Patents

Literature

38results about How to "Improve color sorting effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

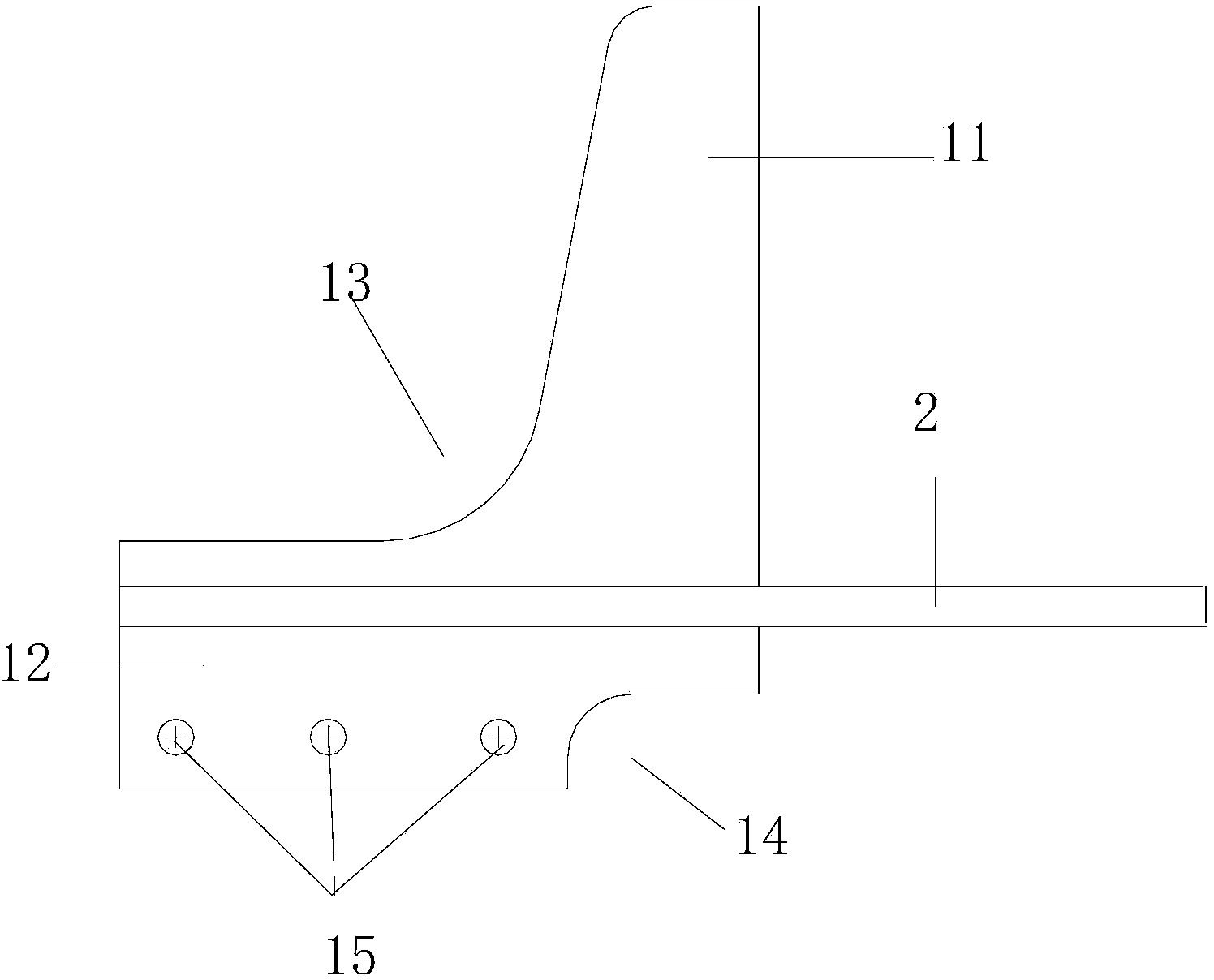

Rice color sorter

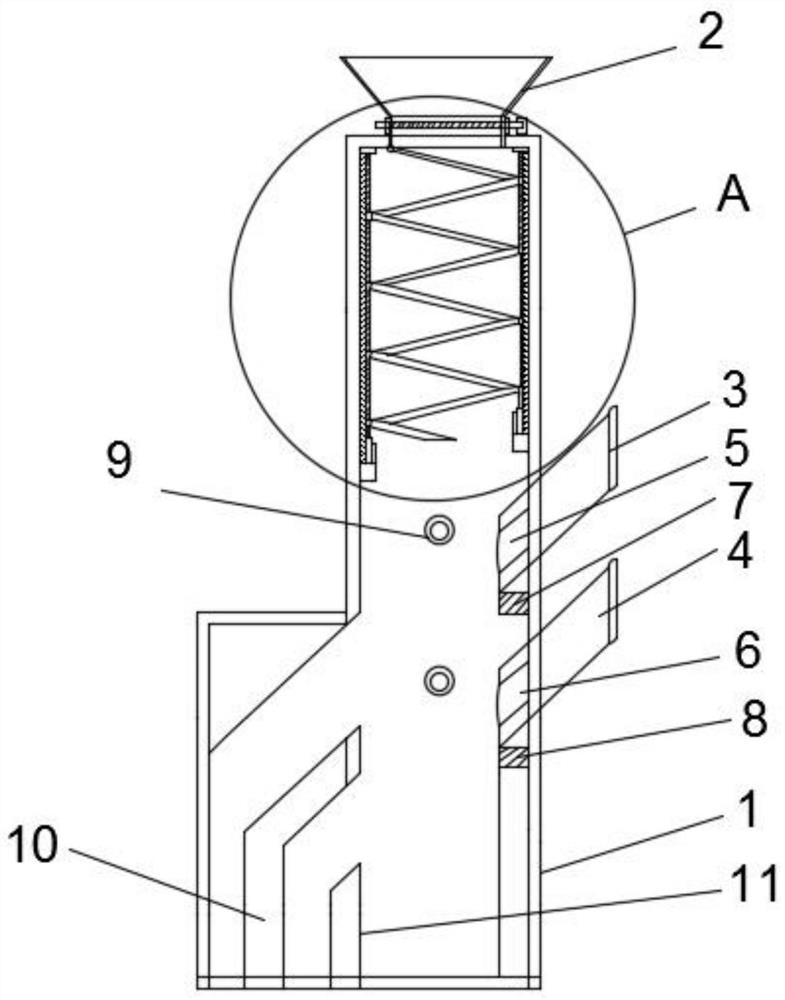

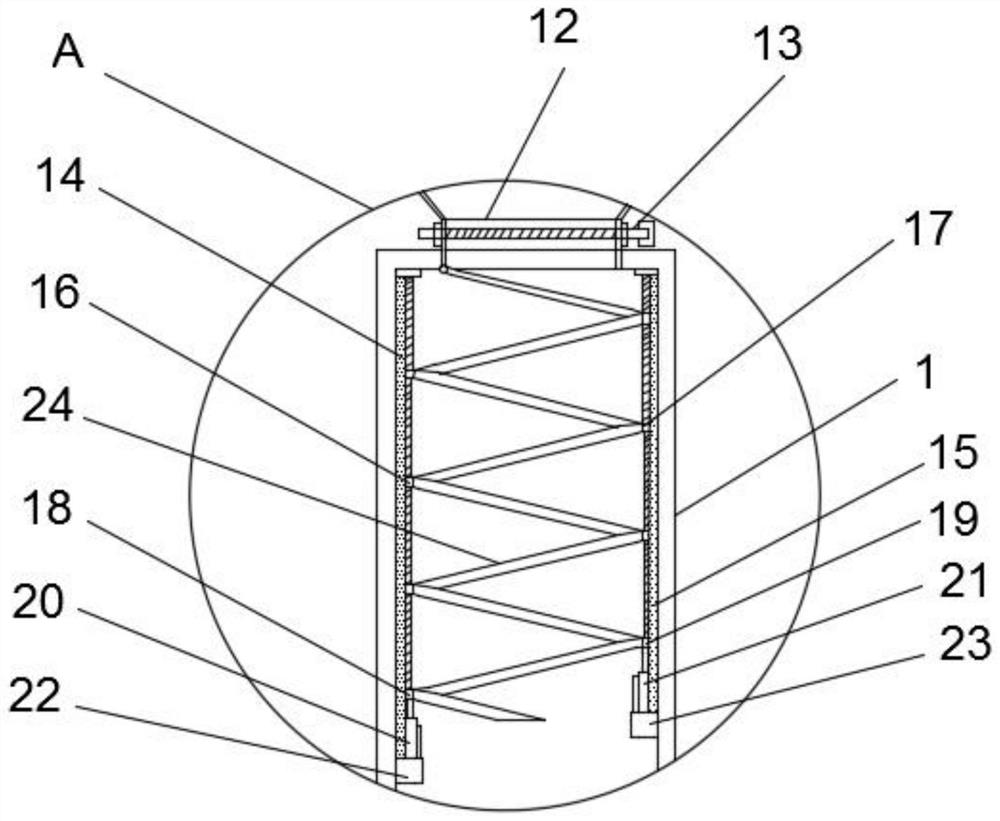

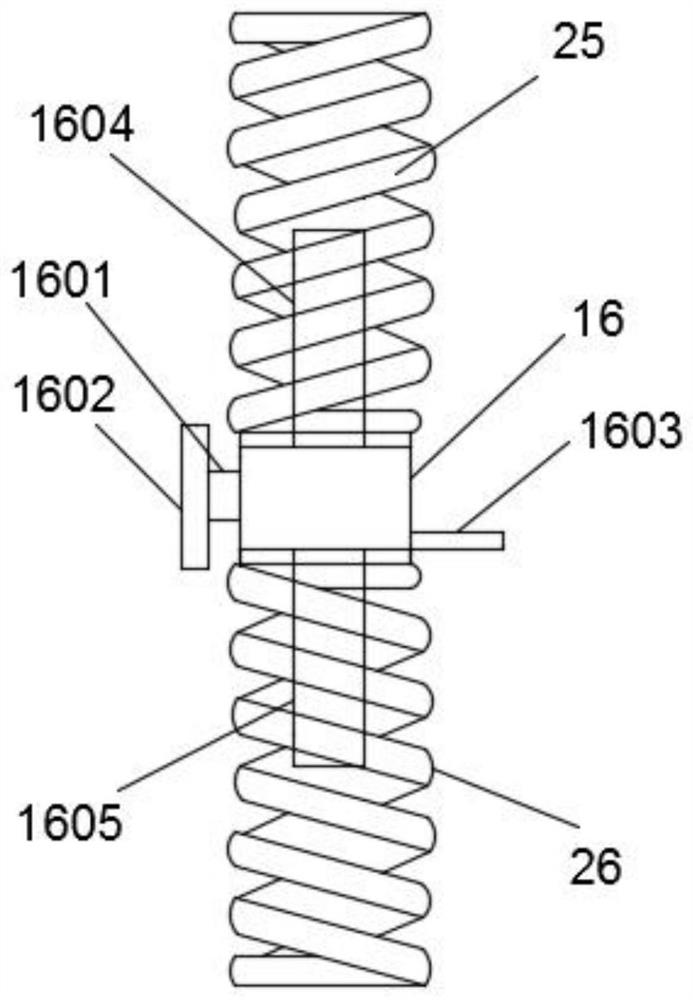

The invention discloses a rice color sorter which comprises a machine bin, a feeding opening, a sliding plate and an induction region branch bin, wherein the feeding opening is mounted above the machine bin; material distributing plates are uniformly mounted inside the feeding opening; a vibrating motor is mounted on one side of the feeding opening; a telescopic rod is hinged below one side insidethe feeding opening remote from the vibrating motor; a discharging plate is hinged to the feeding opening below the telescopic rod; an output end of the telescopic rod is hinged to the discharging plate. The rice color sorter provided by the invention is provided with the feeding opening which is equipped with the vibrating motor and the material distributing plates; the discharging plate is hinged in the feeding opening; an angle of the discharging plate can be adjusted according to the type of rice, so that the rice fall more uniformly and cannot be stacked together, and a color sorting effect is better; the sliding plate is mounted in a hinging manner, so that the angle of the sliding plate can be adjusted to control a falling speed of the rice; the sliding plate has a groove-shaped surface which is adaptive to the shape of the rice and allows the rice to fall, so that the color sorting effect is better.

Owner:陈坤荣

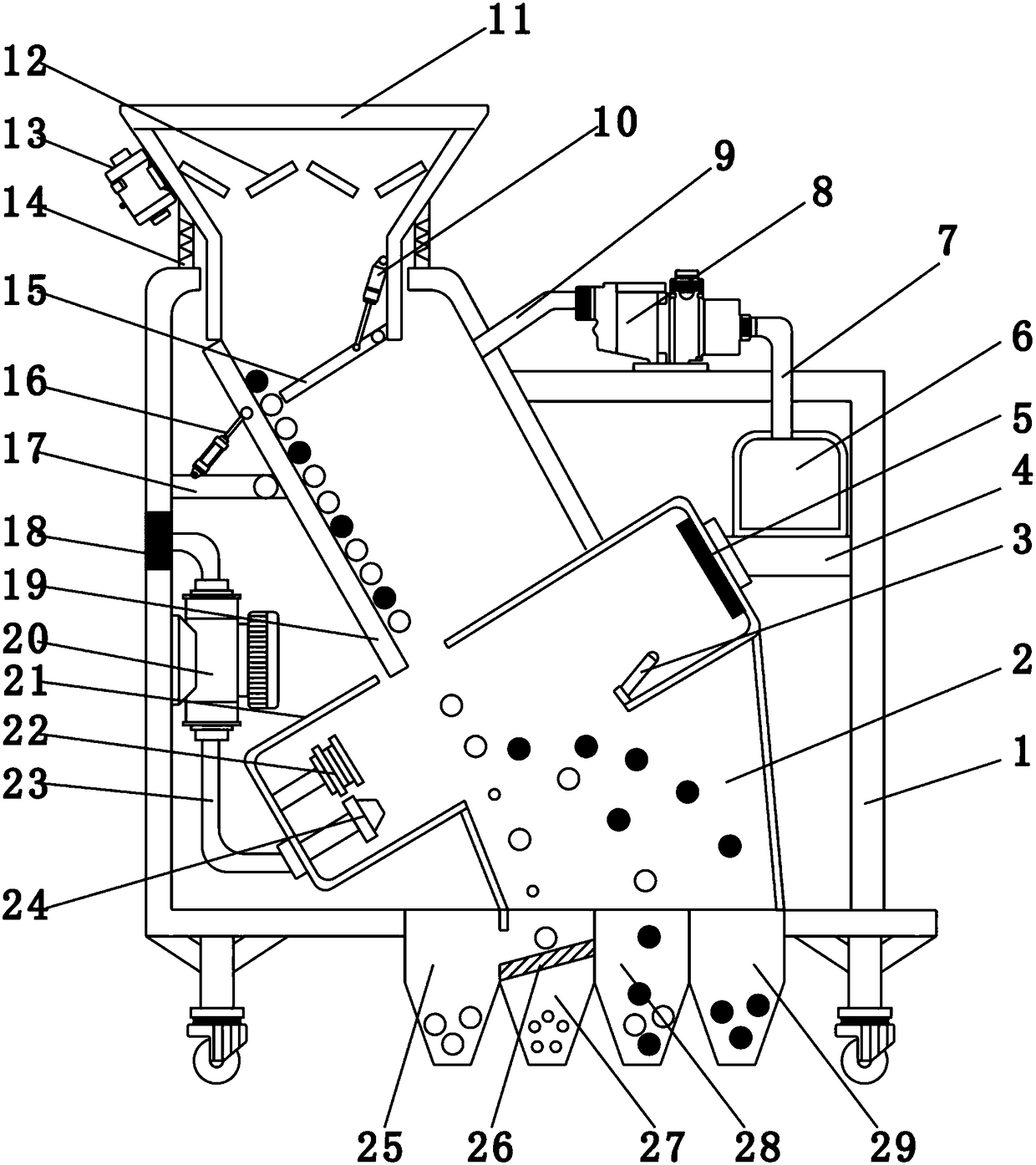

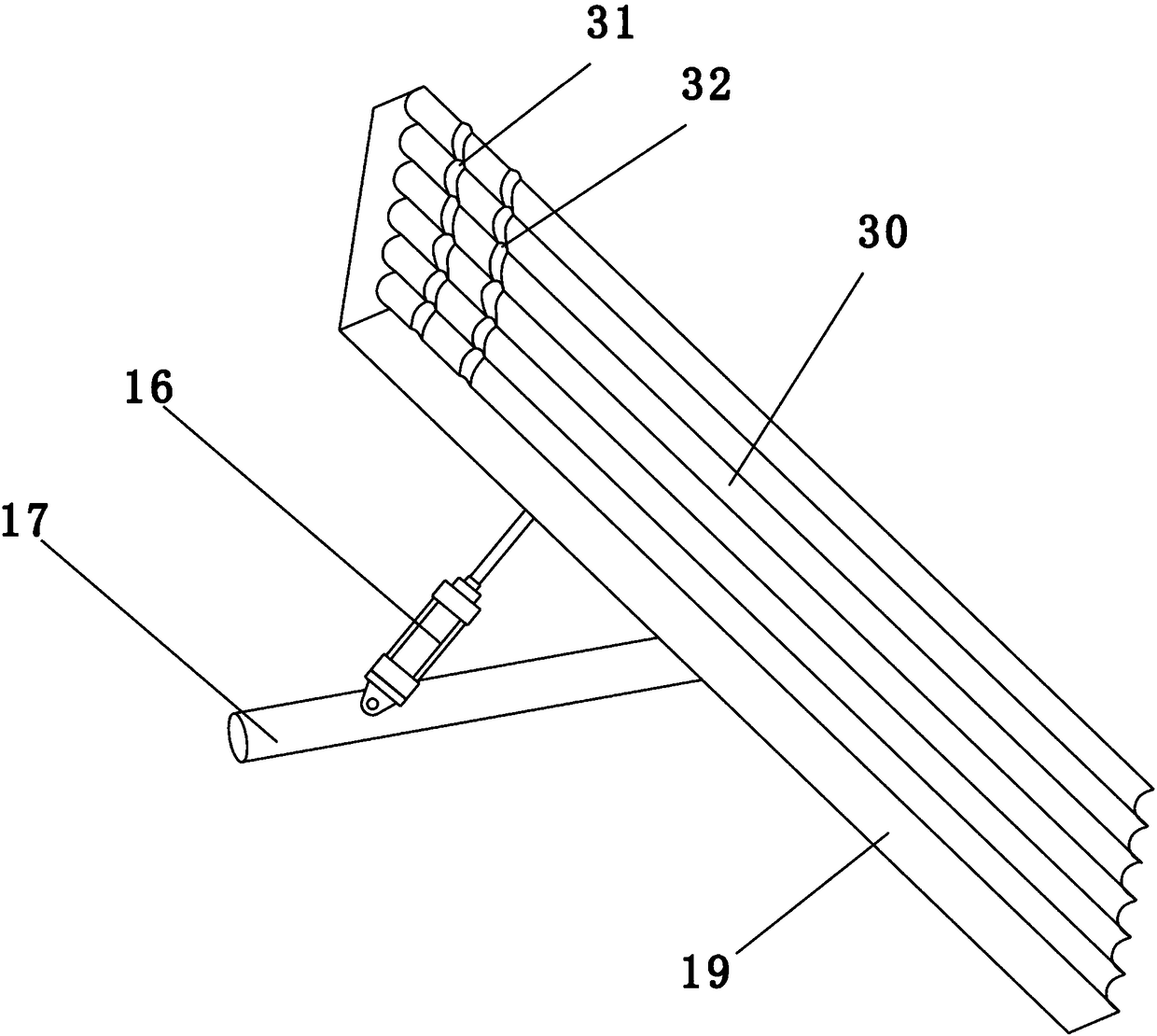

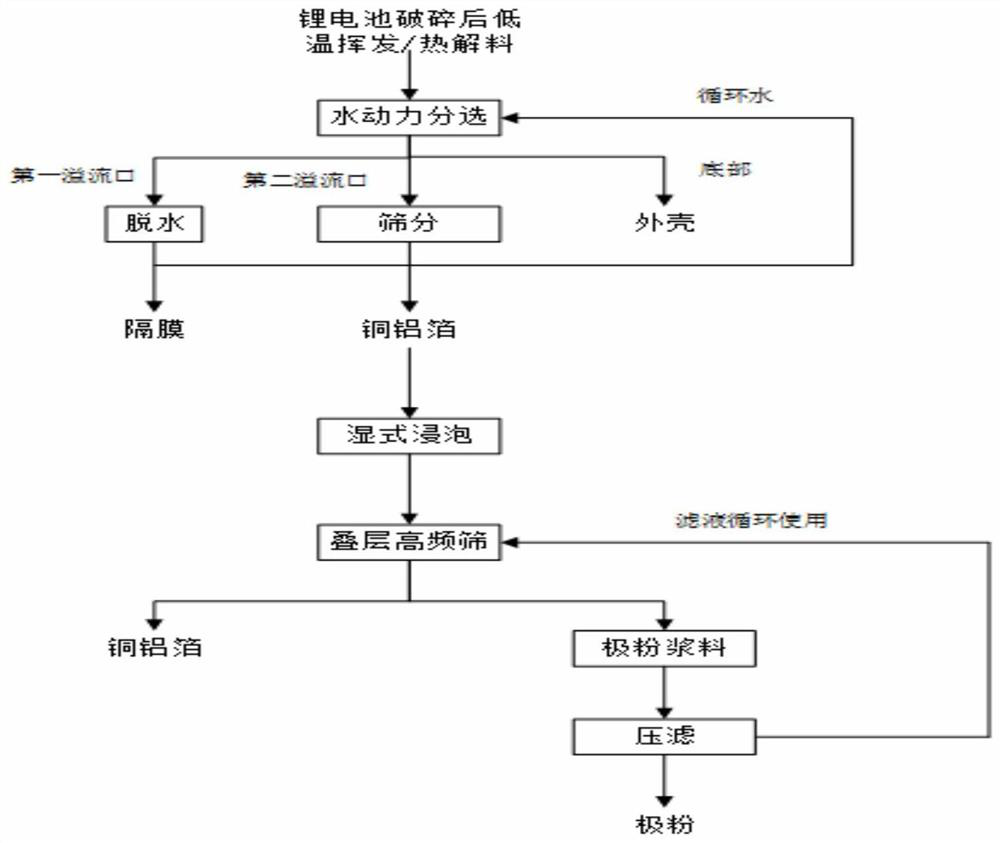

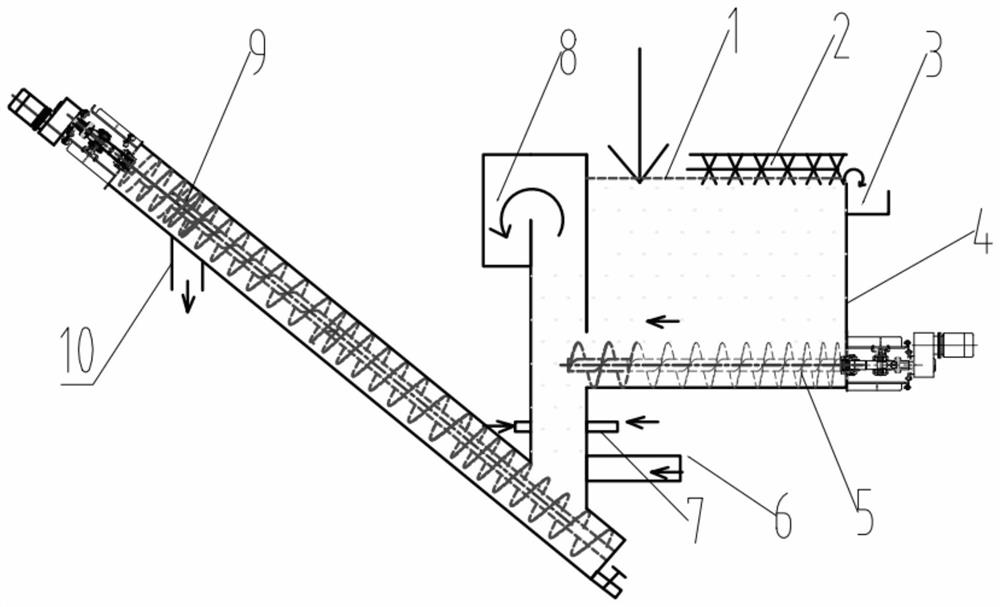

Hydrodynamic separation and wet stripping process for waste lithium ion battery broken materials

PendingCN113499853AAvoid Entrainment LossHigh recovery rateWaste processingSolid separationElectrolytic agentPhysical chemistry

The invention discloses a hydrodynamic separation and wet stripping process for waste lithium ion battery broken materials. The process comprises the following steps of firstly, carrying out crushing and electrolyte low-temperature volatilization or organic matter pyrolysis pretreatment on a waste battery, carrying out hydrodynamic separating on the treated crushed materials to separate out shells, then carrying out one-stage or multi-stage soaking on a sample by using a nucleophilic reagent, due to the fact that the nucleophilic reagent can chemically react with PVDF or aluminum and copper, some reagents can dissolve the PVDF or the aluminum and the copper, therefore, completely stripping and separating leached pole powder from the copper, the aluminum and the like, and improving the recovery rate and grade of the pole powder. According to the process, hydrodynamic force is adopted for efficient and clean pre-sorting of substances such as diaphragms, pole pieces and the shells, the separation effect is greatly improved compared with the prior art, and meanwhile the risks of dust raising, powder explosion and aluminum explosion of traditional wind power winnowing are avoided. The pole powder of the waste lithium ion battery is stripped by adopting a nucleophilic reagent leaching method, the pole powder falling effect is obvious, and the pole powder recovery rate and grade are high.

