A slideway nozzle plate installation tool

A nozzle plate and tooling technology, which is applied in the field of slideway nozzle plate installation tooling, can solve the problems of affecting the accuracy of the nozzle hitting the material, affecting the delay effect, and the impact of the camera capturing the material, etc., achieving simple structure, low cost, and accurate installation position Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

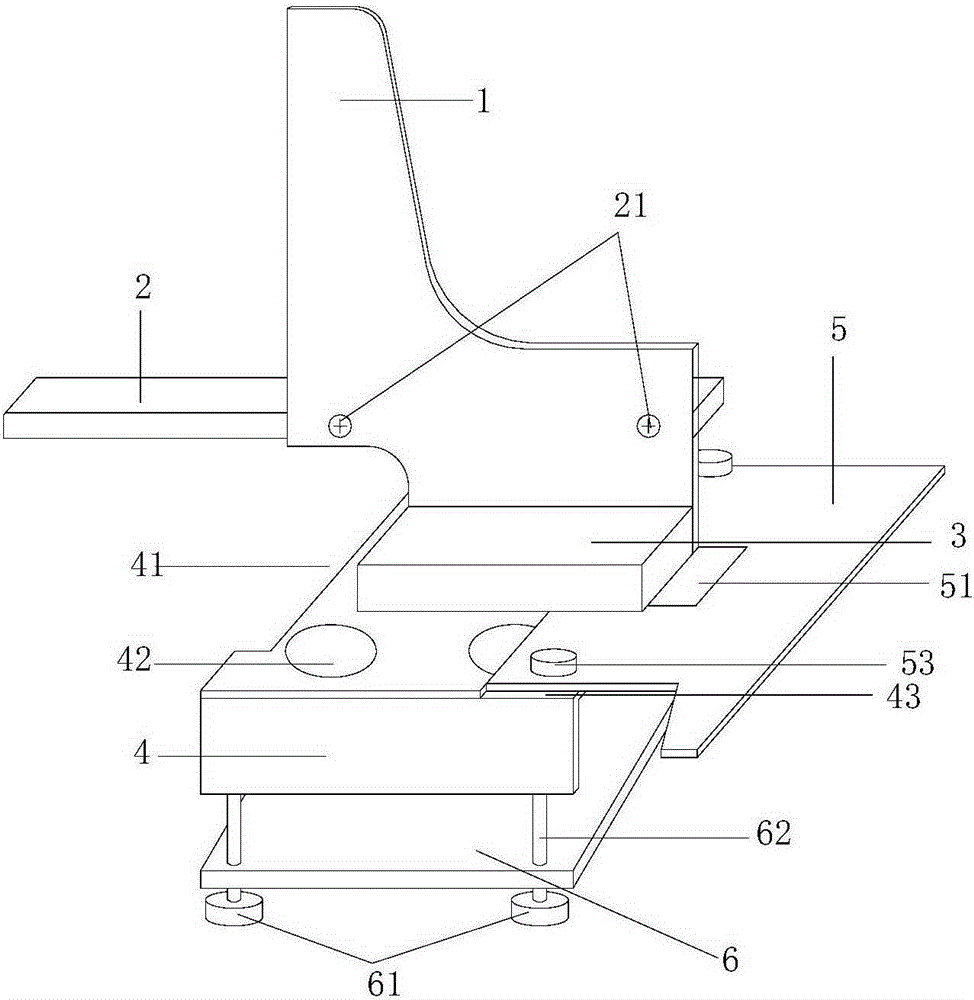

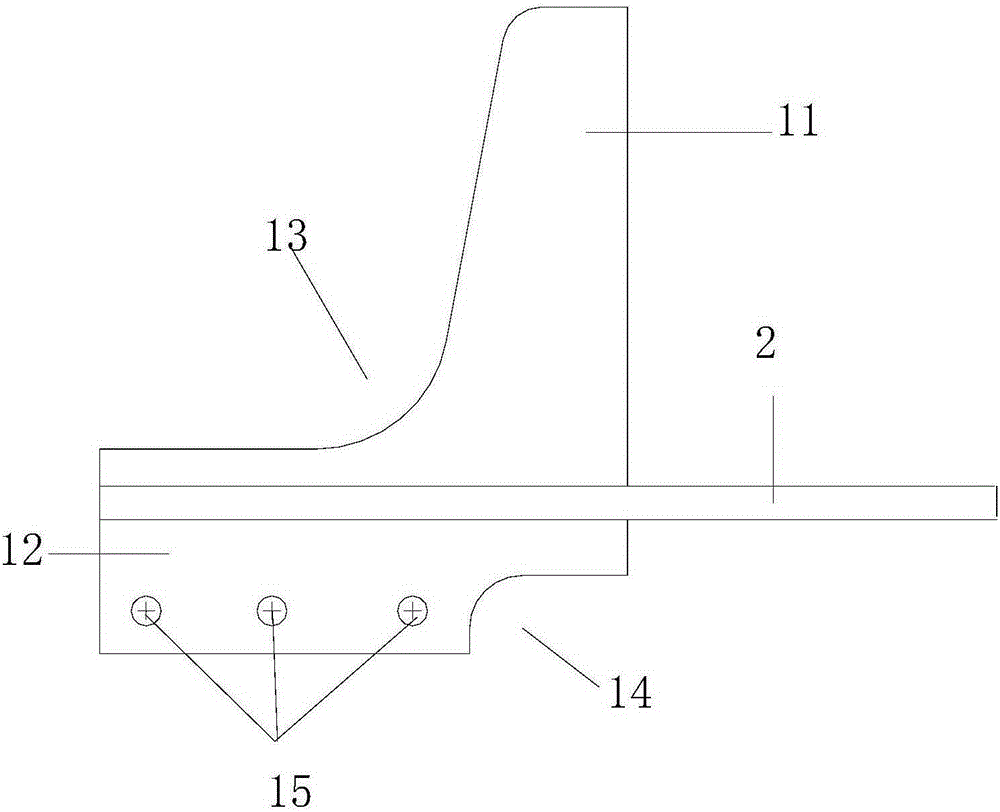

[0020] Such as figure 1 and figure 2 As shown, a slideway nozzle plate installation tooling includes a bottom plate 6, a frame 4, and an L-shaped plate 1. The L-shaped plate 1 is composed of a vertical plate 11 and a horizontal plate 12. The rear end surface of the