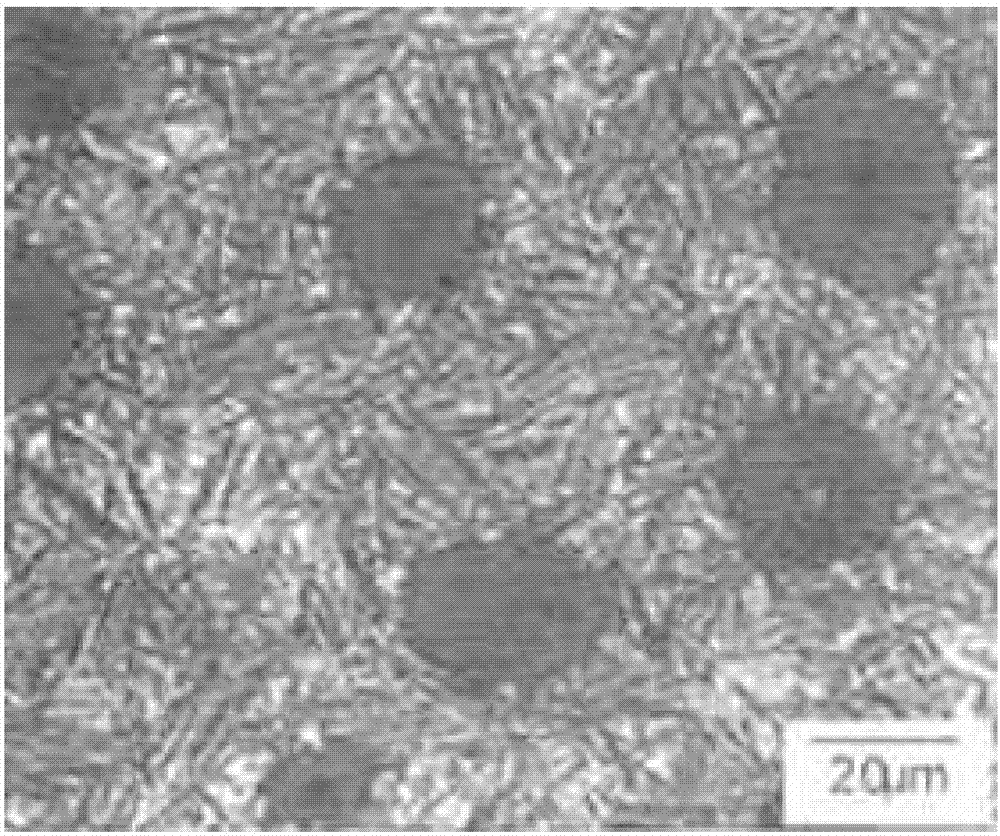

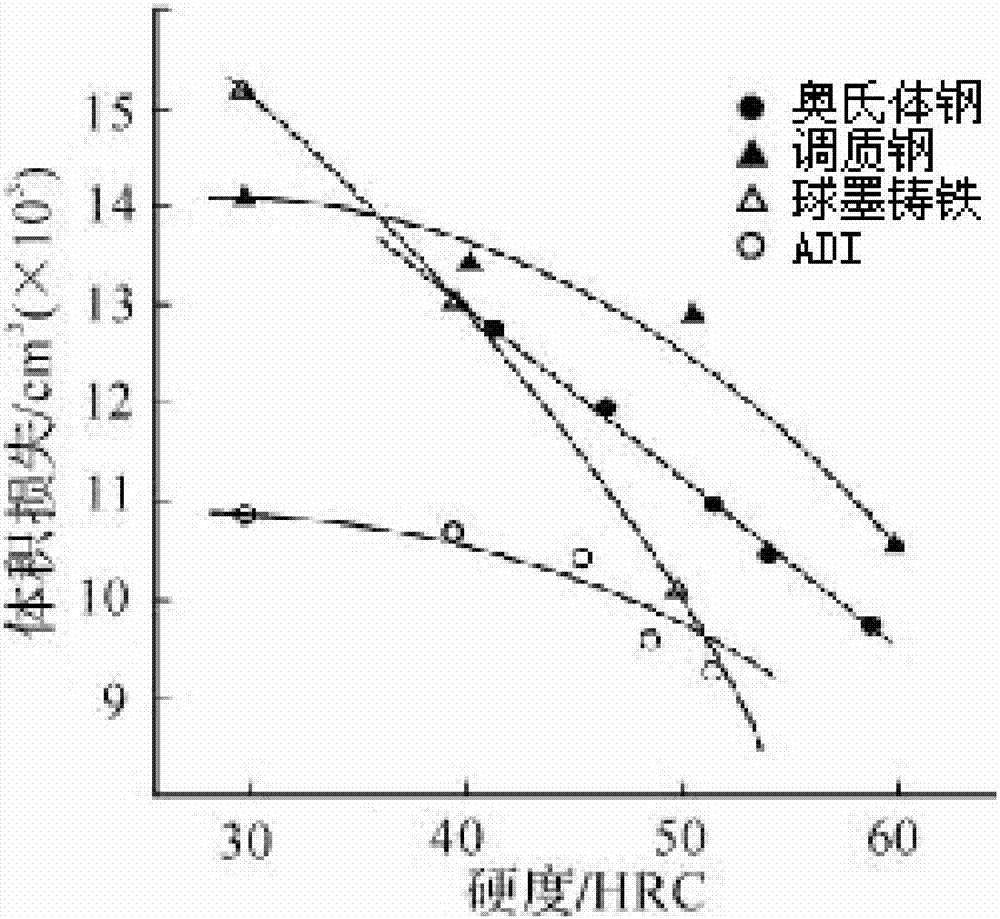

ActiveCN103469108AChange the internal structureImprove mechanical propertiesShaping toolsHardnessMolten steel

The invention relates to a diameter-enlarging cone and a manufacturing process thereof. The diameter-enlarging cone comprises the following material components in percentage by weight: 2.2%-2.4% of C, 1.8%-2.0% of Si, 1%-1.5% of Mn, 0.5%-0.8% of Cr, 0.8%-1.2% of Ni, 0.35%-0.5% of Mo, not more than 0.15% of V, 0.2%-0.3% of Cu, not more than 0.025% of S, not more than 0.025% of P and the balance of Fe element. The manufacturing process comprises the following steps: firstly preparing materials; then formulating a pouring process flow; preparing a pouring tool; pouring by adopting molten steel pouring temperature of 1430 DEG C-1480 DEG C; performing annealing and normalizing thermal treatment after forming by pouring; performing rough machining on the shape and inner hole of the diameter-enlarging cone; placing in a dry and ventilated environment for 30-150 days for natural aging; performing finish machining on the shape and inner hole of the diameter-enlarging cone; enabling the integral thermal treatment hardness HRC of the diameter-enlarging cone to achieve 45-50; grinding a T-shaped slot and inner hole of the diameter-enlarging cone; processing a lubricating oil hole in the diameter-enlarging cone by adopting deep hole drilling; processing a central chamfer angle and then preparing a finished product. The diameter-enlarging cone has the advantages of friction resistance, wear resistance, good self-lubrication function and long service life.

