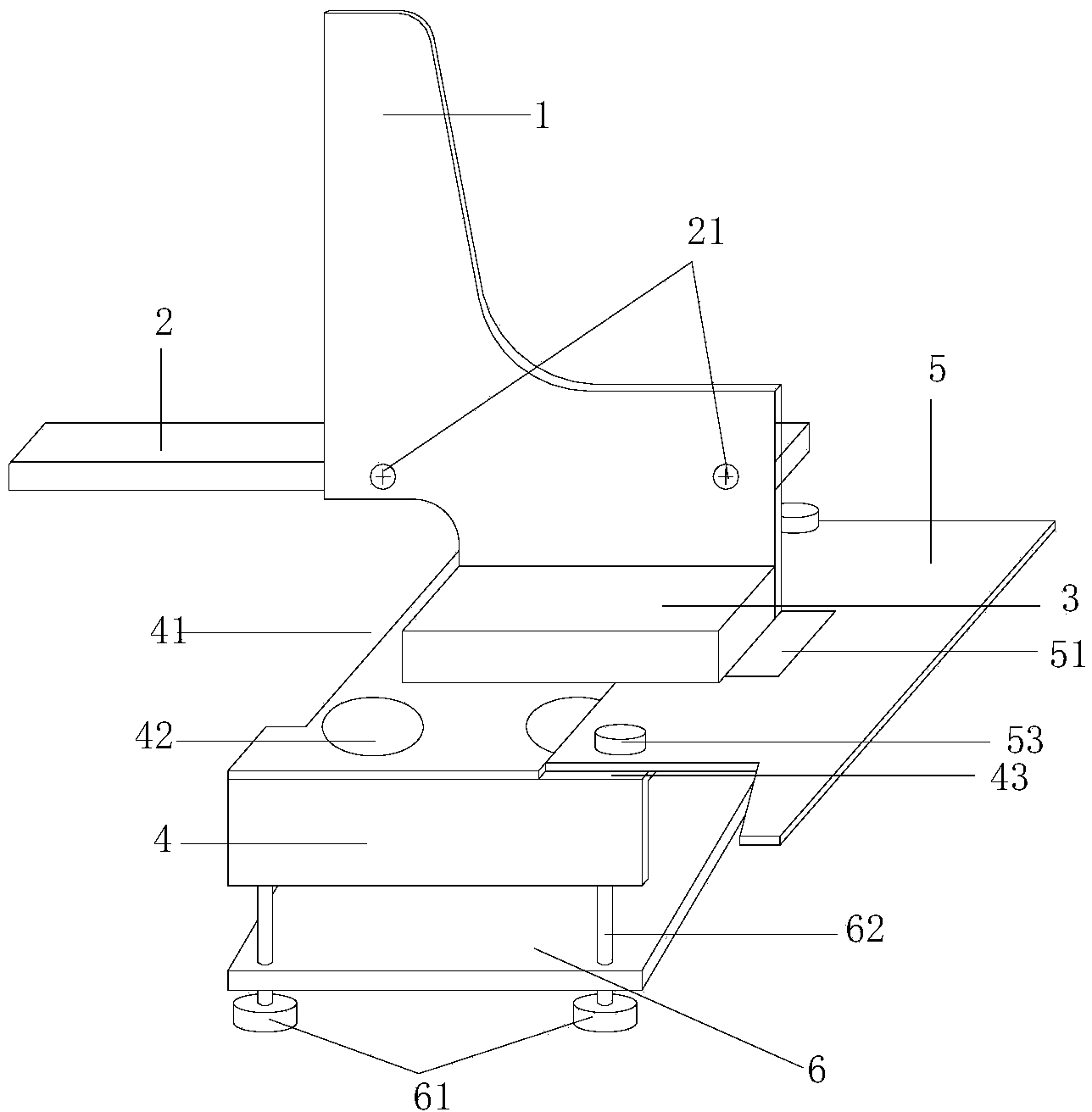

Mounting tool of slideway nozzle plate

A nozzle plate and tooling technology, which is applied in the field of slideway nozzle plate installation tooling, to achieve the effects of low cost, simple structure, and precise installation position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

