Feeding device for marine product color sorter

A technology of feeding device and color sorter, which is applied in the direction of drying solid materials, drying solid materials without heating, lighting and heating equipment, etc., and can solve problems such as low work efficiency and inability to dehydrate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

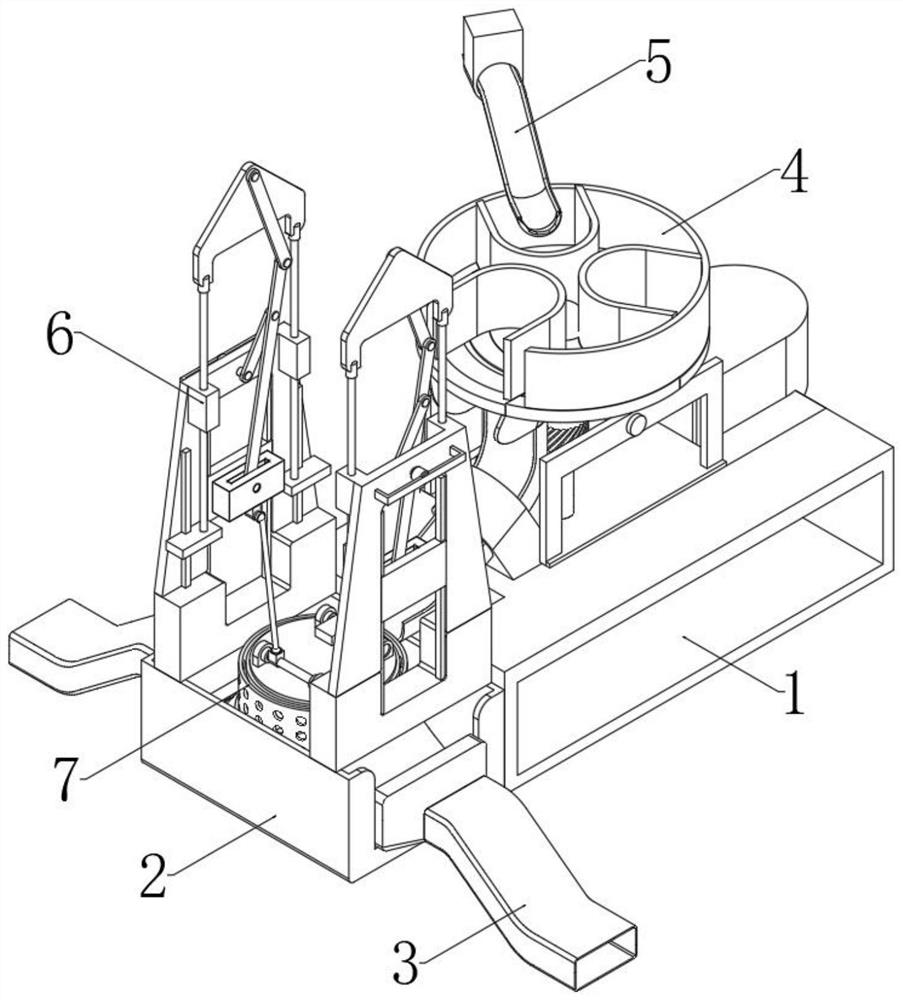

[0037] see Figure 1-5 , a feeding device for a seafood color sorter, comprising an installation box 1, the front side of the installation box 1 is fixedly connected with a receiving box 2, and the lower side of the receiving box 2 is connected to a feeding pipe; both sides of the receiving box 2 are provided with sewage discharge pipes 3 , the end of the sewage pipe 3 is provided with a sewage collection box; the top of the installation box 1 is provided with a material distribution assembly 4, and a feed pipe 5 is provided above one side of the feed assembly 4, and the feed pipe 5 is docked with the discharge port in the previous process , a lifting assembly 6 is arranged above the receiving box 2, and a transmission assembly 8 is arranged at the center above the installation box 1;

[0038] The bottom of one side of the feeding pipe 404 is provided with a control dry barrel 7, and the inner bottom surface of the receiving box 2 is fixedly provided with a liquid collecting b...