Owner:湖南江冶新能源科技股份有限公司

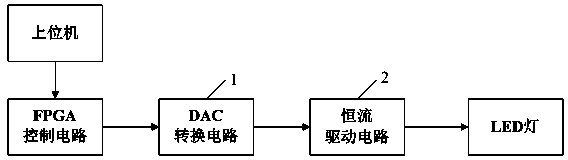

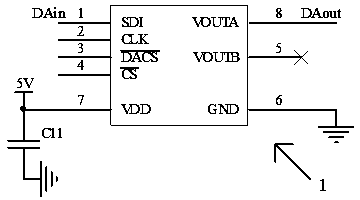

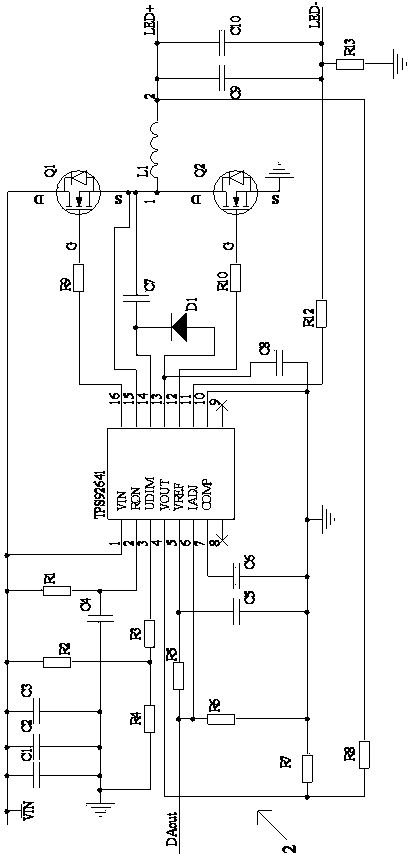

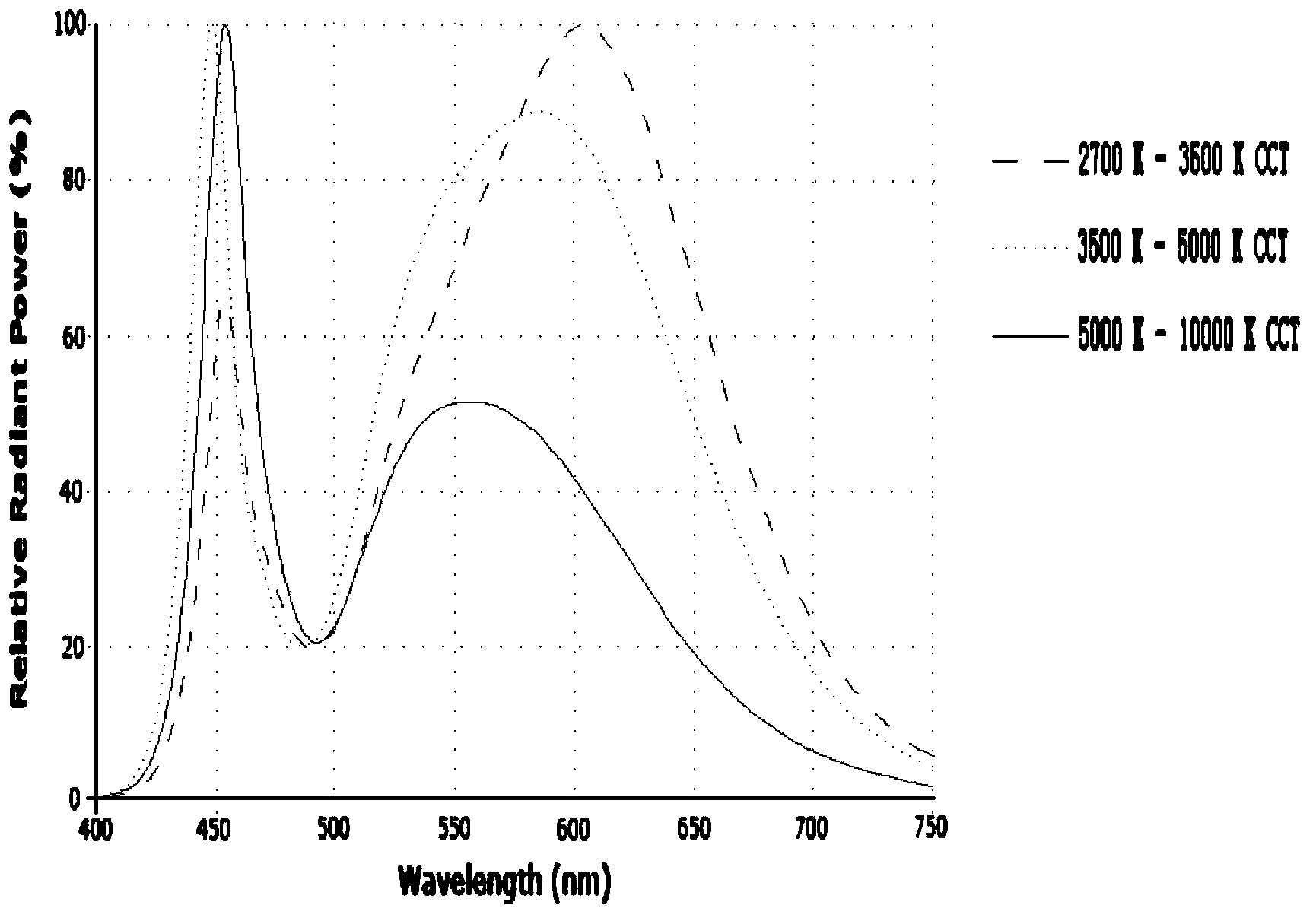

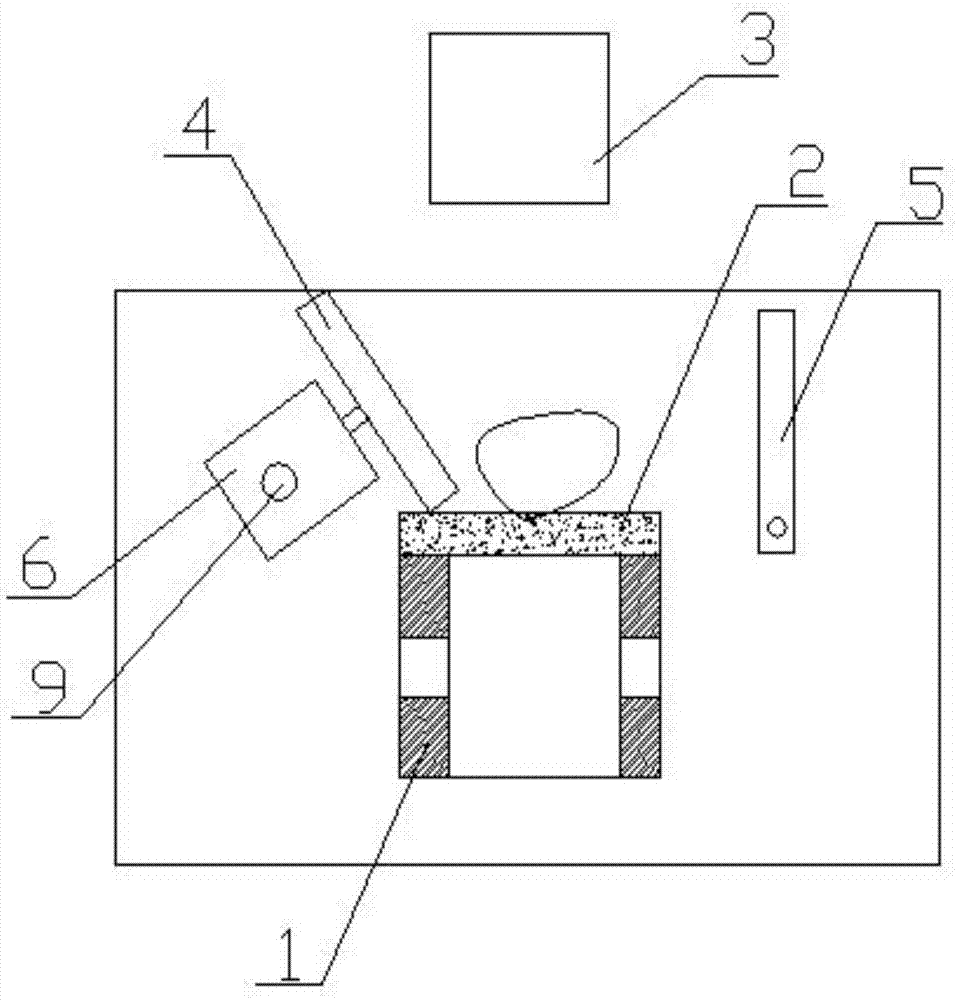

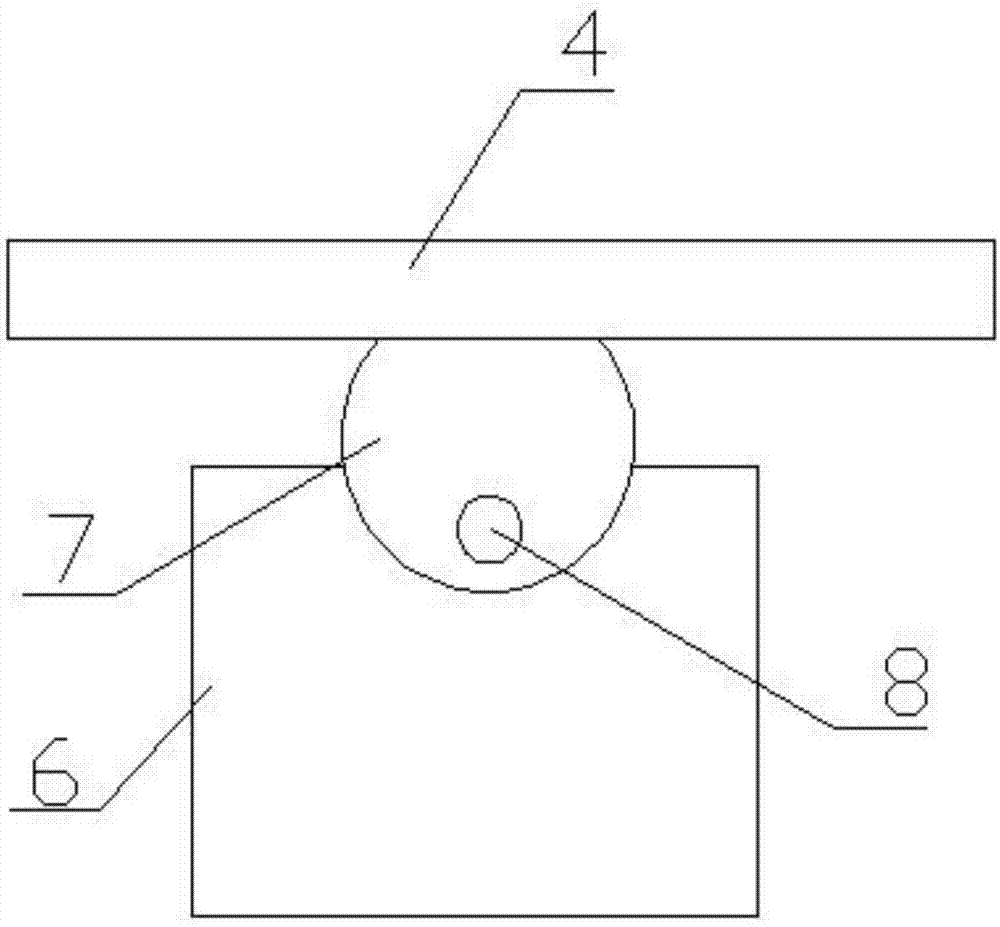

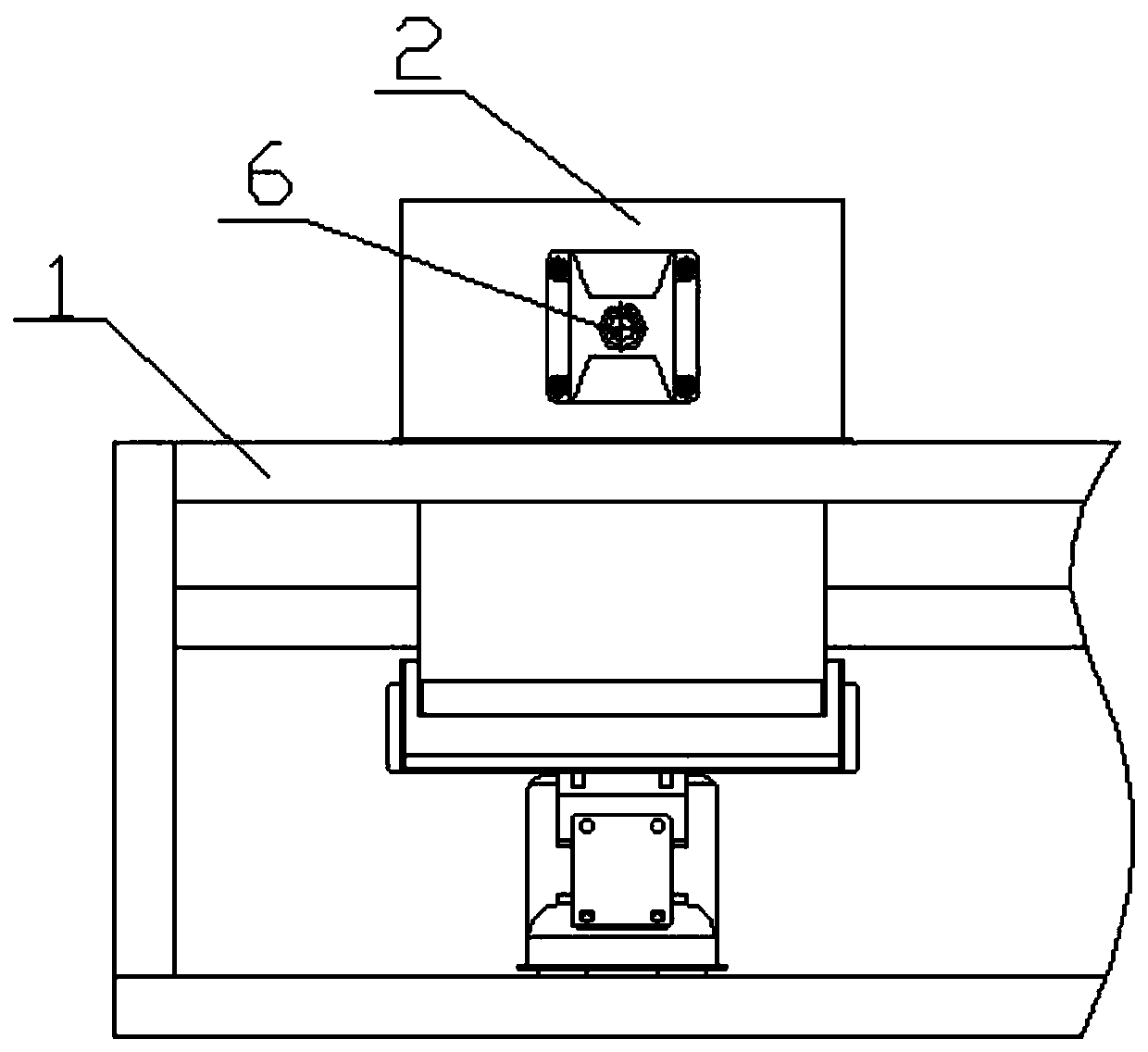

Adjustable light source system used for color selector and light source brightness adjusting method thereof

InactiveCN104185347ALow costHigh precisionElectric light circuit arrangementSortingLight sourceEngineering

The invention relates to an adjustable light source system used for a color selector. The adjustable light source system comprises an upper computer used for sending adjusting instructions. The signal output end of the upper computer is connected with the input end of an FPGA control circuit used for receiving the adjusting instructions, the output end of the FPGA control circuit is connected with the input end of a DAC conversion circuit, the output end of the DAC conversion circuit is connected with the input end of a constant-current driving circuit, the constant-current driving circuit is used for outputting corresponding current values according to the adjusting instructions and the output end of the constant-current driving circuit is connected with LED lamps arranged on an LED light source panel. The invention further discloses a light source brightness adjusting method of the adjustable light source system used for the color selector. According to the adjustable light source system used for the color selector and the light source brightness adjusting method of the adjustable light source system used for the color selector, the mode that a motor is used for driving a background plate does not need to be adopted, and therefore the cost is greatly reduced; the magnitude of the output currents is controlled through the upper computer, therefore, the precision of the output currents is high and ripple noise is low; through the DAC conversion circuit, the purposes that the currents can be adjusted accurately, the speed is high and current output is continuous are realized. The adjustable light source system is long in service life, the color selecting effect is good and stable and the adjustable light source system can be widely applied to the field of color selectors.

Owner:HEFEI MEIYA OPTOELECTRONICS TECH

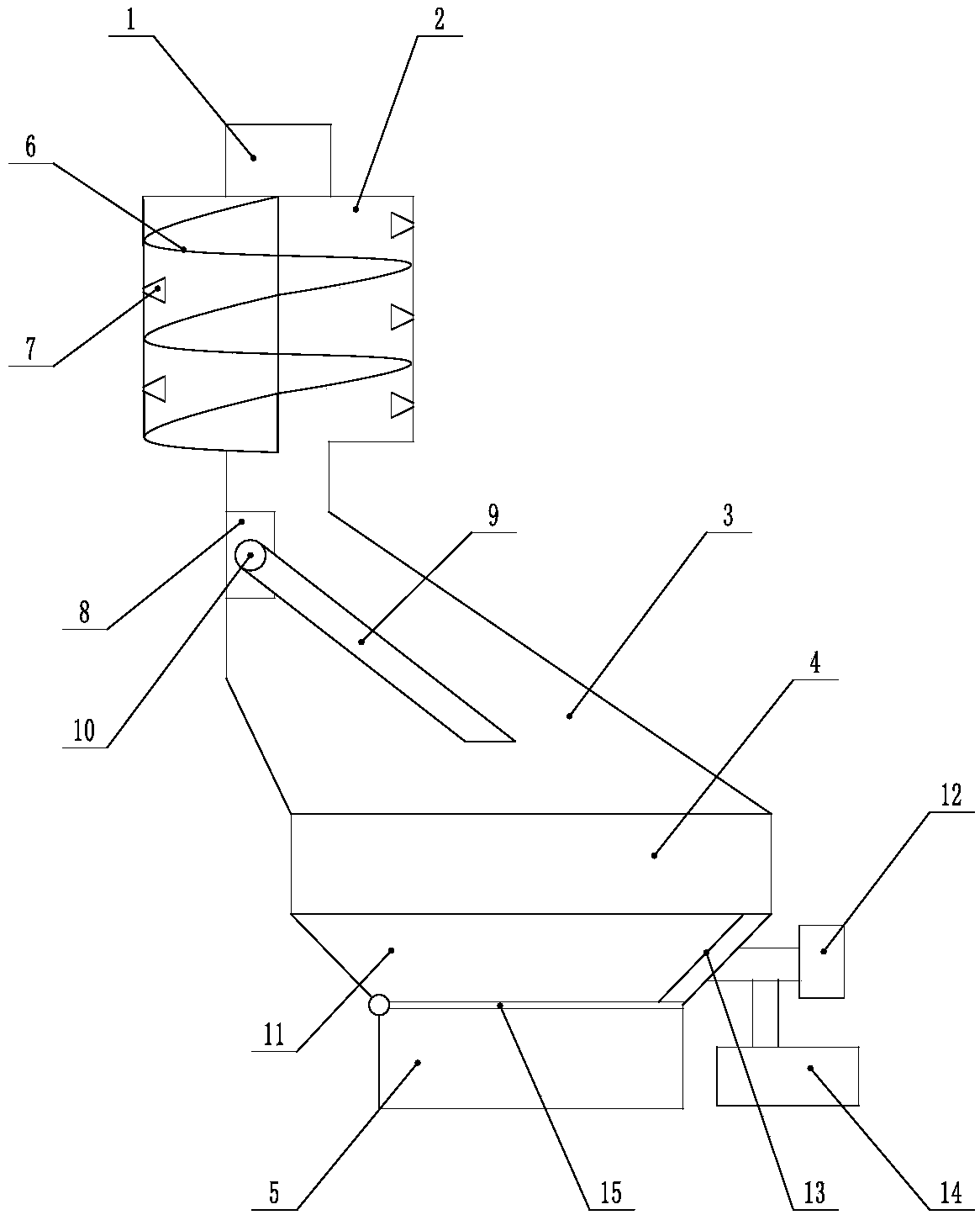

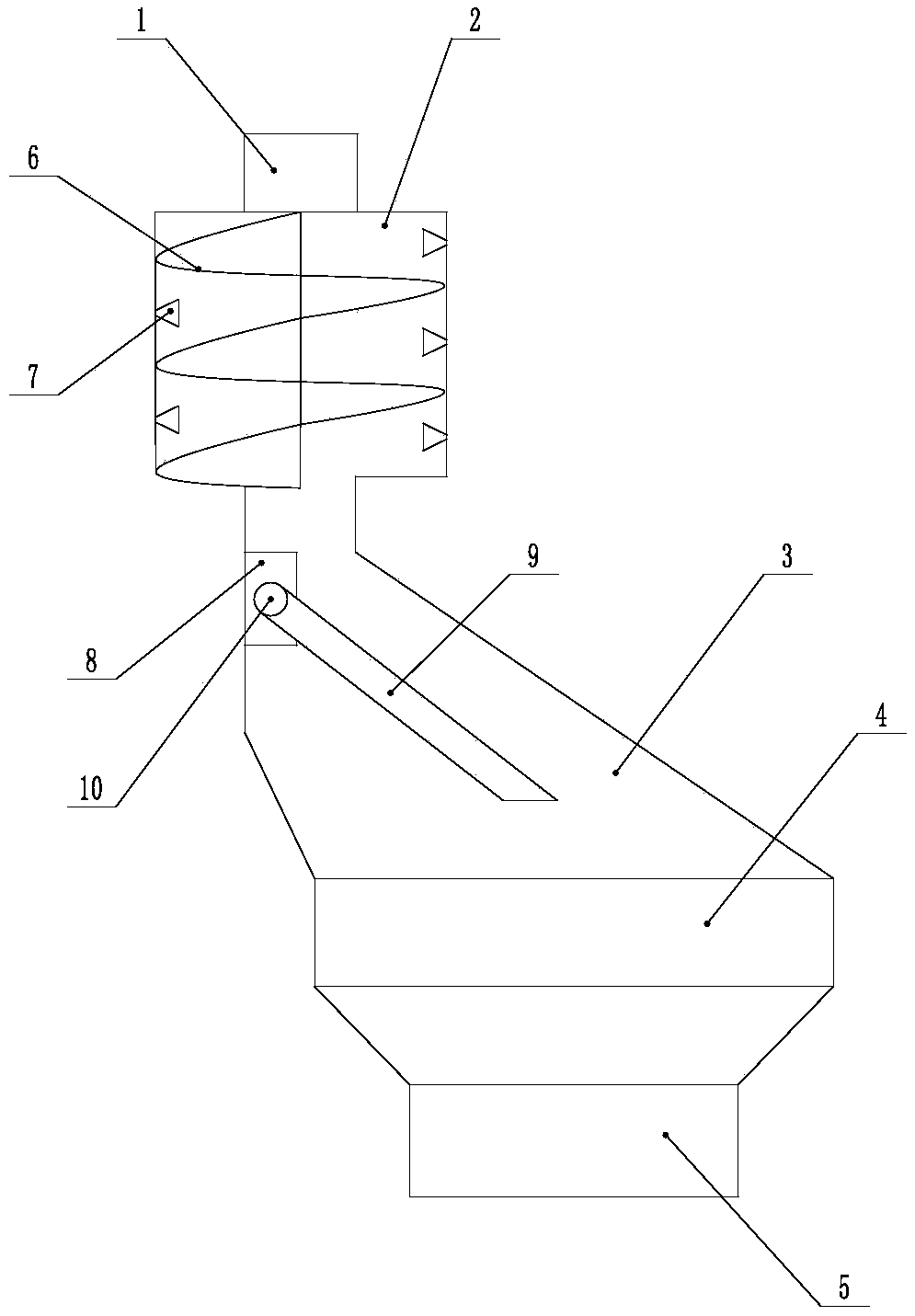

Color selector capable of improving rice selecting accuracy

InactiveCN108940929AImprove the accuracy of rice selectionExtended stayGas current separationSortingEngineering

The invention discloses a color selector capable of improving rice selecting accuracy. The color selector comprises a feeding opening, a pretreating box, a conveying box, a color selecting device, a dust removal device and a discharging opening which are connected in sequence; a spiral plate is arranged in the pretreating box, a plurality of air spraying devices are arranged on the inner wall of the pretreating box, an installing part is arranged in the conveying box, a conveying channel is arranged on the installing part and is connected to the installing part through a rotating shaft, and the rotating shaft is connected with a driving device. According to the color selector, an air spraying device is used for scattering clustering rice, and the follow-up color selection effect is prevented from being influenced by the fact that the rice is prevented from pasting into a cluster; the inclined angle of the conveying channel is adjusted according to the rice weight, the rice conveying speed is adjusted, and the color selection effect of the color selector is better; and powder or dust mixed into the rice can be sucked away through the dust removal device, and the rice with the betterquality is left.

Owner:四川捷兴机械设备有限公司

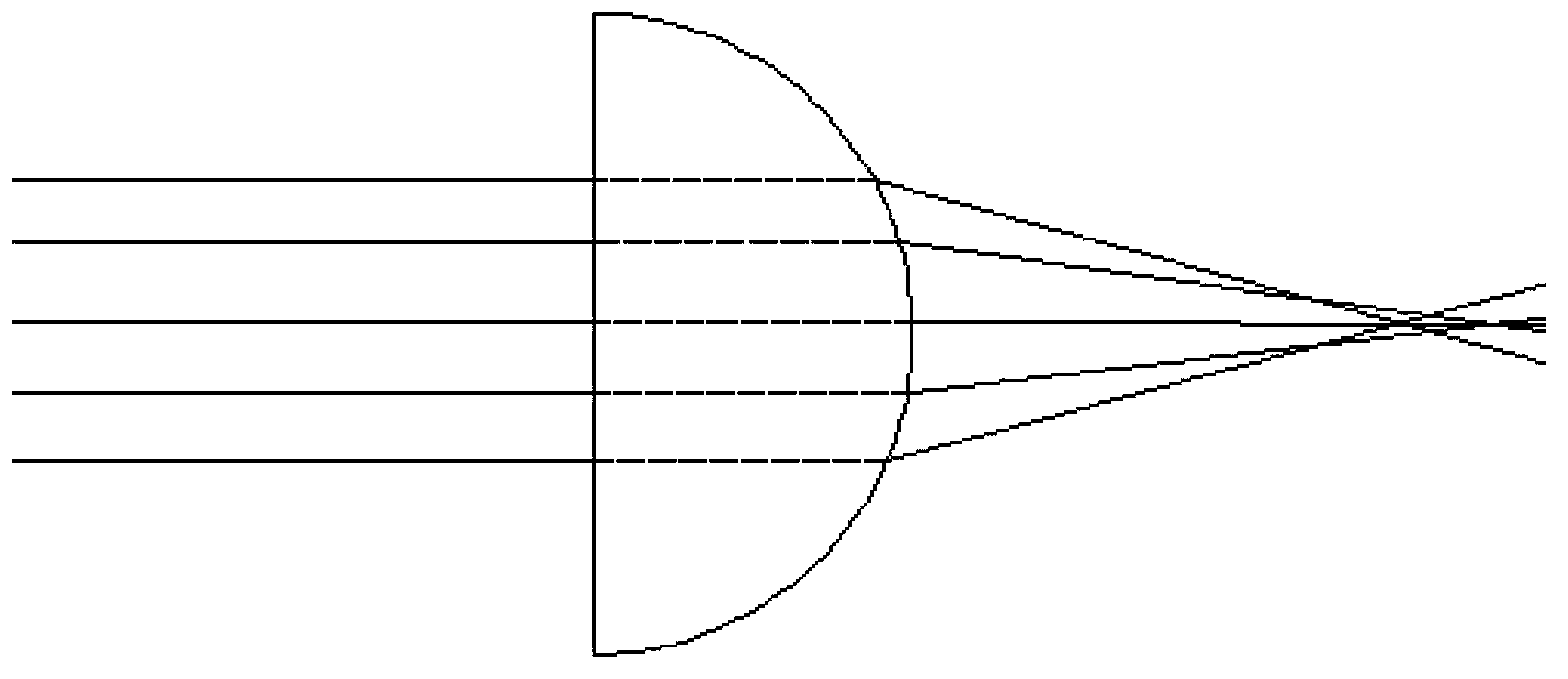

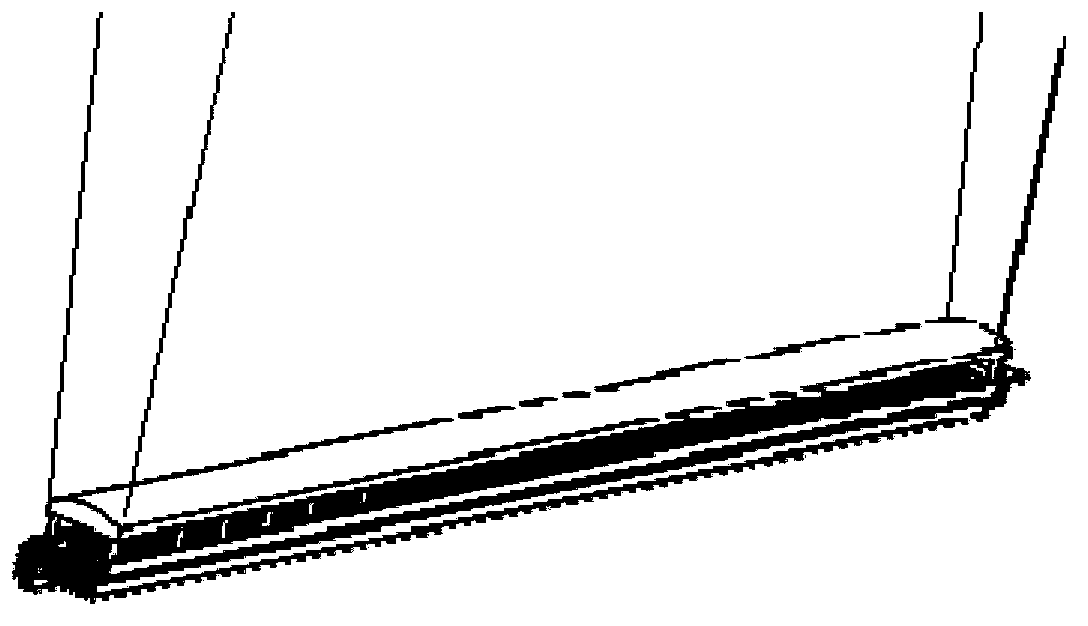

Light source system applicable to tomato color sorting machine

InactiveCN103353076AImprove installation densityIncrease light intensityLighting applicationsPoint-like light sourceUltimate tensile strengthLED circuit

The invention discloses a light source system applicable to a tomato color sorting machine. The light source system comprises a light source plate, a radiator, a lens and a lens bracket, wherein the light source plate comprises a light source LED, an LED drive circuit and a metal base circuit board, the lens is fixed on the radiator through the lens bracket, and the light source plate is located between the lens and the radiator and fixed on the radiator. The light source system abandons an idea of adopting a combination of various monochromatic light LEDs as a light source of the tomato color sorting machine, adopts a composite white-light LED as the light source of the tomato color sorting machine, reduces LED varieties, simplifies a light source driving circuit structure and increases LED installation density; on the basis, the optical lens member is added, so that the illumination intensity of the light source is probable to be improved, and the color sorting effect is enhanced; therefore, the light source system is applicable to the tomato color sorting machine operating indoors or under the condition of field sunshine.

