Preparation method of bearing retainer with cooling and wear-resistant structure for robot

A technology of bearing cage and cage, which is applied in the field of robots, can solve the problems of reducing the service life of bearing cages, temperature rise and wear, etc., so as to improve the overall quality and service life, good surface wear resistance and good adaptability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

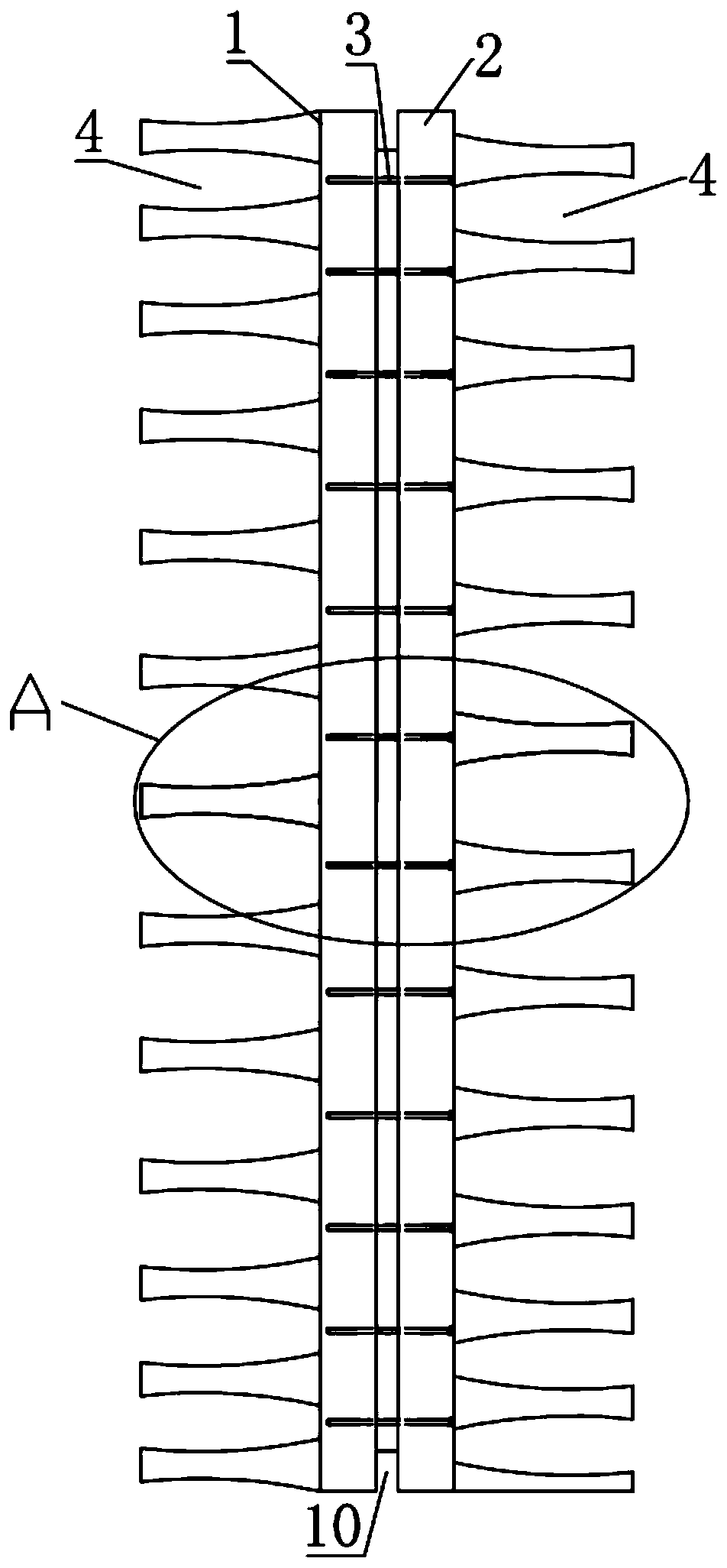

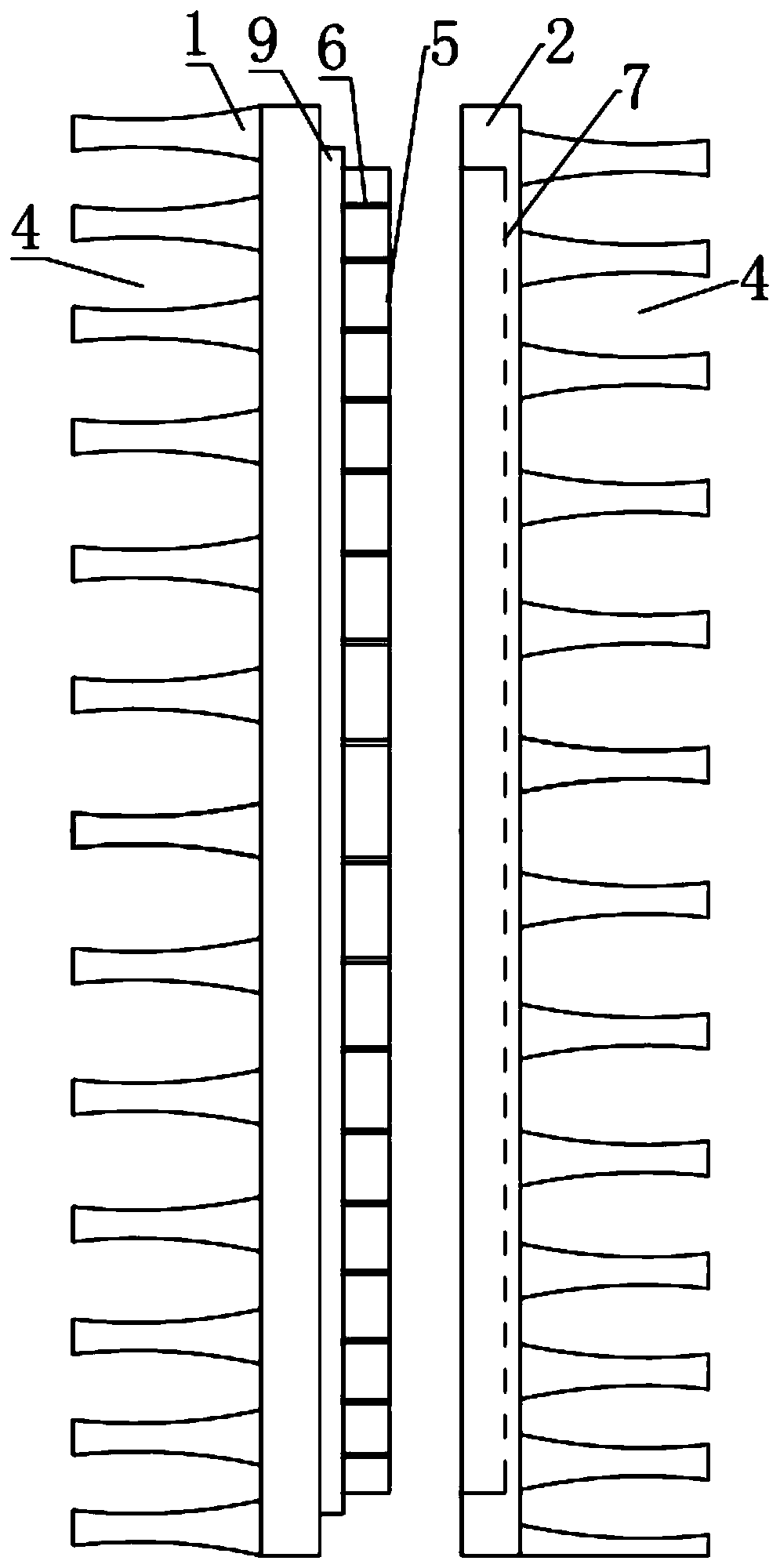

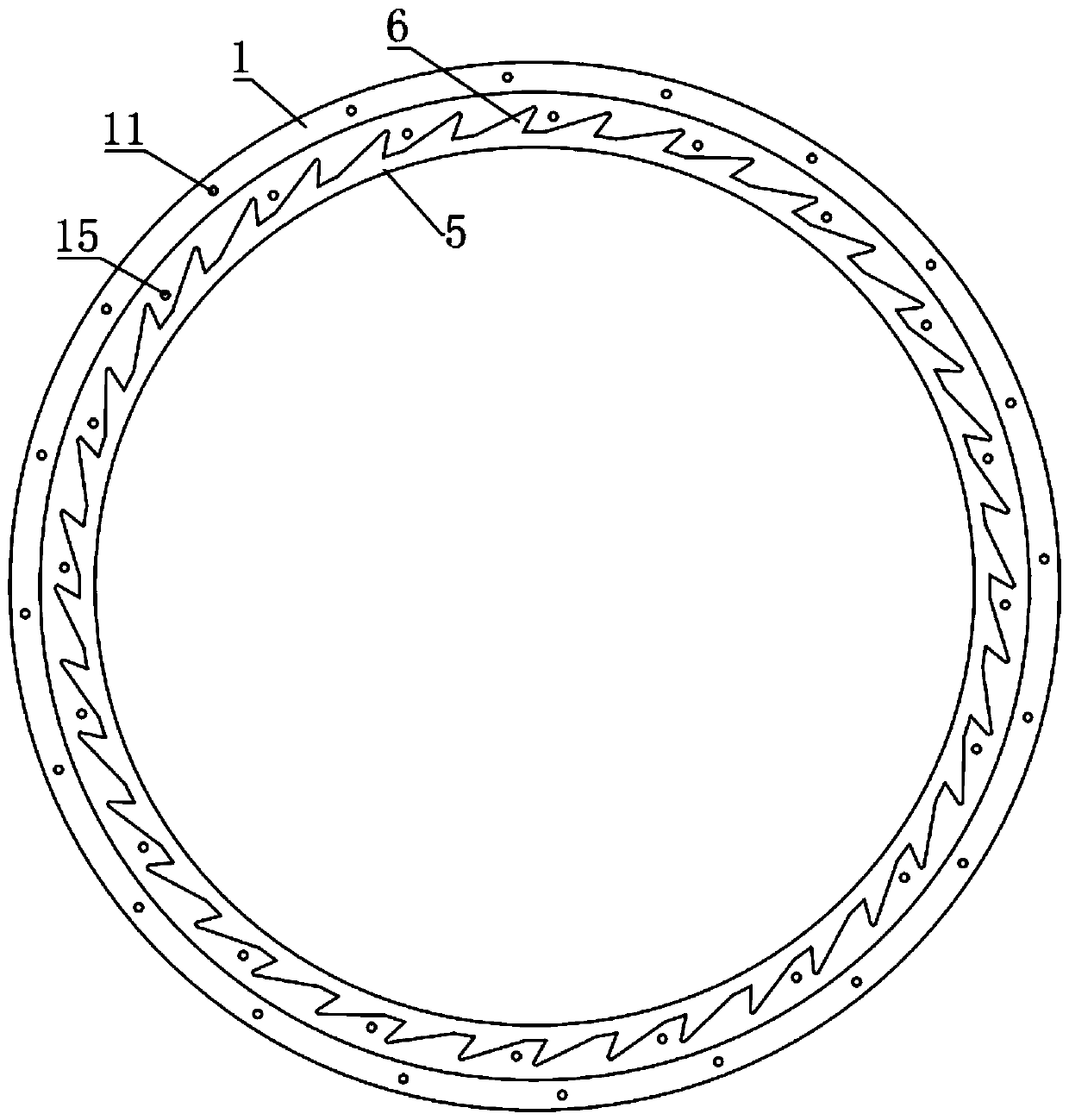

[0051] Such as Figure 1-4 The method for preparing a bearing cage for a robot with a cooling and wear-resistant structure shown in and 6 includes a cage body one 1, a cage body two 2 and a set of hexagon socket head screws 3, the cage body one 1 and Cage body two 2 are connected by a set of hexagon socket head screws 3, a set of roller pockets 4 are provided on the cage body one 1 and cage body two 2, and the cage body one 1 is close to the cage The end surface of the body two 2 