Owner:SUNYO S&T CO LTD

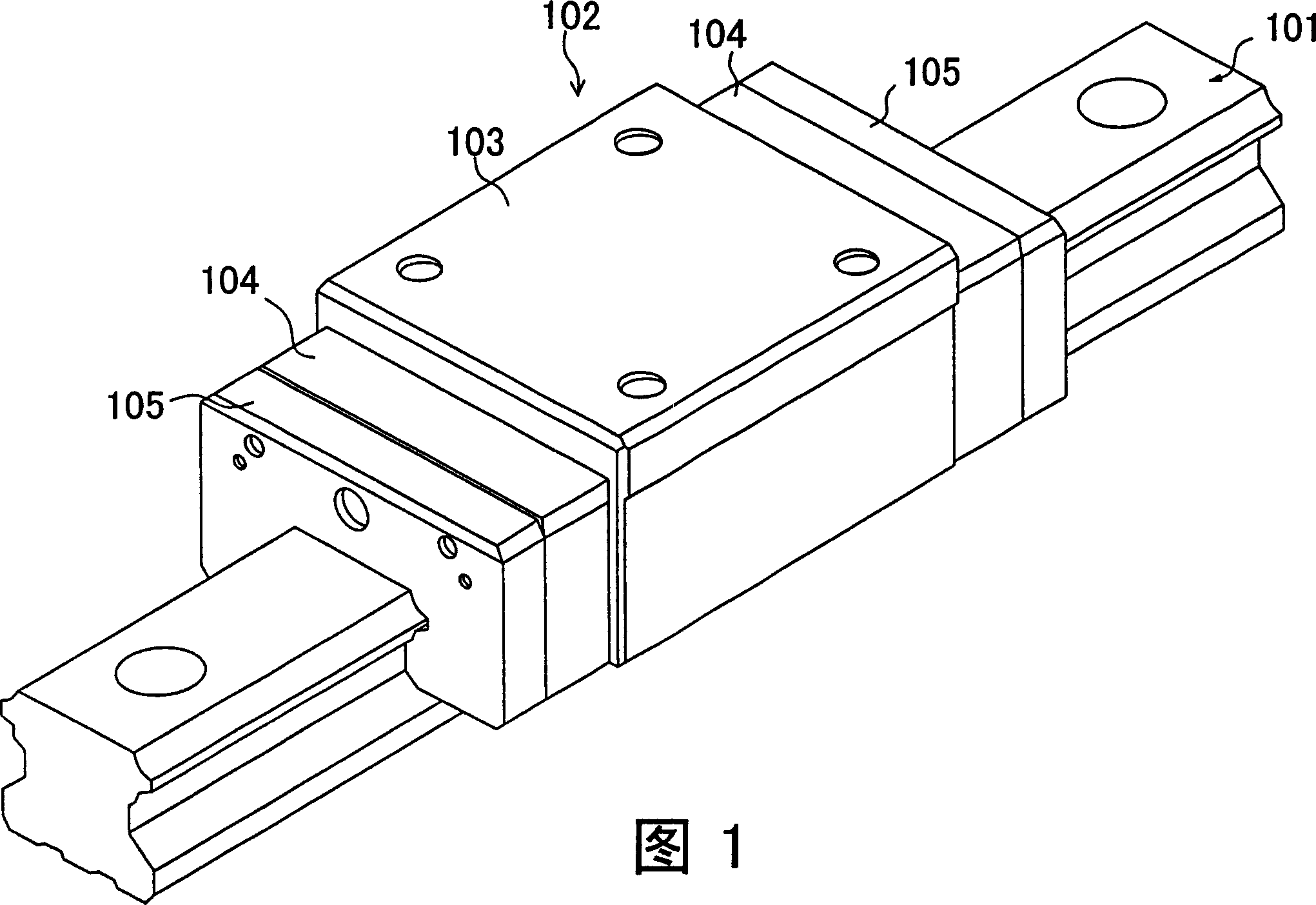

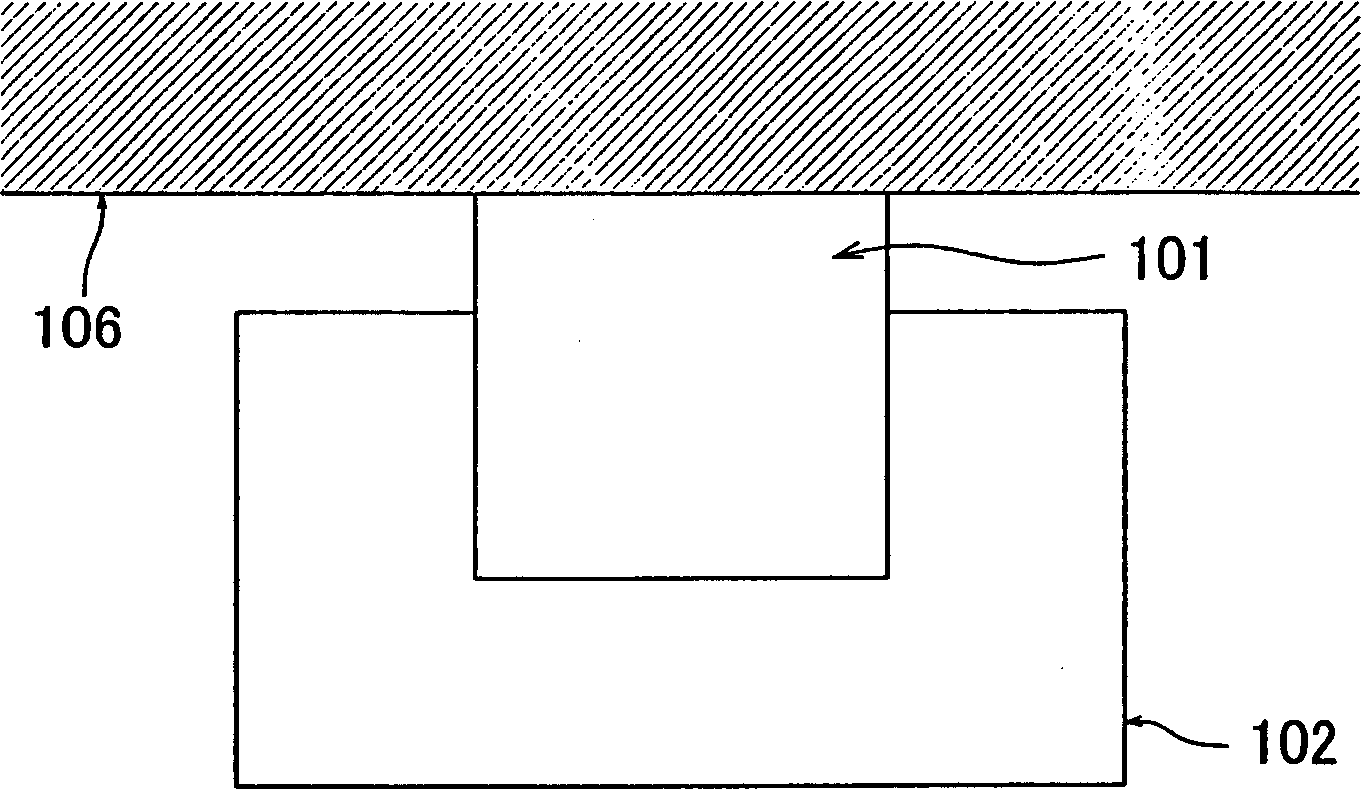

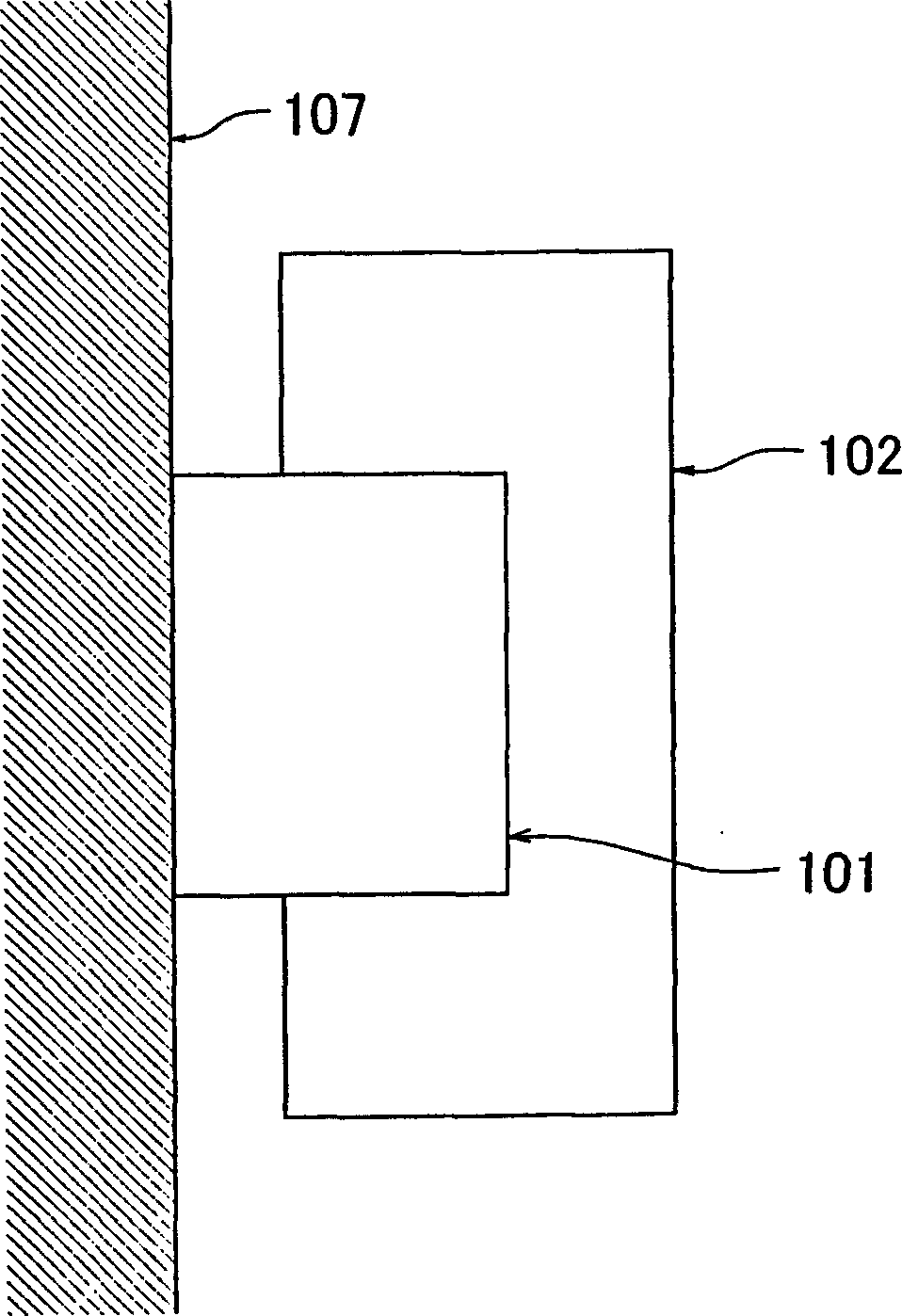

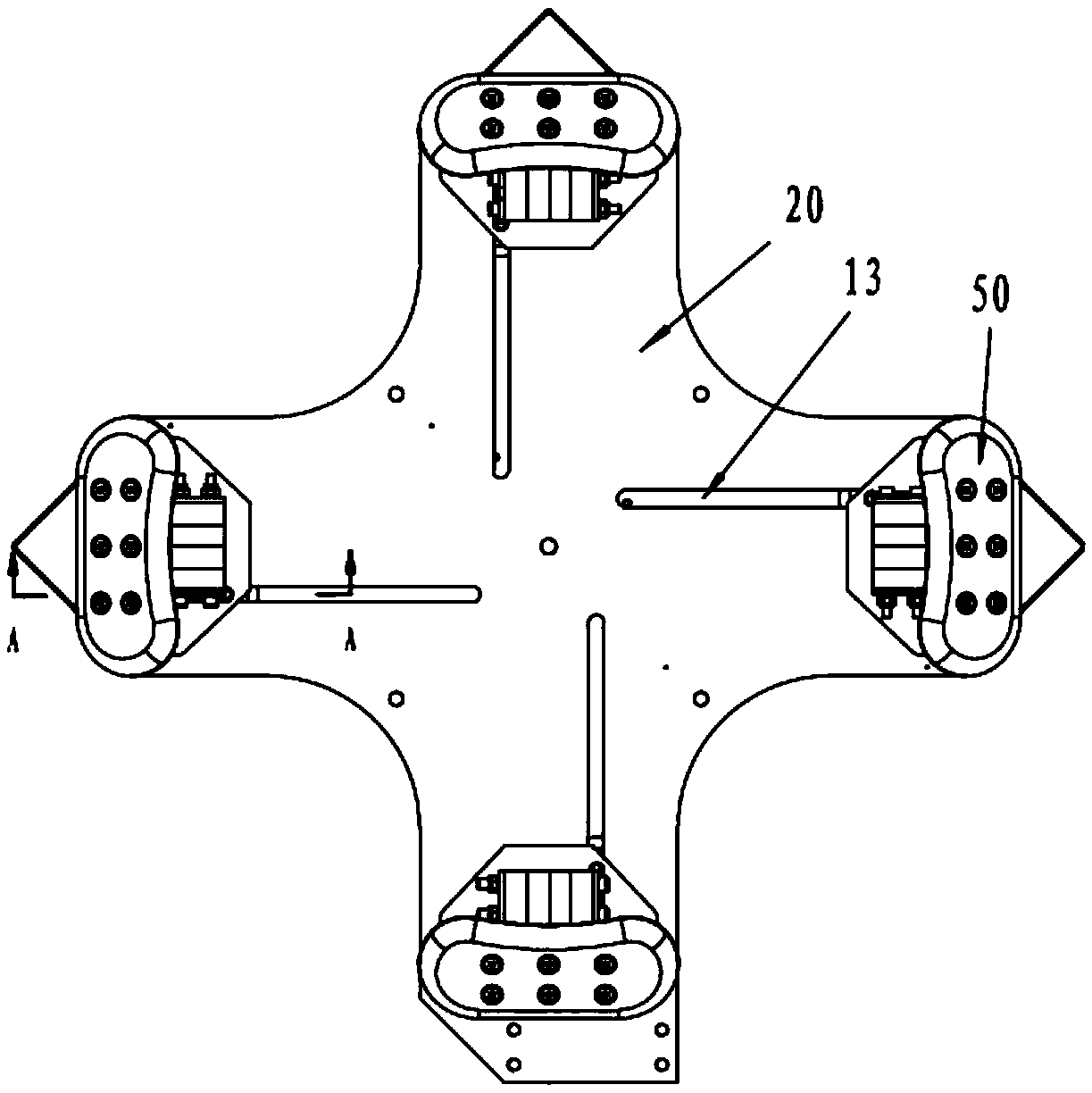

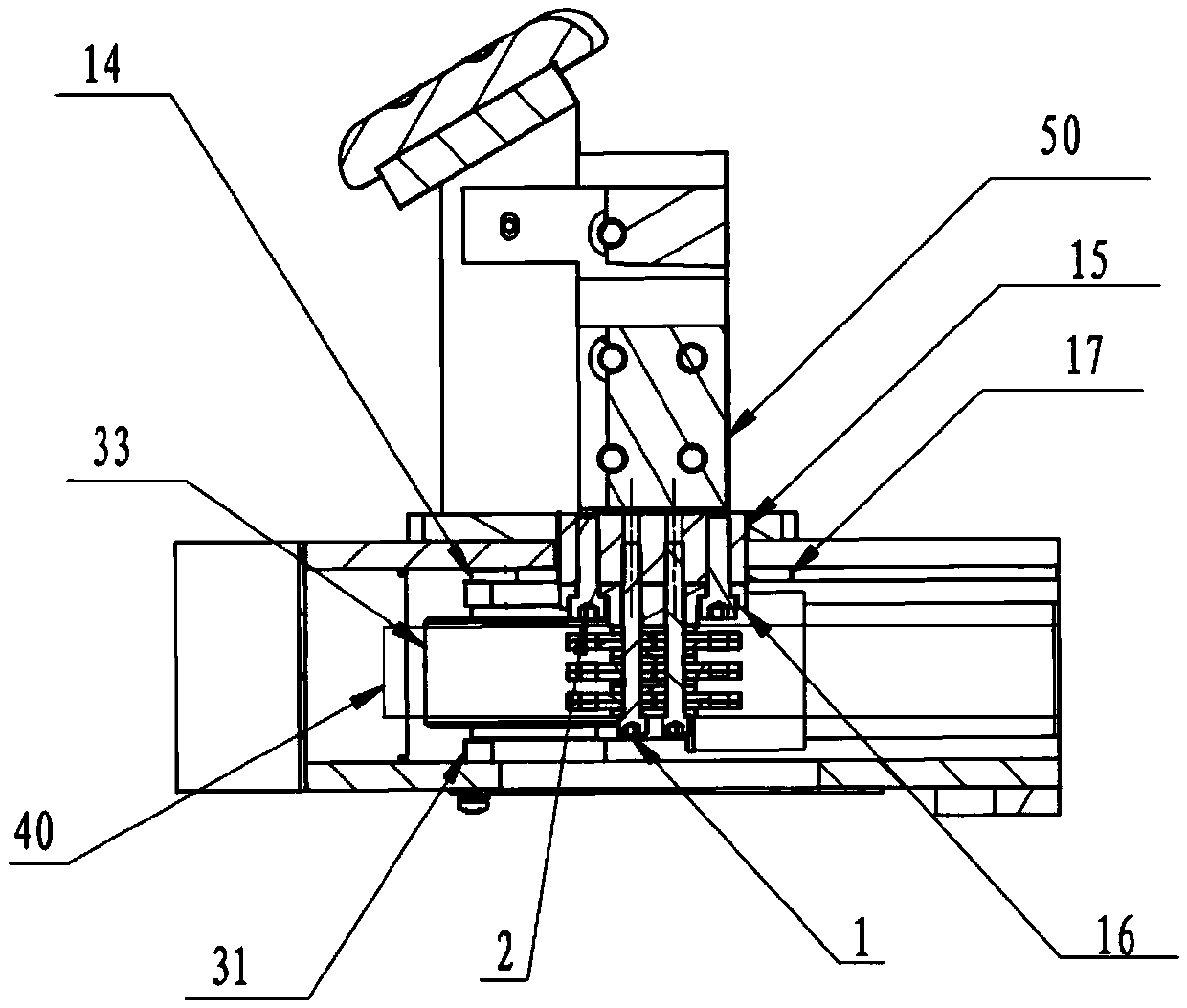

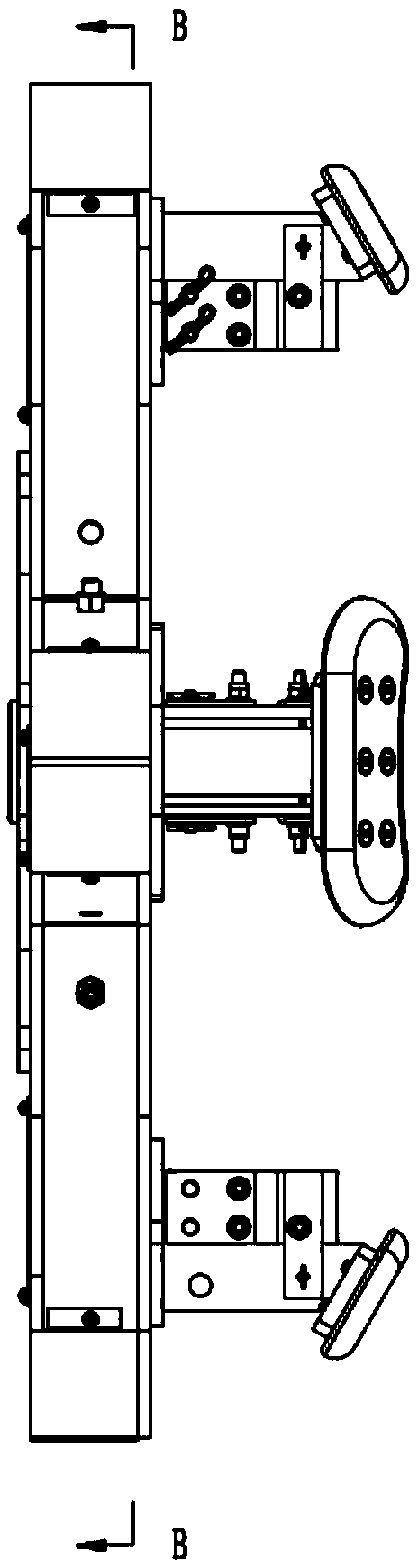

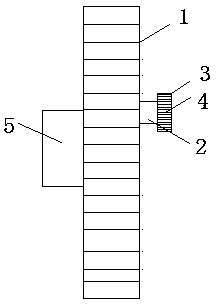

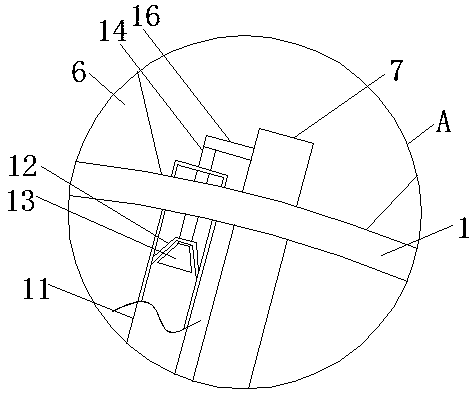

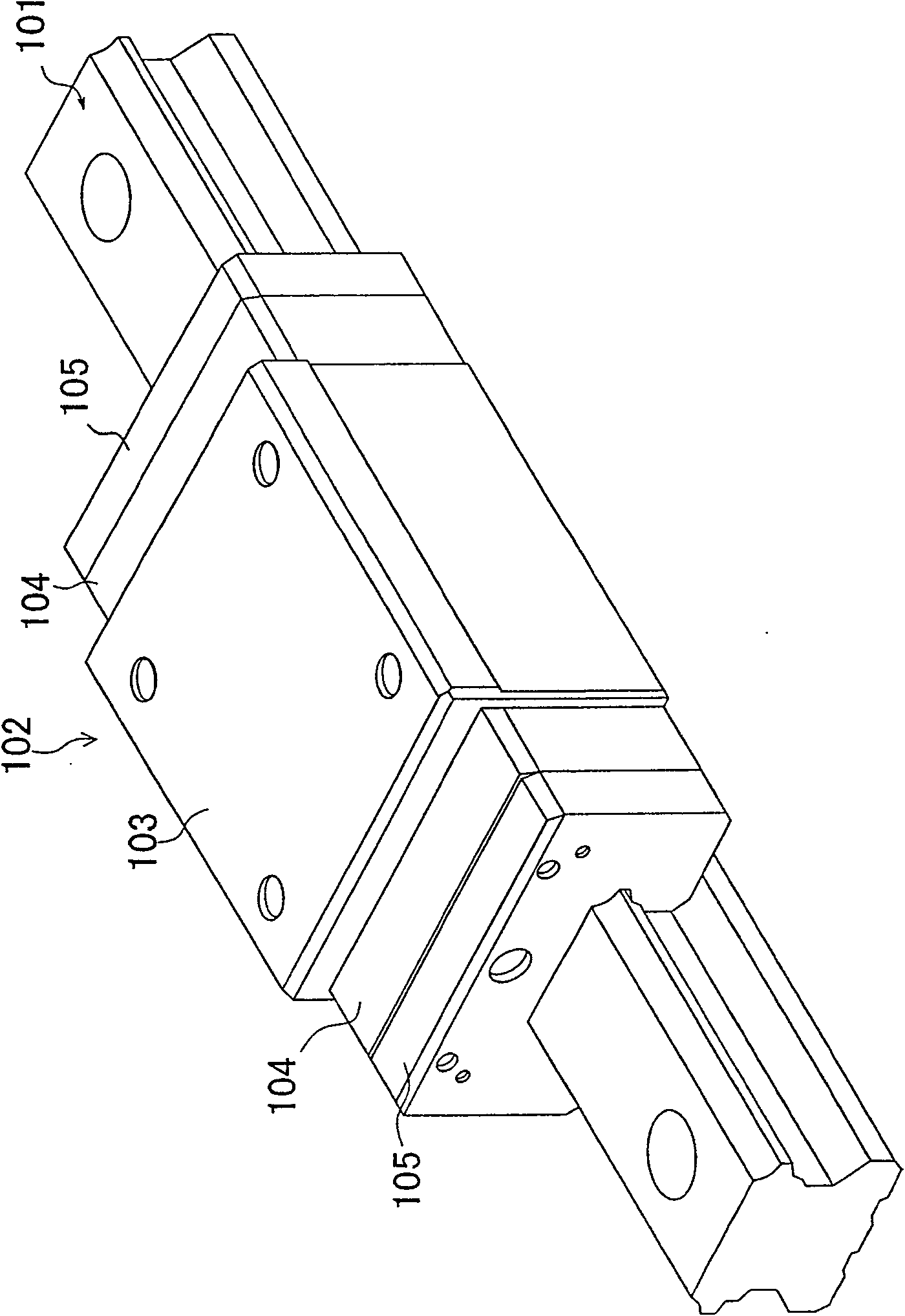

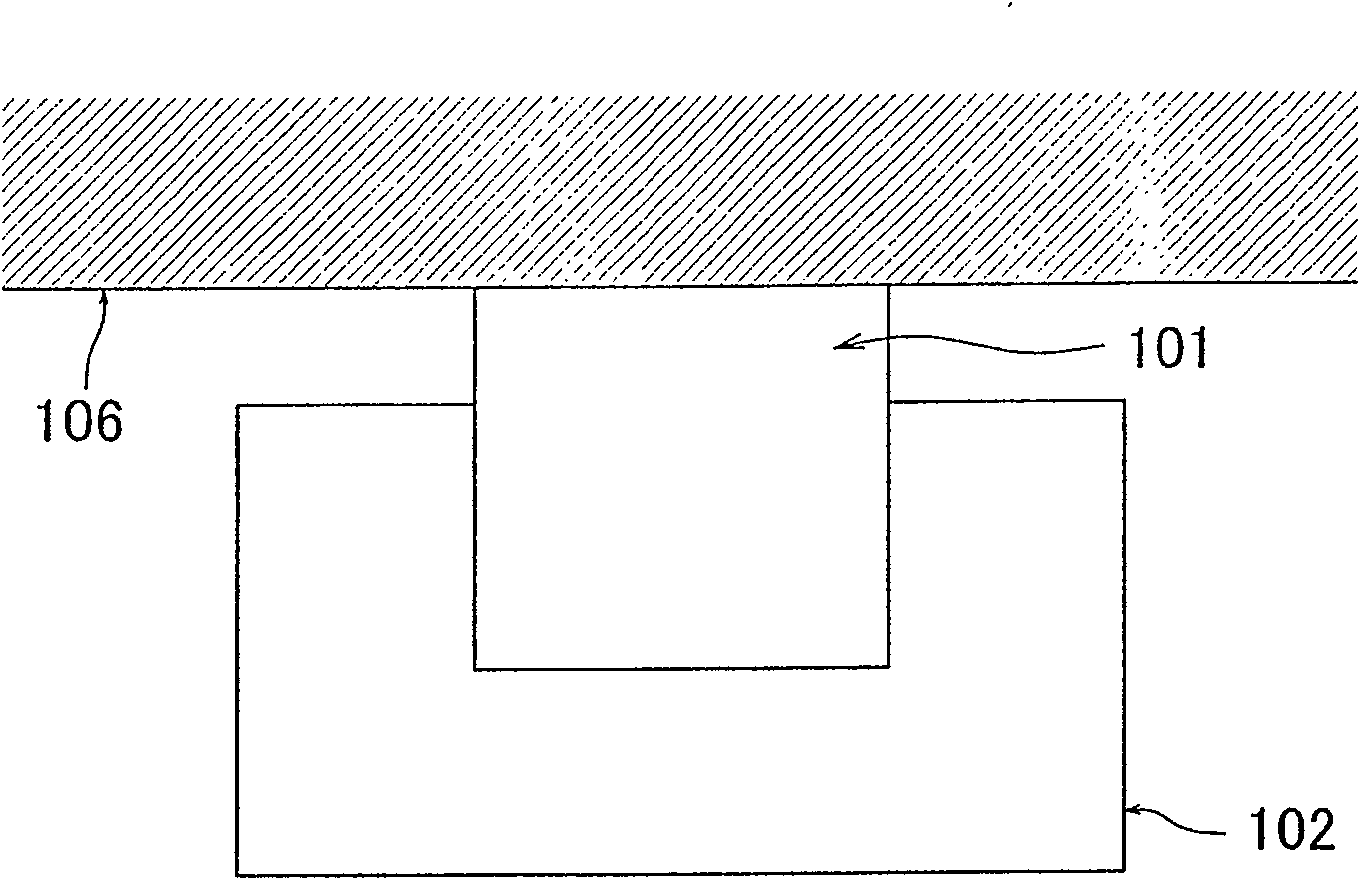

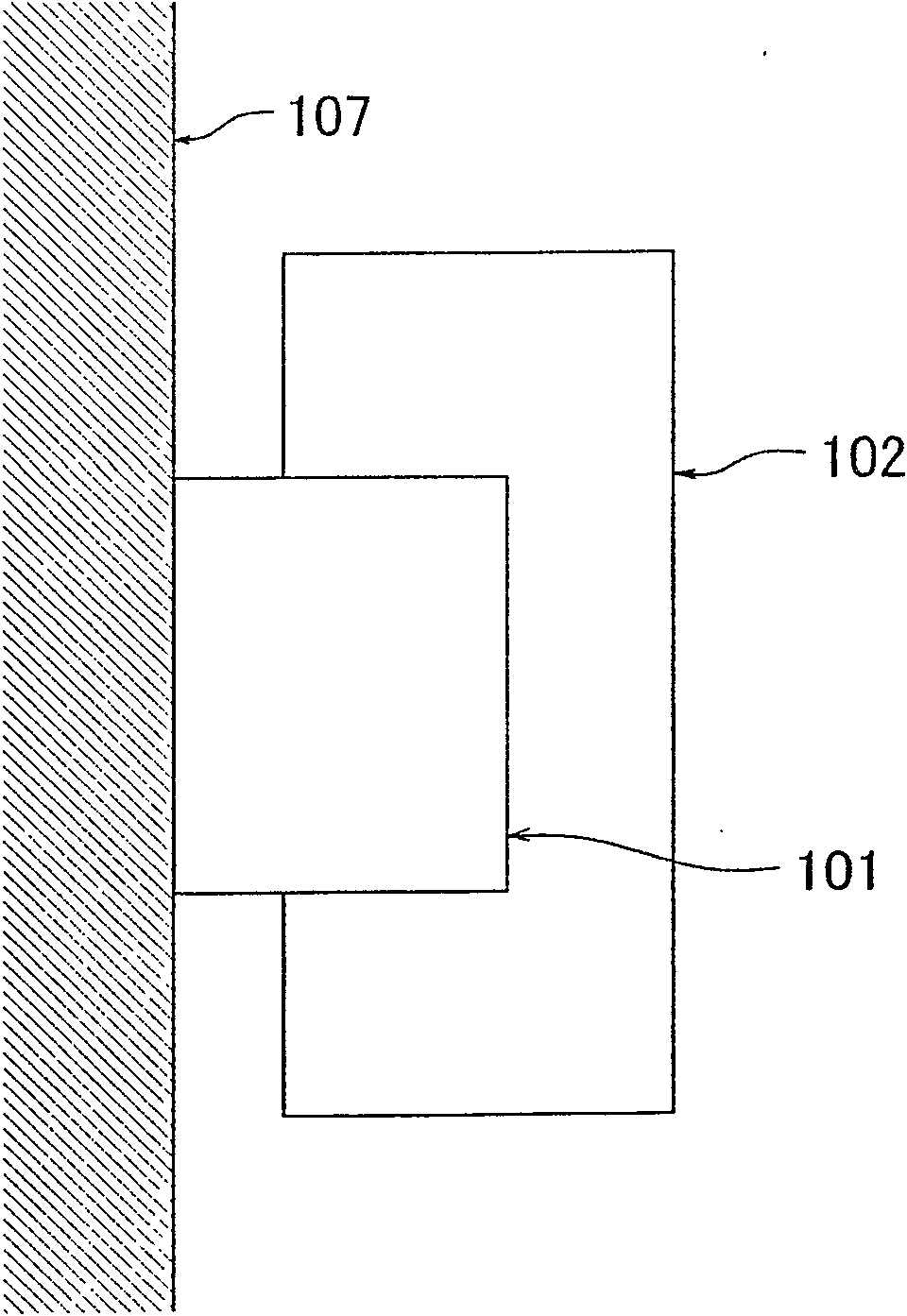

Guiding device

ActiveCN1864010AEasy to moveWith self-lubricating functionLinear bearingsRolling contact bearingsForeign objectEngineering

A guiding device where foreign objects do not enter from gaps into a moving block even in an environment where a large amount of dust is present in the air, the gaps being formed by side faces of a track rail and inner faces of a moving block. A guiding device has a track rail and a moving block (20) and is constructed such that the moving block (20) is assembled so as to be movable relative to the track rail with rolling bodies that circulate in rolling body circulation paths in between. Foreign object entry prevention plates (34) are provided in the guiding device, and head ends of the plates are in contact with side faces of the track rail along its length direction. The plate (34) closes at least gaps formed by inner faces of skirt sections on both sides of the moving body (21) of the moving block (20), side-lid inner faces, and track rail side faces.

Owner:THK CO LTD

Manufacturing method for airplane part stretch-forming mold made of resin matrix composite

ActiveCN105945159AWith self-lubricating functionUniform surface hardnessShaping toolsNumerical controlResin matrix

The invention discloses a manufacturing method for an airplane part stretch-forming mold made of a resin matrix composite and mainly aims to solve the problems that existing molds are large in manufacturing difficulty, hard to store and large in weight and cannot be repaired. The provided manufacturing method for the airplane part stretch-forming mold made of the resin matrix composite comprises the steps that a matrix and a surface are manufactured with the resin matrix composite; and then the airplane part stretch-forming mold is machined and manufactured through a numerical control machine tool. By means of the manufacturing method, the mold using rate is increased, especially, the part productivity is improved, the mold manufacturing cost is reduced, and the mold manufacturing period is shortened.