Owner:ANHUI ZHONGKE OPTIC ELECTRONICS COLOR SORTER MACHINERY

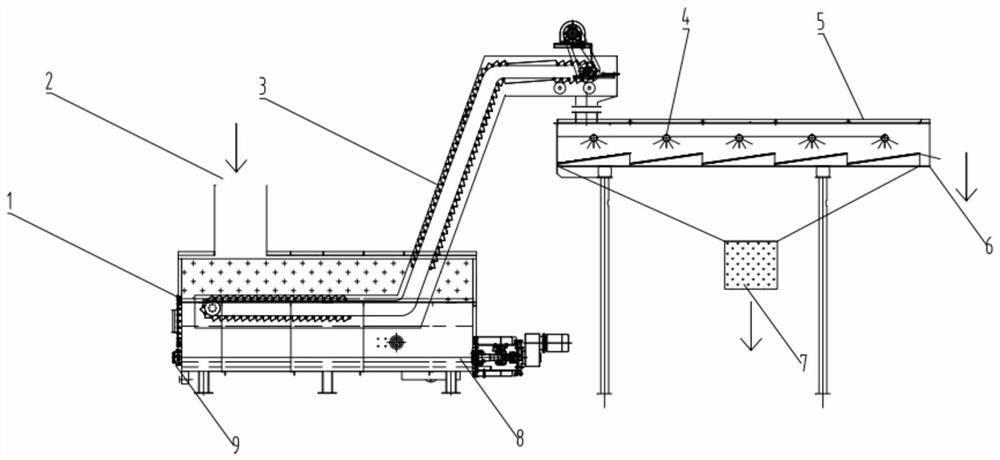

Multi-functional and high-efficiency rice color sorter

Owner:四川捷兴机械设备有限公司

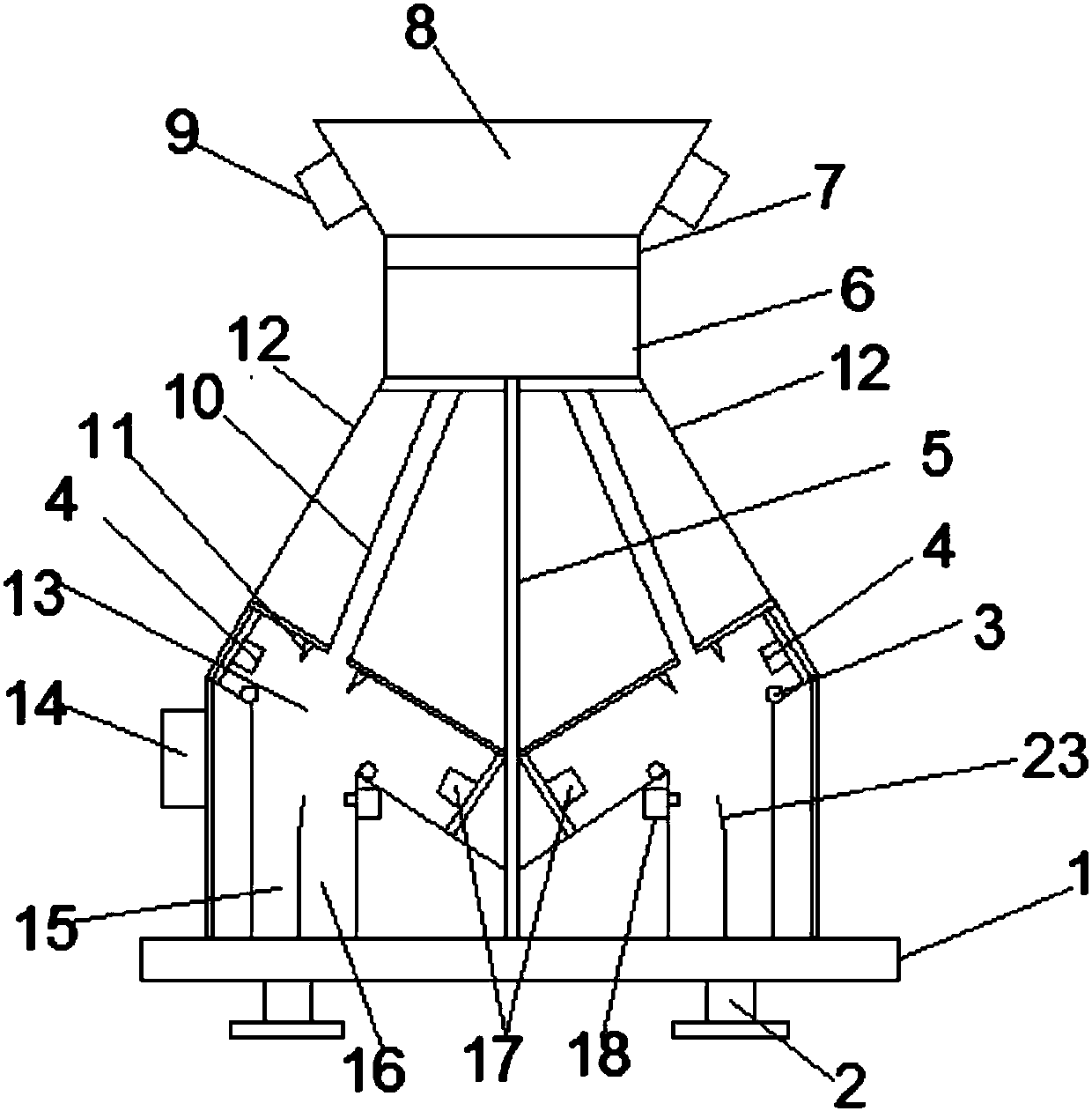

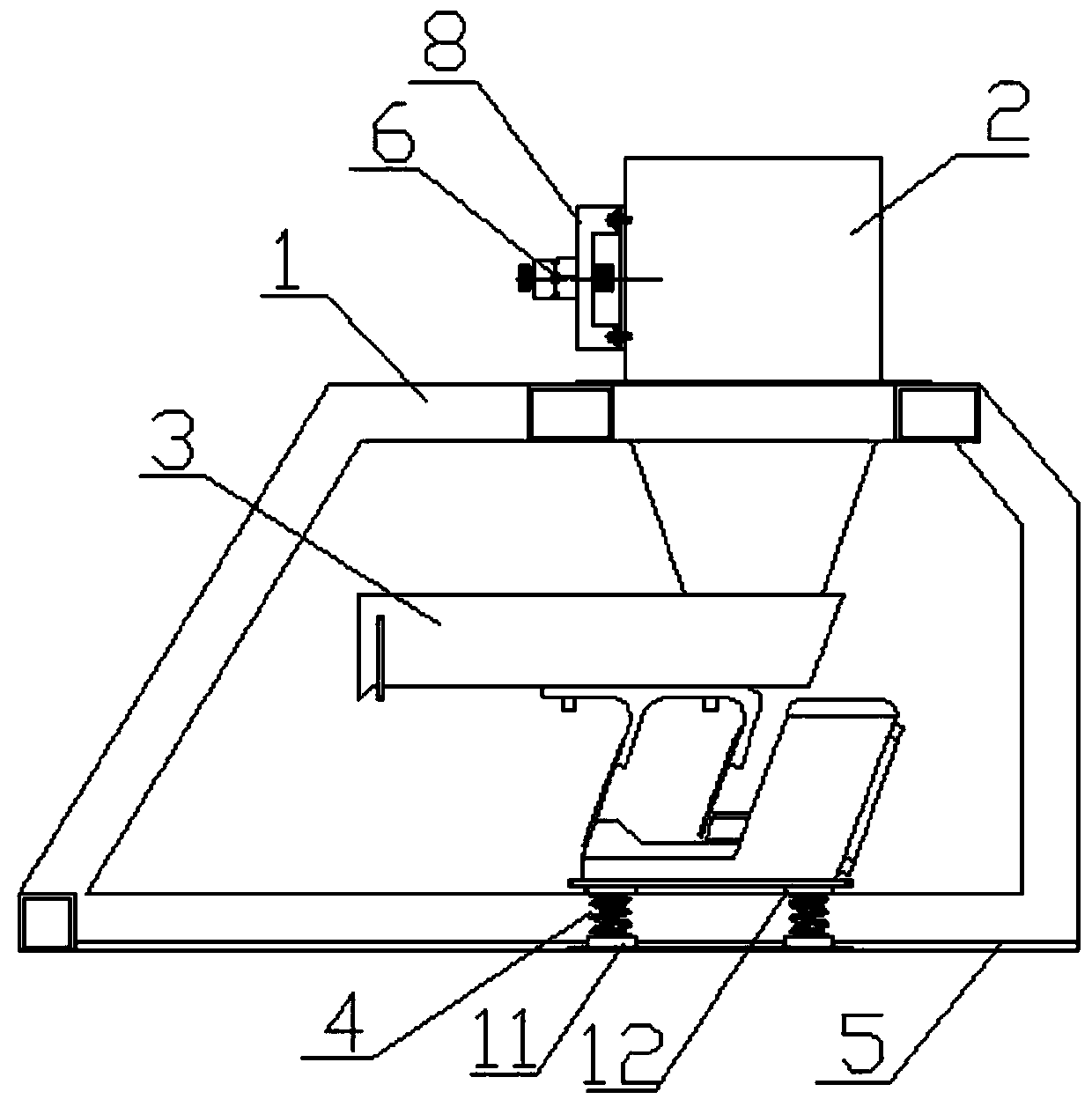

Color selector online detection device

InactiveCN108043751AAvoid gatheringAvoid cloggingCleaning using toolsSortingCamera lensVolumetric Mass Density

The invention discloses a color selector online detection device which comprises an installation base and a fixed machine frame. The installation base is fixed to the ground through four foundation bolts. The bottom end of the fixed machine frame is fixedly installed on the top of the installation base to form an integrated structure. The surfaces of the two sides of the fixed machine frame are each provided with a color selection shell. The color selector online detection device has the beneficial effects that raw materials entering a discharge hopper can be subjected to rectification througha rectification cover and a rectifier arranged inside the discharge hopper, raw materials gathering and blockage are prevented, the density of the color selection raw materials entering a color selection inner cavity is moderate, the missing inspection phenomenon is not likely to appear, the accuracy of a color selector is improved, and the color selection effect is good. In addition, a dust removal device can be controlled by a controller to remove dust on a camera lens, the structure is simple, the effect is obvious, the color selection effect is good, and usability is high.