is provided with a first boss 5, and a group of pawls 6 are arranged on the outer wall of the first boss 5, and the end of the cage body two 2 close to the cage body one 1 is provided with a first Groove 7, the inner wall of the first groove 7 is provided with a set of wedge-shaped grooves 8, the first boss 5 is arranged in the first groove 7, and the set of ratchets 6 are engaged in a set Inside the wedge-shaped groove 8. Wherein, the first cage body 1 and the second cage body 2 adopt No. 10 steel ...

Embodiment 2

[0079] The mass percentage of the alloy formula used in the above bearing cage is:

[0080] Carbon 65 parts

[0081] Silicon 30 parts

[0082] Manganese 2.4 parts

[0083] Chromium 2 parts

[0084] Cerium 10 parts

[0085] Rhenium 3 parts

[0086] Copper 120 parts

[0087] Vanadium 45 parts

[0088] Nickel 3.3 parts

[0089] Sulfur 10 parts

[0090] Phosphorus 32 parts

[0091] The balance is iron.

[0092] Wherein, the formula of the wear-resistant layer is:

[0093] Titanium powder 60 parts

[0094] Graphite 20 parts

[0095] The rest is nickel powder.

[0096] In addition, the wear-resistant layer also includes shellac and absolute ethanol, and the weight ratio of the shellac to the mixed powder of titanium powder, graphite and nickel powder is 1:0.15.

Embodiment 3

[0098] The mass percentage of the alloy formula used in the above bearing cage is:

[0099] Carbon 75 parts

[0100] Silicon 50 parts

[0101] Manganese 3.6 parts

[0102] Chromium 5 parts

[0103] Cerium 12 parts

[0104] Rhenium 4 parts

[0105] Copper 130 parts

[0106] Vanadium 55 parts

[0107] Nickel 3.5 parts

[0108] sulfur 12 parts

[0109] Phosphorus 35 parts

[0110] The balance is iron.

[0111] Wherein, the formula of the wear-resistant layer is:

[0112] Titanium powder 61 parts

[0113] Graphite 21 parts

[0114] The rest is nickel powder.

[0115] In addition, the wear-resistant layer also includes shellac and absolute ethanol, and the weight ratio of the shellac to the mixed powder of titanium powder, graphite and nickel powder is 1:0.2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com