Owner:SHENYANG CHINA AVIATION MERITT IND CO LTD

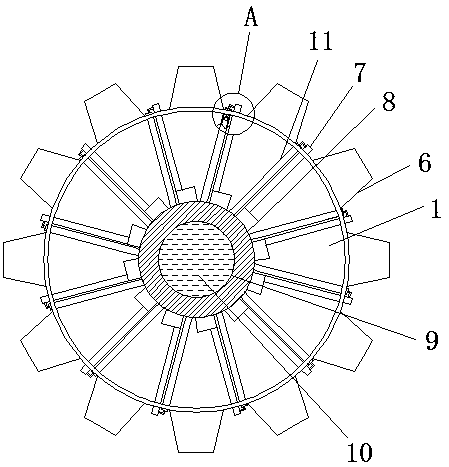

Clamping linkage mechanism and claw disc

The invention discloses a clamping linkage mechanism and a claw disc. Through cooperation of sheave groups and transmission pieces, clamping claws are fixedly arranged on the transmission pieces, one clamping claw is correspondingly arranged at one side of each sheave group, and the clamping claws are distributed in central symmetry with the center of a bottom plate as the center, and move along with the transmission pieces to move towards the center or away from the center synchronously so as to adjust the size of circumference along which the clamping claws are located. In the whole mechanism, only single power is needed to drive each single clamping claw, and the synchronous adjustment of the plurality of clamping claws is realized through the linkage mechanism in the claw disc. The structure is simple and ingenious, the cost is low, and the work efficiency is high.

Owner:VATAPLE MACHINERY KUNSHAN

Ceramic fiber material

InactiveCN107739214AStrong enoughSolve the lack of hardnessInorganic material artificial filamentsAluminiumKaolinite

The invention relates to a ceramic fiber material, which comprises the following raw materials in parts by weight: 8-16 parts of nano titanium dioxide, 5-12 parts of nano magnesium oxide, 3-5 parts ofvanadium pentoxide, 6-10 parts of kaolinite, 1-2 parts of aluminum fiber, 2-3 parts of a dispersing agent, 4-8 parts of colored clay, 1-5 parts of a coupling agent, 3-8 parts of coal cinder, 5-9 parts of dolomite powder, 8-12 parts of trimethyl ethylenediamine, 18-25 parts of alumina, 2-5 parts of aluminum oxide, 5-10 parts of silicon dioxide, 5-9 parts of toughening fiber, 3-9 parts of a lubricant, 2-8 parts of a reinforcing material, and 10-15 parts of a binding agent. The ceramic fiber material provided by the invention has sufficient strength and hardness, sufficient plasticity and toughness, and a self-lubricating function.