Owner:章良盛

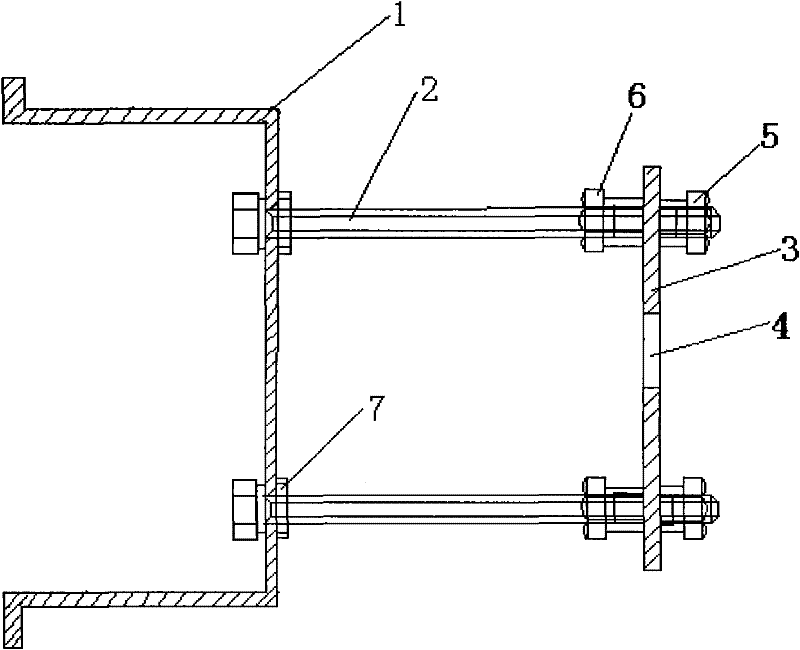

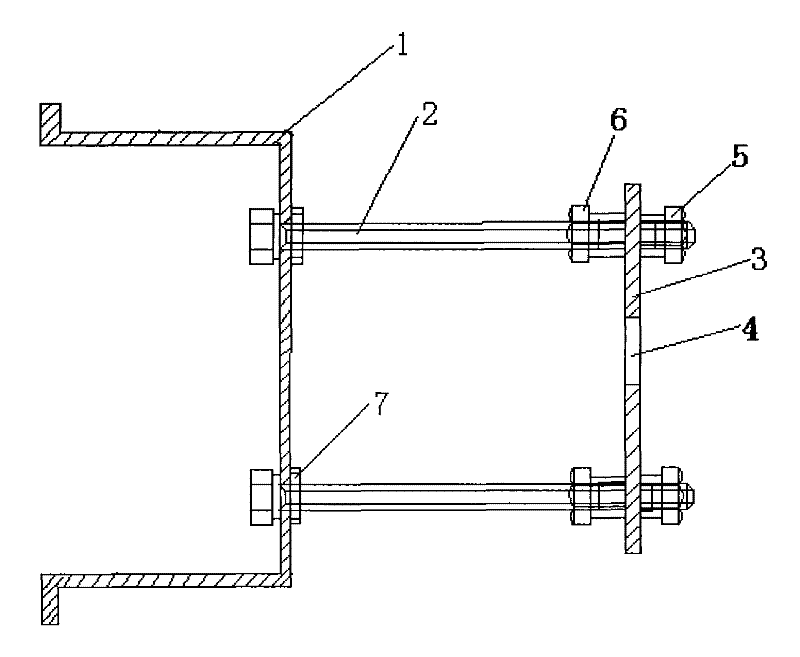

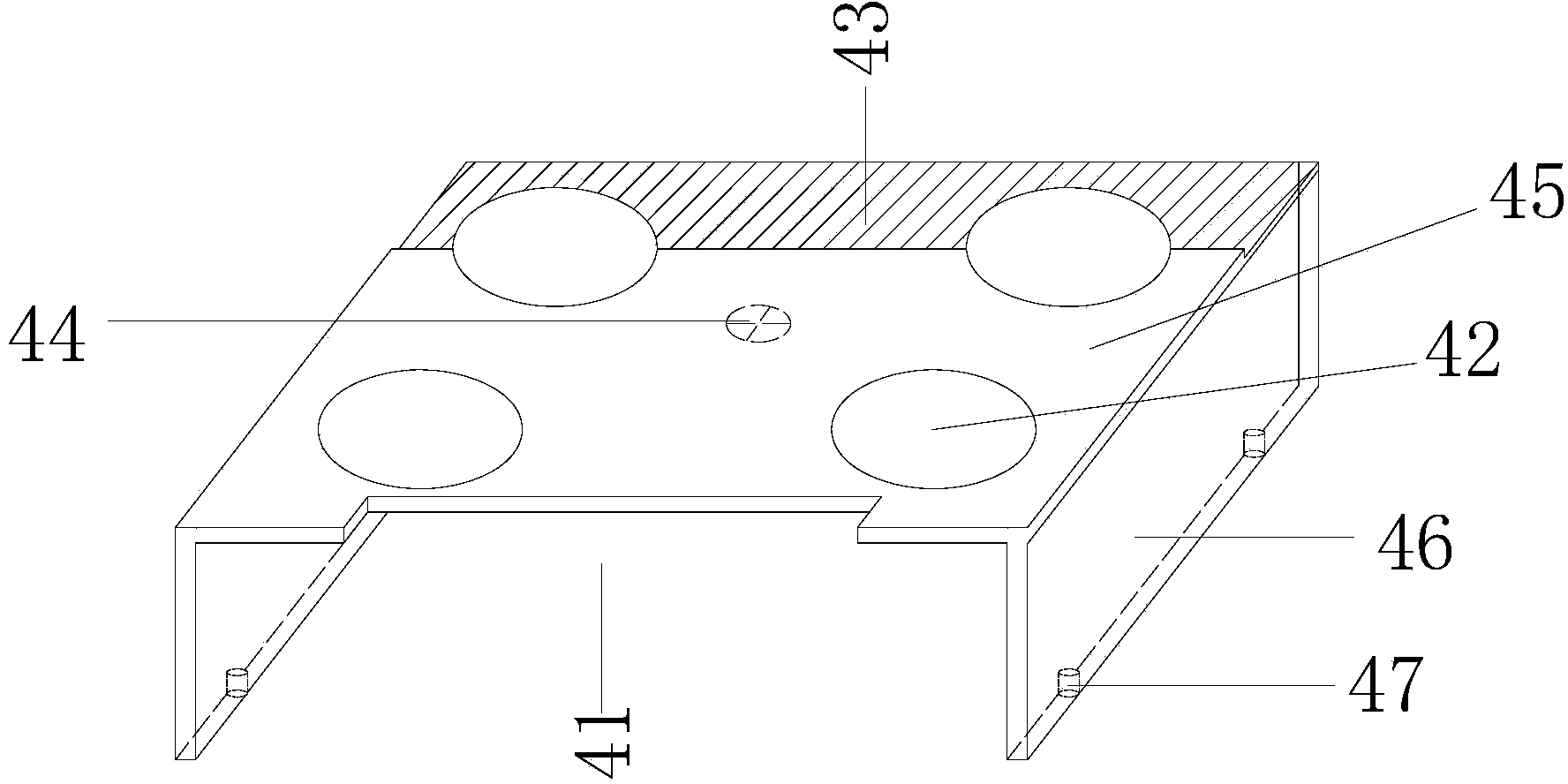

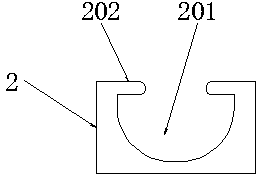

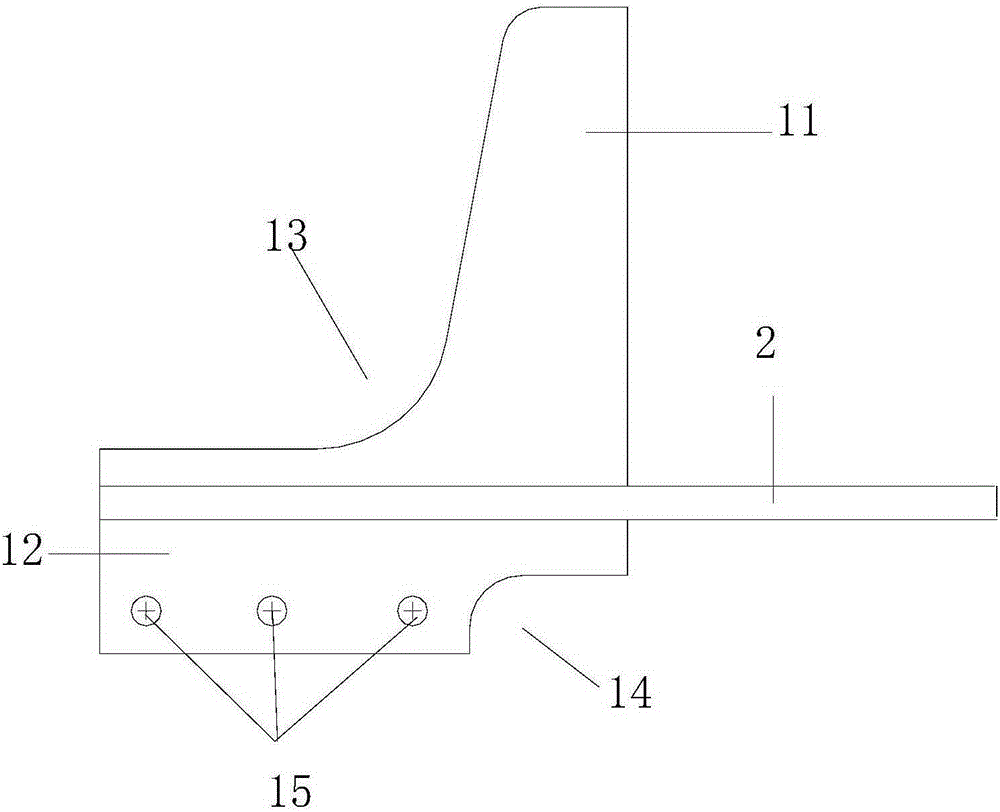

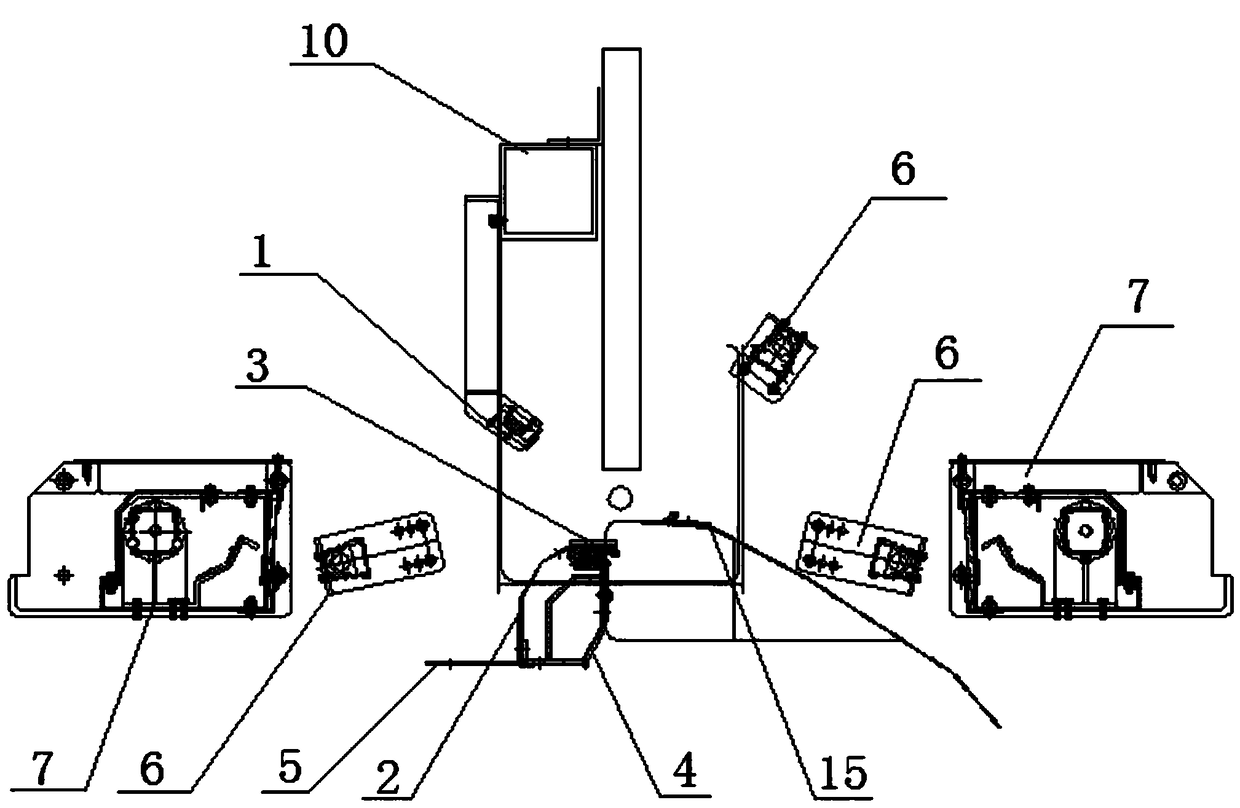

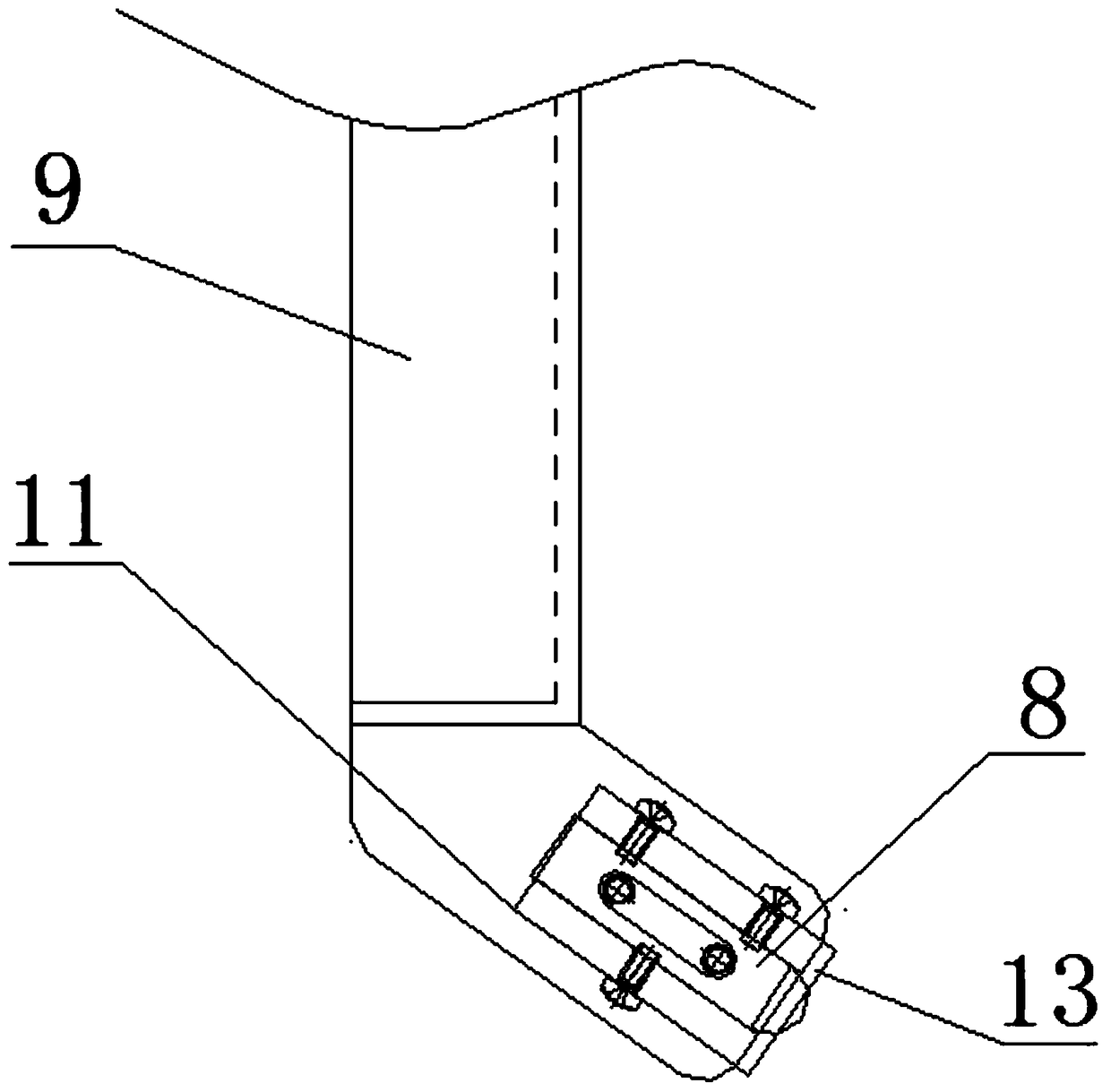

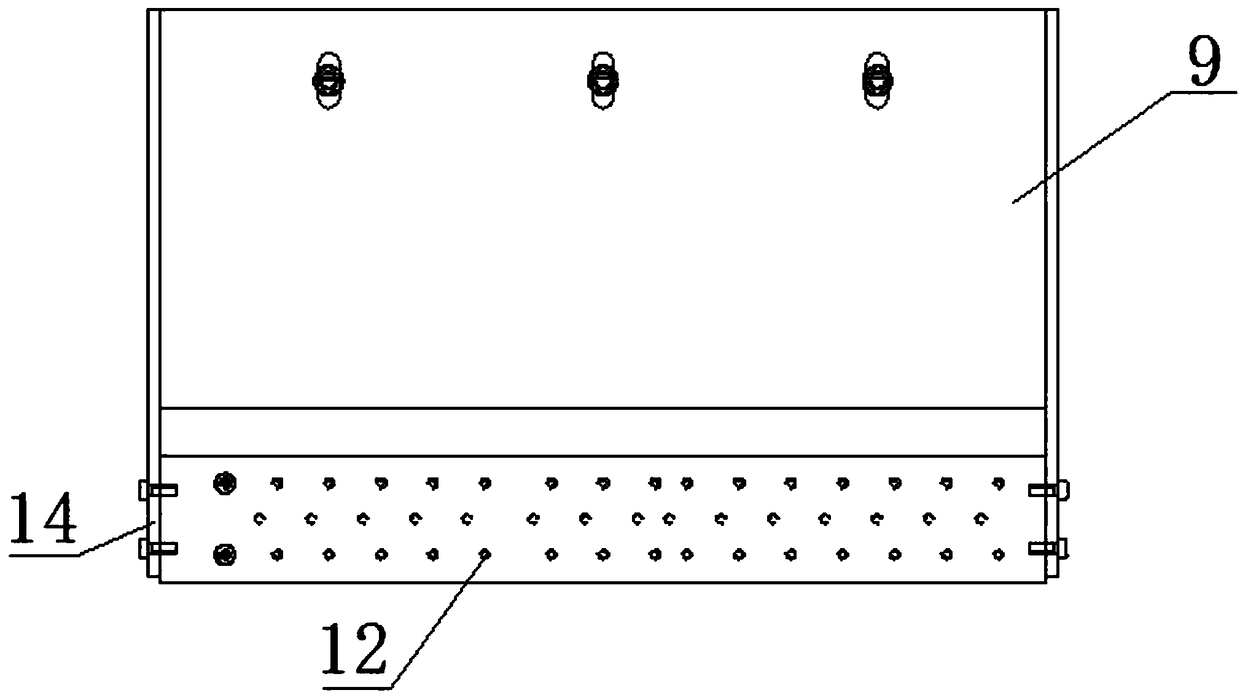

Adjustable CCD lens fixing bracket

InactiveCN102049390AImprove color sorting effectMeet the needs of actual useSortingAgricultural engineering

The invention discloses an adjustable CCD lens fixing bracket, which comprises a U-shaped bearer. Three adjusting bolts are fixedly connected on the upper end surface of the bearer, a lens fixing plate is supported and mounted at the upper ends of the three adjusting bolts, lens mounting holes are arranged on the lens fixing plate, and an upper locking nut and a lower locking nut are screwed on the adjusting bolts on the upper side and the lower sides of the lens fixing plate respectively. The invention solves the problems that the distance between a CCD lens and a selected object is difficult to adjust and the adjustment distance is not accurate, and meanwhile the adjustable CCD lens fixing bracket is suitable for different ground conditions, improves the color sorting performance of the complete machine of a color sorter, and meets the practical production need.

Owner:ANHUI JIEXUN OPTOELECTRONICS TECH

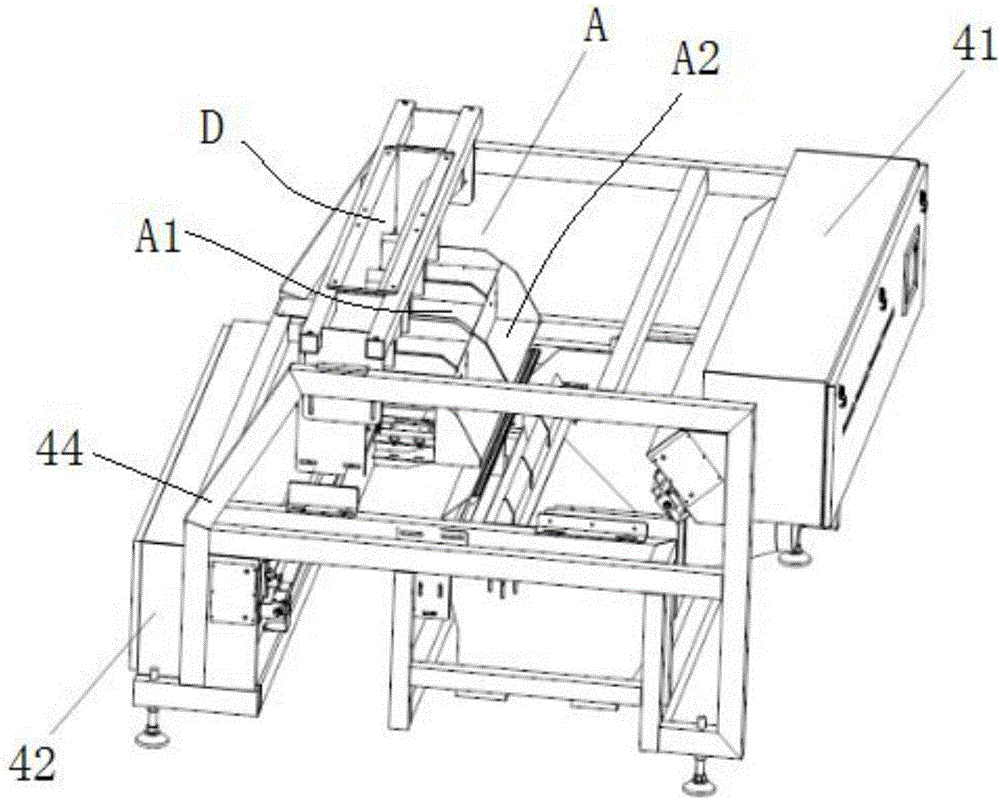

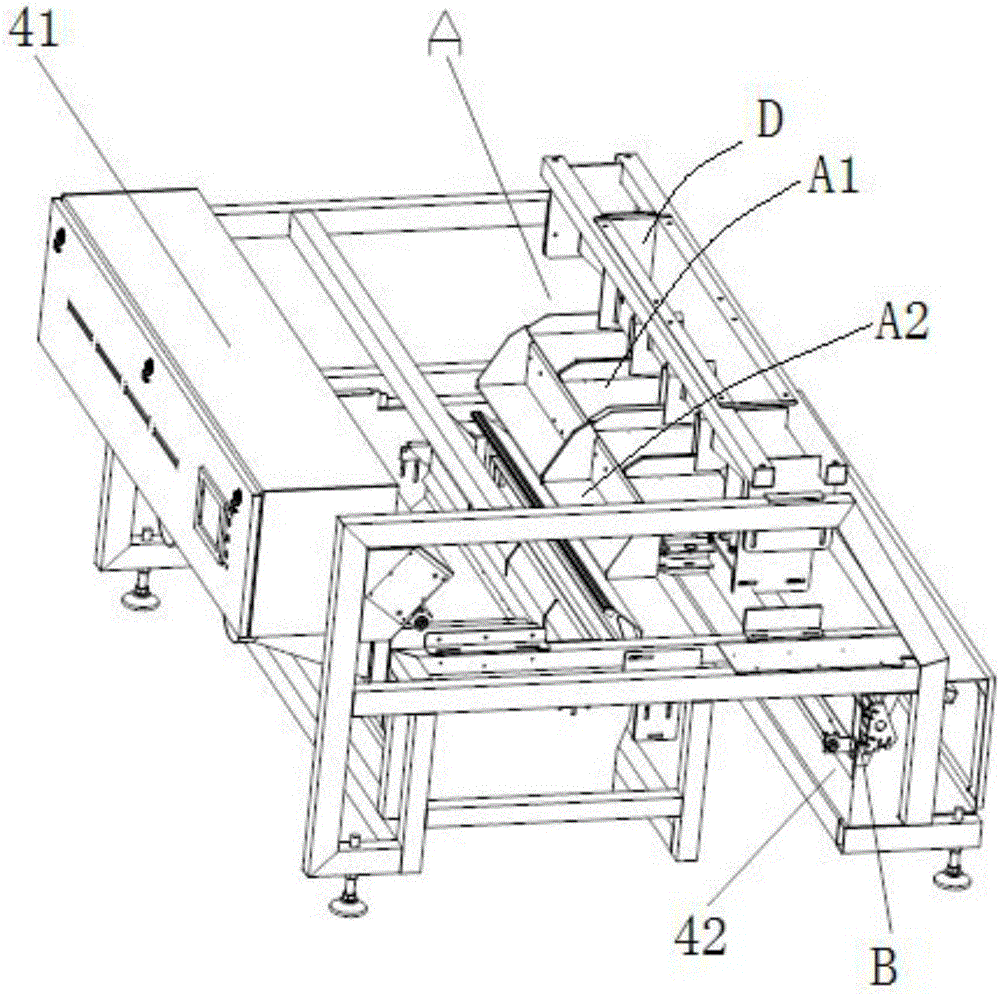

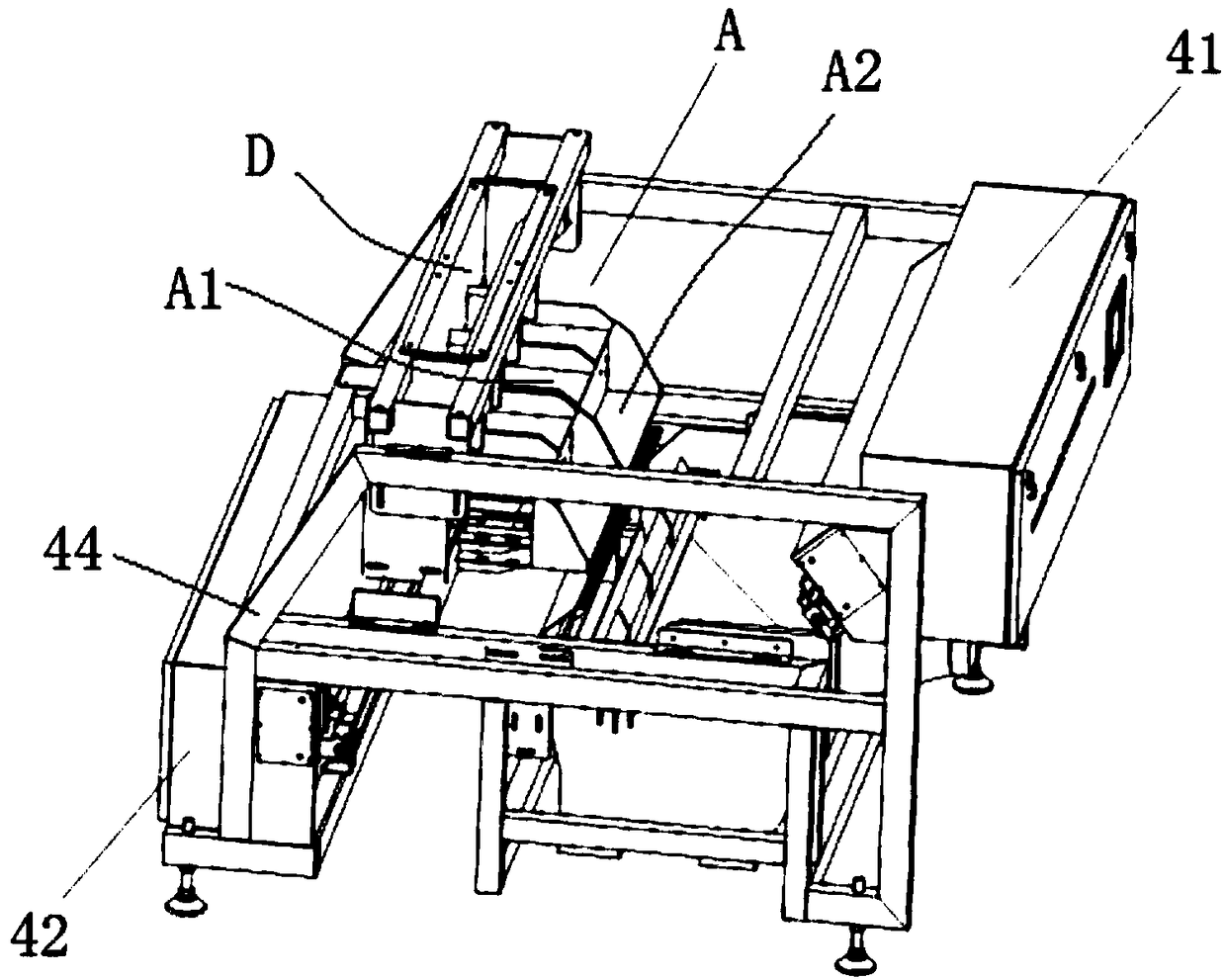

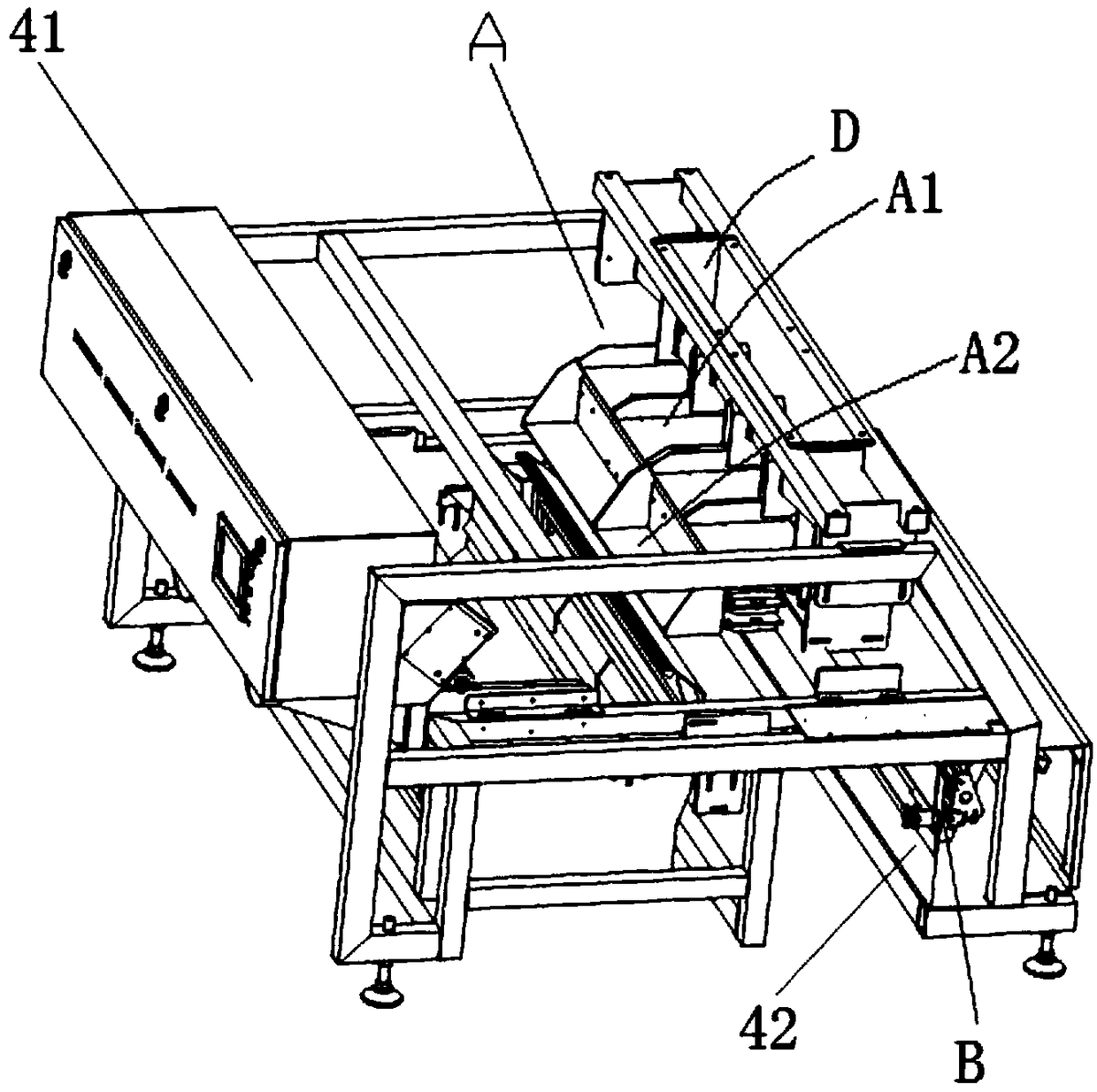

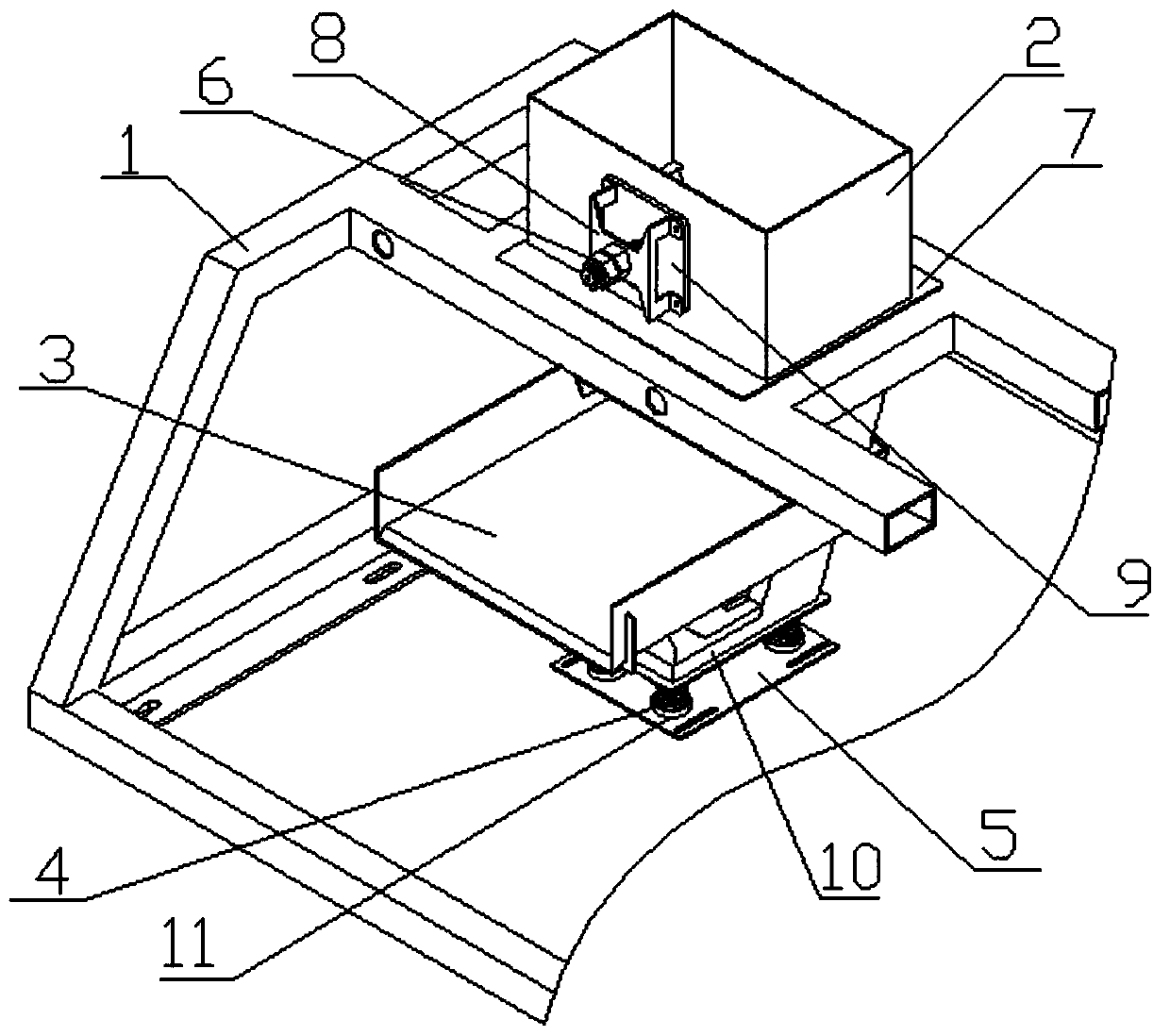

Novel solid material color selector

ActiveCN106000915AEasy color sortingConvenient sorting and removalSortingPhotovoltaic detectorsEngineering

The invention discloses a novel solid material color selector. The novel solid material color selector comprises a front sorting device, a rear sorting device and a double-grade vibration type feed system installed on a vibration support. The double-grade vibration type feed system is located below a vibration feed system of the color selector. The double-grade vibration type feed system is composed of a first-grade vibration system and a second-grade vibration system. The first-grade vibration system comprises a first-grade vibration motor and a first-grade trough installed on the first-grade vibration motor. The second-grade vibration system comprises a second-grade vibration motor and a second-grade trough installed on the second-grade vibration motor. A supporting part bent outwards is arranged on the rear surrounding wall of the second-grade trough. A discharge port of the first-grade trough extends to the portion over the second-grade trough. The first-grade trough is located under the vibration feed system of the color selector. By means of the vibration feed system, the first-grade trough and the second-grade trough, solid materials can freely fall, can be more easily detected by a photoelectric detector compared with an existing parabolic motion trail formed after the solid materials leave a caterpillar band, and can be conveniently sorted and removed.

Owner:ANHUI ZHONGKE OPTIC ELECTRONICS COLOR SORTER MACHINERY

A new type of solid material color sorter

ActiveCN106000915BThere will be no phenomenon of adsorption on the vibrating systemEasy color sortingSortingPhotovoltaic detectorsElectric machinery

The invention discloses a new color sorting machine for solid materials, which includes a front sorting device, a rear sorting device and a two-stage vibrating feeding system installed on a vibrating support; the two-stage vibrating feeding system is located in the color sorting machine Below the vibrating feeding system, the two-stage vibrating feeding system consists of a primary vibration system and a secondary vibration system; the primary vibration system includes a primary vibration motor and a primary trough installed on the primary vibration motor; The secondary vibration system includes a secondary vibration motor and a secondary trough installed on the secondary vibration motor. The rear wall of the secondary trough is provided with a support part that bends outward; the unloading of the primary trough The mouth extends directly above the secondary trough; the primary trough is located directly below the vibrating feeding system of the color sorter. The present invention utilizes a vibrating feeding system, primary troughs, and secondary troughs for free-falling solid materials. Compared with previous solid materials, the parabolic trajectory after leaving the crawler is easier to be detected by photoelectric detectors, which facilitates sorting and removal.