Embodiment 2

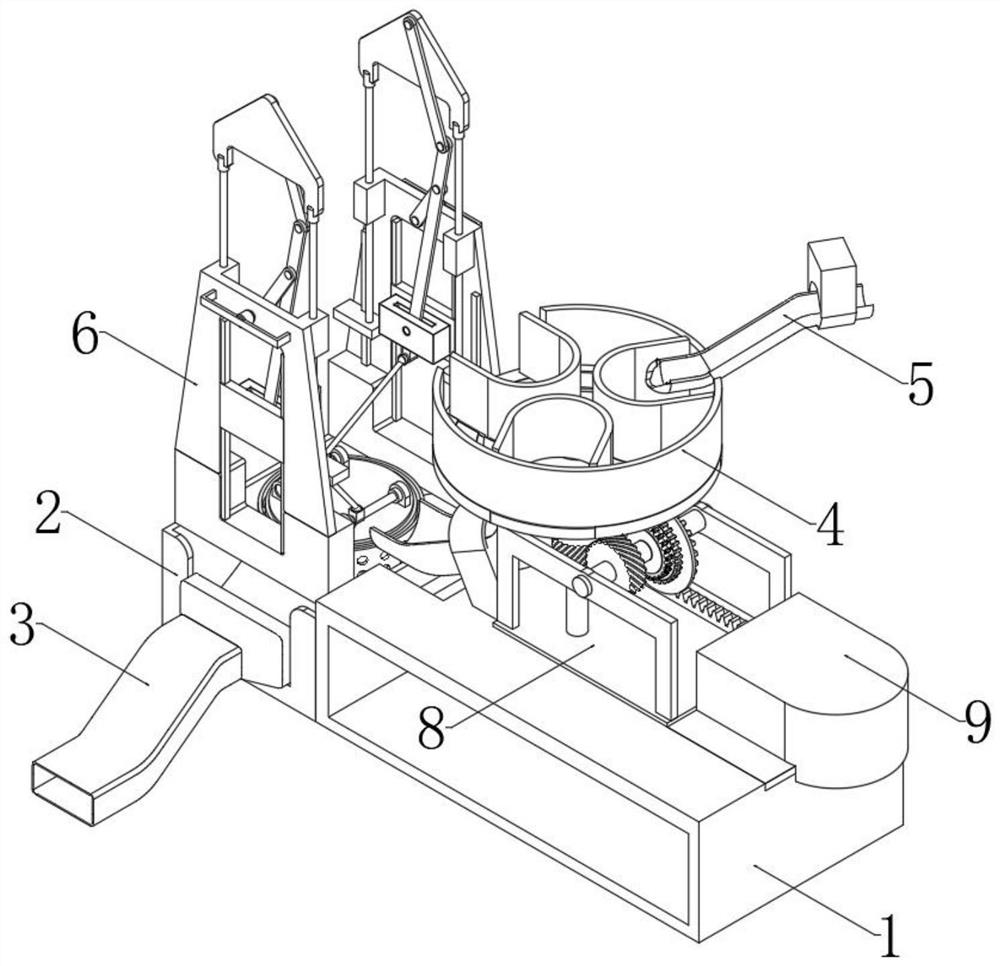

[0041] Such as Figure 6-8 As shown, the differences based on Embodiment 1 are:

[0042] The distributing assembly 4 includes a transmission plate 402 on which a three-component material 403 is fixedly installed, and a limited material ring 401 is slidably arranged on the transmission plate 402. fixed connection;

[0043] A ball connector 409 is arranged in the center of the transmission disc 402, and a connecting arc block is arranged around the ball connector 409. A feeding chute 406 is provided around the transmission disc 402; The inner end is slidably connected around the ball connector 409 through the connecting arc block;

[0044] A transmission assembly 8 is arranged below the transmission disc 402, the transmission assembly 8 includes a motor A802, the lower end of the motor A802 is fixedly connected to the upper side of the installation box 1, and the upper end of the output shaft of the motor A802 is provided with a double-link assembly 803; the double-link assemb...