Owner:桂林市晟博科技服务有限公司

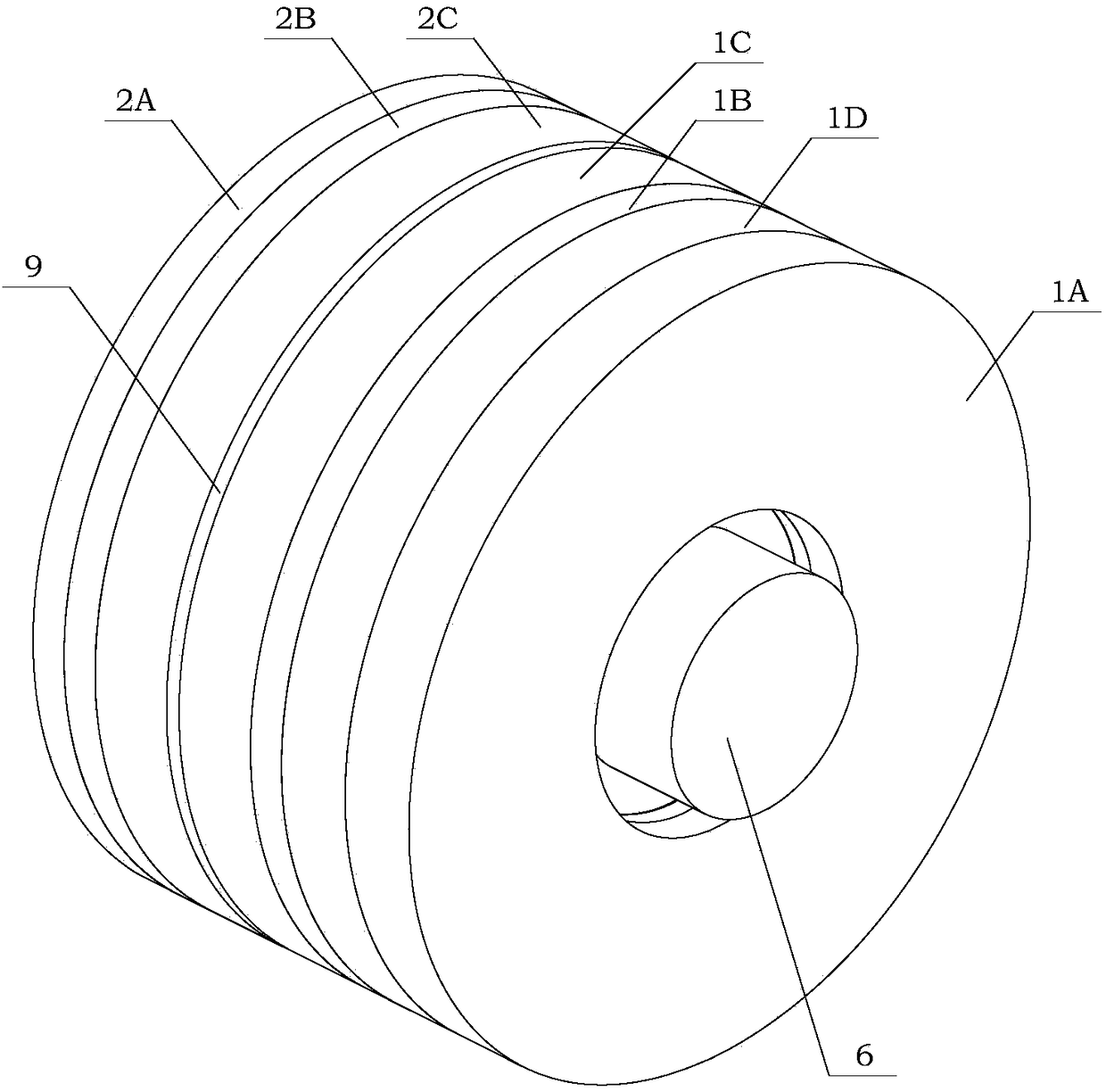

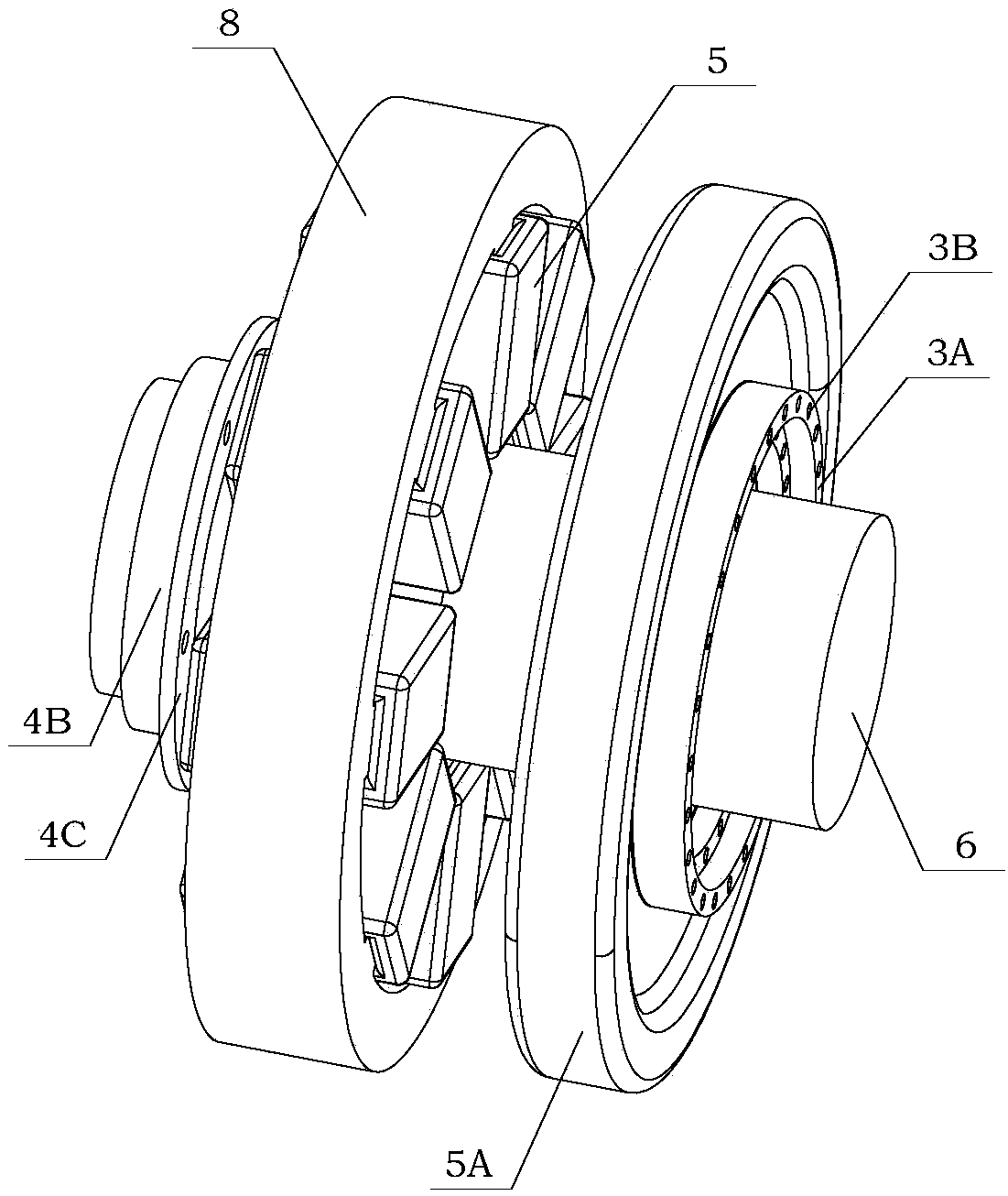

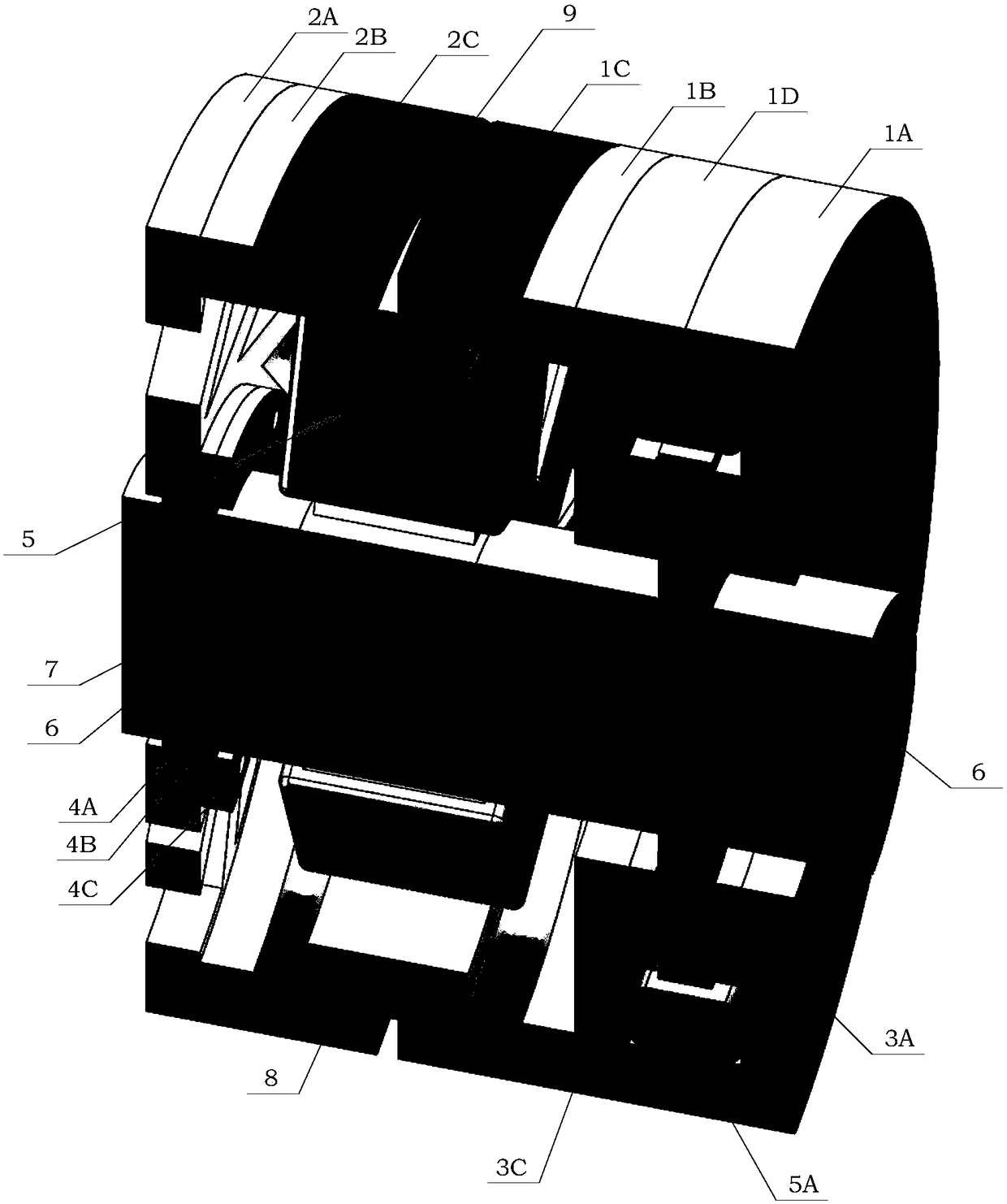

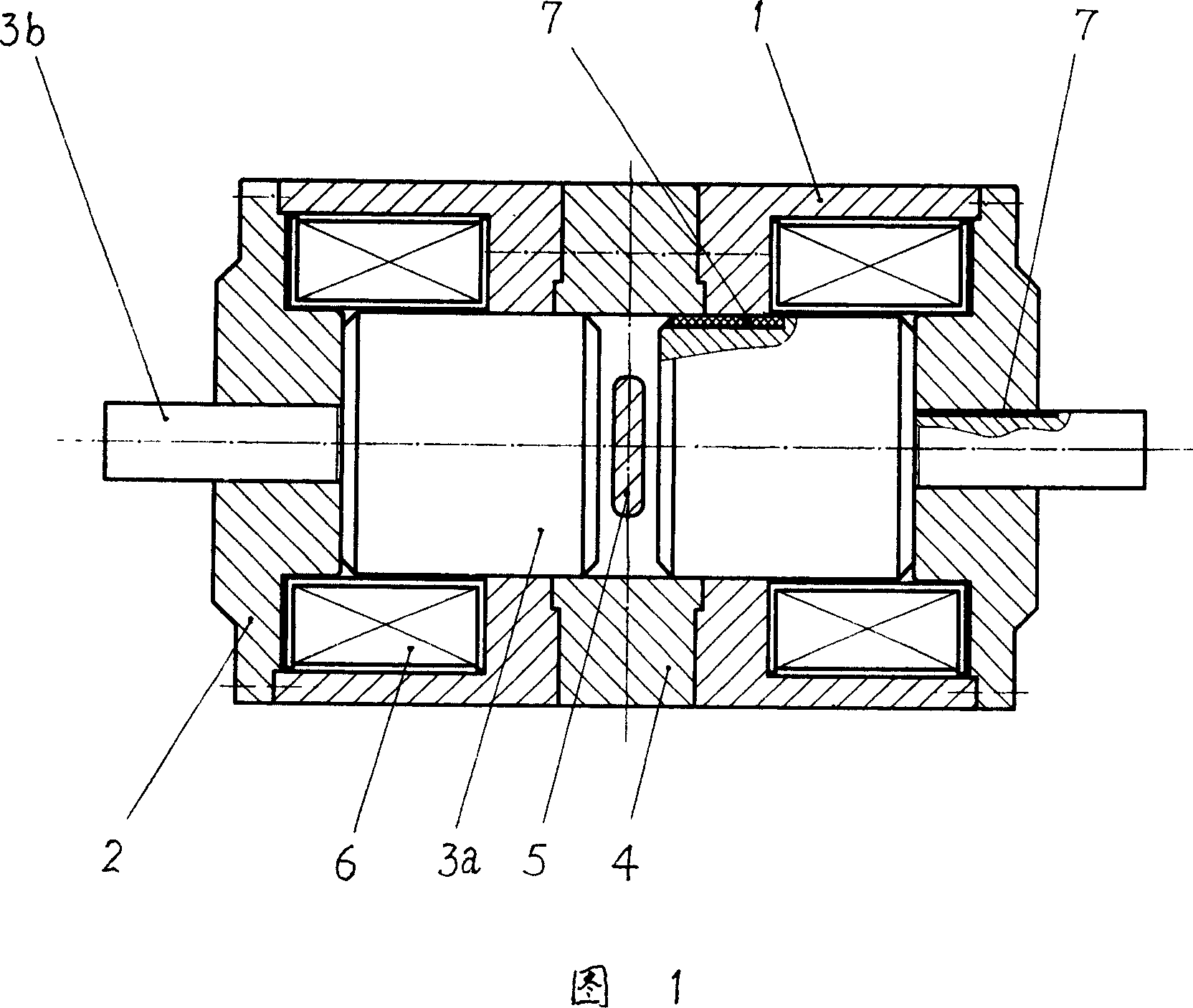

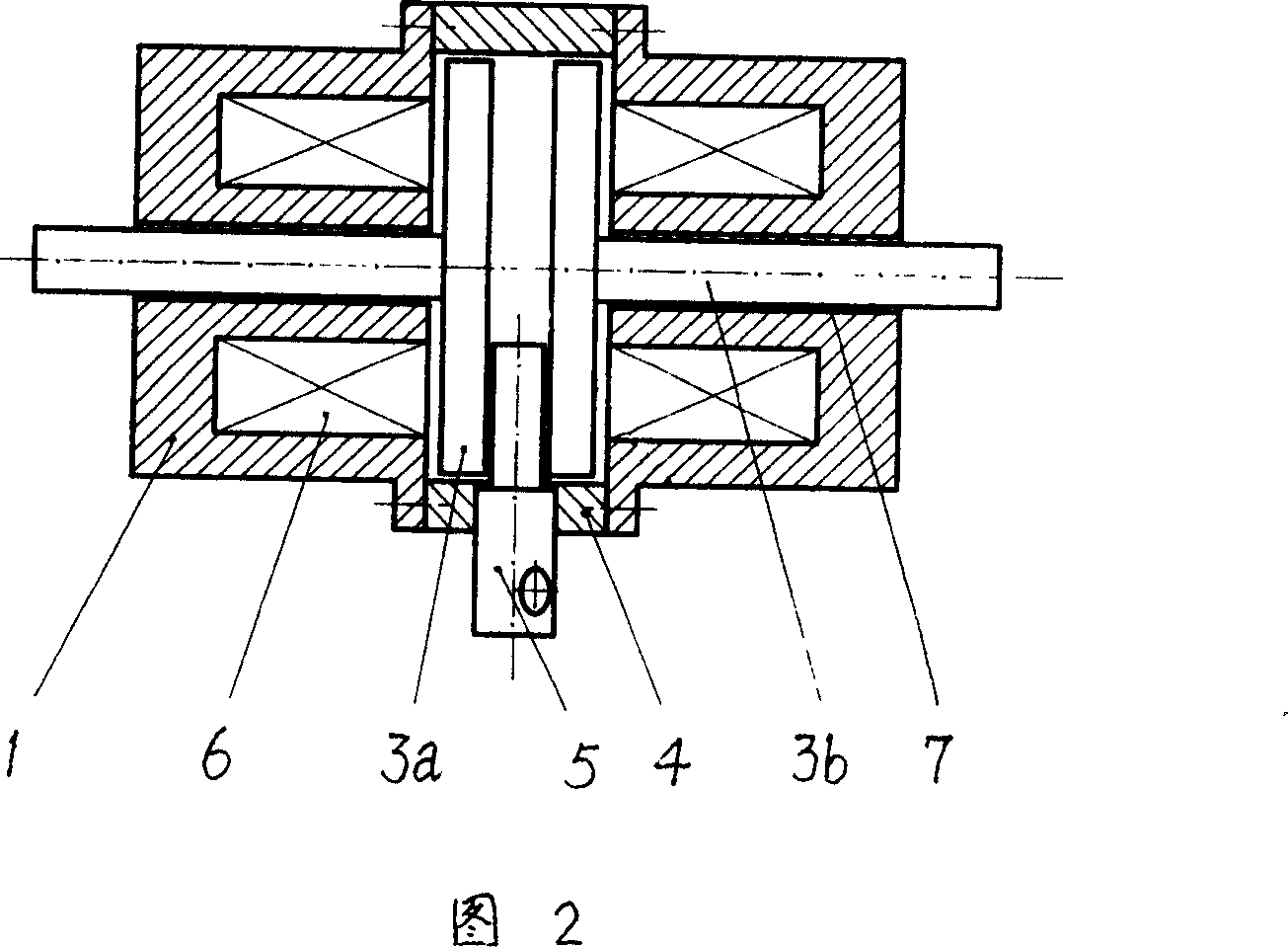

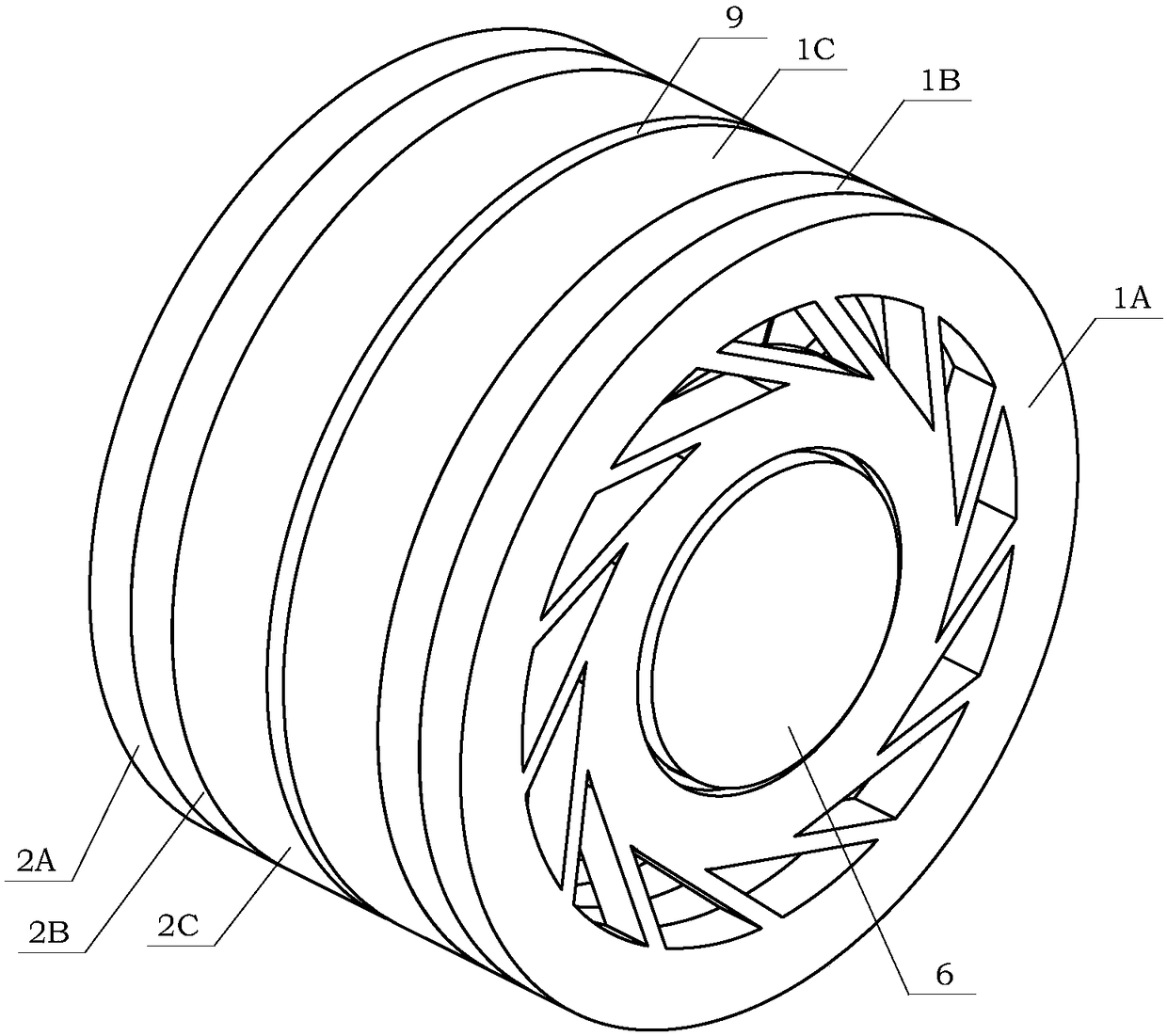

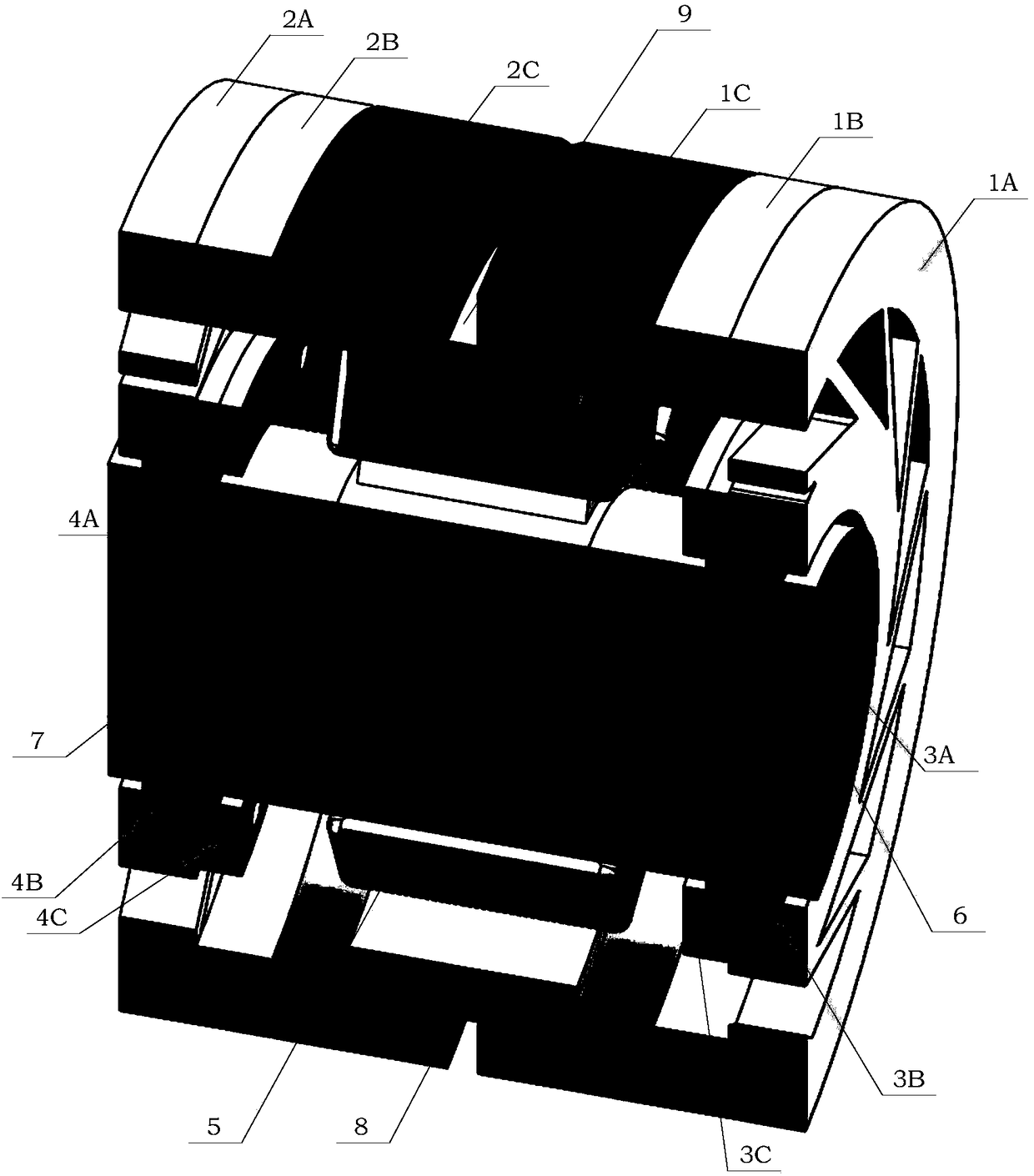

Orthogonal magnetic circuit radial-axial-integrated magnetic bearing based on symmetrical self-lubricating flexible backup bearing structure