Owner:ANHUI ZHONGKE OPTIC ELECTRONICS COLOR SORTER MACHINERY

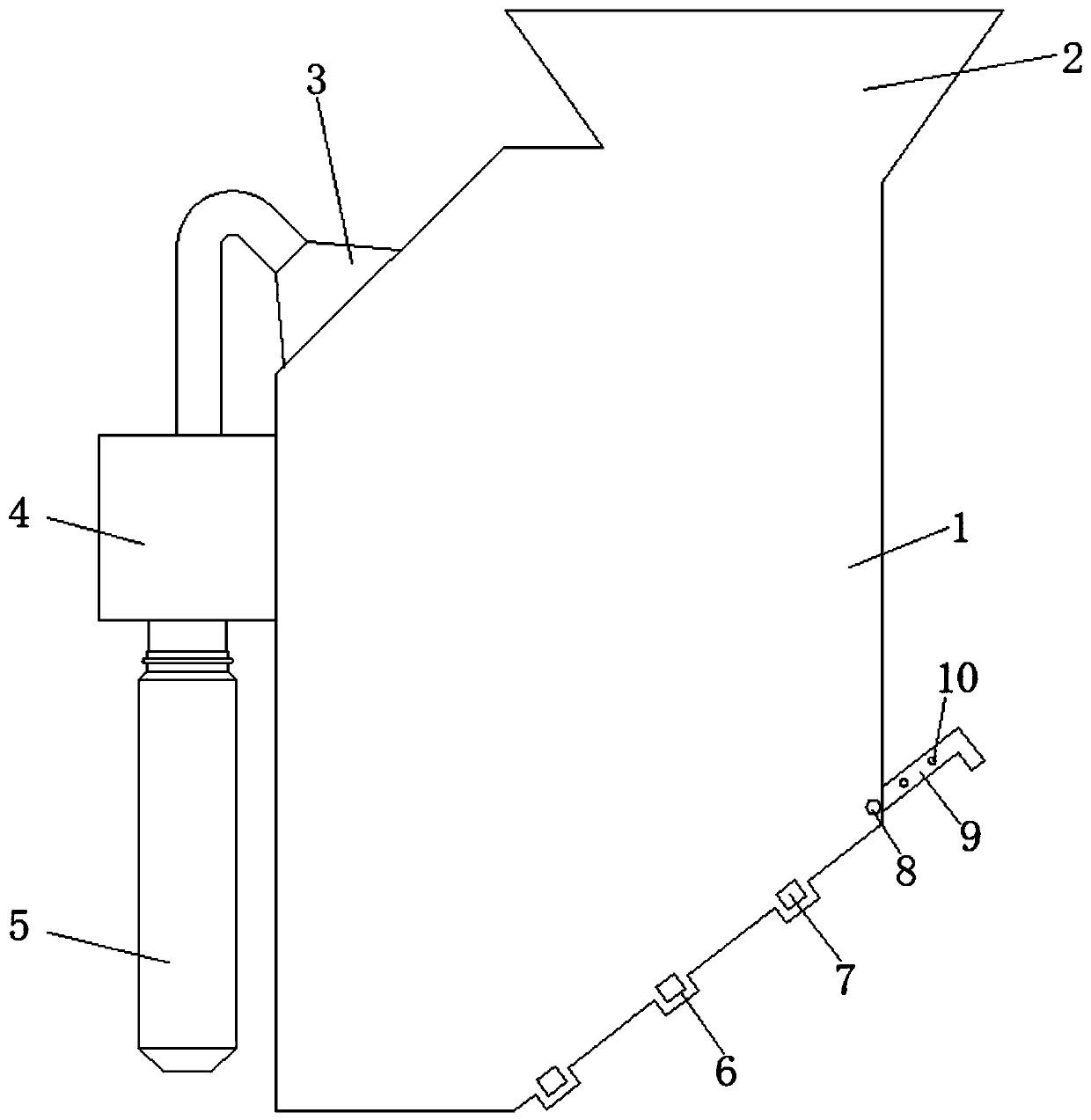

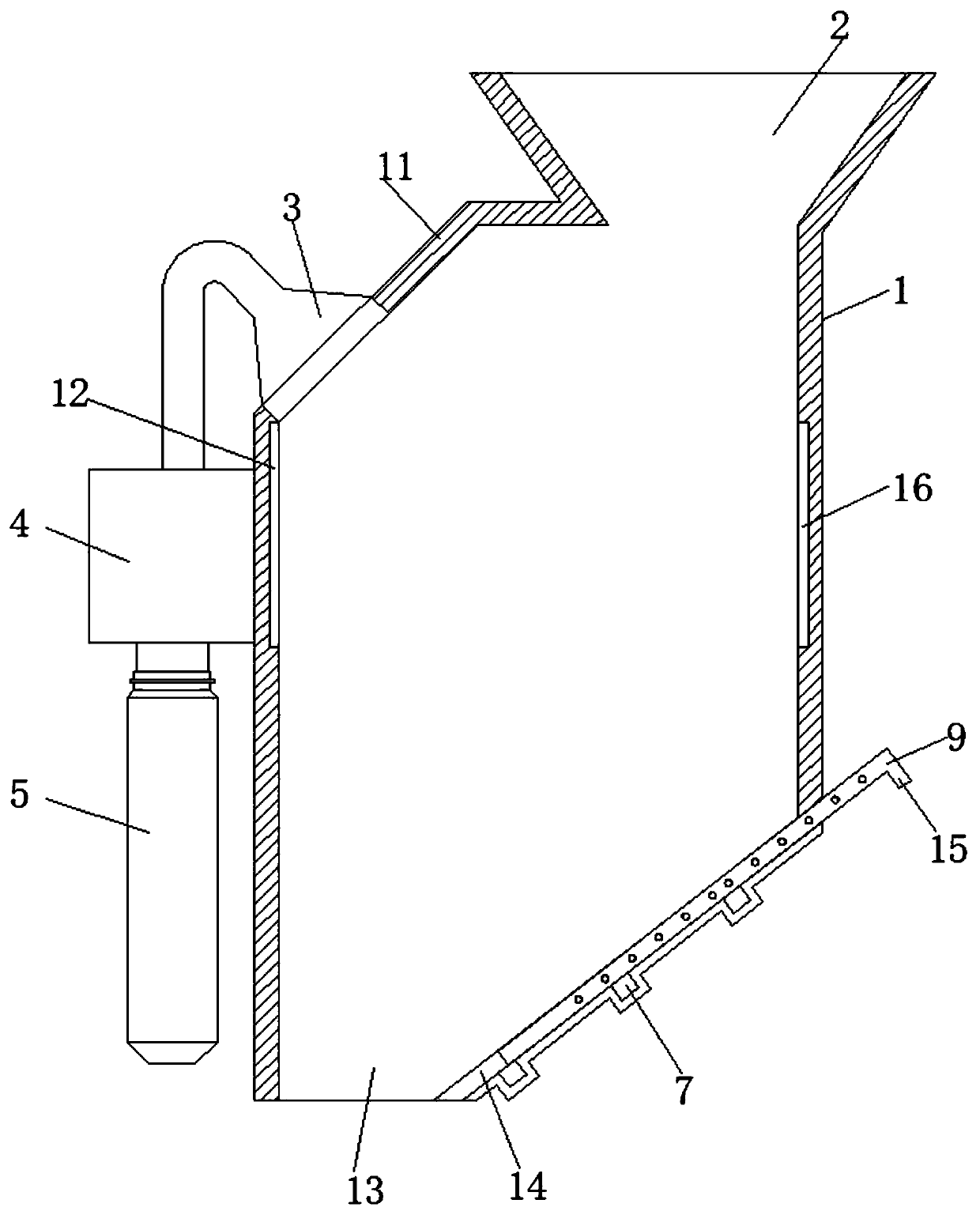

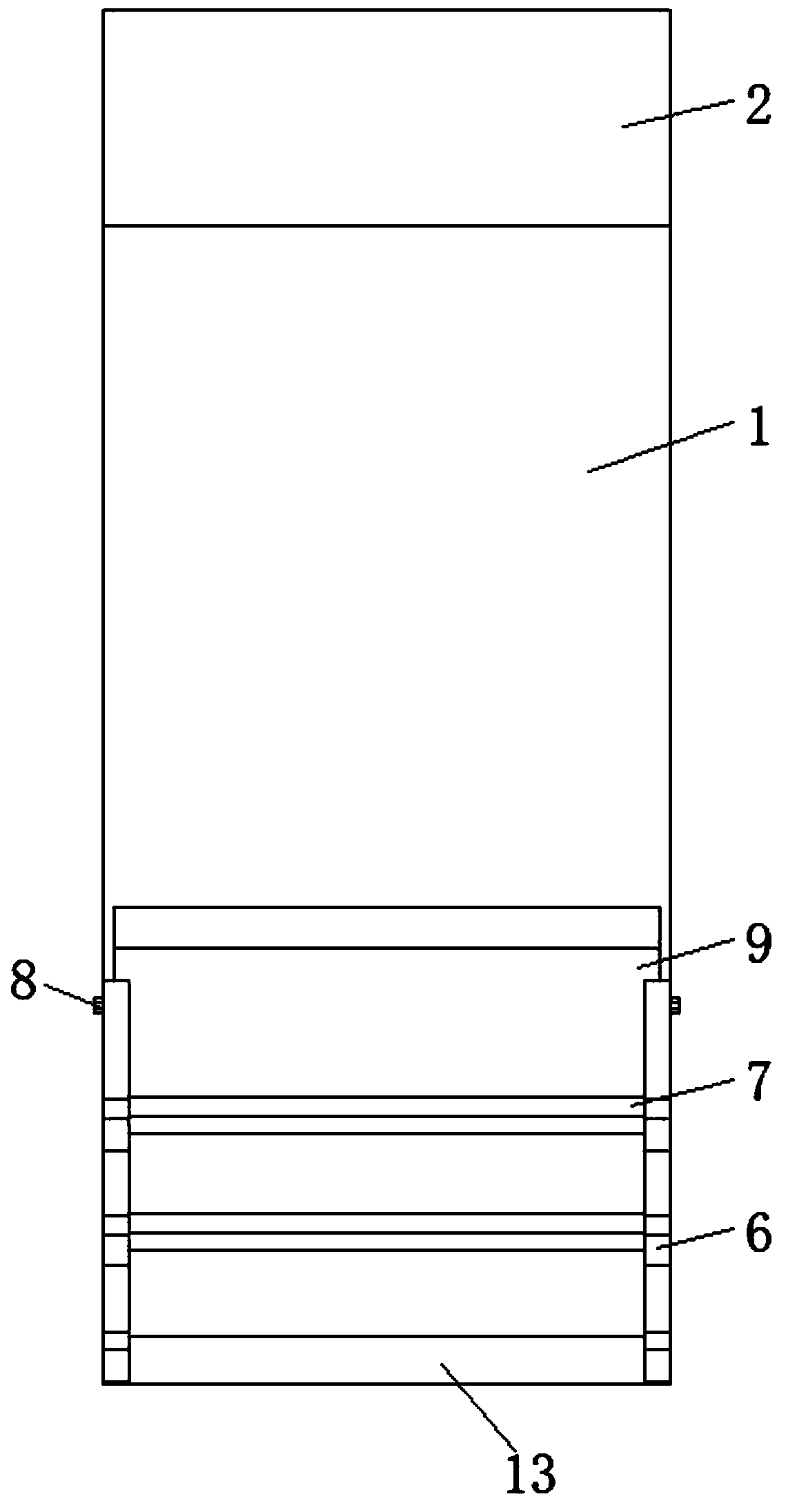

A color sorter for rice processing

ActiveCN110614235BReduce the probability of cloggingReduce error rateSortingAgricultural engineeringElectric machinery

Owner:宁夏昊帅粮油有限责任公司

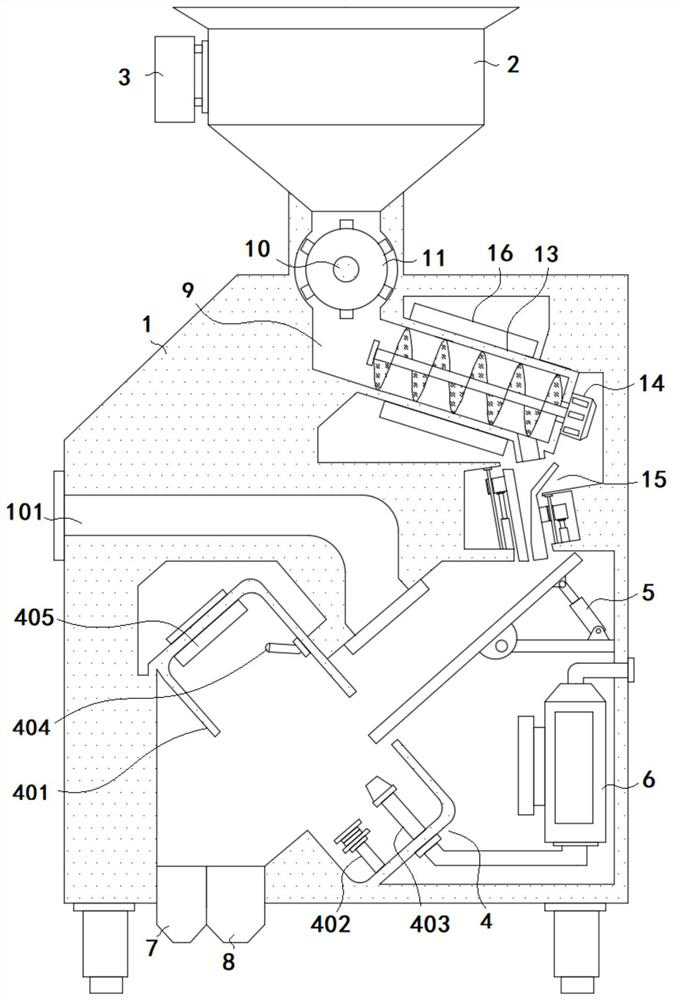

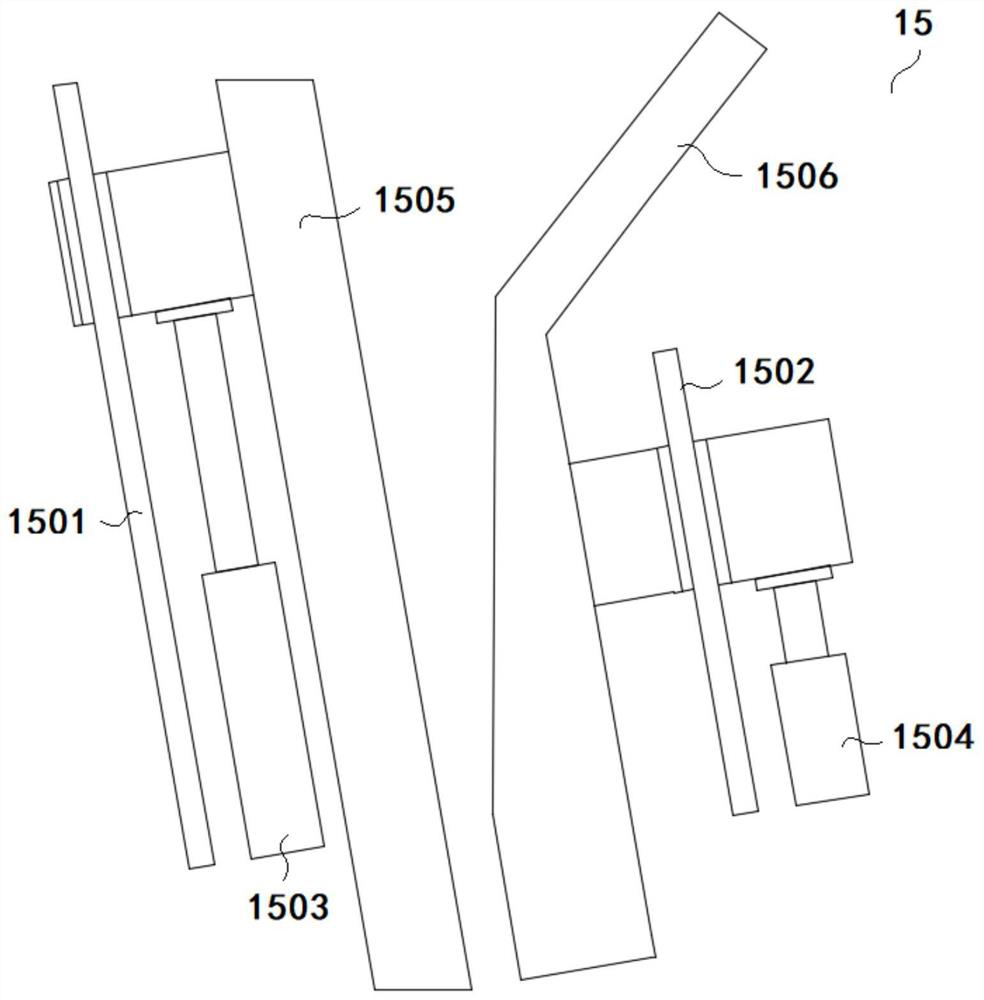

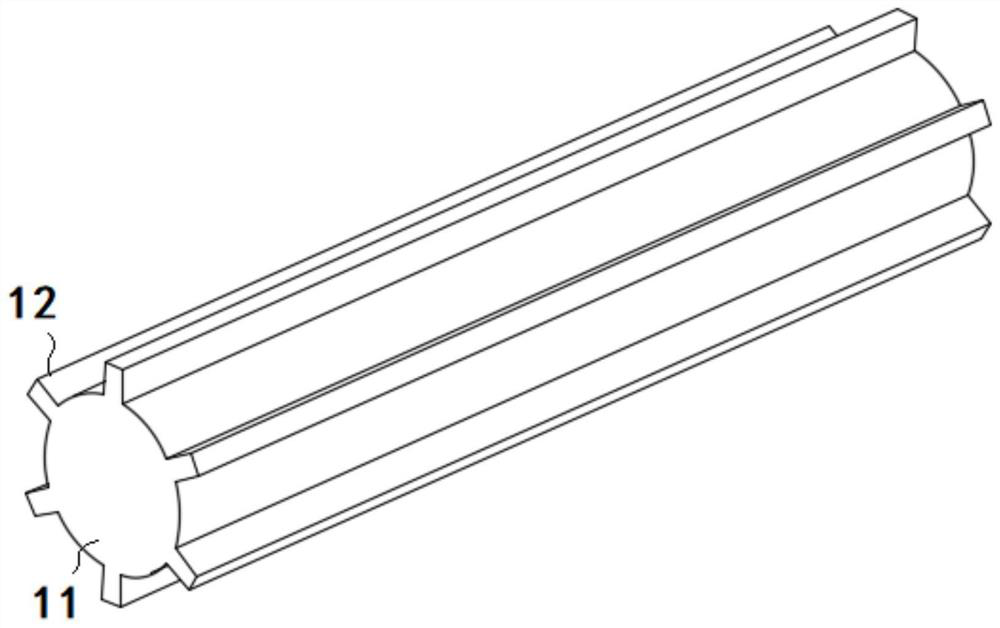

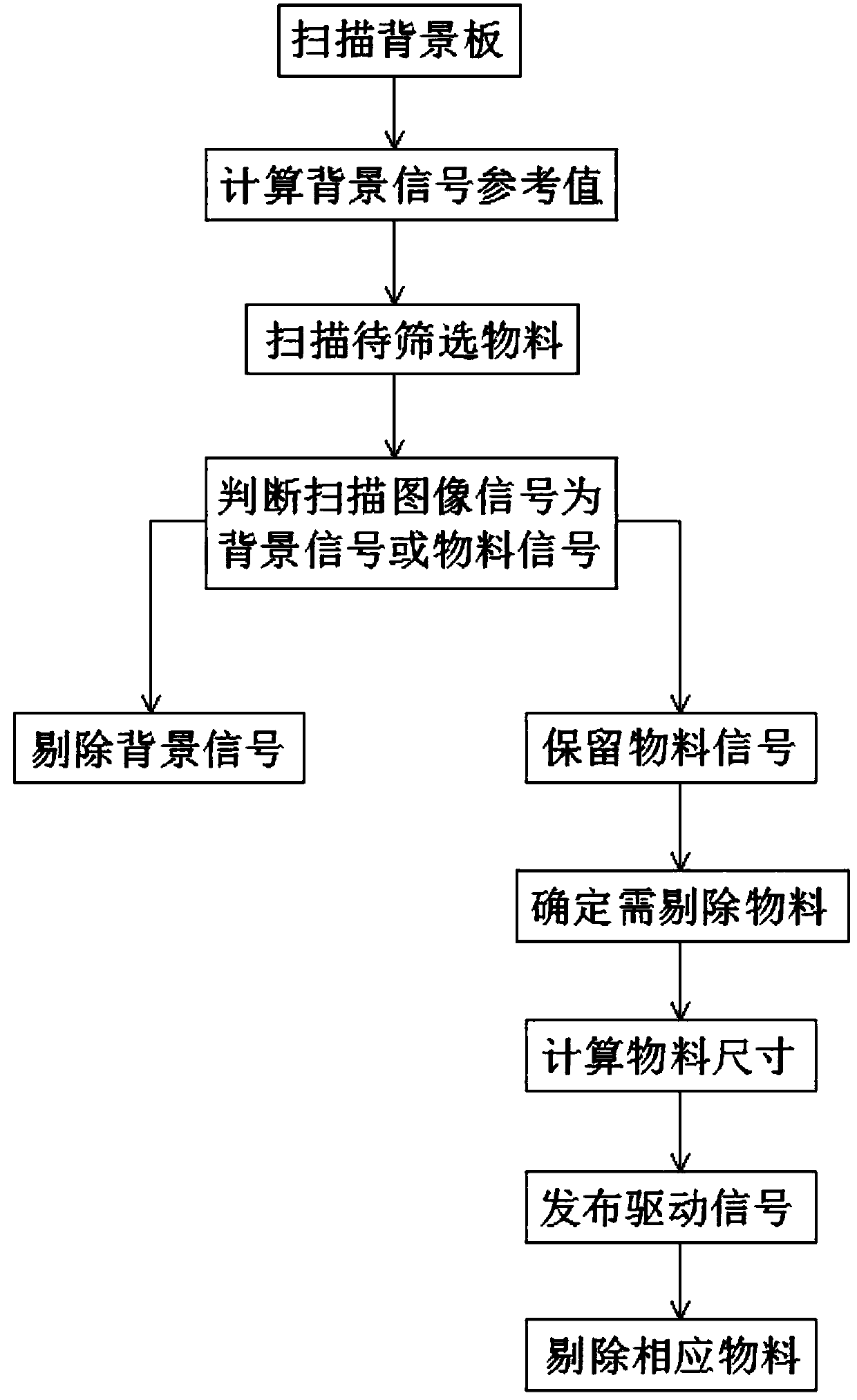

Large-size material removing process based on color sorting technology

The invention discloses a large-size material removing process based on color sorting technology. A reference value of a background signal is obtained by scanning a color sorter background plate, allscanned image signals obtained by scanning to-be-screened material and the background signal are subjected to contrastive analysis, background signals are removed, material signals are reserved, thenwhether the material signals are from material needing to be removed is judged, and a driving signal is sent to drive a removing mechanism to remove the material according to size of the material needing to be removed. Simple, convenient, efficient and fast effects are achieved, the problems that in the prior art, the size of large material is large, the bad material area being marked with characteristics is small, and the whole material cannot be blown out during blowing are solved, and the color sorting effect is improved greatly.

Owner:ANHUI SHARPVISION OPTOELECTRONICS TECH

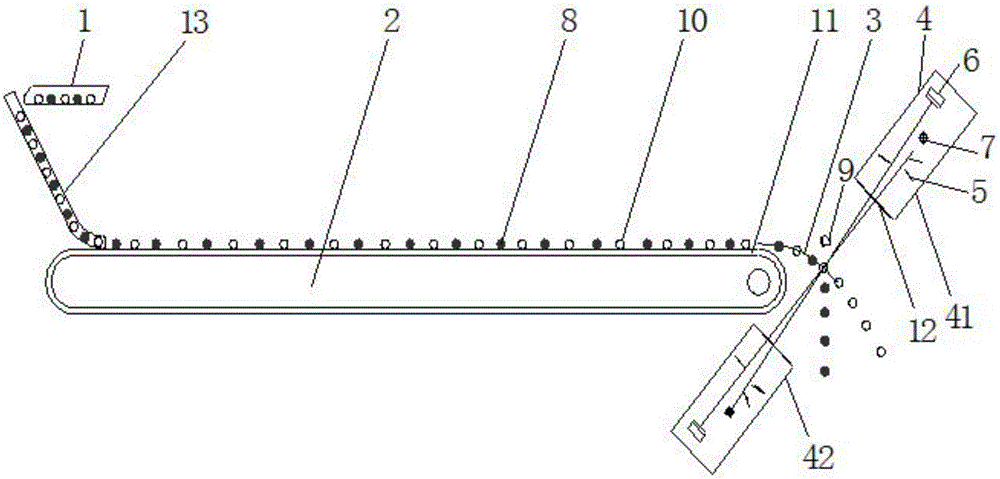

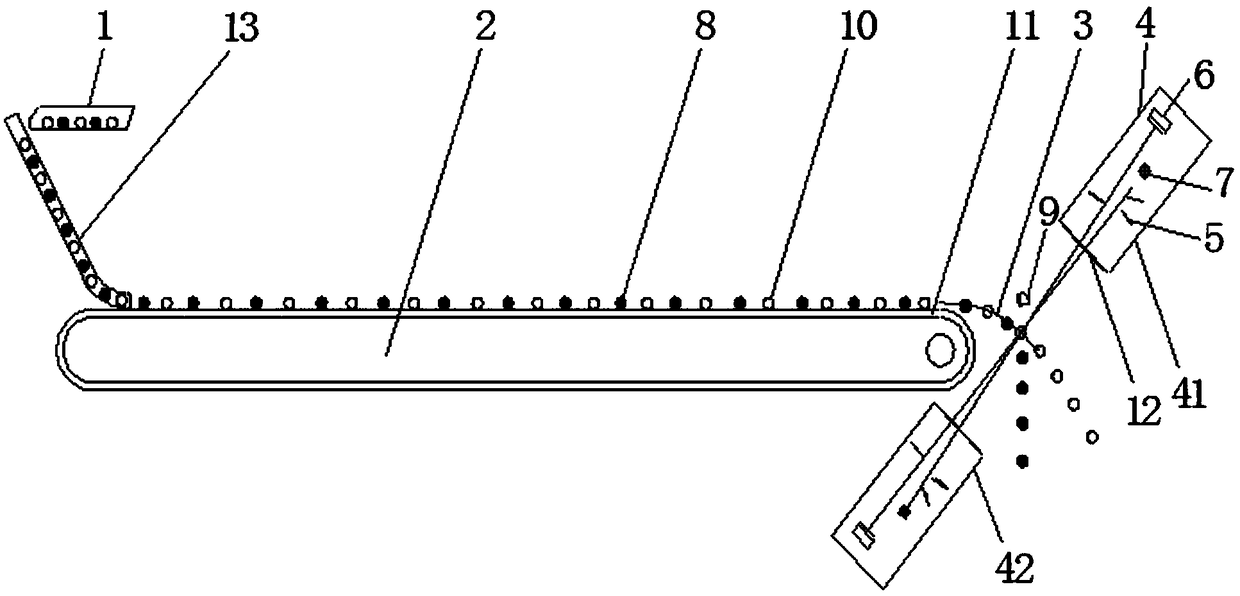

Visual inspection mechanism for use on color sorter

InactiveCN107064018AImprove imaging effectImprove color sorting effectInvestigation of vegetal materialOptically investigating flaws/contaminationVisual inspectionMechanical engineering

The invention discloses a visual inspection mechanism for use on a color sorter; the visual inspection mechanism comprises a conveying platform; a conveyer belt for conveying material is arranged on the conveying platform, a camera for monitoring the material is arranged above the conveyer belt, a reflector is arranged on one side of the conveyer belt, a backlight source is arranged on the other side of the conveyer belt, the reflector is connected to a mounting support that is fixed on a mounting plate, the mounting support comprises a connection block and a rotation block connected with the reflector, the rotation block is arranged in a rotation cavity of the connection block, a first spindle runs through the rotation block, a second spindle runs through the connection block, and the first spindle is perpendicular to the second spindle. The visual inspection mechanism is capable of monitoring the front and back of material at the same time, thereby arriving at better monitoring.

