Flexible tunneling machine for installing sleeve

A technology of telescopic casing and roadheader, which is applied in drilling equipment, drilling equipment and methods, earthwork drilling and production, etc., and can solve the problems of failure of casing ramming, high degree of sinking at the end of casing, difficulty in tamping casing, etc. problem, to achieve the effect of no jamming, small deformation, and simple and reliable recycling scheme

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

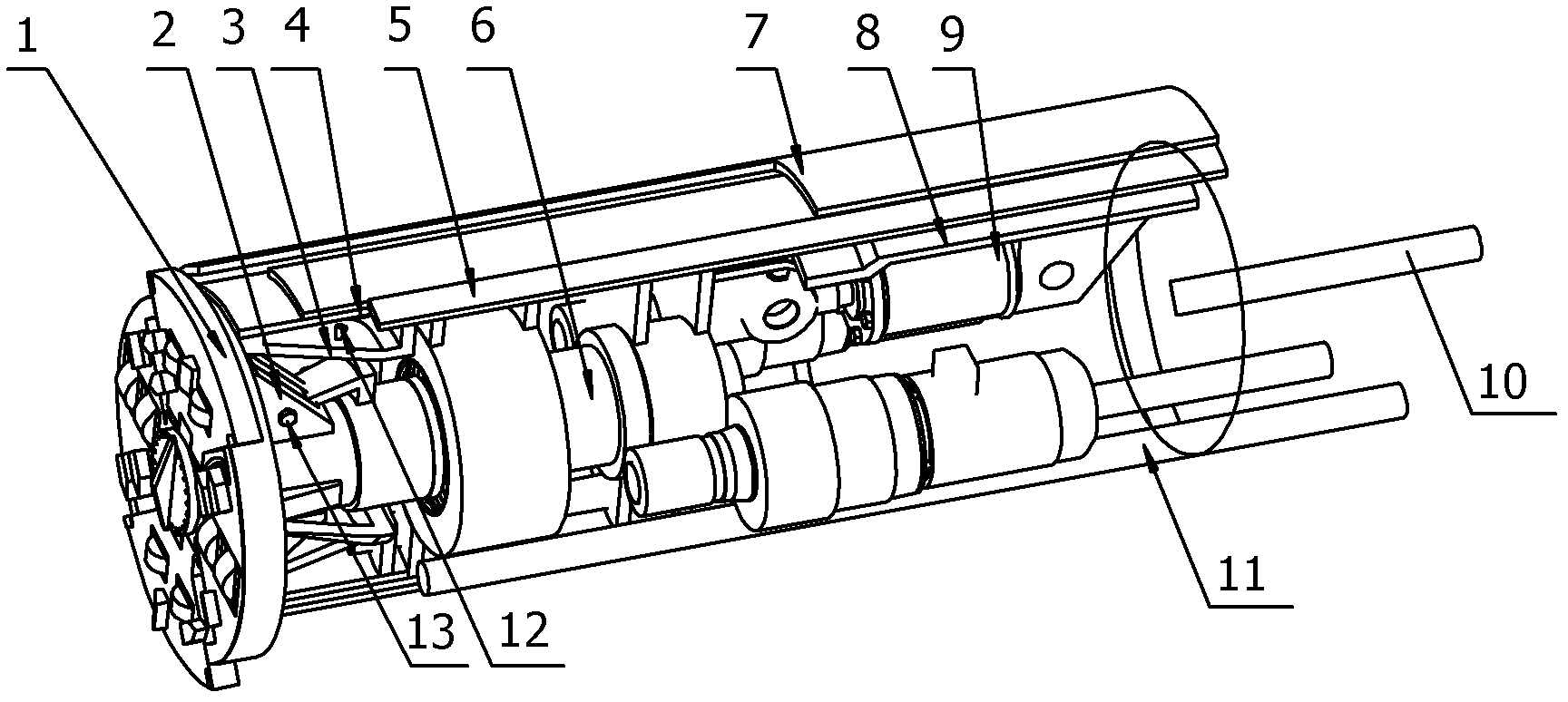

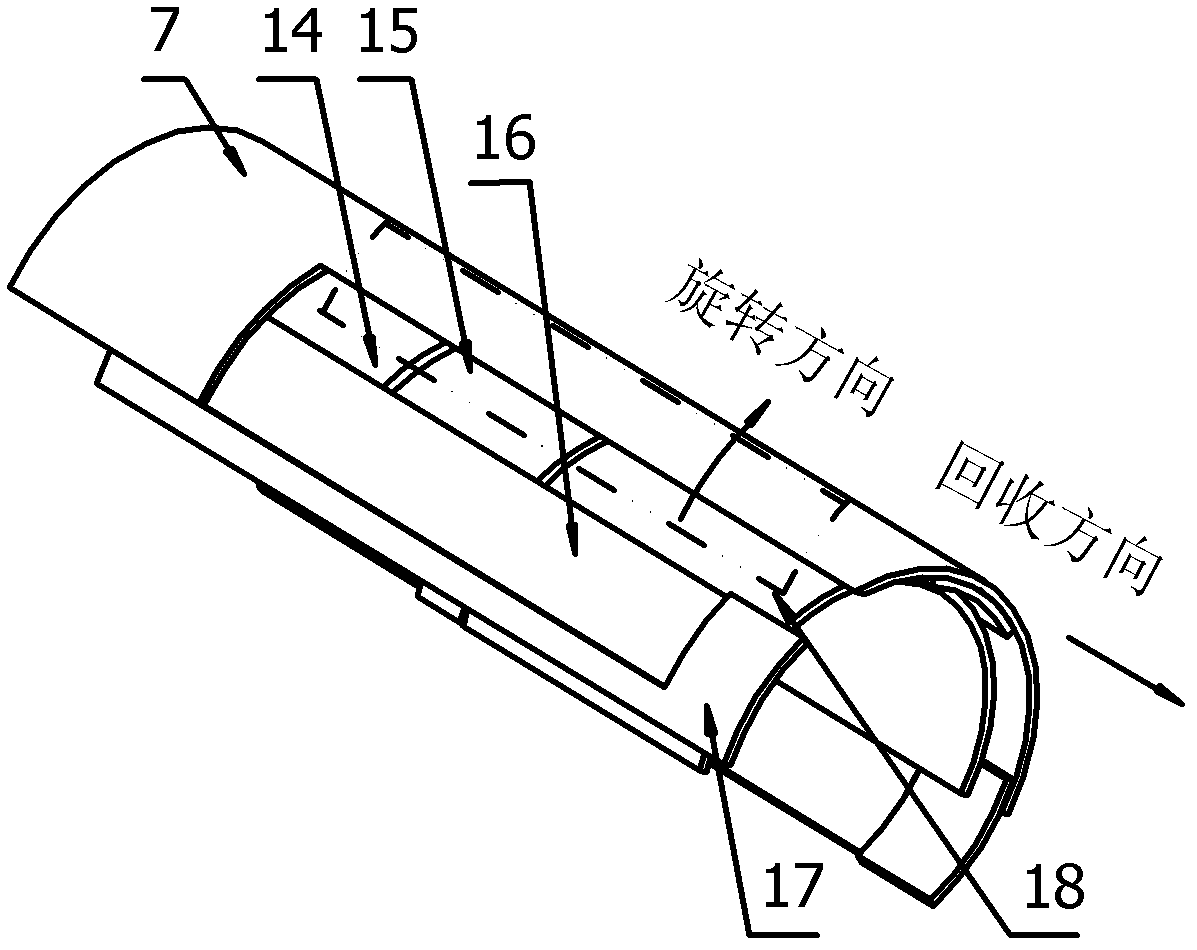

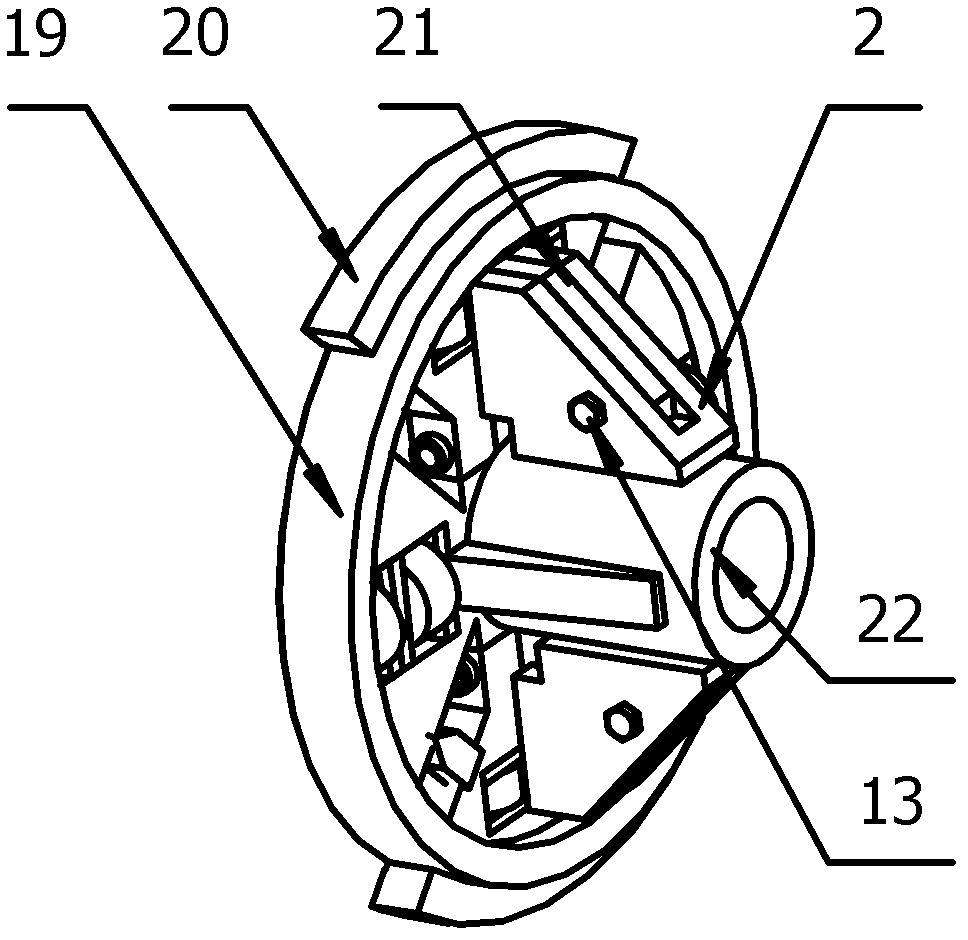

[0012] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0013] The embodiment of the present invention adopts the principles of mechanical cutting, cutter head opening and closing shrinkage recovery and muddy water transportation to discharge slag, and develops a mechanical equipment for horizontal directional drilling to penetrate sand layers and gravel installation casings, and can be taken out from the casing as a whole , can be used for overall recovery of the machine head, removal of obstacles or replacement of tools during pipe jacking under complex geological conditions.

[0014] Such as figure 1 As shown, the embodiment of the present invention provides a telescopic casing installation tunneling machine, including a telescopic cutter head 1, a cutter head support plate 2, a cone crushing device 3, a front housing 4, a fixing device 5, and a power system 6 , rear housing 8,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com