horizontal plate 12 is The upper part is fixed with a horizontally placed carrier plate 2, one end of the carrier plate 2 is aligned with one end of the horizontal plate 12, the length of the carrier plate 2 is greater than the horizontal plate 12, and the L-shaped plate 1 is located on the rear end surface of the horizontal plate 12. Several first bolts 15 of the bottom are fixed on the rear end face of the fixed block 3, and the fixed block 3 is provided with at the center of the top plate 45 lower surface of the frame 4, and the third bolt 44 passing through the top plate 45 is fixed on the bottom of the top plate 45. middle part;

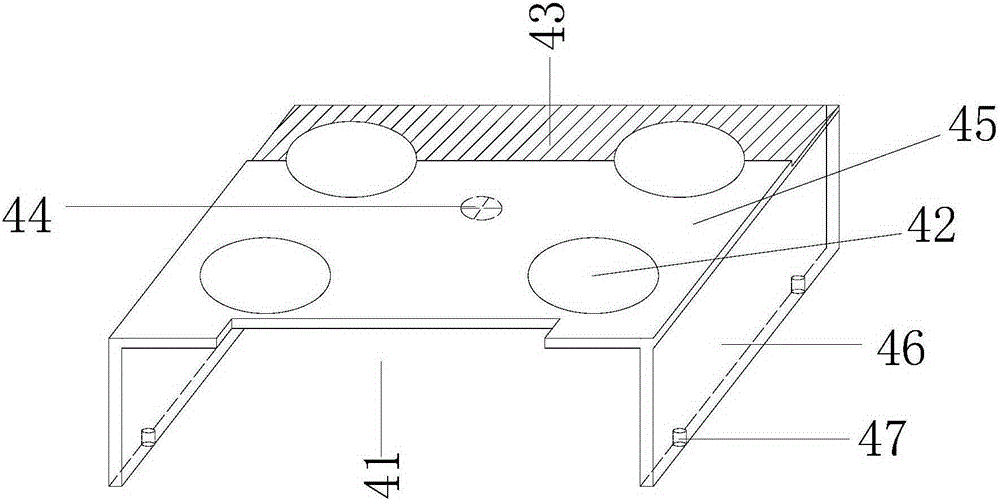

[0021] Such as image 3 As shown, the frame 4 is composed of a top plate 45 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com