ActiveCN108361279AAvoid hyperthermiaAvoid scrapping the whole machineShaftsMagnetic bearingsStatorEngineering

The invention discloses an orthogonal magnetic circuit radial-axial-integrated magnetic bearing based on a symmetrical self-lubricating flexible backup bearing structure. A radial magnetic bearing coil of the orthogonal magnetic circuit radial-axial-integrated magnetic bearing is mounted on a stator tooth set of a stator iron core; two radial rigid magnetic-conductive rings are mounted at an outerdisc of the stator iron core so as to prevent the short circuit problem of permanent magnetic circuits, wherein a certain gap exists between the two radial rigid magnetic-conductive rings; an axial magnetic bearing coil is located at a thrust disc of a rotor shaft and mounted in a cavity formed by the two magnetic-conductive rings; graphite rings and backup bearing skeletons which achieve the axial self-lubricating effect are arranged on the two sides of the thrust disc correspondingly; and a radial backup bearing skeleton and a graphite internal convex ring are arranged in an inner ring cavity of a radial flexible magnetic conductive ring for achieving the radial self-lubricating effect. By adopting the technical means that axial and radial electromagnetic circuits are combined into a whole, and a radial magnetic bearing and a backup bearing are combined into a whole, the technical problem that traditional magnetic bearings are low in coaxiality is solved.

Owner:BEIHANG UNIV

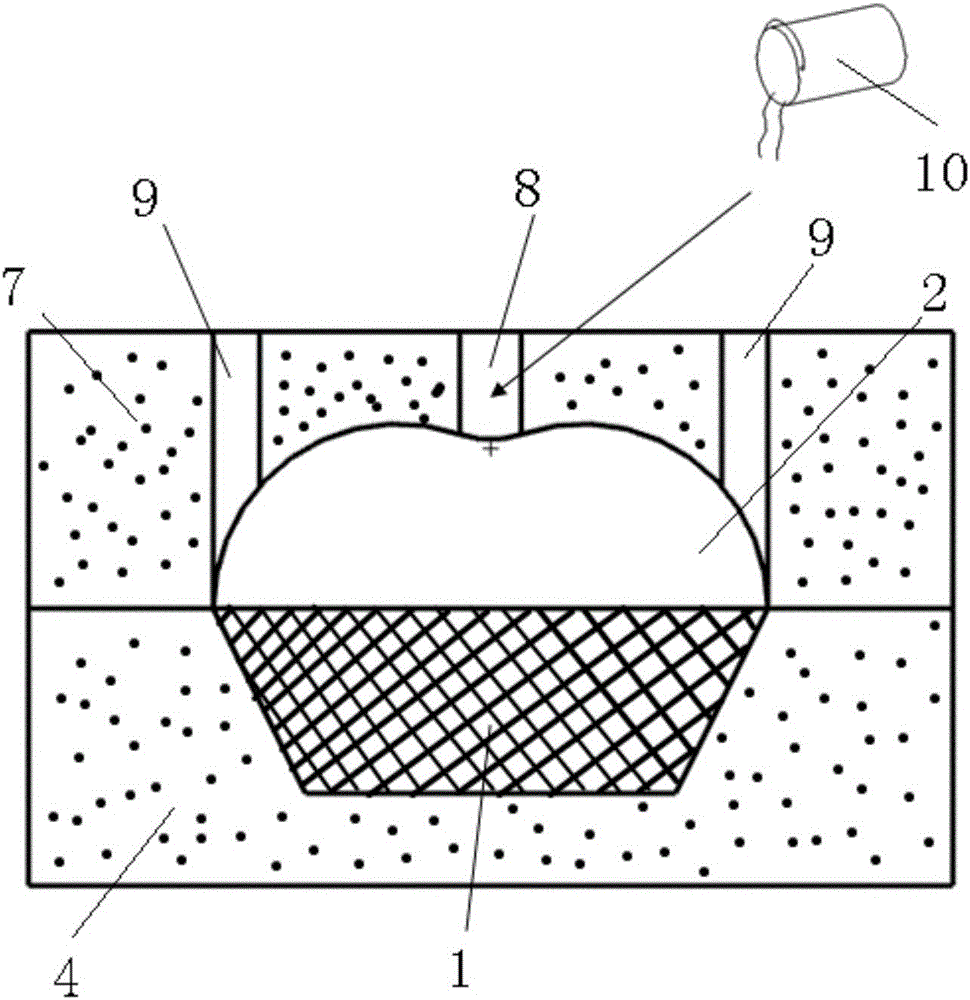

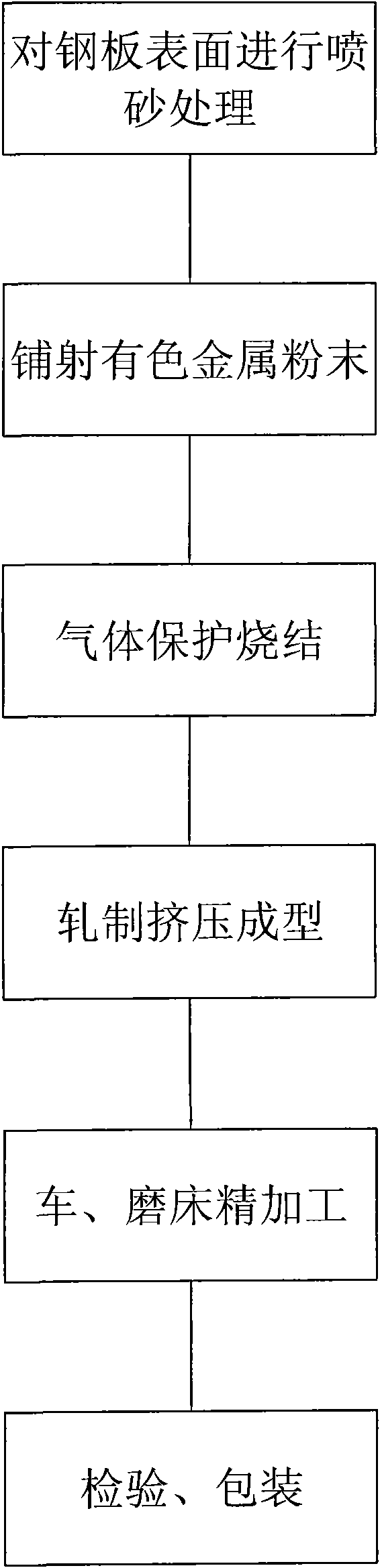

Processing method for sintering bimetallic lining

InactiveCN101648270AReduce labor intensityNo pollution in the processAbrasive blasting machinesNonferrous metalMetallic materials

The invention provides a processing method for sintering a bimetallic lining. The method comprises the following steps: firstly, carrying out surface treatment on cold rolling and hot rolling plates;secondly, uniformly spreading nonferrous metal powder on the surfaces of the plates through a powder spreading device; thirdly, carrying out gas shielded sintering on the plates with the spread metalpowder; fourthly, rolling the sintered bimetallic plates by a precise rolling mill, and then reeling and welding for molding. The processing method for sintering the bimetallic lining simplifies the production process, greatly lightens the labor intensity of workers in a production process, has no environmental pollution and effectively improves the labor production efficiency and the mechanical performance of products simultaneously. Moreover, when in use, a product of the method has self-lubricating function without adding lubricating oil, and can be suitable for rotating speed with a largeload and hostile working conditions.

Owner:SHIYAN GANGRUI IND & TRADE

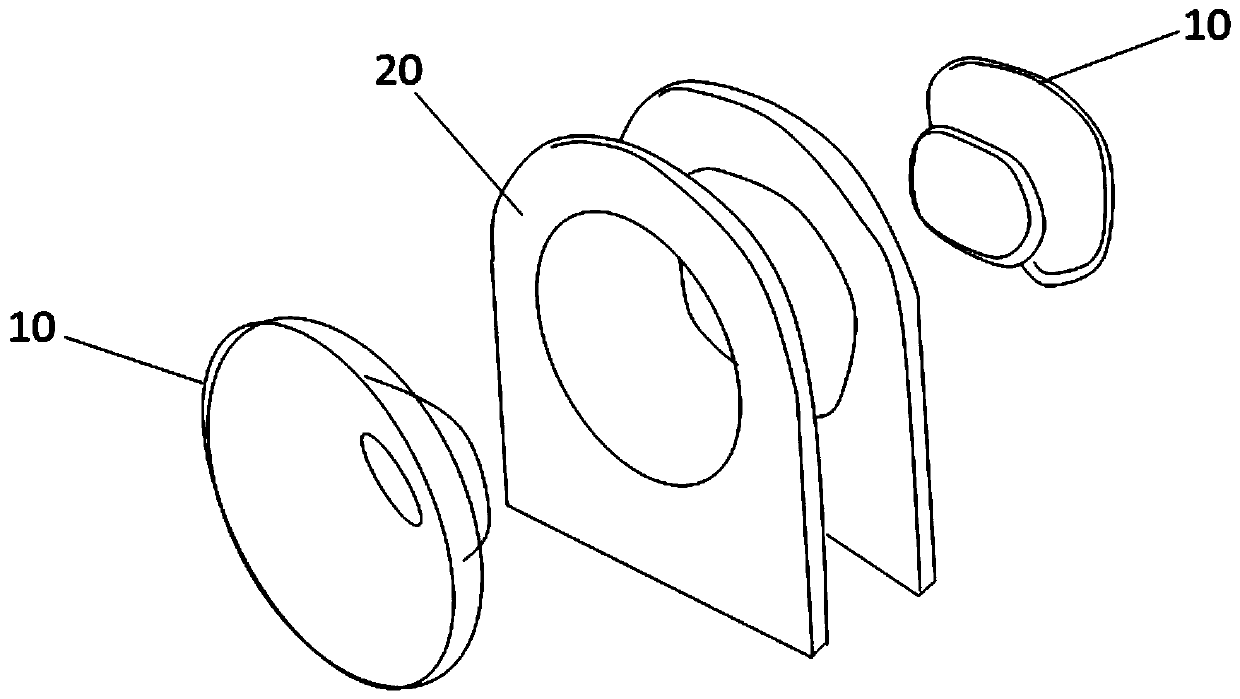

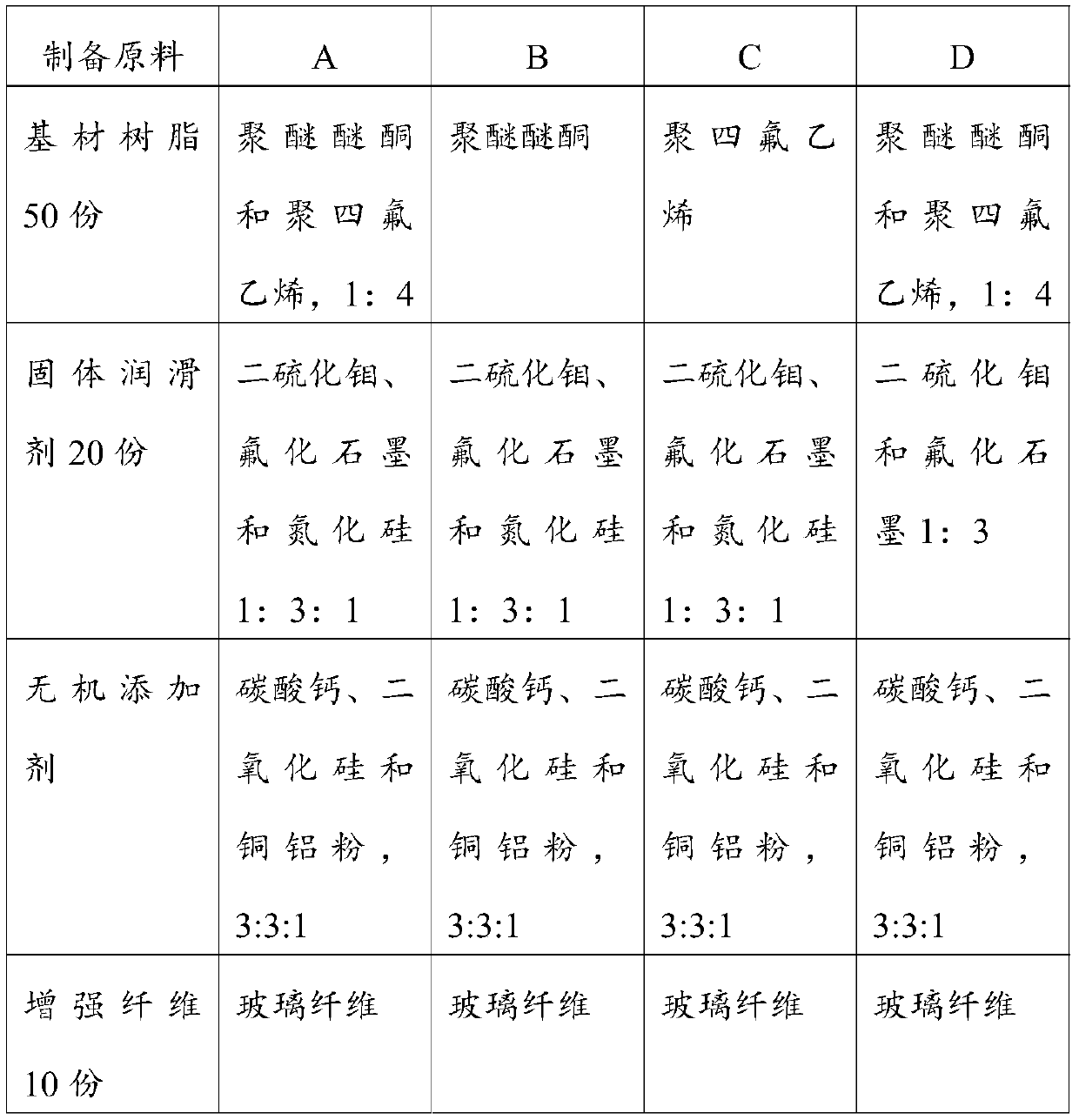

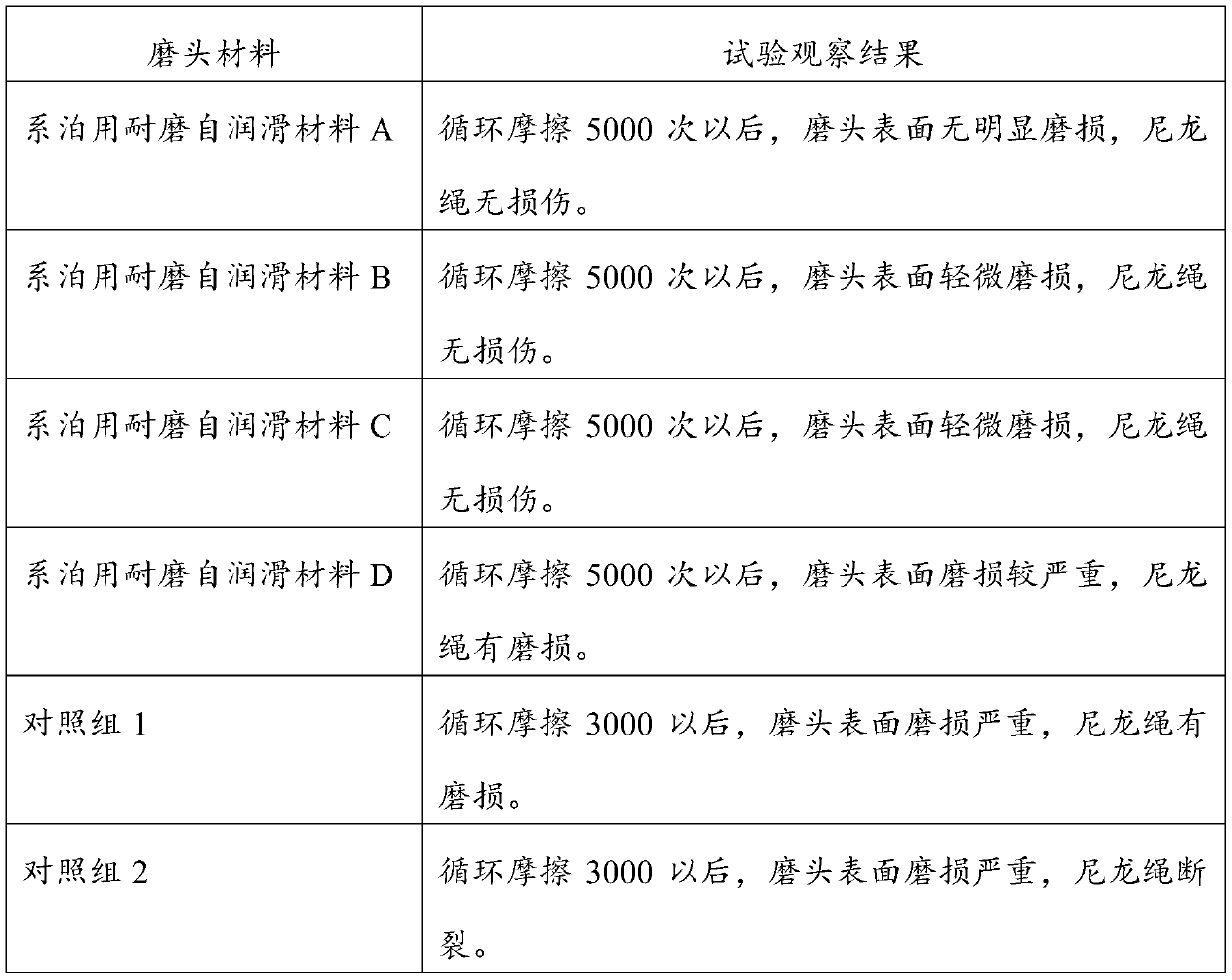

Wear-resistant self-lubricating material for mooring, preparation method thereof and fairlead

The invention provides a wear-resistant self-lubricating material for mooring, which is prepared from the following raw materials: a base material resin, a solid lubricant, an inorganic additive and reinforcing fibers, and is suitable for preparing a fairlead. The fairlead prepared from the material has a self-lubricating function, the abrasion of a mooring rope can be effectively relieved, the service life of the mooring rope is prolonged, the operation cost of a ship company is reduced, and the material is easily available in raw materials, simple in preparation process and easy to produce and popularize.

