No-oil lubricant dual-push electromagnetic iron

An oil-free lubrication, electromagnet technology, applied in the field of electromagnets, can solve problems such as elevator crash, elevator crashing or falling straight, brake braking effect failure, etc., to achieve the effect of enhanced wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

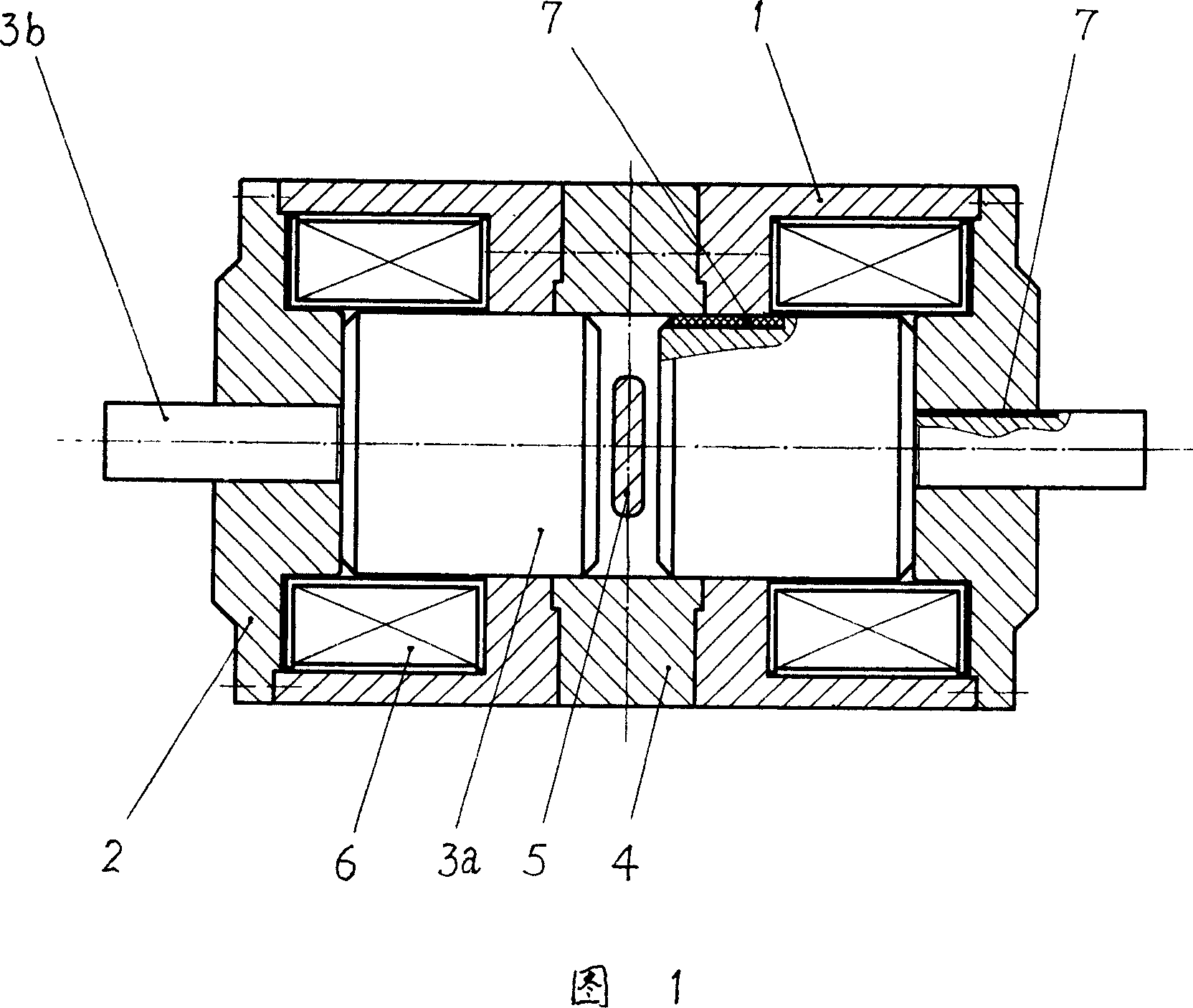

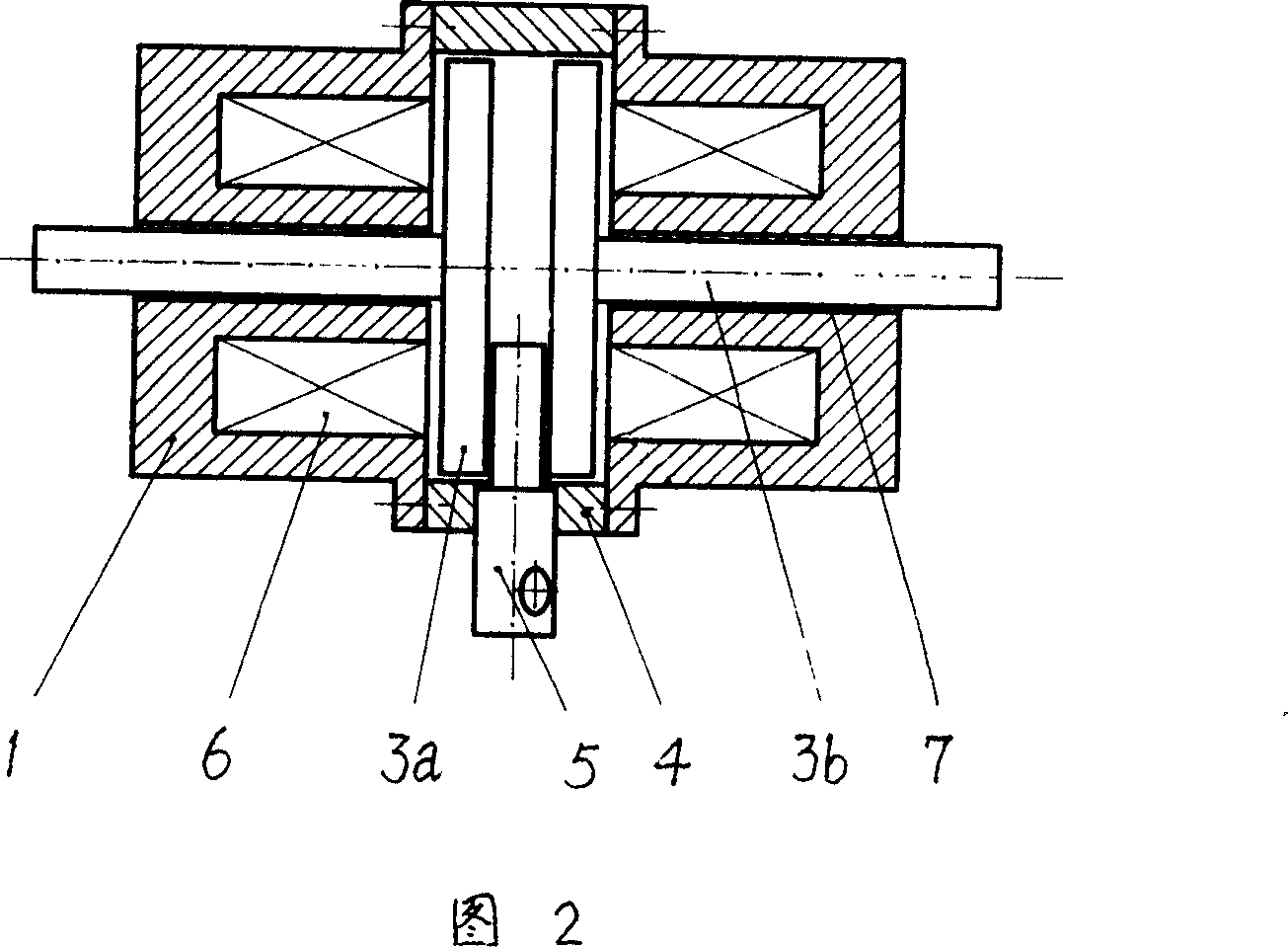

[0016] This kind of double-push electromagnet shown in Fig. 1, its housing 1 is cylindrical, and the middle part is the connector 4 that plays connection and magnetic isolation effect, and the two ends of the housing are sealed with end caps 2, on the housing 1 An electromagnetic coil 6 and a moving iron core are housed in the inner cavity, and the release handle 5 is threaded through the connecting body 4 . The core body 3a of the moving iron core is supported in the inner cavity of the housing, and the core shaft 3b of the moving iron core is supported in the core hole on the end cover 2 of the housing. Wherein, the sliding support contact surface between the core body of the moving iron core and the inner cavity of the housing and the sliding support contact surface between the mandrel shaft and the core hole of the end cover respectively constitute the moving core support friction pair in the double-push electromagnet.

[0017] The double-push electromagnet shown in Figure...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com