Embodiment 3

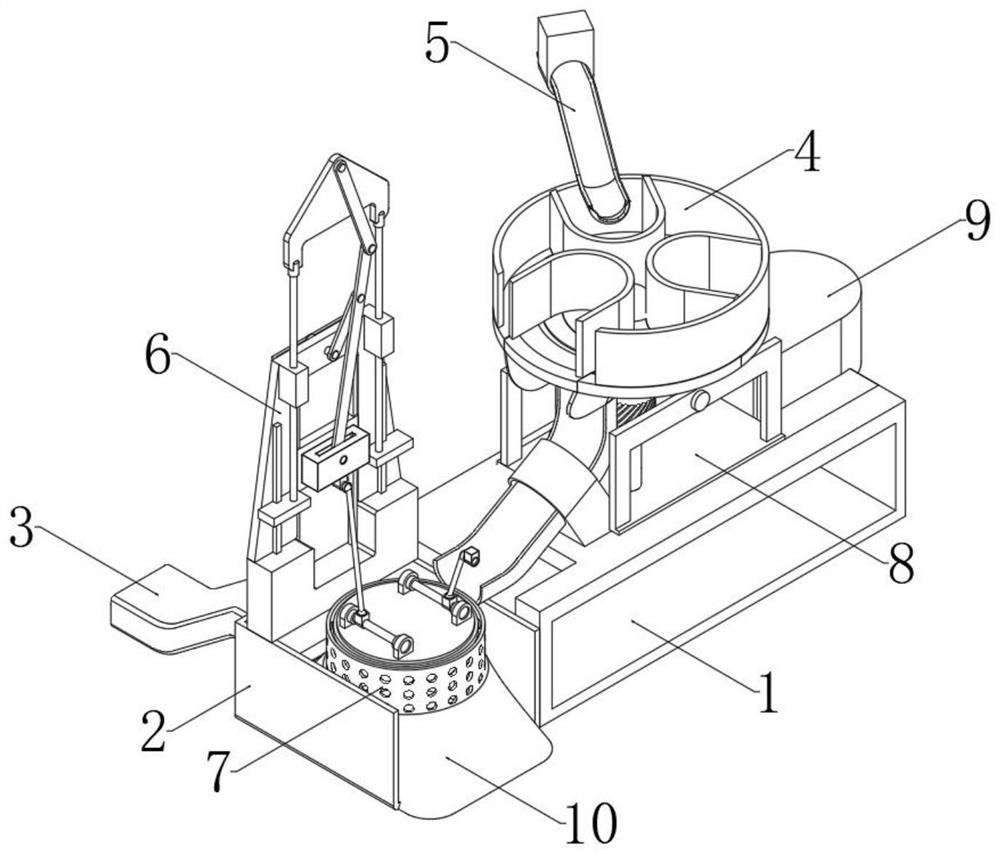

[0050] Such as Figure 9-11 As shown, based on embodiment 1-2, what is different is:

[0051] A hemispherical extruding block 11 is arranged inside the top of the dry control barrel 7, and a connecting seat 12 is fixedly connected above the hemispherical extruding block 11, and a connecting cross bar 13 is fixedly connected between adjacent connecting seats 12; There are telescopic connecting rods 14, and positioning seats are arranged at both ends of the telescopic connecting rods 14, the lower positioning seats are slidably connected to the connecting cross bar 13, and the upper positioning seats are fixedly connected below the lifting block 603;

[0052] The lifting assembly 6 includes a mounting base 601, which is fixedly connected to one side of the upper end of the receiving box 2, a lifting plate 602 is movable above the mounting base 601, and a lifting rod 607 is fixedly connected to the lower ends of both sides of the lifting plate 602; The lower end is fixedly conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com