Owner:中山中科育成实业有限公司

Special lubricating device for novel planetary speed reducer

InactiveCN102588555AWith self-lubricating functionWith self-healing functionGear lubrication/coolingPortable liftingWear resistantWear resistance

A special lubricating device for a novel planetary speed reducer relates to the technical field of planetary speed reducers and is characterized in that a layer of novel carbon fiber composite material is coated on the surface of each gear in the planetary speed reducer and special lubricating grease for the planetary speed reducer is coated on the surface of the novel carbon fiber composite material, wherein the special lubricating grease for the planetary speed reducer comprises base grease, densifier, antioxidant, extreme-pressure wear-resistant agent, metal antirusting agent, magnetic-field response smart materials and self-repairing additive. The novel carbon fiber composite material has a self-lubricating function, the special lubricating grease coated on the surface of the novel carbon fiber composite material has high water resistance, extreme-pressure wear resistance and adhesion and high dropping point and particularly has a self-repair function for damaged bearings and gears.

Owner:引领散料设备技术(大连)有限公司

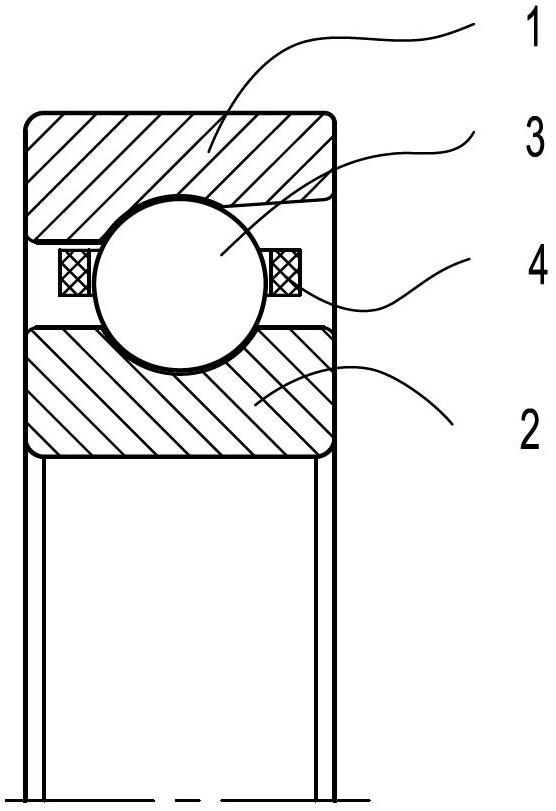

Low-temperature deep cooling bearing

ActiveCN102678740AExtended service lifeStrong load capacityBall bearingsBearing componentsPolyether ether ketoneTungsten disulfide

The invention relates to high-speed refrigeration equipment, in particular to a low-temperature deep cooling bearing which is applied to a liquid nitrogen pump. The low-temperature deep cooling bearing comprises an outer ring, an inner ring, a rolling body and a retainer; the outer ring and the inner ring adopt stainless steel materials; a rolling path of the outer ring and a rolling path of the inner ring are both sequentially subjected to superfinishing and tungsten disulfide surface treatment; the rolling body is a ceramic ball; and the retainer adopts a PEEK (polyether-ether-ketone) material. According to the low-temperature deep cooling bearing, the outer ring and the inner ring adopt the stainless steel materials, the rolling body adopts the ceramic ball, and the retainer adopts the PEEK material, so that the bearing can meet requirements on shape change and rust prevention under deep cooling condition; and the rolling paths of the inner and outer rings are sequentially subjected to the superfinishing and the tungsten disulfide surface treatment, so that the bearing has self-lubricating function, and the service life of the bearing under low temperature condition can be prolonged.

Owner:WUXI NO 2 BEARING

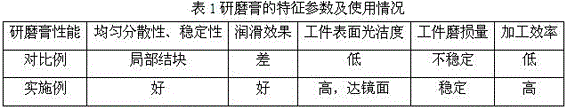

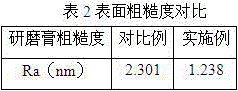

Water-oil soluble nanocarbon crystal abrasive paste and preparation method thereof

InactiveCN106010441ANo reunionUniform and stable dispersionOther chemical processesPolishing compositions with abrasivesKeroseneAlloy

The invention discloses water-oil soluble nanocarbon crystal abrasive paste. The water-oil soluble nanocarbon crystal abrasive paste is mainly prepared from, by weight, 10-25 parts of nano carbon crystals, 1-10 parts of water, 20-30 parts of oleic acid, 10-20 parts of vaseline, 15-30 parts of kerosene, 15-25 parts of peanut oil, 5-15 parts of fungicide, 0.2-2 parts of sorbitan fatty acid ester and 0.2-2 parts of an OP-emulsifier. The invention further discloses a preparation method of the water-oil soluble nanocarbon crystal abrasive paste. The prepared abrasive paste has the advantages of being green, environmentally friendly, non-corrosive, low in cost and good in grinding effect and is applicable to measuring tools, cutting tools and optical instruments made from glass, ceramic, hard alloy, natural diamonds, precious stones and other hard materials and machining of other high-finish-degree workpieces.