Owner:ANHUI JIEXUN OPTOELECTRONICS TECH

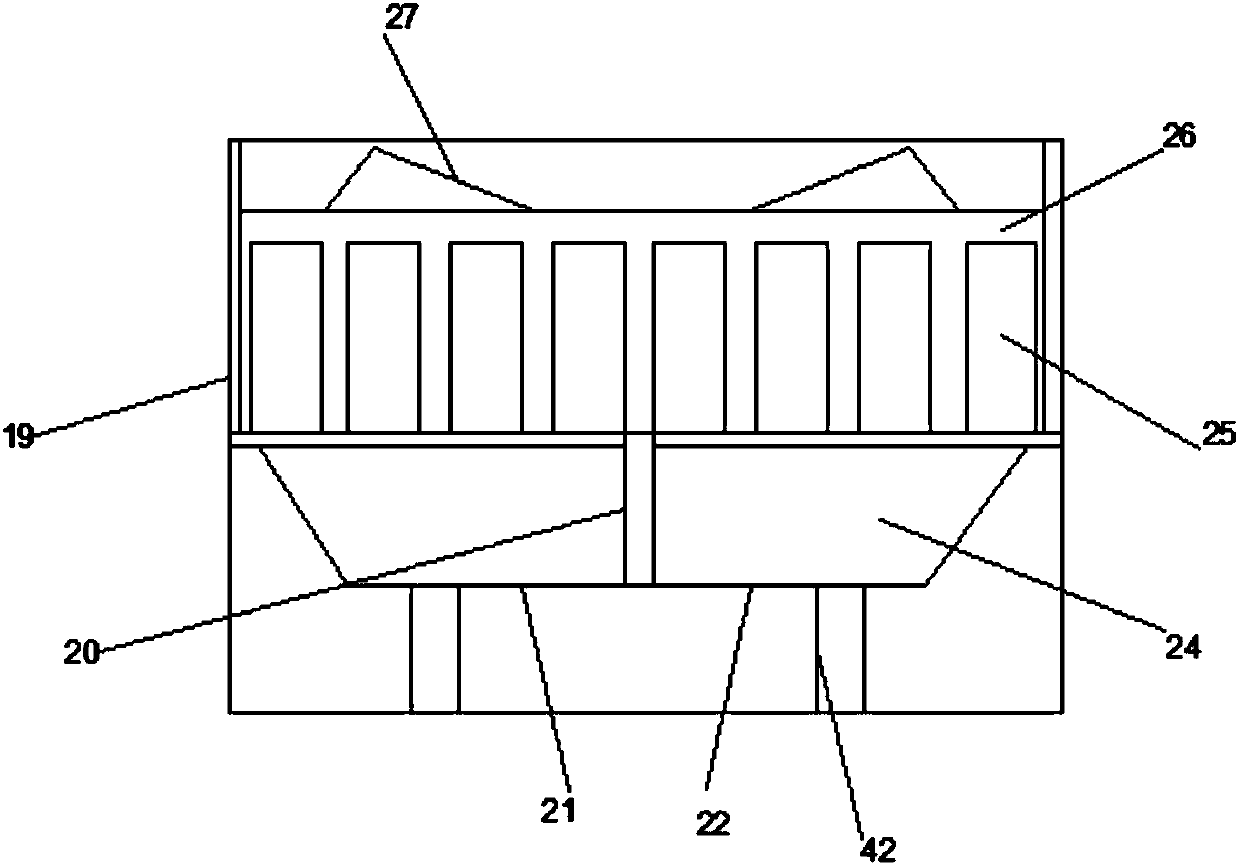

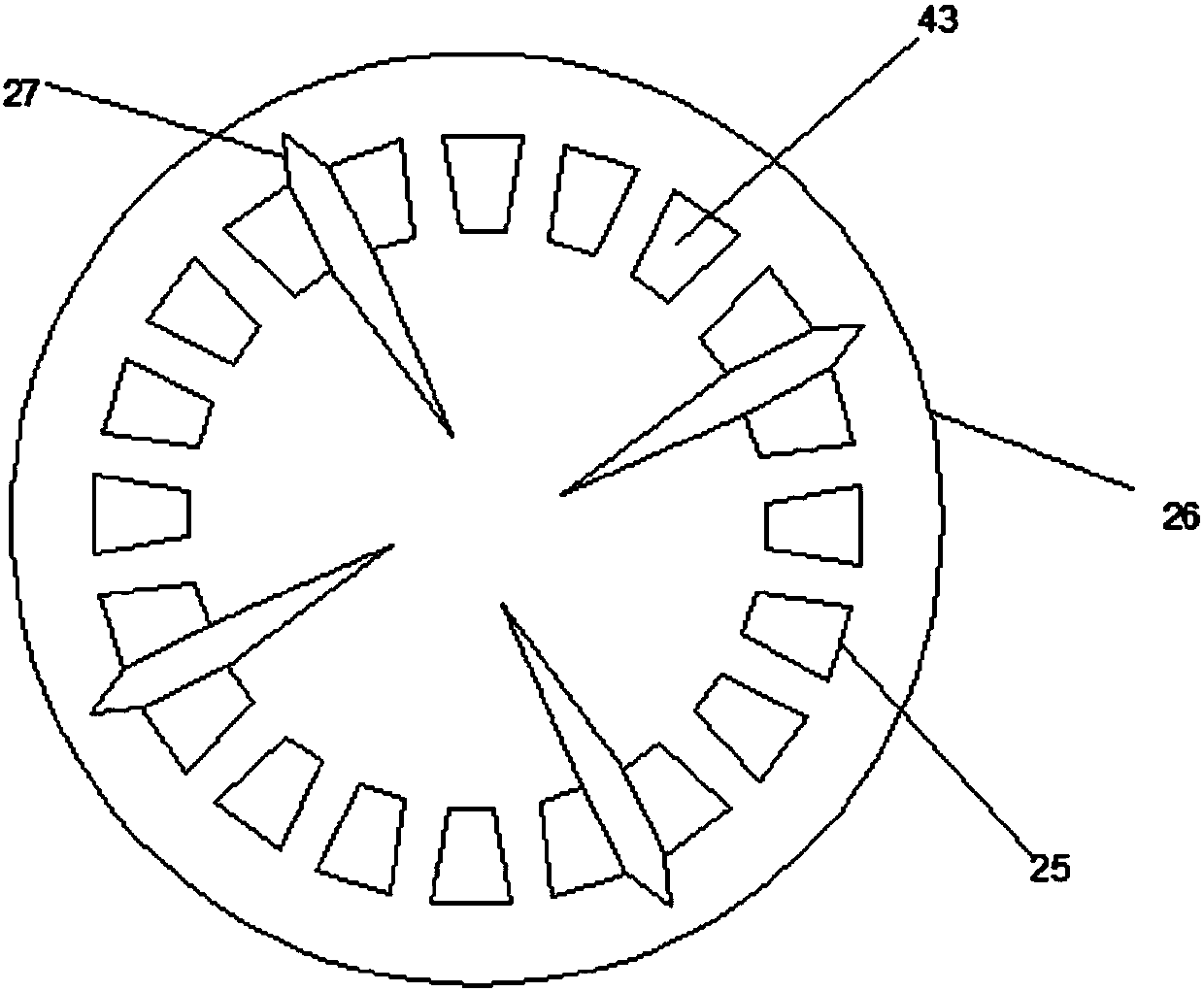

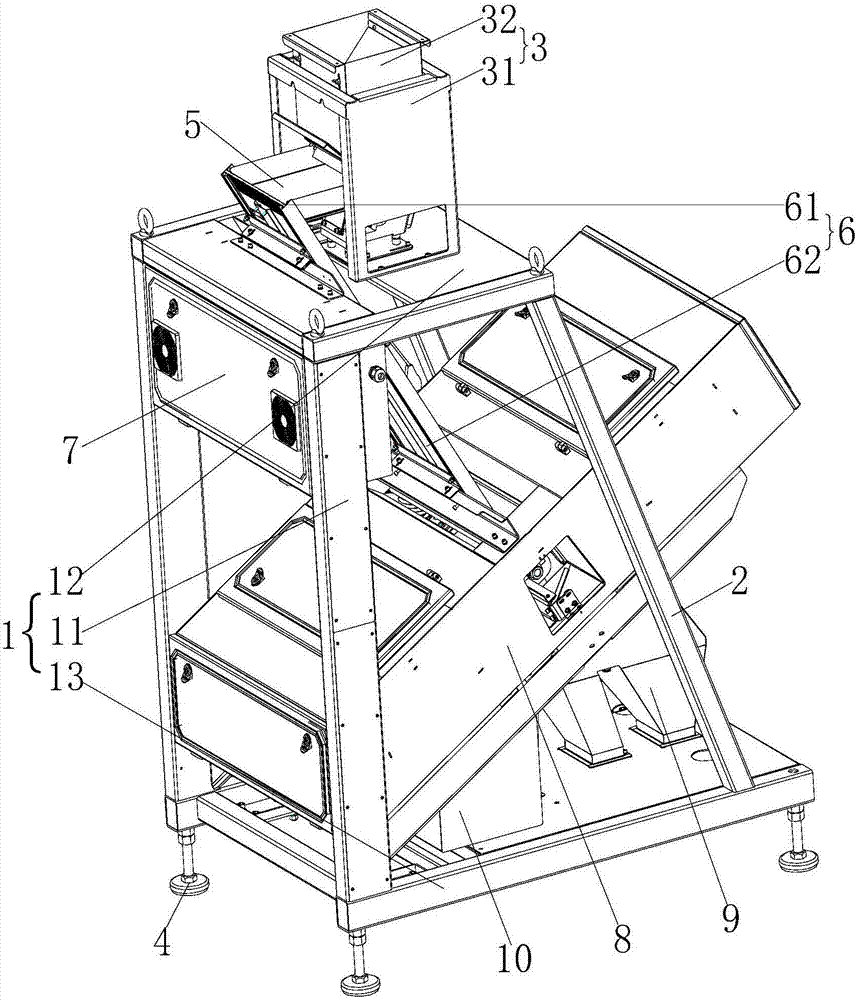

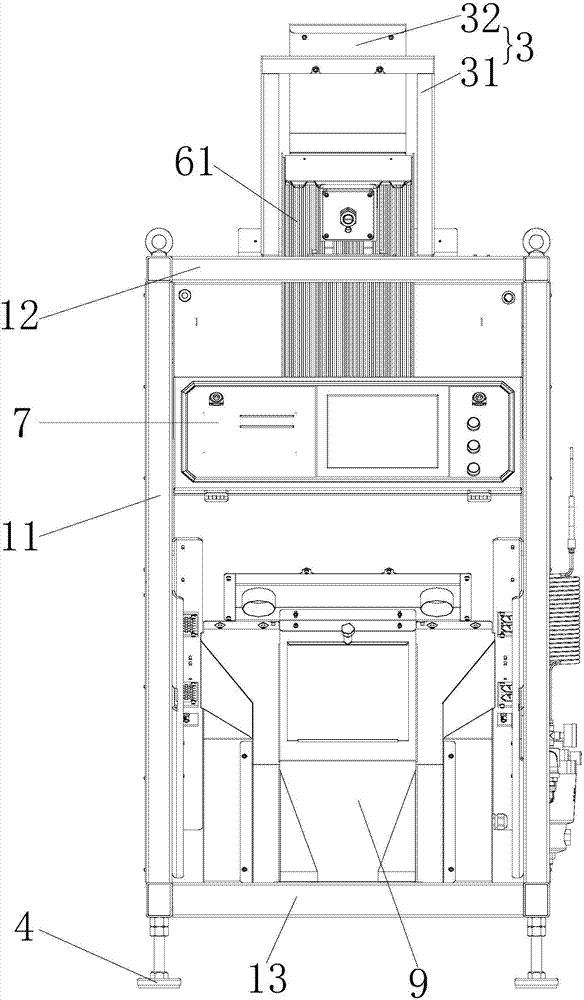

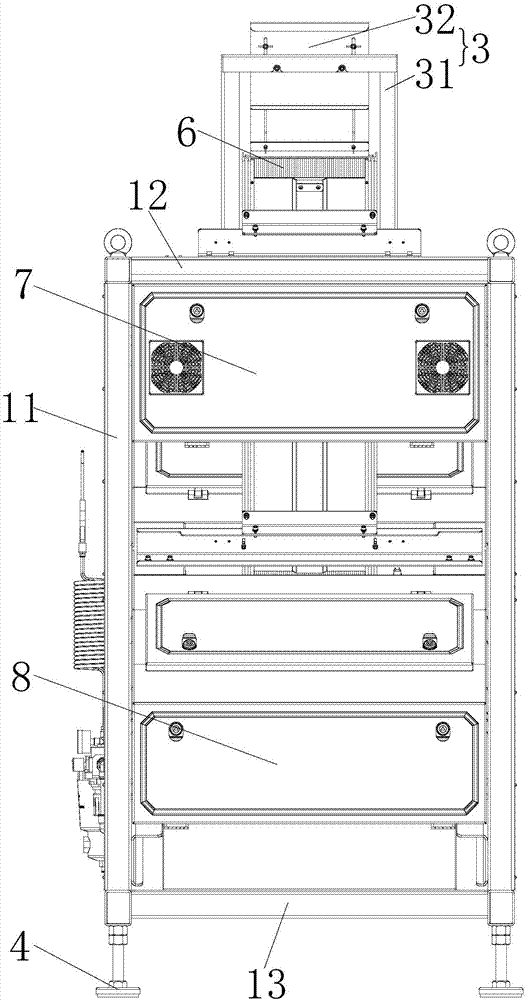

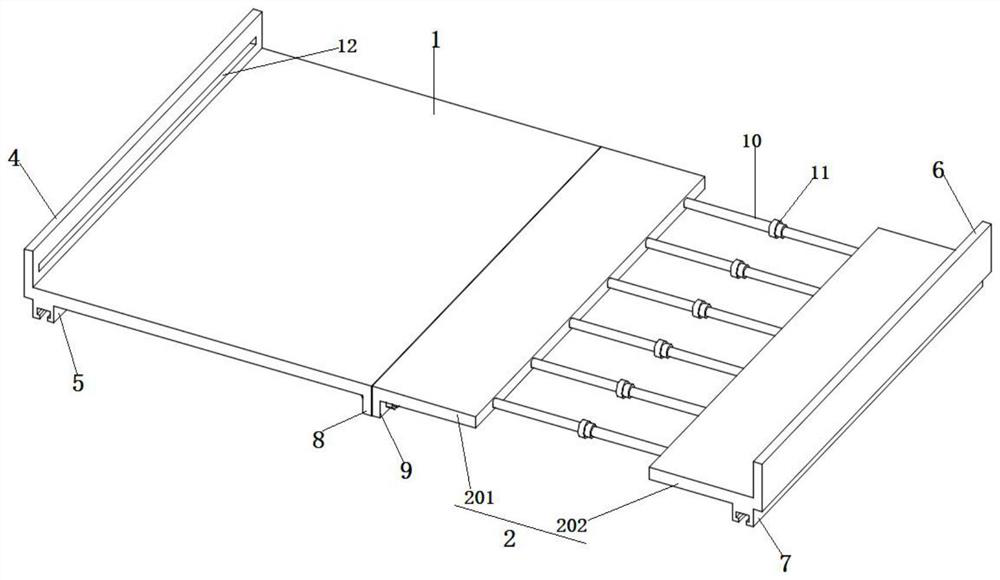

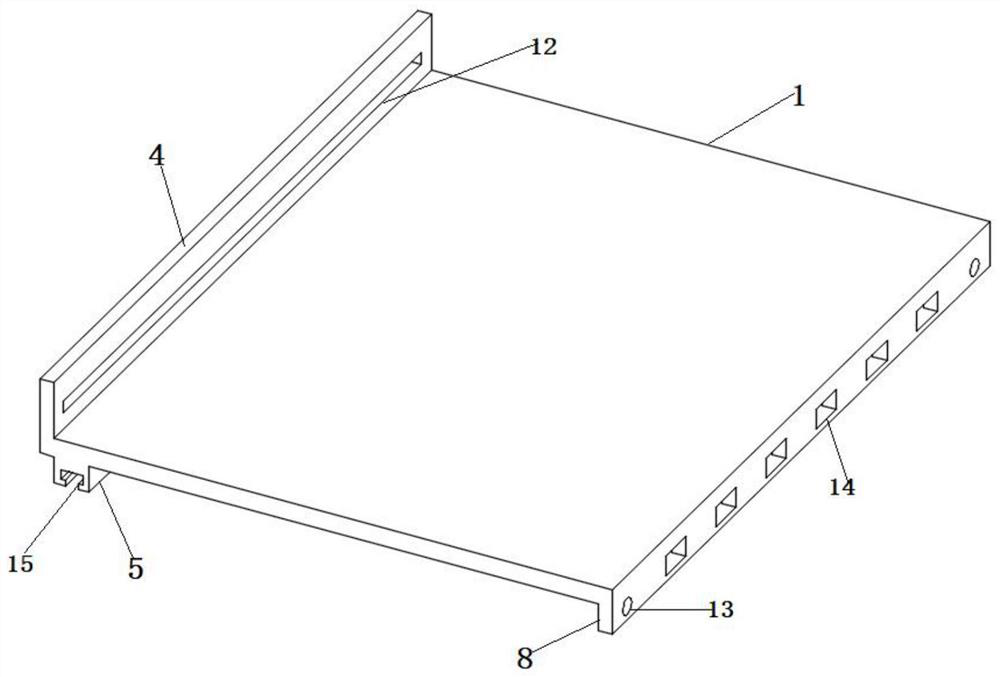

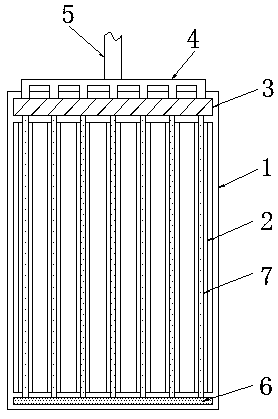

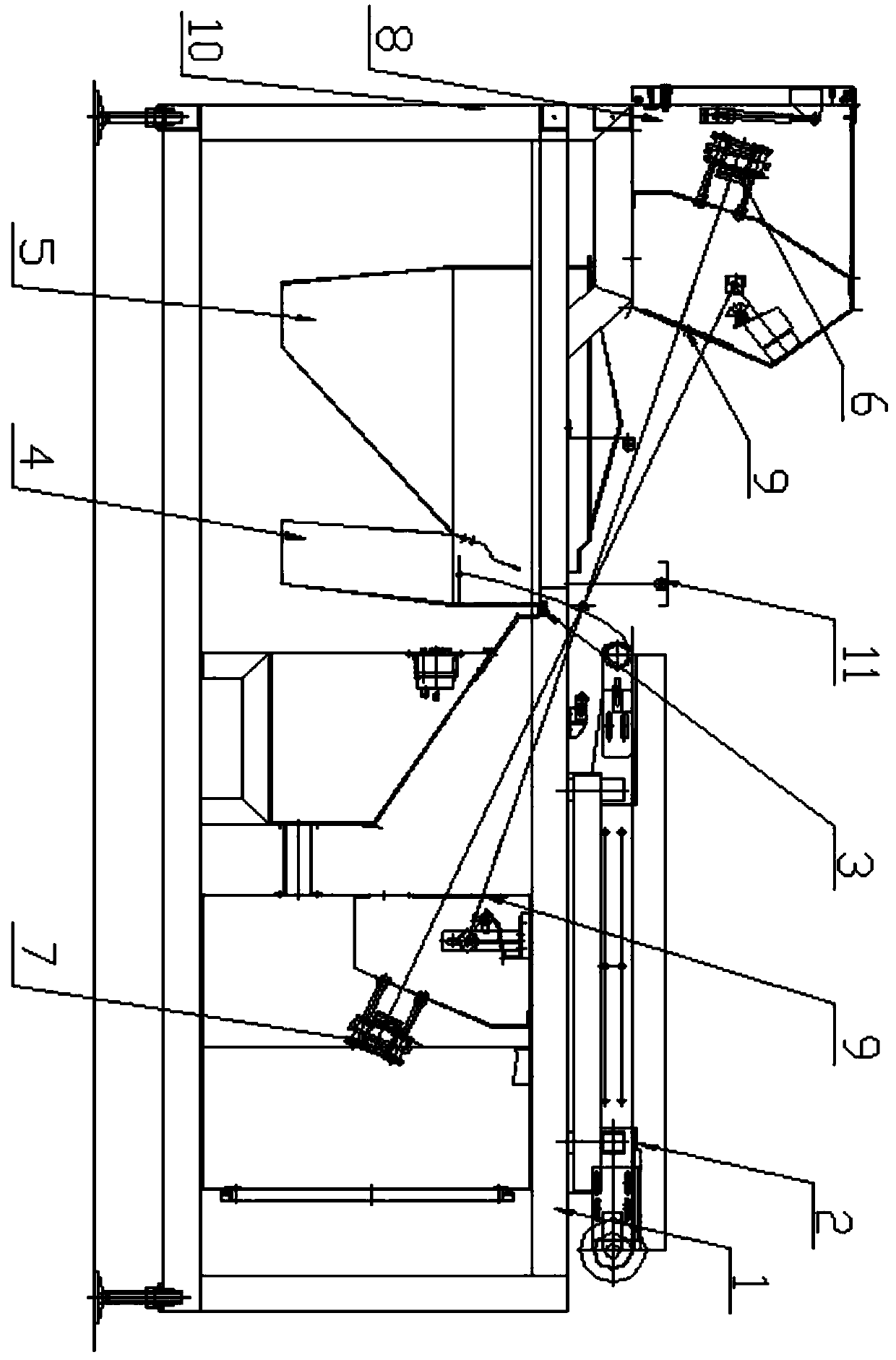

Assembled color sorter

The invention discloses an assembled color sorter. The assembled color sorter comprises a machine frame body, wherein a supporting beam is arranged on one side of the machine frame body, a feeding hopper device is arranged at the top of the machine frame body, and a vibrating hopper assembly and a trough device are arranged on the lower portion of the feeding hopper device; an electric control box and a sorting box are arranged on the upper portion and the lower portion of the inner sides of supporting columns, and a discharging hopper device and a valve seat box are arranged on the lower portion of the sorting box. The supporting beam and a bottom plate are arranged at the angle of 70 degrees, so the stretching-out length of the bottom plate is effectively reduced; meanwhile, the whole color sorter is compact in structure and small in occupied space, the space utilization rate is improved, and the manufacturing cost is reduced; through the feeding hopper device, the trough device, the discharging hopper device and the like which are arranged in sequence, continuous conveying of materials is realized, assembly line type work of the color sorter is facilitated, color sorting is quick, the labor intensity of workers is relieved, the work efficiency of the color sorter is improved, and the color sorting effect is good.

Owner:ANHUI HONGSHI ZIJING PHOTOELECTRIC INST

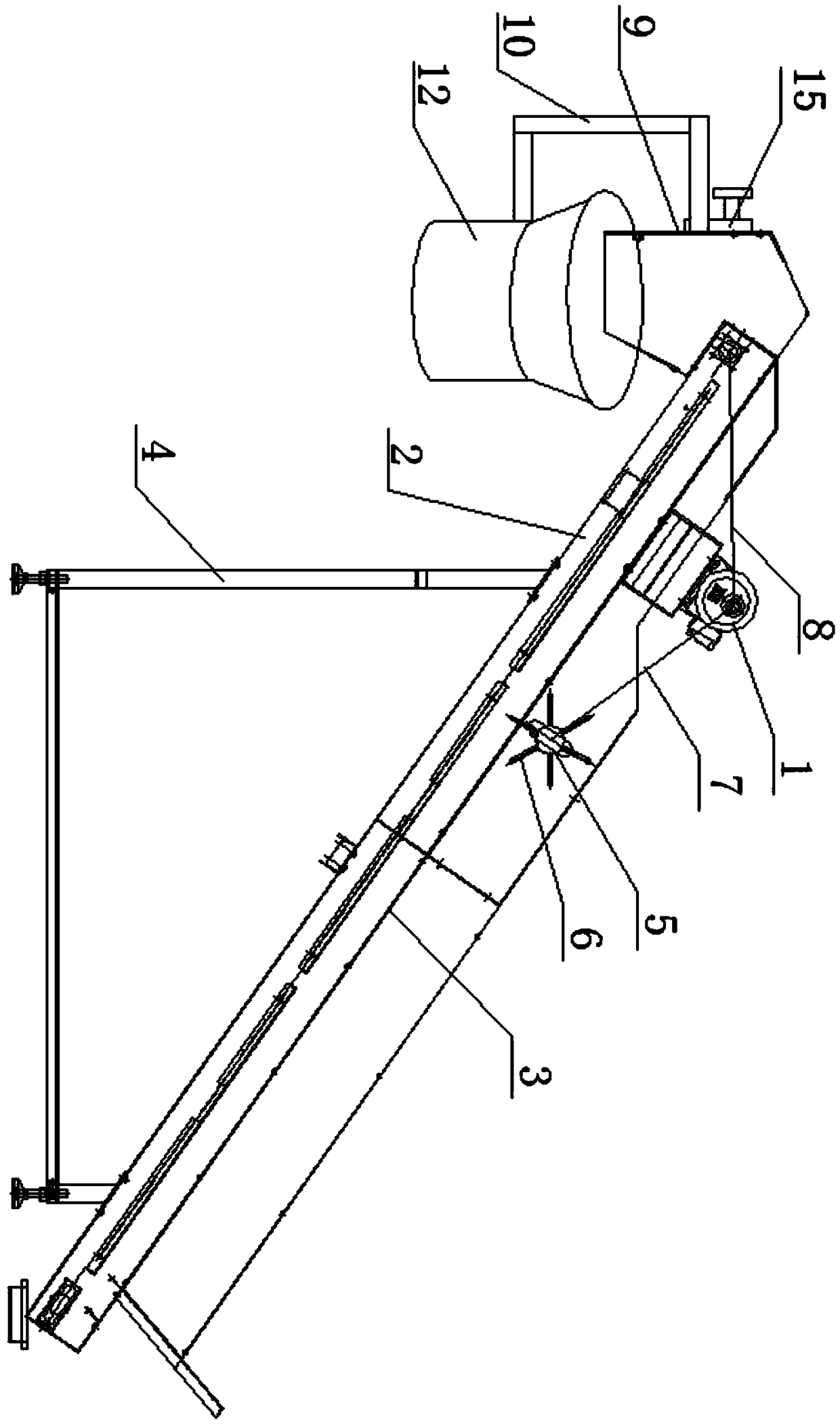

Tea feeding and conveying device

The invention discloses a tea feeding and conveying device. The tea feeding and conveying device is characterized in that the tea feeding and conveying device comprises a driving motor, a conveying device rack, a tea scattering assembly and a conveyor belt arranged on the conveying device rack; the conveyor belt is wound between a driving roller and a driven roller, and the conveying device rack is supported on the ground through supporting rods; a rotary shaft is arranged above the conveyor belt, and tea stirring rods are distributed on the surface of the rotary shaft; the driving motor drives the rotary shaft and the driving roller to rotate through a first transmission belt and a second transmission belt; a discharging hopper is connected to the upper portion of the conveyor belt, and the tea scattering assembly comprises a tea channel formed in the lower portion of the discharging hopper; and the tea channel is connected with the discharging hopper through a connecting piece, and blocking rods are distributed on the inner wall of the tea channel. According to the tea feeding and conveying device, feeding and transporting of tea can be achieved, and meanwhile the tea is carded and scattered in the transporting process, so that the color sorting effect of the tea is improved.

Owner:ANHUI JIEXUN OPTOELECTRONICS TECH

Feeding device of color sorter

InactiveCN110385285AImprove applicabilityEasy to handleLarge containersSortingEngineeringLarge particle

The invention discloses a feeding device of a color sorter. The feeding device of the color sorter comprises a material box, wherein an inclined plate is integrally shaped on the left side of the topend of the material box, a dust collection hood in a funnel shape is fixed on the inclined plate, an inlet of the dust collection hood communicates with an inner cavity of the material box, and is used for collecting dust, a feeding hopper fixedly connected with the top end of the inclined plate is arranged on the right side of the top end of the wide material box, the bottom end of the feeding hopper communicates with an inner cavity of the material box, sliding chutes are obliquely formed in right sides of inner walls of a front plate and a rear plate of the material box, and baffles are connected in the sliding chutes in the front plate and the rear plate in a sliding mode. The feeding device of the color sorter can effectively clear the dust entering materials in the material box, prevents the dust from shielding a lens of a camera, effectively improves color sorting effect, and meanwhile performs regulation on the baffles, can change the size of a feeding port so as to adapt to color sorting of different materials, prevents bridging in the color sorting of the large particle materials, and improves applicability of the color sorter.