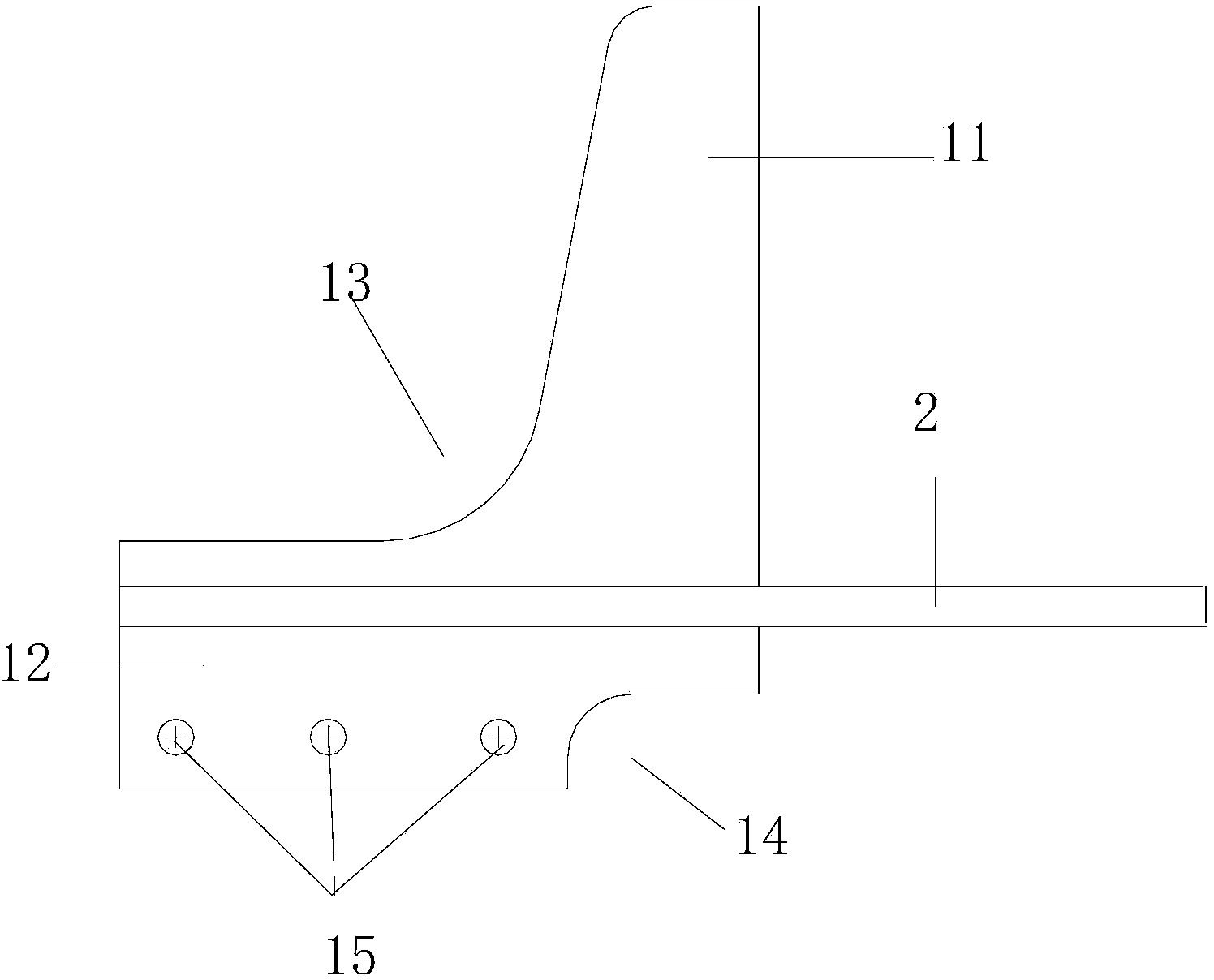

Embodiment Construction

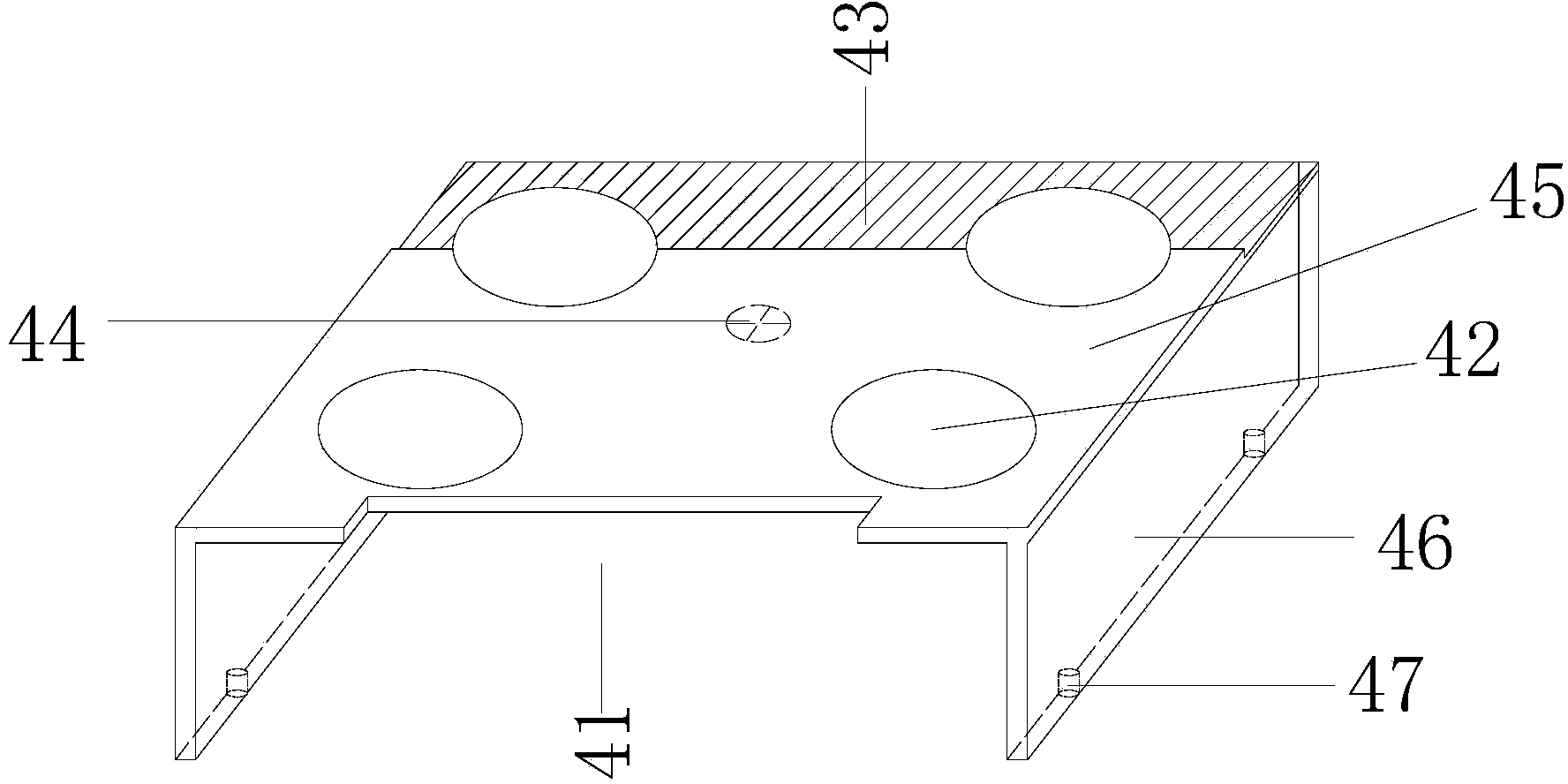

[0022] like image 3 As shown, the frame 4 is composed of a top plate 45 and two vertical vertical plates 46 positioned at both ends of the top plate 45. On the top plate 45 and on the left and right sides of the fixed block 3, two A circular hole 42 symmetrical to the center line, the left middle part of the top plate 45 has a first rectangular opening 41, the length of the first rectangular opening 41 is equal to the distance between the centers of the two circular holes 42 on the left side of the top plate 45, so The right side of described top plate 45 is provided with groove 42, and the length of described groove 42 equals the length of top plate 45, and its width equals the distance that is positioned at the center of circle 42 of round hole 42 on the right side of top plate 45 to top plate 45 right boundary lines, and its depth is less than The height of the top plate 45, a blind hole 47 is respectively provided on the front and rear sides of the lower surface of the ve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com