Owner:ZHENGZHOU ARTIFICIAL DIAMOND & PROD ENG TECH RES CENT

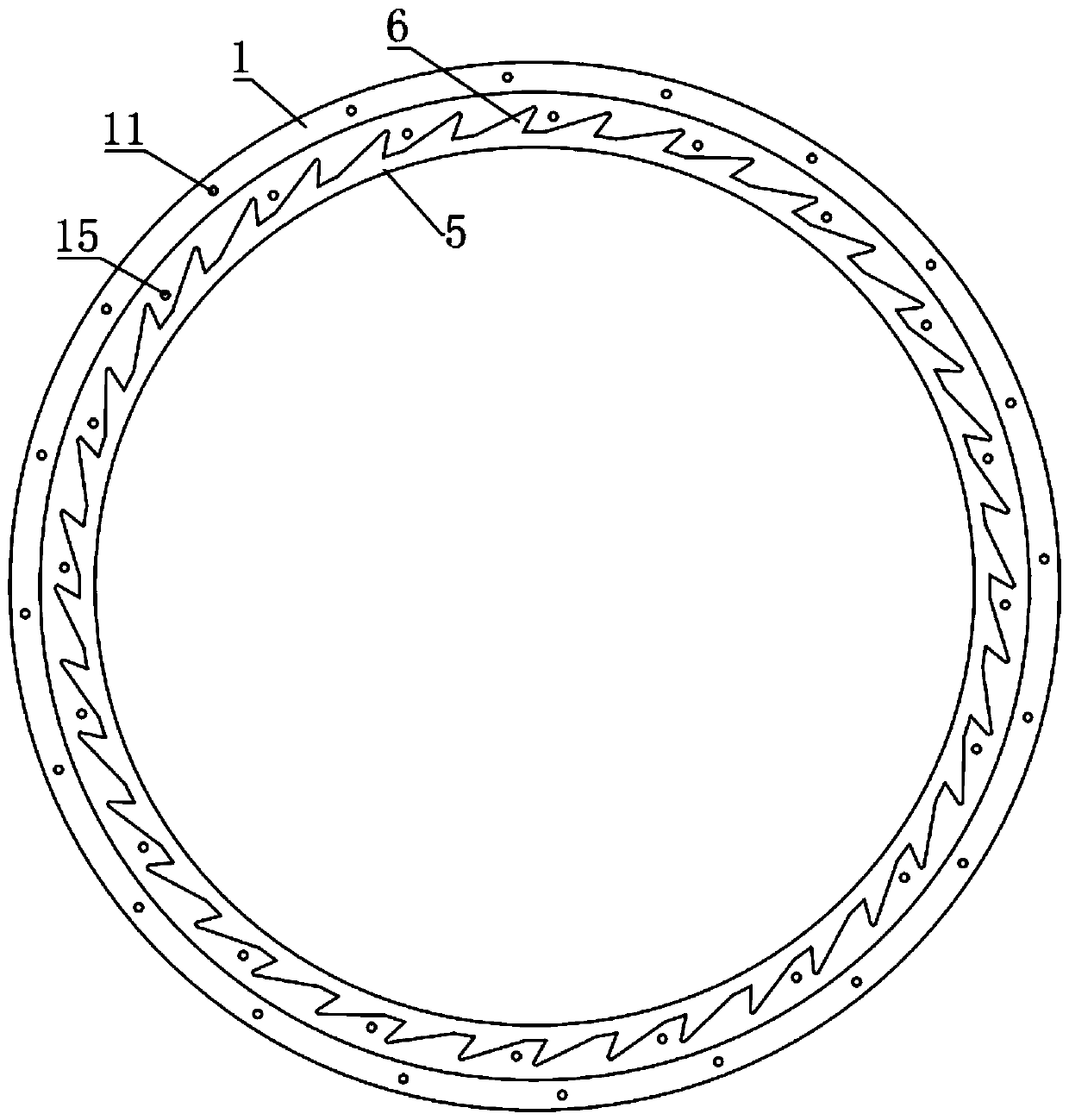

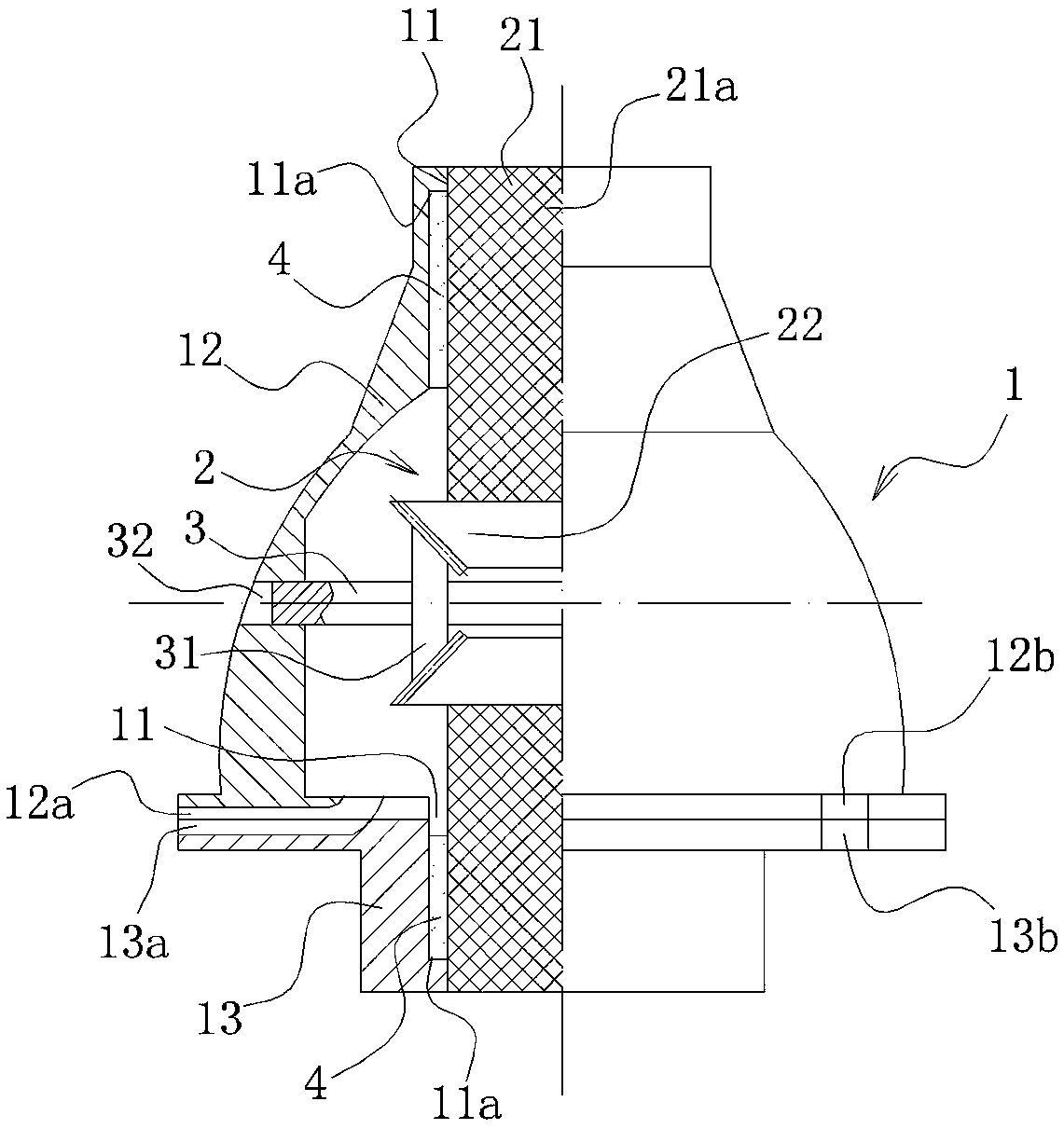

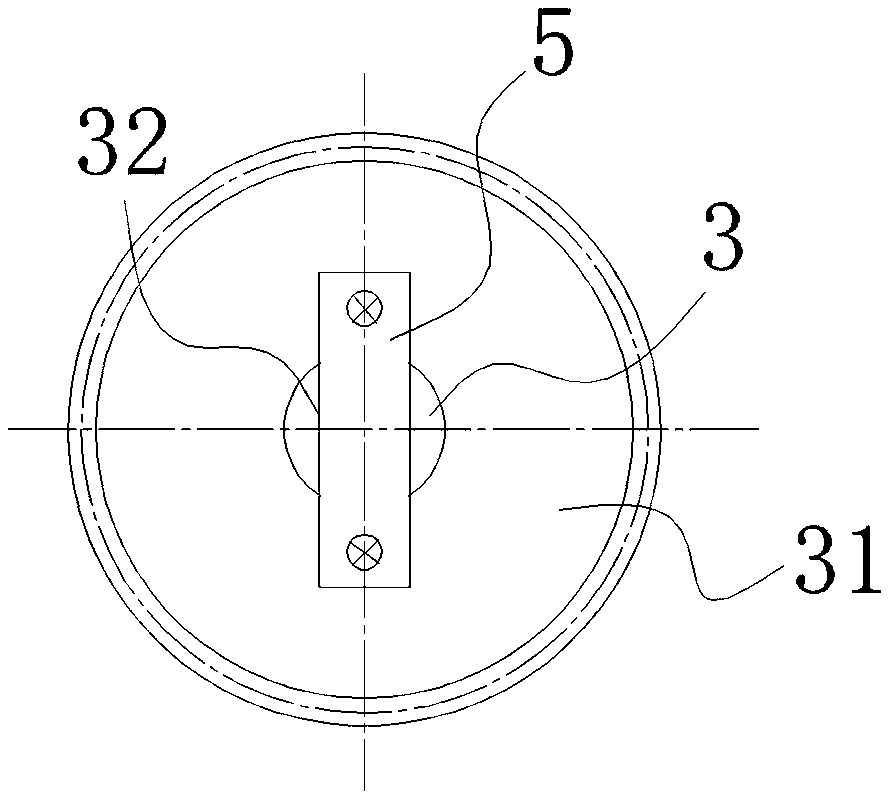

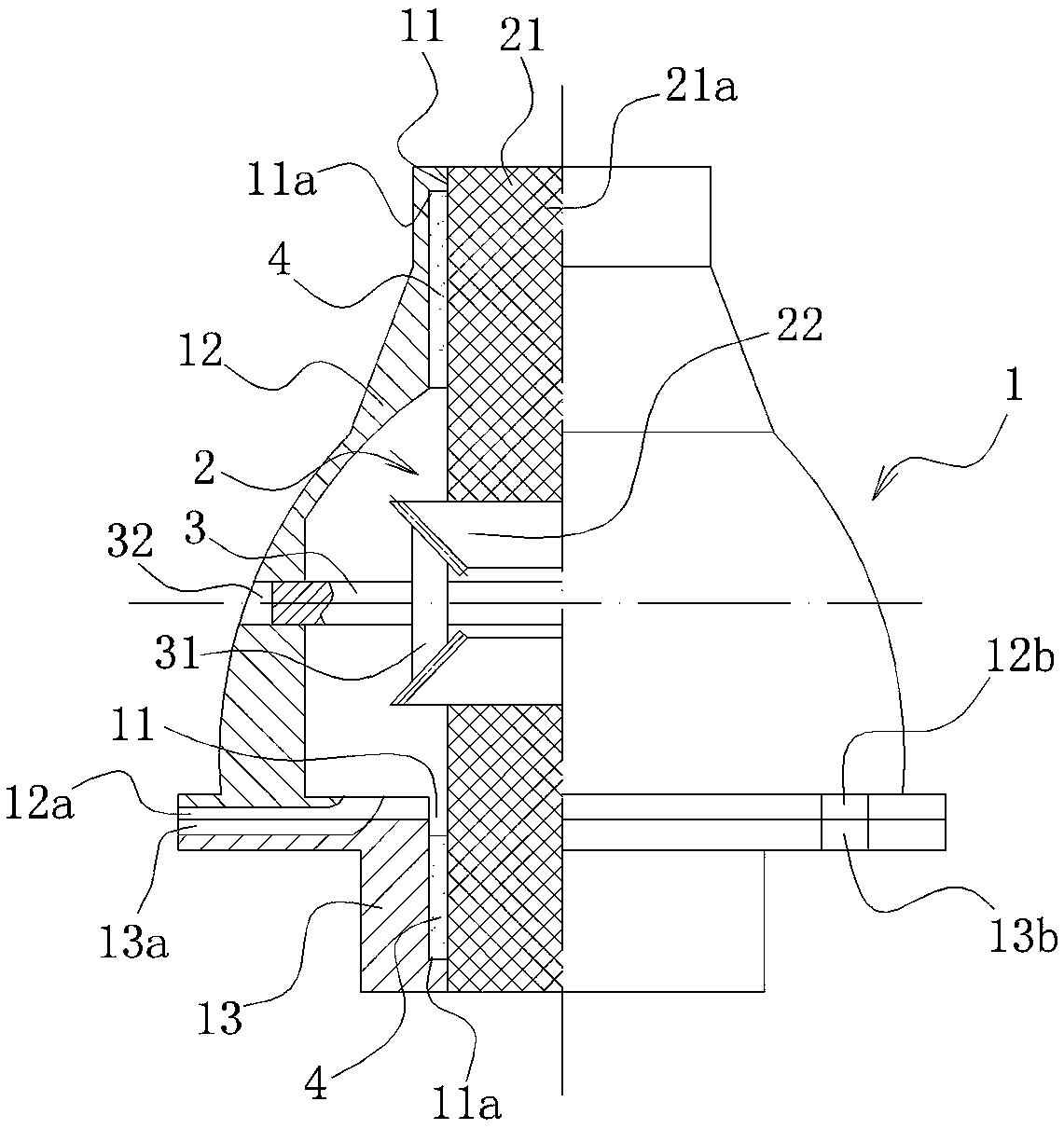

Abrasion-resistant precision harmonic speed reducer

InactiveCN107448581AWith self-lubricating functionImprove wear resistancePortable liftingGearing elementsReduction driveEngineering

The invention provides an abrasion-resistant precision harmonic speed reducer. Material selecting and a hot working process of an internal circular spline of the harmonic speed reducer are greatly changed, the abrasion-resistant precision harmonic speed reducer aims to provide good service conditions for a flexible wheel on the other side of a transmission pair by means of a self-lubricating and temperature rise coefficient reducing method, the service life of the flexible wheel on the other side of the transmission pair is prolonged, and finally the quality of the precision harmonic speed reducer used by an industrial robot is improved.

Owner:张天贵

Gear with self-lubricating function

InactiveCN107842592AWith self-lubricating functionTo achieve the effect of automatic lubricationPortable liftingGear lubrication/coolingInternal cavityCover slip

The invention relates to the technical field of gears, and discloses a gear with a self-lubricating function, including a disc body, the front of the disc body is fixedly connected with a filling pipe, and the end of the filling pipe away from the disc body is provided with a cap, so The surface of the tube cover is provided with an anti-skid layer, the back of the disc body is fixedly connected with a connecting frame, the surface of the disc body is fixedly connected with gear teeth, the surface of the disc body is inserted with a moving rod, and the moving rod The bottom of the pressure block is fixedly connected with the top of the pressure block, the bottom of the pressure block is fixedly connected with the surface of the elastic bag, and the back of the elastic bag is fixedly connected with the inner wall of the disc body. The gear with self-lubricating function, through the pressing block fixedly connected at the bottom of the moving rod and the elastic bag fixedly connected at the bottom of the pressing block, cooperates with the cavity inside the elastic bag and the oil pipe fixedly connected on the surface of the elastic bag, and the elastic bag is pressed by the pressing block. After the extrusion, the lubricating oil in the cavity is squeezed out to achieve the effect of automatic lubrication.

Owner:无锡华利达金属制品有限公司

Self-lubricating dual gear

InactiveCN103133642AExtended service lifeWith self-lubricating functionGear lubrication/coolingPortable liftingEngineeringAutomotive transmission

The invention discloses a self-lubricating dual gear which comprises a first gear body, a second gear body, a gear connection end, a bearing groove, an oil storage bearing and oil grooves. The middle of the first gear body is connected with the middle of the second gear body through the gear connection end, the bearing groove is arranged in the middle of the gear connection end, the oil storage bearing is mounted inside the bearing groove, and the oil grooves are arranged on the surfaces of the first gear body and the second gear body. By the aid of the mode, the self-lubricating dual gear is used for automotive transmissions and has a self-lubricating function, and the service life of the gear is prolonged.

Owner:JIANGSU BAOJIE FORGING

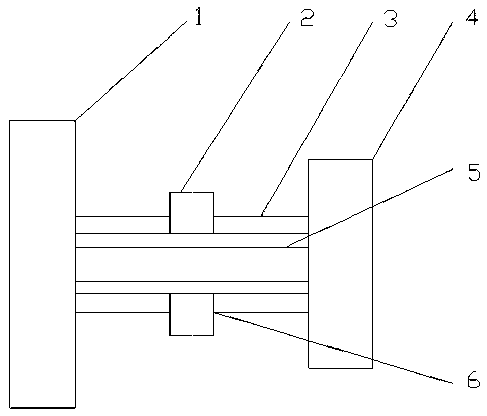

No-oil lubricant dual-push electromagnetic iron

InactiveCN101034612AMeet the needs of actual useImprove wear resistanceElectromagnets with armaturesLubricationSafe operation

The invention relates to an armature translational motion non-oil lubrication double push electro-magnet, its structure is that has two magnet coils and two move iron core in the tube shape shell, the core of move iron core support in the shell cavity, the core axis of move iron core support in the shell or on the shell endcover core hole, the ceramics spurt coating setup on the move core bearing friction of the electro-magnet. This invention primely solved the present elevator move iron core wear well and lubrication question of using brake with double push electro-magnet, under no maintain, non-lubrication operating mode condition, the safe operation times might reach 1000-15 million; can definitely meet the elevator safe operation needs in main engine service life period. It is a new elecetromagnet of using elevator brake with no open solution, no maintenance, no lubrication.

Owner:韩伍林

Ceramic refractory material

The invention relates to a ceramic refractory material. The ceramic refractory material comprises raw materials in parts by weight as follows: 8-16 parts of nanometer titania, 5-12 parts of nanometermagnesia, 3-5 parts of vanadium pentoxide, 6-10 parts of kaolinite, 1-2 parts of aluminum fiber, 2-3 parts of a dispersing agent, 4-8 parts of quartz sand, 1-5 parts of a coupling agent, 3-8 parts ofcoal cinder, 5-9 parts of silicon carbide, 8-12 parts of trimethyl ethylenediamine, 18-25 parts of alumina, 2-5 parts of aluminum oxide, 5-9 parts of toughening fibers, 3-9 parts of a lubricant, 2-8 parts of sodium silicate and 10-15 parts of a binding agent. The ceramic refractory material has sufficient strength, hardness, plasticity and toughness and further has a self-lubricating function.

Owner:广西银英生物质能源科技开发股份有限公司

Diamond polishing paste in high purity, and preparation method

InactiveCN100535070CImprove surface roughnessGood dispersionOther chemical processesCoupling light guidesDispersion stabilityOptical fiber connector

This invention relates to a method for preparing polishing paste containing high-purity nanoscale diamond for precision polishing of the small inner pores of ceramic ferrule used in optical fiber connector. The polishing paste is prepared from: diamond micropowder 0.05-5 wt.%, wetting agent 0.01-25 wt.%, surfactant 0.1-5 wt.%, dispersion stabilizer 0.1-50 wt.%, pH regulator 0.1-1 wt.%, and glycerol 14-99.64 wt.%. The purity of the diamond micropowder is greater than or equal to 99.9%, and the particle sizes are 100-200 nm. The polishing paste is amphipathic, and has such advantages as high polishing speed, high dispersion stability, and appropriate viscosity. The polishing paste can effectively prevent the generation of small inner pores on the surface of polished ceramic ferrule.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

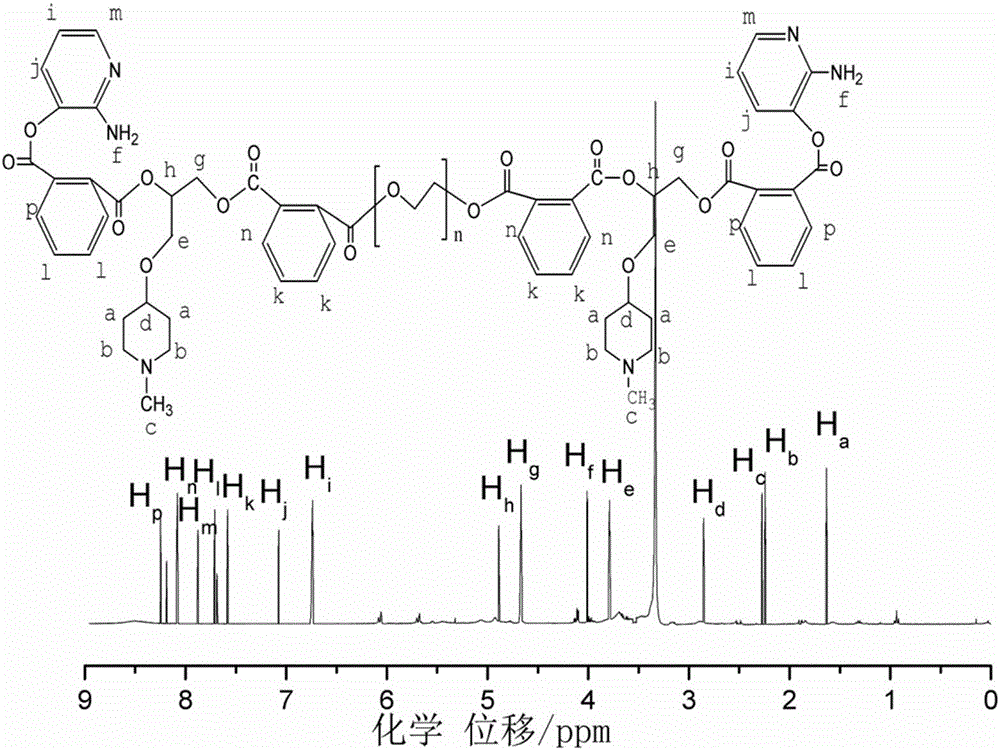

Self-lubricating water-based environment-friendly coating as well as preparation method and application thereof

InactiveCN112375495AGood film formingImprove passivation effectRosin coatingsAnti-corrosive paintsAl powderPhosphoric Acid Esters

The invention discloses a self-lubricating water-based environment-friendly coating. The water-based environment-friendly coating is composed of the components in percentage by mass: 20%-40% of A, 15%-25% of B, 10%-20% of Al powder and Zn powder, 1%-3% of an organic silicon defoamer, 2%-8% of a corrosion inhibitor, 1%-5% of a cosolvent, 10%-20% of a lubricant and 10%-15% of water, wherein the A isa reaction product of rosin and a silane coupling agent, and the B is a reaction product of ZrCl4, quaternary ammonium salt and tripolyphosphate in triethanolamine. A preparation method comprises thesteps: weighing the A and the B, and uniformly stirring; and adding the Al powder, the Zn powder, the organic silicon defoamer, the corrosion inhibitor, the cosolvent, the lubricant and water, and fully stirring and uniformly mixing to obtain the coating. The coating has excellent corrosion resistance, self-lubricating property, film-forming property, passivation property, slow release property and the like.

Owner:JIANGSU UNIV OF SCI & TECH

Orthogonal magnetic circuit radial magnetic suspension bearing based on symmetric self-lubricating flexible auxiliary bearing structure

The invention discloses an orthogonal magnetic circuit radial magnetic suspension bearing based on a symmetric self-lubricating flexible auxiliary bearing structure. A rotor shaft (6) of the magneticsuspension bearing is sleeved with a rotor core (7), and the rotor core (7) is located on a stator tooth set (8A) of a stator core (8). A coil is mounted on the stator tooth set (8A) of the stator core (8), and two radial rigid magnetic conducting rings are mounted on an outer disc of the stator core (8). A certain clearance exists between the two radial rigid magnetic conducting rings in the axial direction to prevent the short circuit of a permanent magnetic circuit. A graphite inward protruding ring cooperates with a radial auxiliary bearing framework, is arranged in an inner ring cavity ofa radial flexible magnetic conducting ring and is compressed by a radial bearing check ring, and the graphite inner ring is prevented from axially sliding. A permanent magnet is mounted between the radial rigid magnetic conducting rings and the radial flexible magnetic conducting ring. The magnetic suspension bearing is divided into two parts in bilateral symmetry around the stator core in the axial direction, the design method that a radial magnetic bearing and an auxiliary bearing are combined into a whole is adopted, and the technical problem that the coaxiality of a traditional magnetic bearing and auxiliary bearing is low is solved.

Owner:BEIHANG UNIV

Guiding device

ActiveCN100569437CEasy to moveWith self-lubricating functionLinear bearingsLarge fixed membersForeign matterEngineering

The present invention provides a guide device that prevents foreign matter from entering the moving block from the gap between the side surface of the guide rail and the inner surface of the moving block even in an environment where a large amount of fine dust is flying. The structure of the device is provided with a guide rail and a moving block (20), and the moving block (20) is relatively moved freely assembled on the guide rail by the rotating body circulating on the rotating body circulation path; The gap between the inner side of the side skirt part of the block body (21), the inner side of the side cover and the side of the guide rail, and the foreign matter intrusion prevention plate (34) whose top end contacts the side of the guide rail along the length direction.