Owner:ANHUI ZHONGKE OPTIC ELECTRONICS COLOR SORTER MACHINERY

Flexible feeding device

InactiveCN109956337AControl feed rateMeet the needs of useSortingLoading/unloadingElectric machineryLevel sensor

The invention discloses a flexible feeding device. The flexible feeding device comprises a feeding frame and a feeding hopper mounted on the feeding frame, a vibrating feeding device for receiving materials in the feeding hopper is arranged on the lower part of the feeding hopper and comprises a vibrating hopper and a vibrating motor fixedly connected to the vibrating hopper, the bottom of the vibrating hopper is connected to a fixed bottom plate through a vibrating spring, a material level sensor used for detecting the storage quantity of the materials in the feeding hopper is arranged on theouter side wall of the feeding hopper, and the material level sensor feeds back a detected material level signal to the vibrating feeding device and controls the vibrating frequency of the vibratingmotor. The vibrating frequency of the vibrating motor can be adjusted in real time according to the situation of the storage quantity of the materials in the feeding hopper, then the feeding rate of the vibrating feeding device is controlled, and the situation that the color sorting effect on the materials is seriously affected due to uneven feeding is avoided.

Owner:ANHUI JIEXUN OPTOELECTRONICS TECH

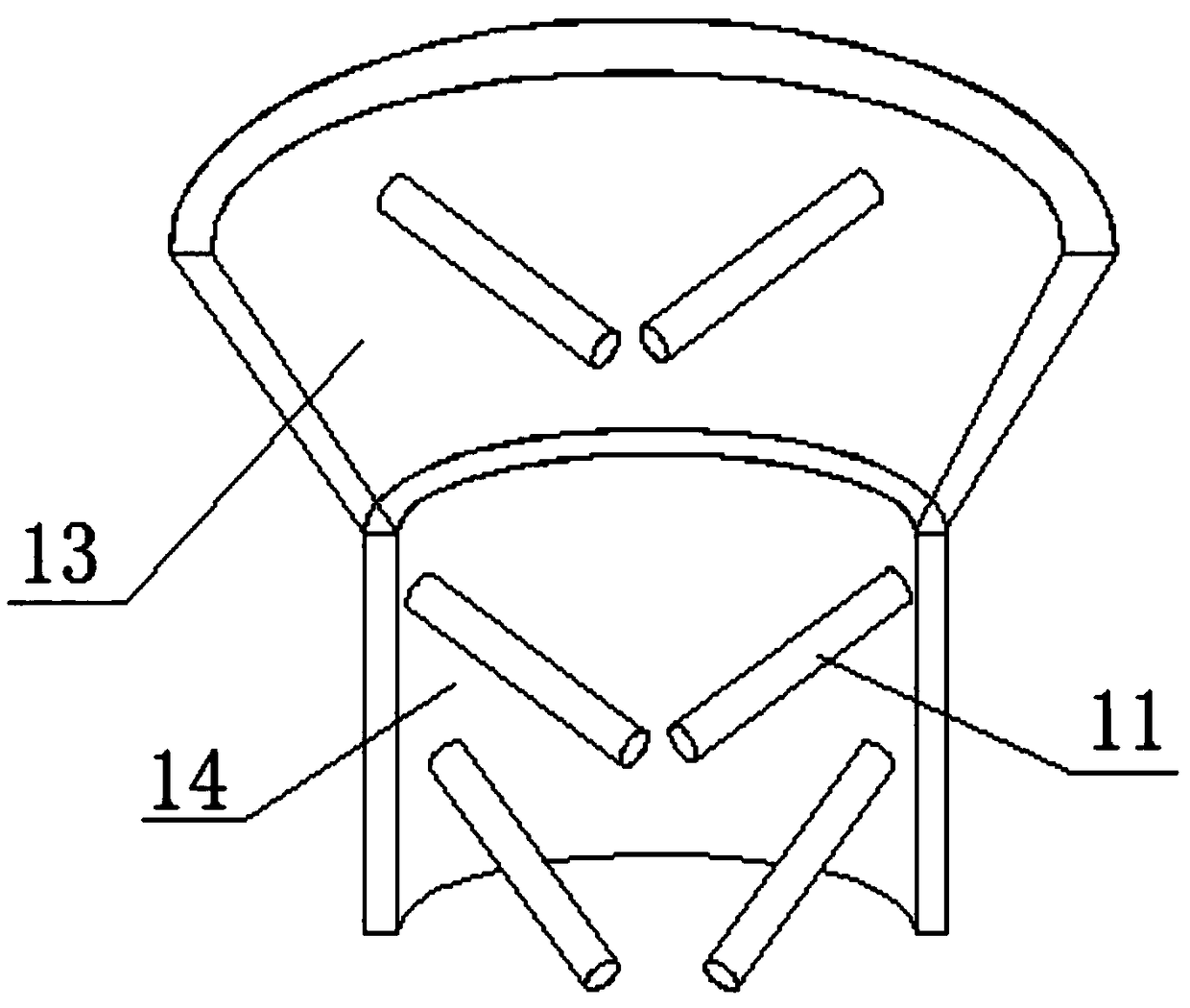

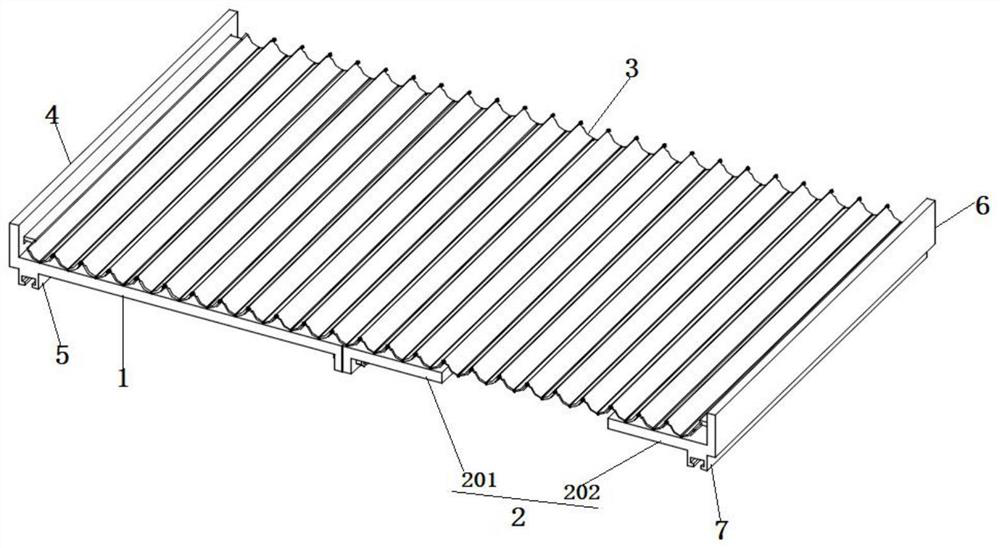

Combined material groove for tea color sorter

ActiveCN113649292AEasy to captureAdapt to flatnessPre-extraction tea treatmentSortingStructural engineeringMechanical engineering

Owner:ANHUI ZHONGKE OPTIC ELECTRONICS COLOR SORTER MACHINERY

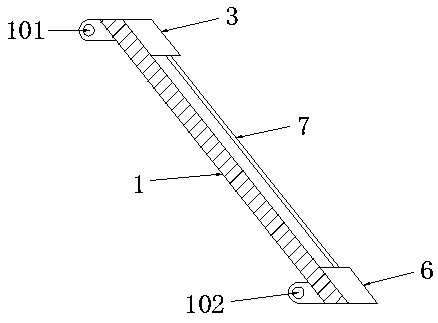

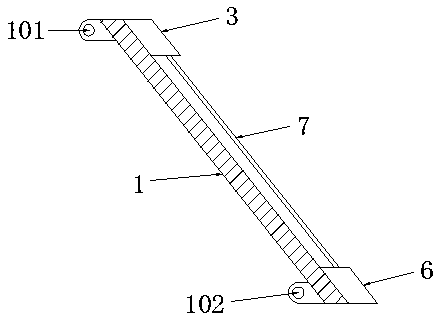

A chute with anti-jump function

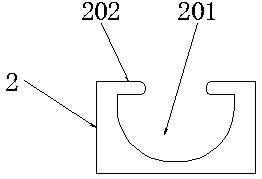

The invention discloses a sliding chute with a jump-out-of-chute preventing function, comprising a sliding chute body, and an upper connecting lug plate and a lower connecting lug plate which are mounted at the two ends of the sliding chute body, wherein skirts are arranged at the two sides of the sliding chute body, slideways are arranged on the surface of the sliding chute body, each slideway comprises a U-shaped groove and stoppers which are symmetrically arranged on the top end of the U-shaped groove, the top end of the sliding chute body is provided with an air blowing nozzle which is internally provided with air blowing holes, the air blowing holes inside the air blowing nozzle are connected with a child air inlet pipe, and the child air inlet pipe communicates with a mother air inlet tube. The sliding chute with the jump-out-of-chute preventing function is simple in structure and novel in design, the air blowing nozzle and a rubber strip can limit the material moving track, theair blowing nozzle can favorably form pressure above the slideways, and the rubber strip can rebound materials jumping out of the chute, so that the condition that the materials jump out of the chuteis prevented from occurring; and the slideway structure is improved, so that material is more uniformly stressed during downward sliding in the U-shaped grooves, the jumping rate of the materials is reduced, and the color sorting effect is improved.

Owner:ANHUI JIETAI INTELLIGENT TECH

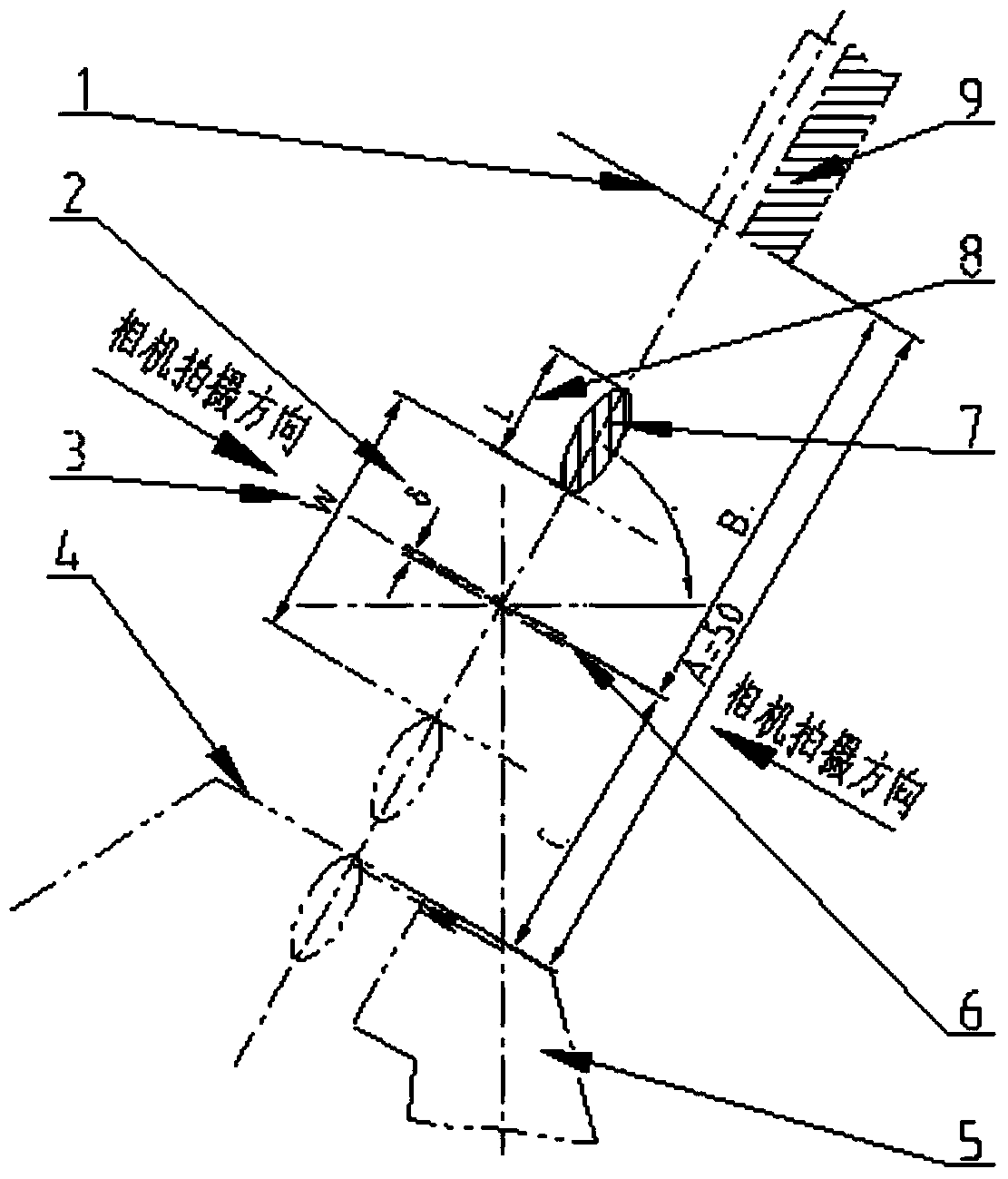

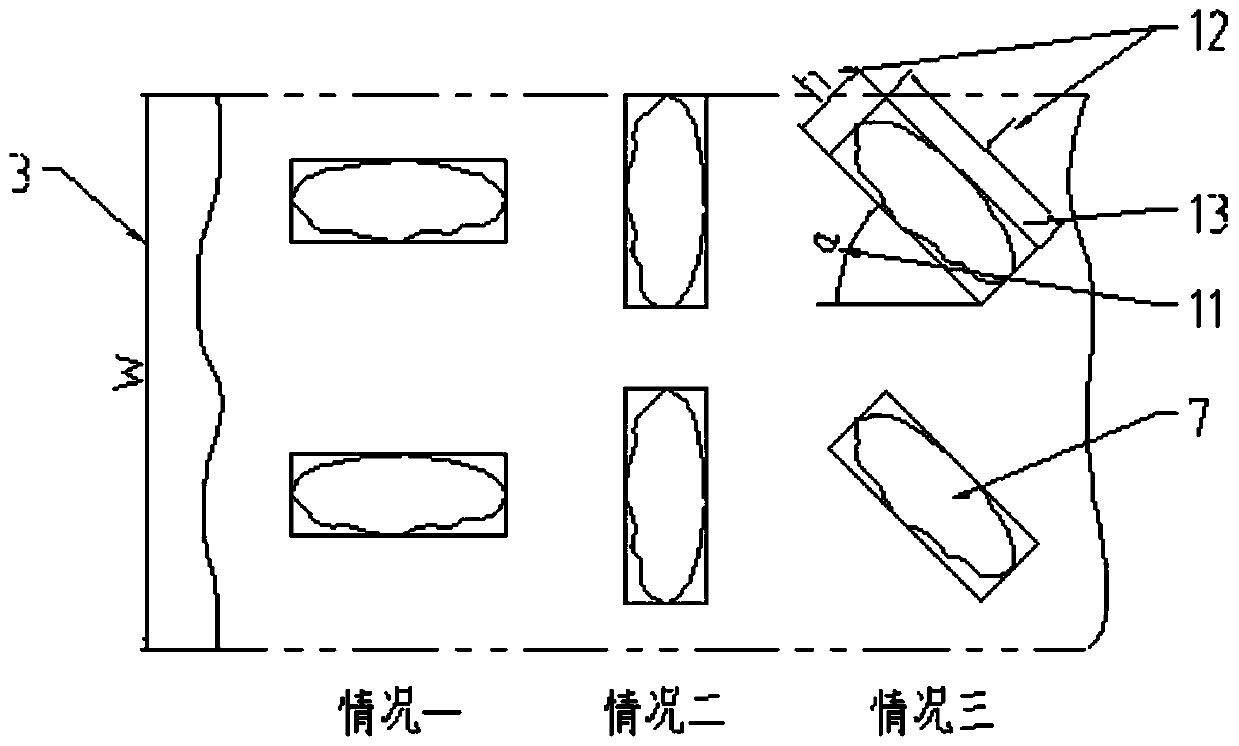

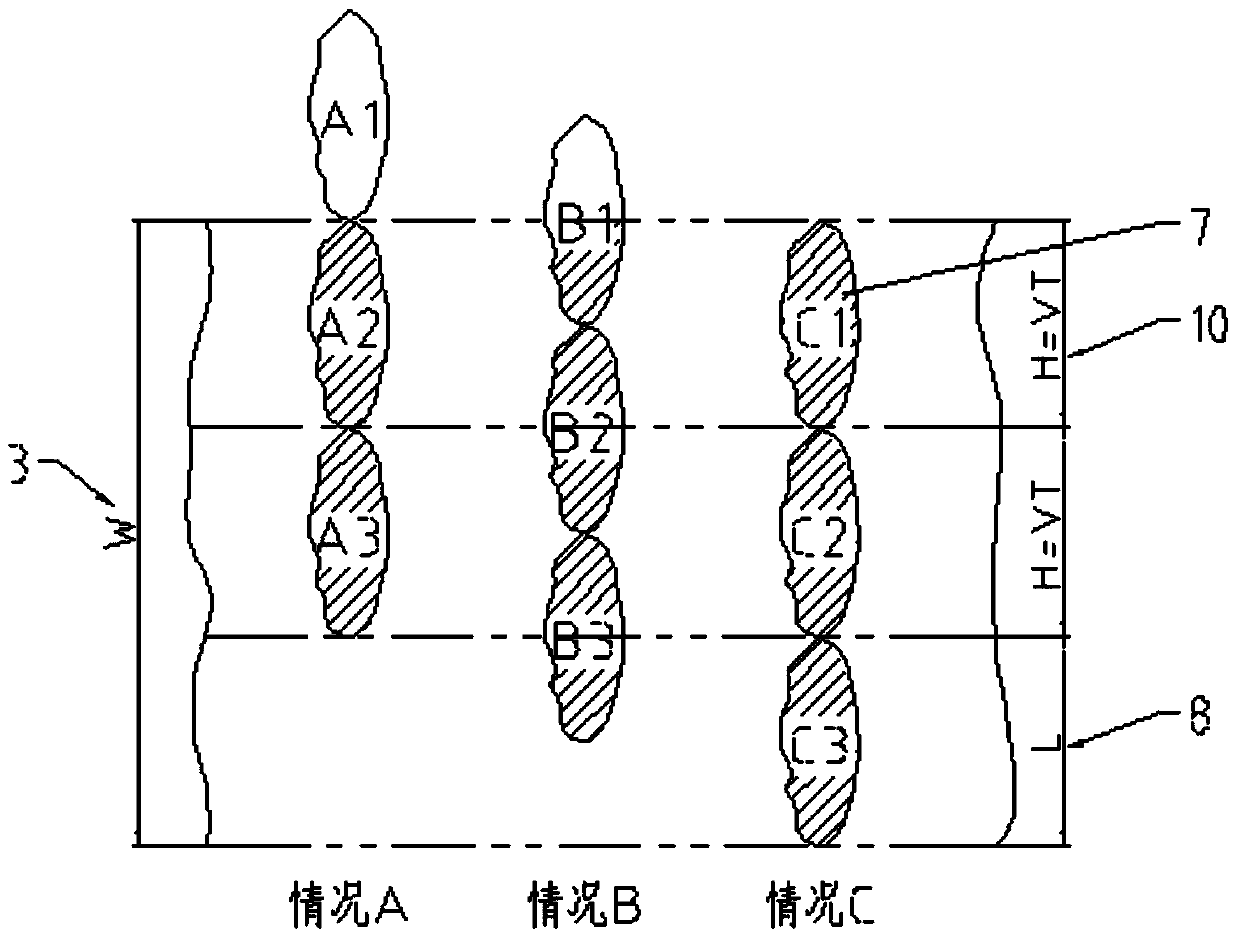

A speed measurement algorithm for automatic material identification of color sorter

ActiveCN105067836BAccurate removalImprove color sorting effectFluid speed measurementRecognition algorithmTime duration

The invention discloses an algorithm for automatic material identification and speed measurement of a color sorter, which comprises the following steps: (1) determining the shooting cycle, (2) determining the physical height of the shooting area, (3) determining the material identification method, (4) taking images: the same The material has been photographed at least twice in two adjacent cycles. (5) Speed measurement, through precise recognition algorithm, and setting a reasonable shooting cycle and physical height of the shooting area, to measure the real-time speed of each material , and then set the time point and duration of the spray valve action according to this speed and its position information, so that each material can be accurately removed, and the color sorting effect of the color sorter is greatly improved.

Owner:ANHUI VISION OPTOELECTRONICS TECH

Broken plastic color sorting device for recycling of waste lead-acid storage batteries

InactiveCN112372888AAdjustable speedSolve the problem that the speed cannot be adjustedPlastic recyclingWaste accumulators reclaimingProcess engineeringMechanical engineering

Owner:骆驼集团(安徽)再生资源有限公司

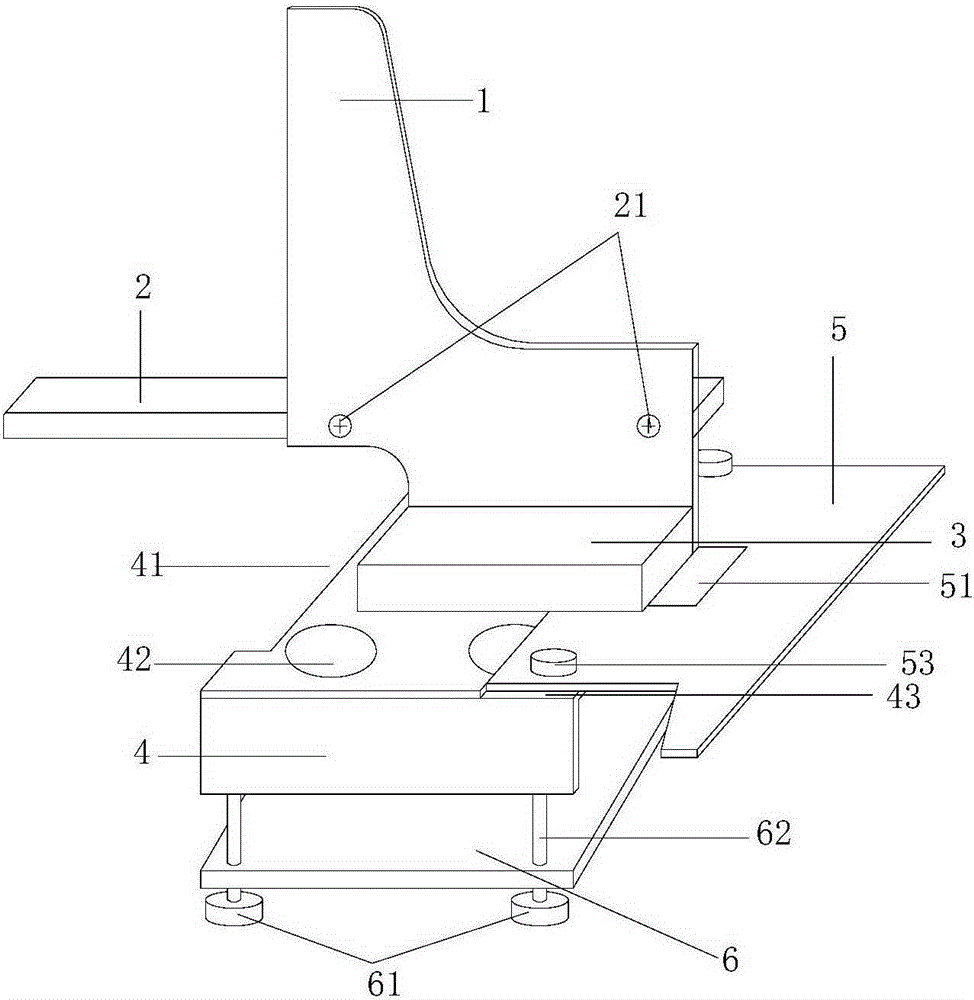

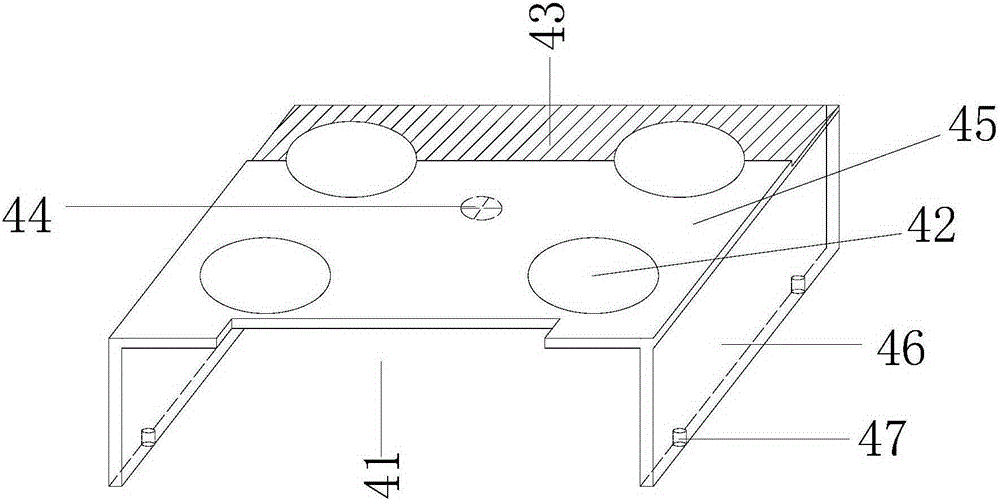

Mounting tool of slideway nozzle plate

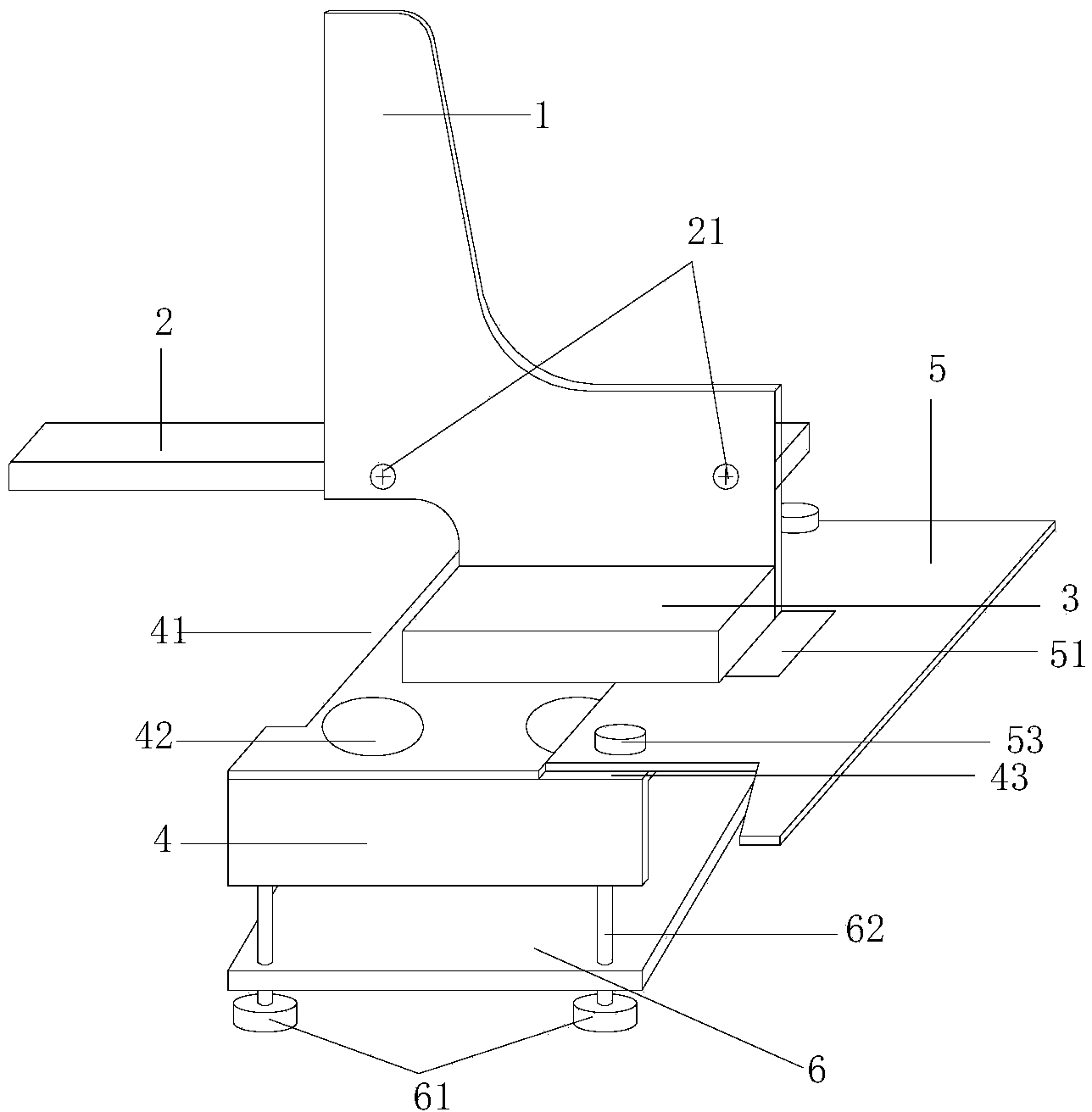

ActiveCN104339307AThe installation position is accurateUnified installation locationMetal-working hand toolsEngineeringPhysics

The invention discloses a mounting tool of a slideway nozzle plate, and belongs to the field of color sorter production. The tool comprises a bottom plate, a rack and an L-shaped plate, wherein a horizontally placed carrier plate is fixed at the upper part of the rear end surface of a transverse plate; the L-shaped plate is located on the rear end surface of a fixed block; the fixed block is located in the middle of a top plate; the rack consists of the top plate and two vertical stand plates located at the two ends of the top plate; two round holes symmetric to a longitudinal center line of the top plate are formed in the top plate and on the left side and the right side of the fixed block respectively; a first rectangular opening is formed in the middle of the left side of the top plate; a groove is formed on the right side of the top plate; an inserting plate is arranged among the groove, the fixed block and the L-shaped plate; a second rectangular opening is formed in the middle of the left side of the inserting plate; a trapezoid bulge is arranged at the front end of the right side of the inserting plate; and the bottom plate is arranged below the rack. The tool allows mounting positions of the nozzle plate and an air cylinder to be precise and unified, effectively improves a color sorting effect of a color sorter, and is simple in structure, low in cost and practical.

