Light source system applicable to tomato color sorting machine

A light source system and color sorter technology, applied in the field of light source system of tomato color sorter, can solve the problems of difficult to block sunlight, large volume, low light source illumination, etc. Effects of LED Types

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

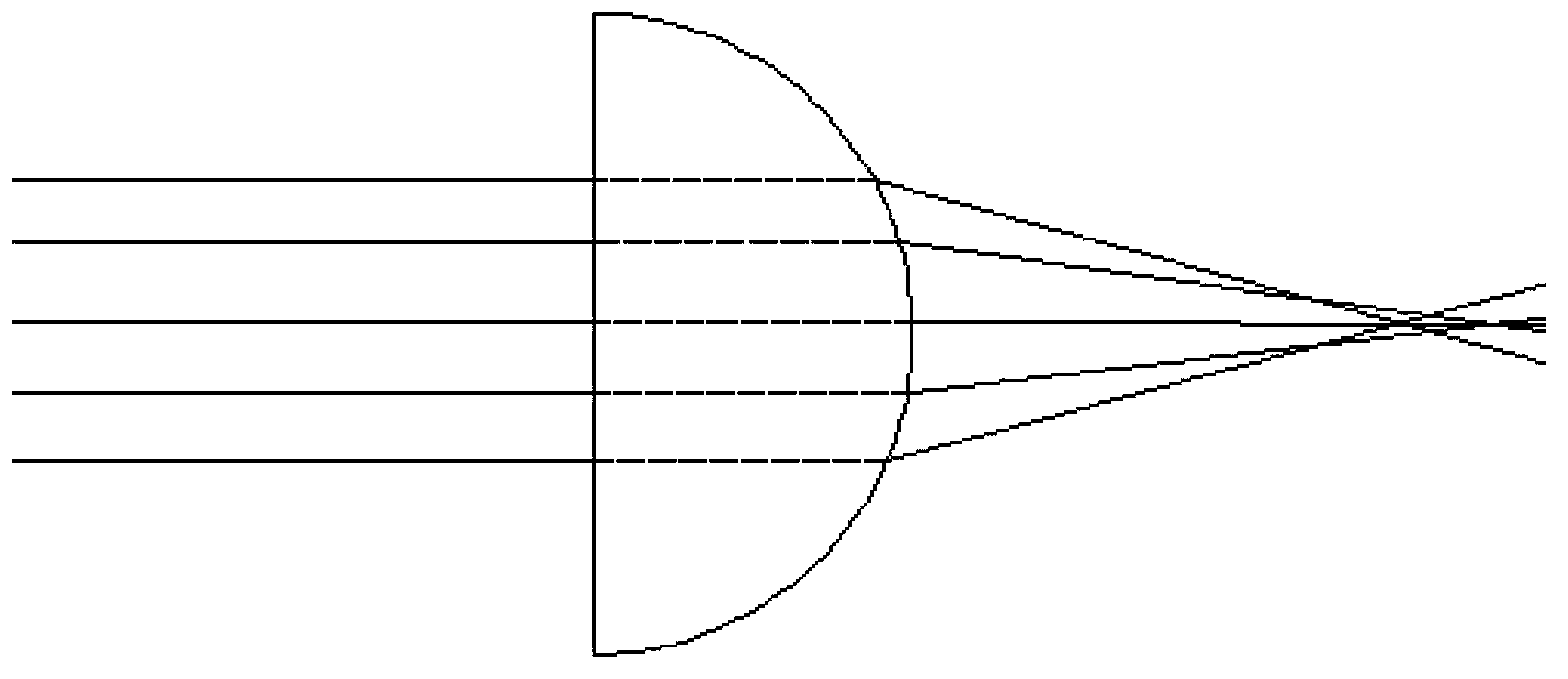

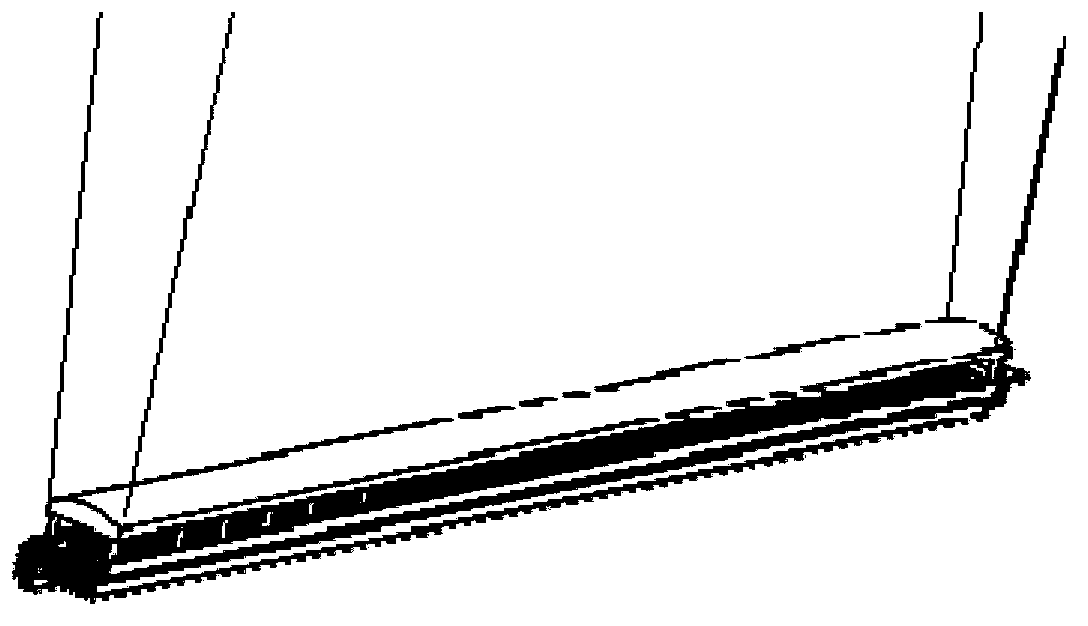

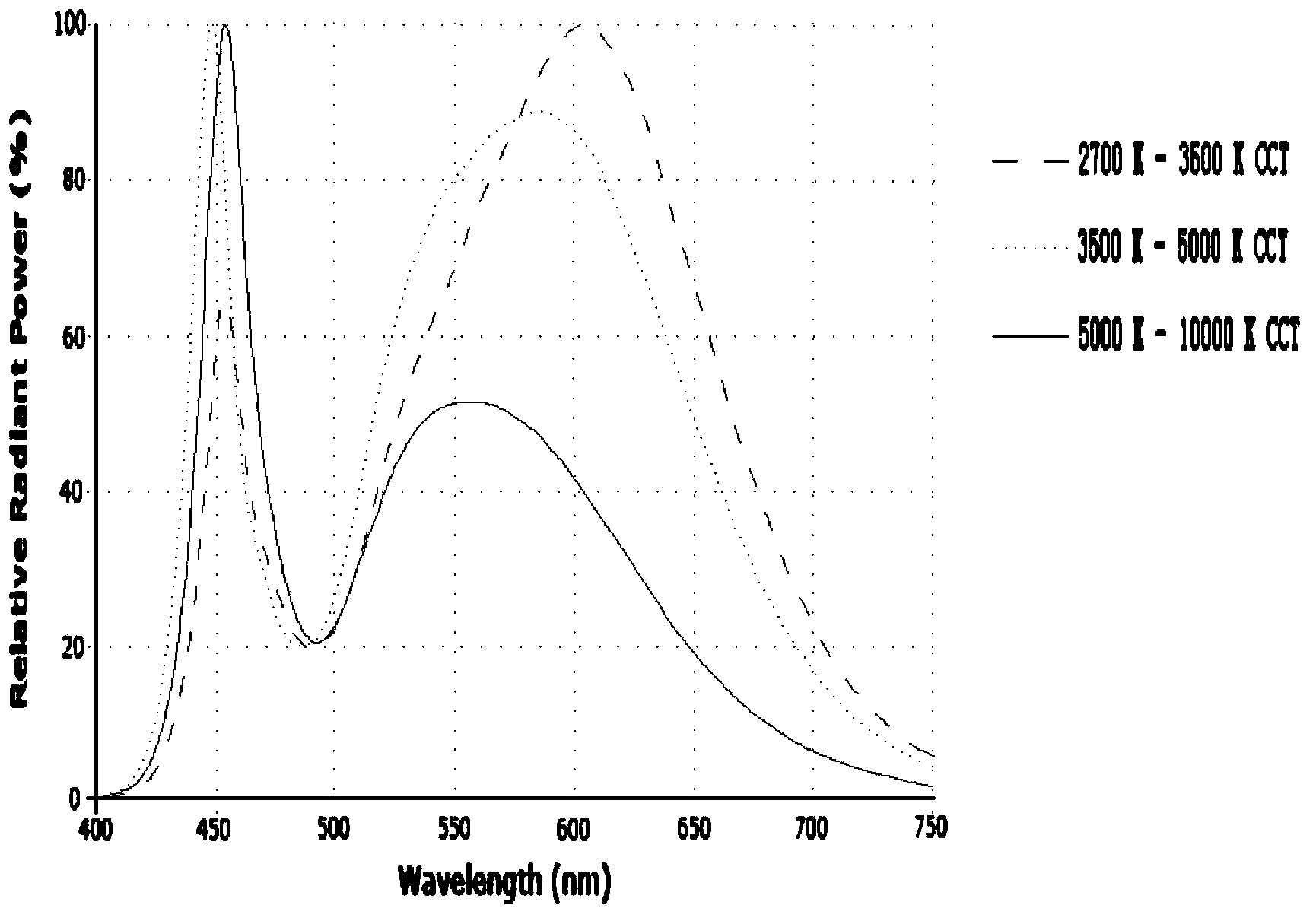

[0027] Such as figure 1 As shown, the present invention is a light source system suitable for a tomato color sorter, including a lens 1 and its bracket 2 , a light source board 3 , and a radiator 4 . The lens 1 is a plano-convex cylindrical lens, which is integrally formed with the bracket 2, which reduces the structural components, reduces the weight of the optical system, and reduces the difficulty of installation and debugging; the light source board 3 is flat and strip-shaped, and adopts a metal-based PCB board In order to facilitate heat dissipation, composite white light LEDs are mounted in an array near the long axis; the light source board installation surface of the heat sink 4 is elongated, and the long sides on both sides have guide grooves, so that the light source board can be inserted into the guide grooves and closely attached The radiator is installed, and other surfaces are provided with cooling fins, which are parallel to the long sides and made black to faci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com