Owner:THK CO LTD

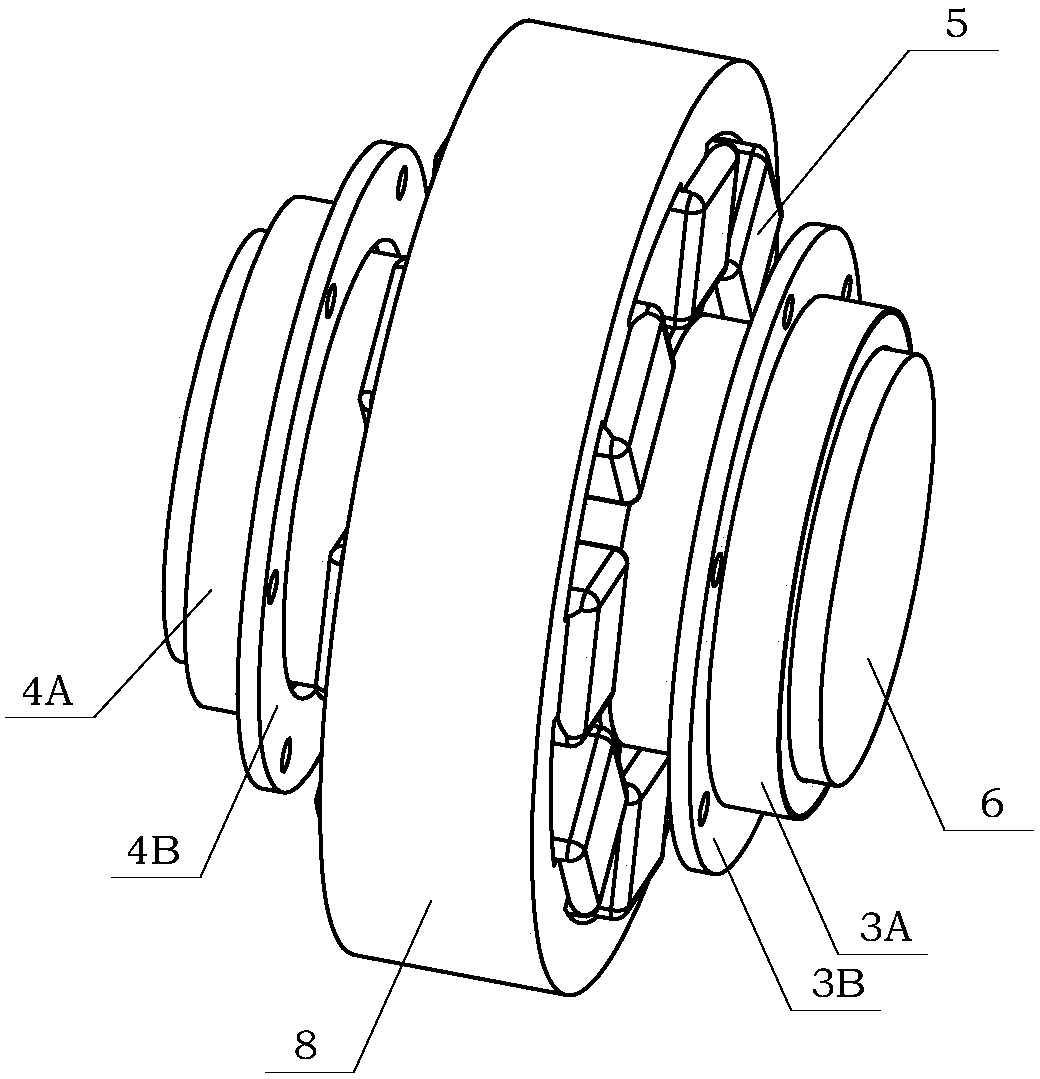

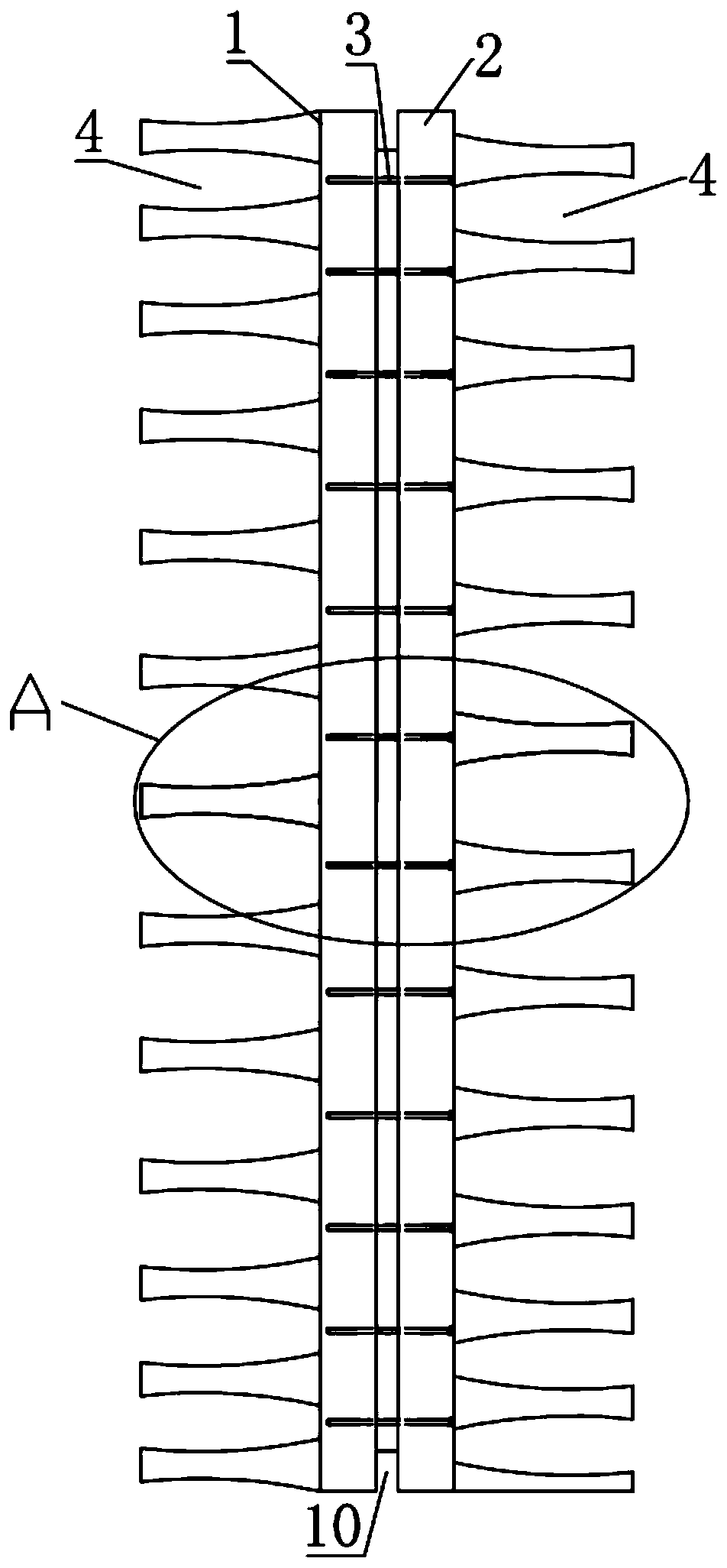

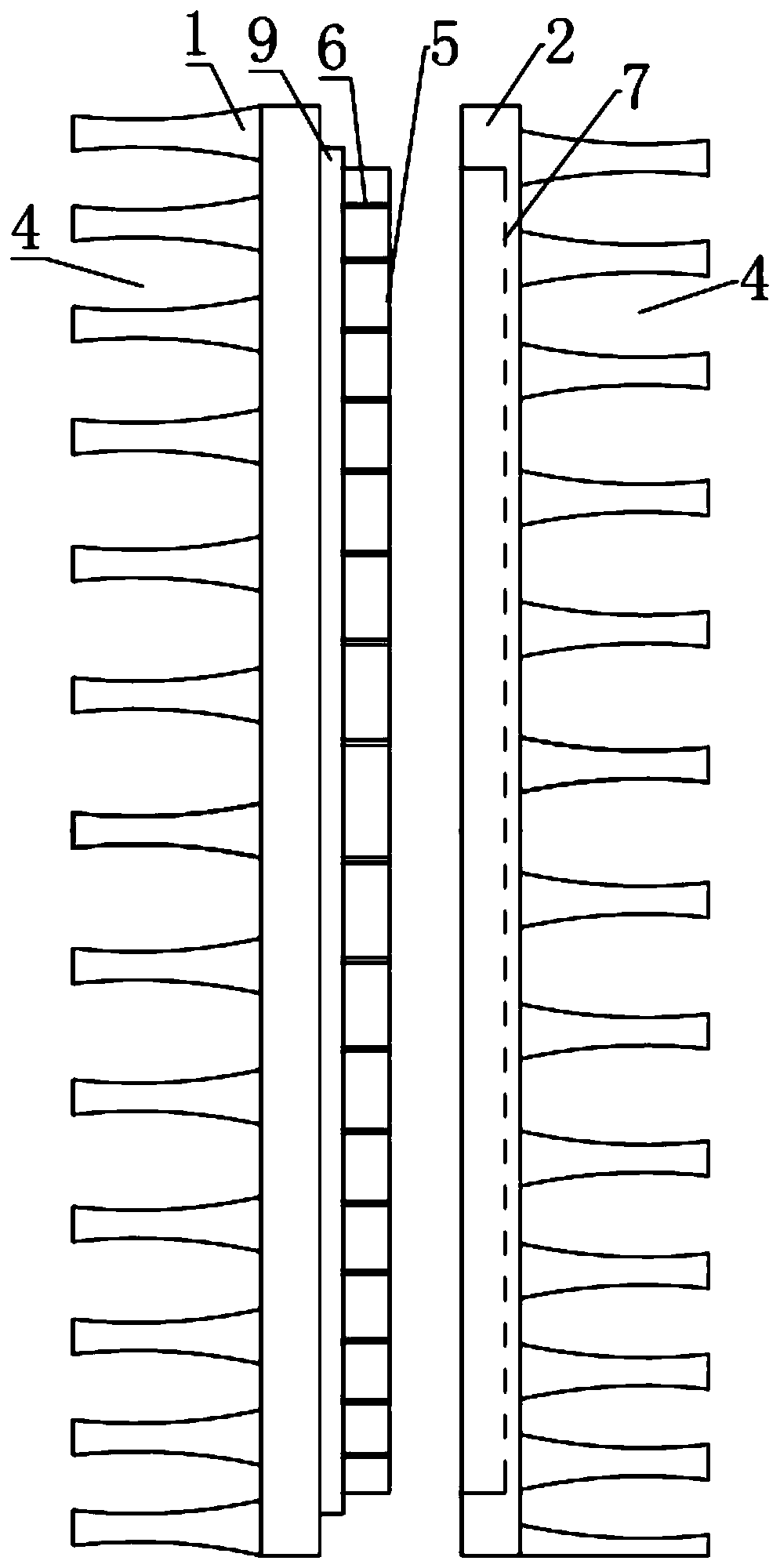

Preparation method of bearing retainer with cooling and wear-resistant structure for robot

ActiveCN110848264AWith self-lubricating functionImprove cooling effectMetallic material coating processesBearing coolingStructural engineeringIndustrial engineering

The invention relates to a preparation method of a bearing retainer with a cooling and wear-resistant structure for a robot, and belongs to the technical field of mechanical basic parts and manufacture. A first retainer body, a second retainer body and a group of inner hexagon countersunk head screws are included, the first retainer body and the second retainer body are each provided with a groupof roller pockets, the end face, close to the first retainer body, of the second retainer body is provided with a first boss, the outer wall of the first boss is provided with a group of pawls, one end, close to the first retainer body, of the second retainer body is provided with a first groove, the inner wall of the first groove is provided with a group of wedge-shaped grooves, the first boss isarranged in the first groove, and the group of pawls are clamped in the group of wedge-shaped grooves. According to the preparation method, the design of a split structure is adopted, so that the replacement of the retainer part is facilitated, the pawls and the wedge-shaped grooves are arranged for radial rotation, the first retainer body and the second retainer body form a structurally stable whole through the group of inner hexagon countersunk head screws, and the service life of a bearing is prolonged.

Owner:苏州圣典企业管理咨询有限公司 +1

Differential assembly with self-lubricating function

InactiveCN109838531AWith self-lubricating functionReasonable designGear lubrication/coolingDifferential gearingsGear wheelEngineering

The invention belongs to the technical field of automobile accessories, and particularly relates to a differential assembly with a self-lubricating function. The technical problems such as short service life in the prior art are solved. The differential assembly with the self-lubricating function comprises a differential shell, half-axle installation channels are arranged at the two ends of the differential shell correspondingly, half-axle gears are arranged in the half-axle installation channels correspondingly, a planetary gear axle is fixedly arranged on the differential shell, planetary gears engaged with the half-axle gears are arranged at the two ends of the planetary gear axle correspondingly, the differential shell comprises a first shell and a second shell, the first shell is provided with at least two first arc-shaped gaps, second arc-shaped gaps corresponding to the first arc-shaped gaps one to one are formed in the second shell, each half-axle gear comprises an axle body and a bevel gear fixedly arranged at one end of the axle body, the axle bodies are arranged in the half-axle installation channels in a penetrating mode, and a self-lubricating structure is arranged between the axle bodies and the half-axle installation channels. The differential assembly with the self-lubricating function has the advantage of long service life.

Owner:温岭市如波机械有限公司

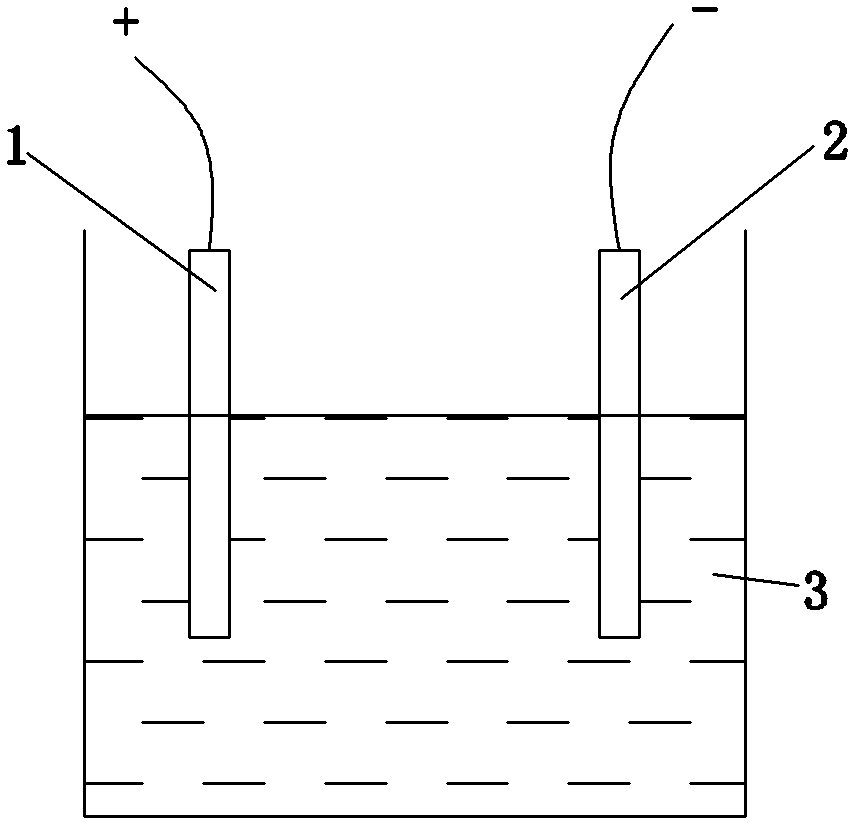

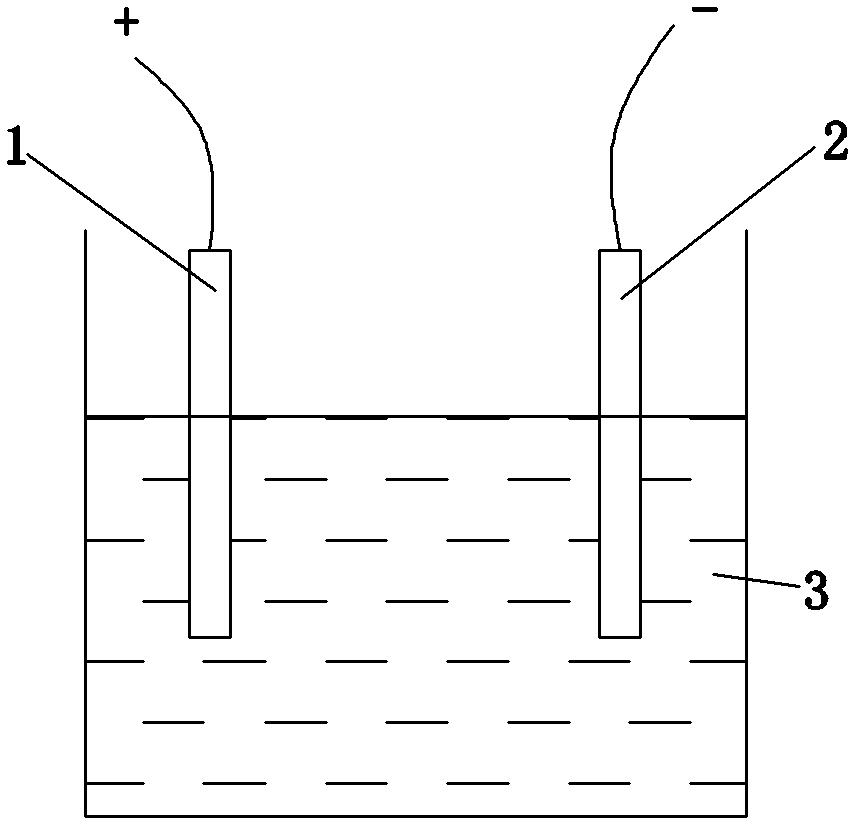

Surface treatment technique of flow control valve

InactiveCN102358947AWith self-lubricating functionReduce frictionAnodisationPower flowControl valves

The invention relates to a surface treatment technique of a flow control valve, belonging to the technical field of metal surface treatment. In the treatment process, a flow control valve is used as an anode, and the anode and a cathode are arranged in an oxidant solution. The invention is characterized in that the oxidant solution is a mixed solution formed by mixing a 2.24 mol / L sulfuric acid water solution and a 224 mol / L polytetrafluoroethylene water dispersion in a volume ratio of 3:1, the temperature of the oxidant solution is -3--4 DEG C, the stable oxidation current density of the anode is 2.5 A / dm, the oxidation time is 2.5-3 hours, and a composite hard anodic oxidation layer is formed on the surface of the flow control valve. The flow control valve subjected to the surface treatment technique has the self-lubricating function, and can greatly reduce the friction force in the friction process with a pump body.

Owner:NINGBO HONGBO MACHINERY MFG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com