Owner:ANHUI JIEXUN OPTOELECTRONICS TECH

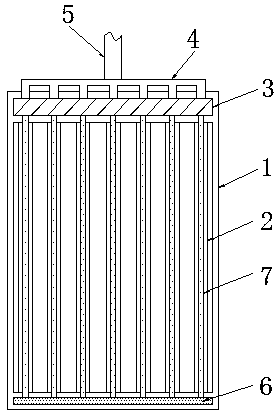

Sliding chute with jump-out-of-chute preventing function

The invention discloses a sliding chute with a jump-out-of-chute preventing function, comprising a sliding chute body, and an upper connecting lug plate and a lower connecting lug plate which are mounted at the two ends of the sliding chute body, wherein skirts are arranged at the two sides of the sliding chute body, slideways are arranged on the surface of the sliding chute body, each slideway comprises a U-shaped groove and stoppers which are symmetrically arranged on the top end of the U-shaped groove, the top end of the sliding chute body is provided with an air blowing nozzle which is internally provided with air blowing holes, the air blowing holes inside the air blowing nozzle are connected with a child air inlet pipe, and the child air inlet pipe communicates with a mother air inlet tube. The sliding chute with the jump-out-of-chute preventing function is simple in structure and novel in design, the air blowing nozzle and a rubber strip can limit the material moving track, theair blowing nozzle can favorably form pressure above the slideways, and the rubber strip can rebound materials jumping out of the chute, so that the condition that the materials jump out of the chuteis prevented from occurring; and the slideway structure is improved, so that material is more uniformly stressed during downward sliding in the U-shaped grooves, the jumping rate of the materials is reduced, and the color sorting effect is improved.

Owner:ANHUI JIETAI INTELLIGENT TECH

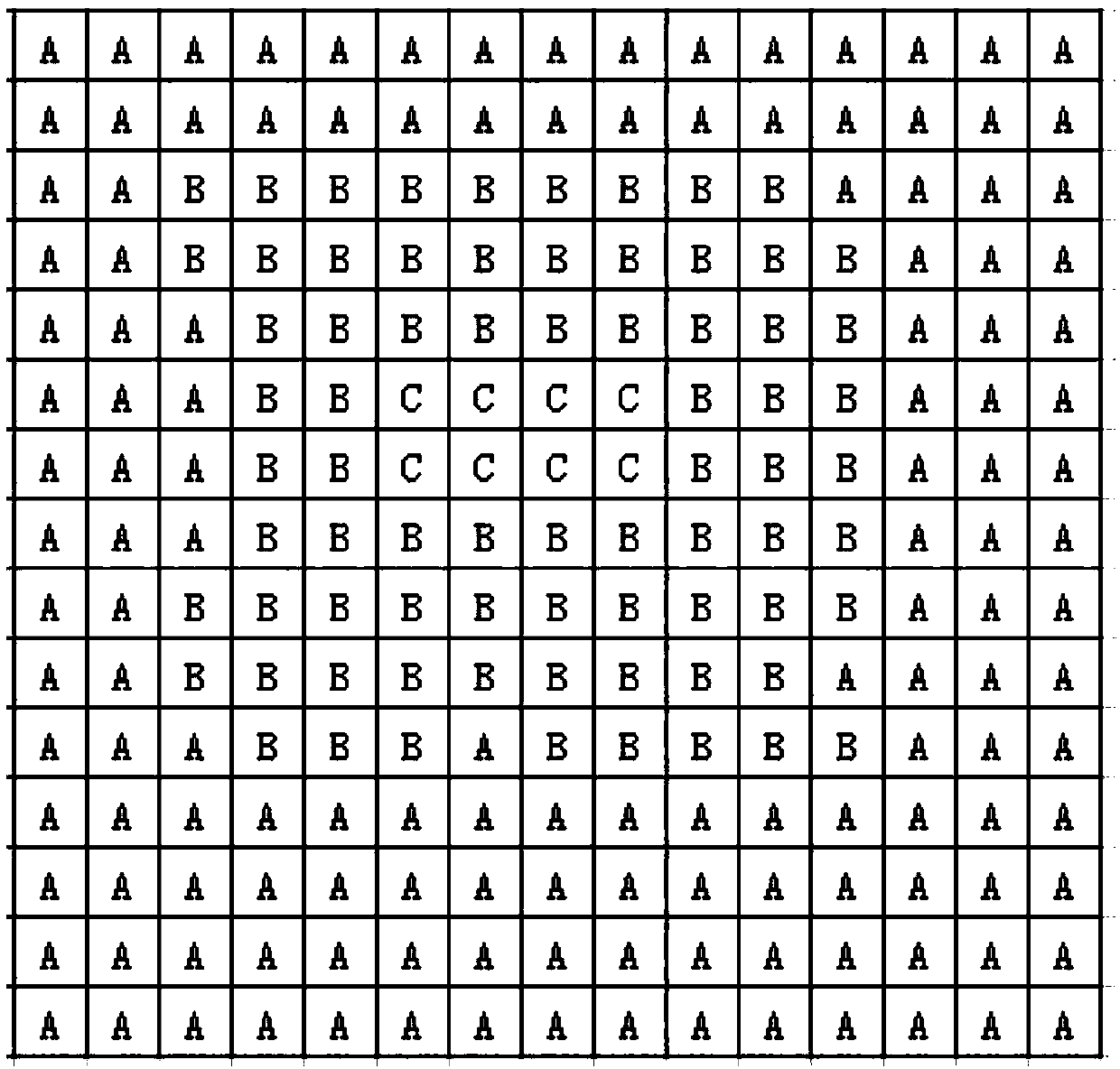

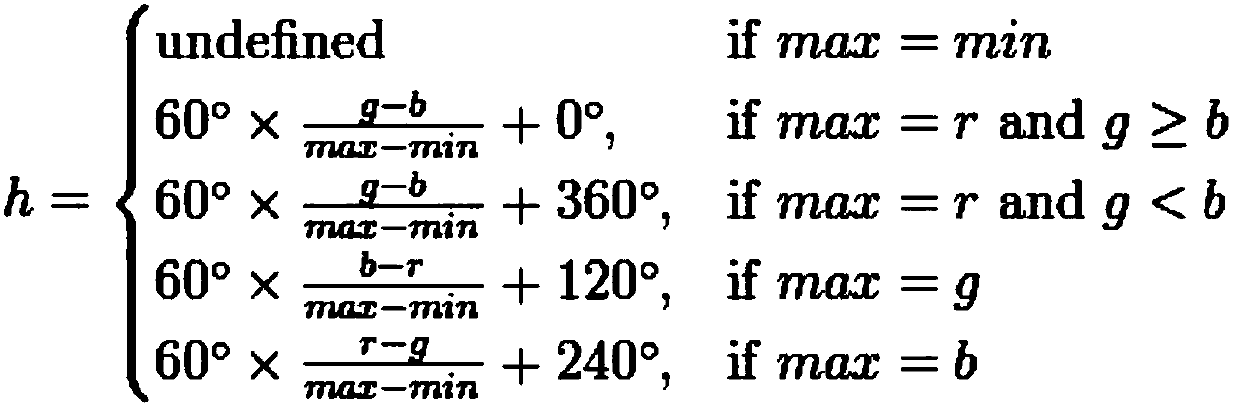

An Algorithm for an Intelligent Color Sorter

InactiveCN107081281BImprove color sorting accuracyPrecision strikeSortingPattern recognitionColor signal

The invention discloses an algorithm of an intelligent color selector. The algorithm comprises the following steps that 1, signals are collected, particularly, a CCD sensor on the color selector is used for collecting alternative material signals, and the alternative material signals at least comprise alternative material color signals; 2, the signals are decomposed, particularly, a processor is set for processing the alternative material color signals, and the alternative color signals are decomposed to be R grey scale signals, G grey scale signals and B grey scale signals; 3, the signals are processed, particularly, an algorithm rule device is set for receiving the R grey scale signals, the G grey scale signals and the B grey scale signals; and the R grey scale signals, the G grey scale signals and the B grey scale signals are calculated respectively according to the algorithm rule. The color selection precision is high, beating is accurate, precision beating can be carried out on various kinds of materials during coarse cereal color selection and industrial color selection, and the color selection effect is good.

Owner:ANHUI BIDA OPTOELECTRONICS TECH

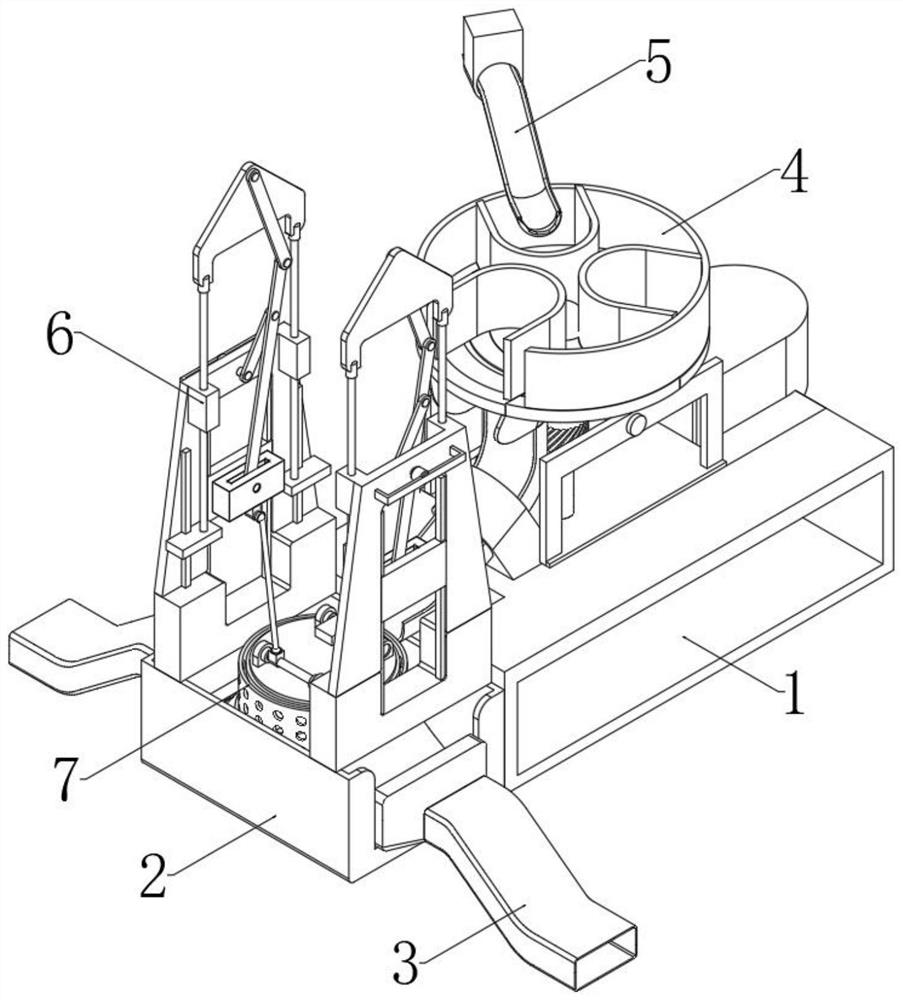

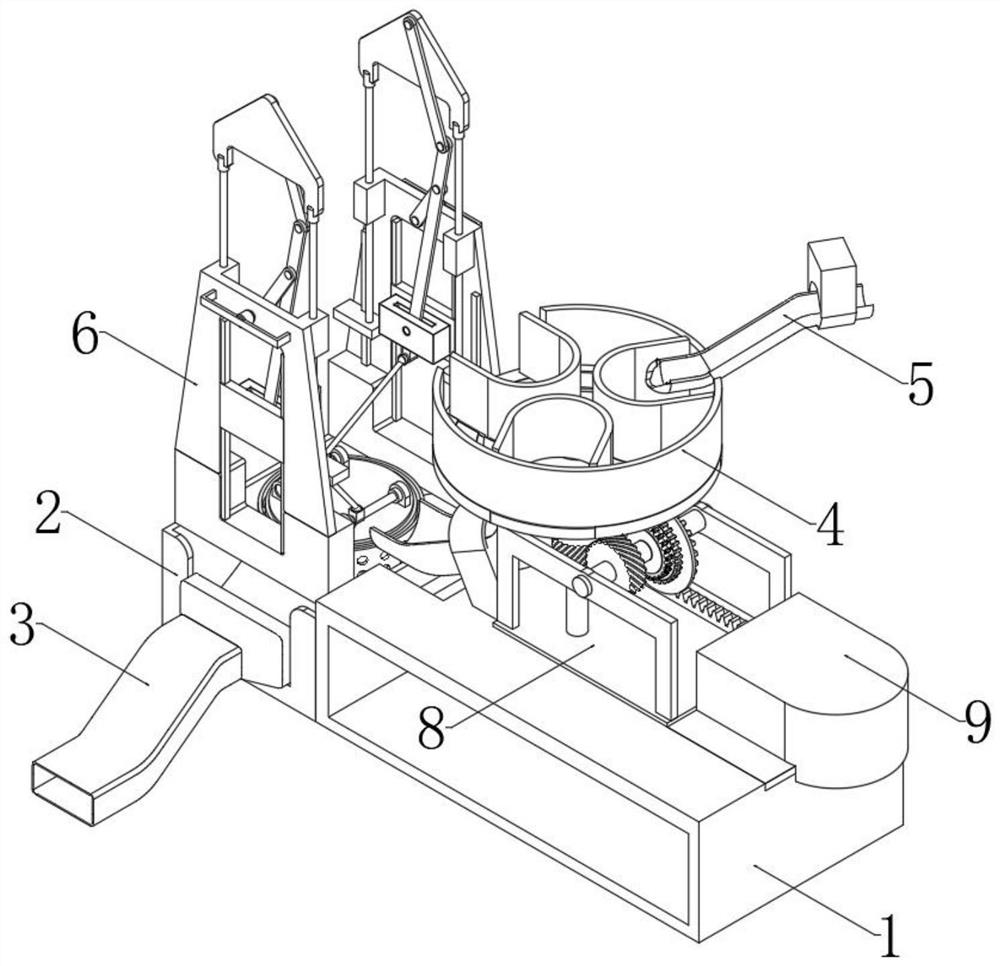

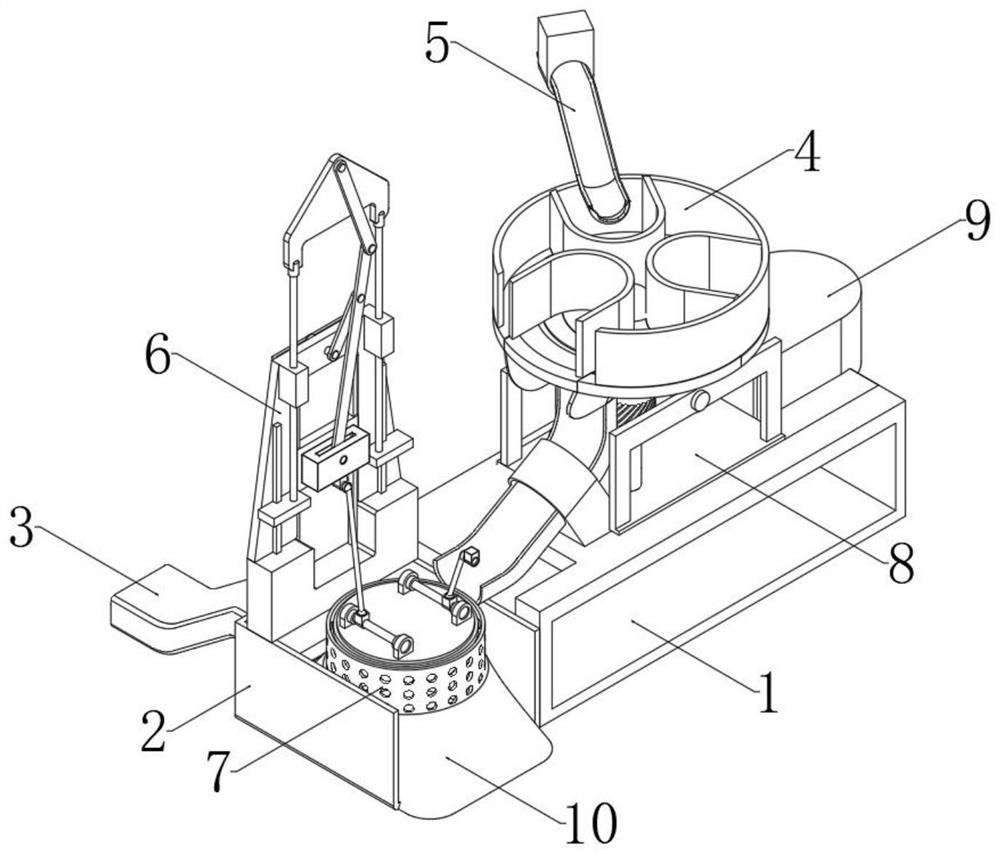

Feeding device for marine product color sorter

PendingCN113828535ARealize batch transportationImprove color sorting effectDrying solid materials without heatSortingEngineeringMechanical engineering

The invention discloses a feeding device for a marine product color sorter, and belongs to the technical field of material conveying of color sorters. The feeding device for the marine product color sorter comprises a mounting box, wherein the front side of the mounting box is fixedly connected with a receiving box, and the lower side of the receiving box is connected with a feeding pipe; blow-off pipes are arranged at the two sides of the receiving box, and a dirt collecting box is arranged at the tail end of each blow-off pipe; a material distributing assembly is arranged above the mounting box, a material conveying pipe is arranged above one side of the material distributing assembly, the material conveying pipe is in butt joint with a discharging port in the previous working procedure, a lifting assembly is arranged above the bearing box, and a transmission assembly is arranged in the center of the upper portion of the mounting box; and the material distributing assembly comprises a transmission disc, three groups of material distributing parts are fixedly installed on the transmission disc, a material limiting ring is arranged on the transmission disc in a sliding manner, and the periphery of the rear side of the material limiting ring is fixedly connected with the upper side of the mounting box through fixing parts. According to the feeding device, the problem that in the prior art, because dewatering cannot be conducted during marine product color sorting feeding, the working efficiency is low is solved.

Owner:合肥峻茂视觉科技有限公司

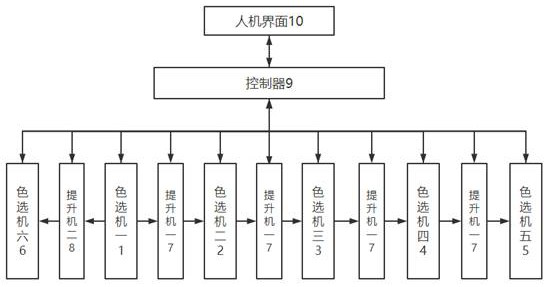

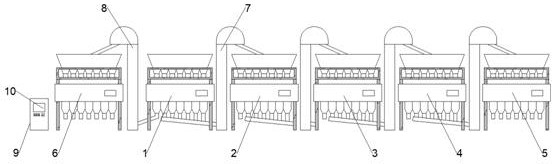

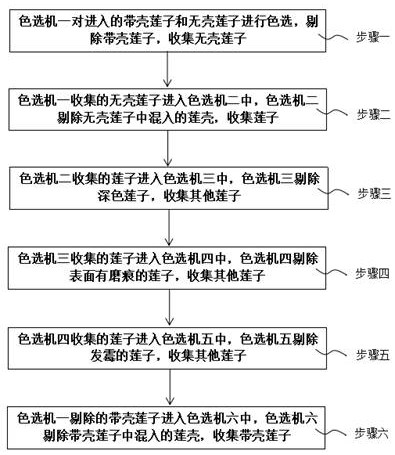

Color sorting system and method for lotus seed processing

The invention discloses a color sorting system and method for lotus seed processing, the color sorting system comprises a controller and a color sorter 1, a color sorter 2, a color sorter 3, a color sorter 4, a color sorter 5 and a color sorter 6 which are electrically connected with the controller, and the controller is provided with a human-computer interface. The color sorting method comprises the following steps that the first color sorter removes lotus seeds with shells; the color sorter II removes lotus shells in the shell-free lotus seeds collected by the color sorter I; the third color selector removes dark lotus seeds in the lotus seeds collected by the second color selector; the fourth color sorter removes the lotus seeds with grinding cracks on the surfaces in the lotus seeds collected by the third color sorter; the fifth color sorter removes moldy lotus seeds in the lotus seeds collected by the fourth color sorter; and the sixth color sorter performs color sorting on the lotus seeds with the shells removed by the first color sorter, and connected shells are removed. According to the color sorting device, lotus seeds with shells, lotus shells, dark lotus seeds, lotus seeds with grinding cracks on the surfaces and mildewed lotus seeds can be conveniently removed in sequence, the color sorting efficiency is improved, and the color sorting effect is good.

Owner:湖北联创食品有限公司

Double-sight-glass sorting box for color sorter

InactiveCN105516623ATo achieve the purpose of color selectionImprove color sorting effectTelevision system detailsColor television detailsInfraredEngineering

The invention discloses a double-sight-glass sorting box for a color sorter. The double-sight-glass sorting box comprises a sorting box body, wherein a hollow panel is arranged in the middle of the sorting box body, a balance reinforcing pillar is erected above the hollow panel, a first infrared camera and a second infrared camera are installed on the upper left corner and the upper right corner of the hollow panel respectively, and a first common camera and a second common camera are installed on the lower left corner and the lower right corner of the hollow panel respectively. By additionally arranging the infrared cameras on the front side and the back side of the sorting box, the density change of materials can be sensed by the color sorter in a crossing mode through infrared rays so that color sorting can be achieved, and the infrared cameras especially aim at glass, stone and mildewed materials which can not be recognized by common cameras.

Owner:ANHUI JIEXUN OPTOELECTRONICS TECH

Foreign body removal device on color sorter

InactiveCN108672323AImprove color sorting efficiency and color sorting effectReduce dustSortingCamera lensLeather belt

The invention discloses a foreign body removal device on a color sorter. The foreign body removal device comprises a device rack, a belt conveyor and two groups of long object distance lenses, and a nozzle used for removing foreign bodies is arranged below one end of the belt conveyor; a finished product hopper used for receiving finished materials, and a waste hopper used for receiving the foreign bodies are arranged below one side of the nozzle; the two groups of the long object distance lenses are the first group of long object distance lenses and the second group of long object distance lenses separately, and the first group of the long object distance lenses and the second group of the long object distance lenses are arranged above the part in front of the nozzle and below the part behind the nozzle separately; the two groups of the long object distance lenses are arranged in a lens dust-proof room, and the side, facing the nozzle, of the lens dust-proof room is provided with sight glass; and the lens dust-proof room is arranged on the device rack supported on ground through support legs. According to the foreign body removal device, the foreign bodies in the materials can beremoved, and the distance between the long object distance lenses and the materials is far, so that dust on the sight glass can be reduced, and the sight glass is prevented from being damaged.

Owner:ANHUI JIEXUN OPTOELECTRONICS TECH

A slideway nozzle plate installation tool

ActiveCN104339307BThe installation position is accurateUnified installation locationMetal-working hand toolsTransverse planeEngineering

The invention discloses a mounting tool of a slideway nozzle plate, and belongs to the field of color sorter production. The tool comprises a bottom plate, a rack and an L-shaped plate, wherein a horizontally placed carrier plate is fixed at the upper part of the rear end surface of a transverse plate; the L-shaped plate is located on the rear end surface of a fixed block; the fixed block is located in the middle of a top plate; the rack consists of the top plate and two vertical stand plates located at the two ends of the top plate; two round holes symmetric to a longitudinal center line of the top plate are formed in the top plate and on the left side and the right side of the fixed block respectively; a first rectangular opening is formed in the middle of the left side of the top plate; a groove is formed on the right side of the top plate; an inserting plate is arranged among the groove, the fixed block and the L-shaped plate; a second rectangular opening is formed in the middle of the left side of the inserting plate; a trapezoid bulge is arranged at the front end of the right side of the inserting plate; and the bottom plate is arranged below the rack. The tool allows mounting positions of the nozzle plate and an air cylinder to be precise and unified, effectively improves a color sorting effect of a color sorter, and is simple in structure, low in cost and practical.

Owner:ANHUI JIEXUN OPTOELECTRONICS TECH

Impurity identification and elimination structure on color sorter

The invention discloses an impurity identification and elimination structure on a color sorter. The impurity identification and elimination structure comprises a laser head assembly and a nozzle assembly used for eliminating impurities, wherein the nozzle assembly comprises a nozzle rear cover and a nozzle formed in the nozzle rear cover; the nozzle is connected to a nozzle installation cross beam; the nozzle installation cross beam is connected with a nozzle adjustment plate used for adjusting the angle of the nozzle; an illumination lamp and a background lamp are arranged at the two sides ofthe nozzle separately; the laser head assembly comprises a laser head and a laser head support; the upper end of the laser head support is connected with a color sorter rack; the lower end of the laser head support is connected with a laser head installation plate; a laser head installation hole used for placing the laser head is formed in the laser head installation plate; and a laser head coverplate is arranged at the outer end of the laser head. The impurity identification and elimination structure disclosed by the invention is capable of eliminating foreign matters such as peanuts or soybeans with interior mildew, and good in color sorting effect.

Owner:ANHUI JIEXUN OPTOELECTRONICS TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com