Clamping linkage mechanism and claw disc

A linkage mechanism and clamping technology, used in workpiece clamping devices, manufacturing tools, etc., can solve the problems of time-consuming, labor-intensive, high cost, low work efficiency and other problems of clamping jaws, and achieve simple and ingenious structure, high work efficiency and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

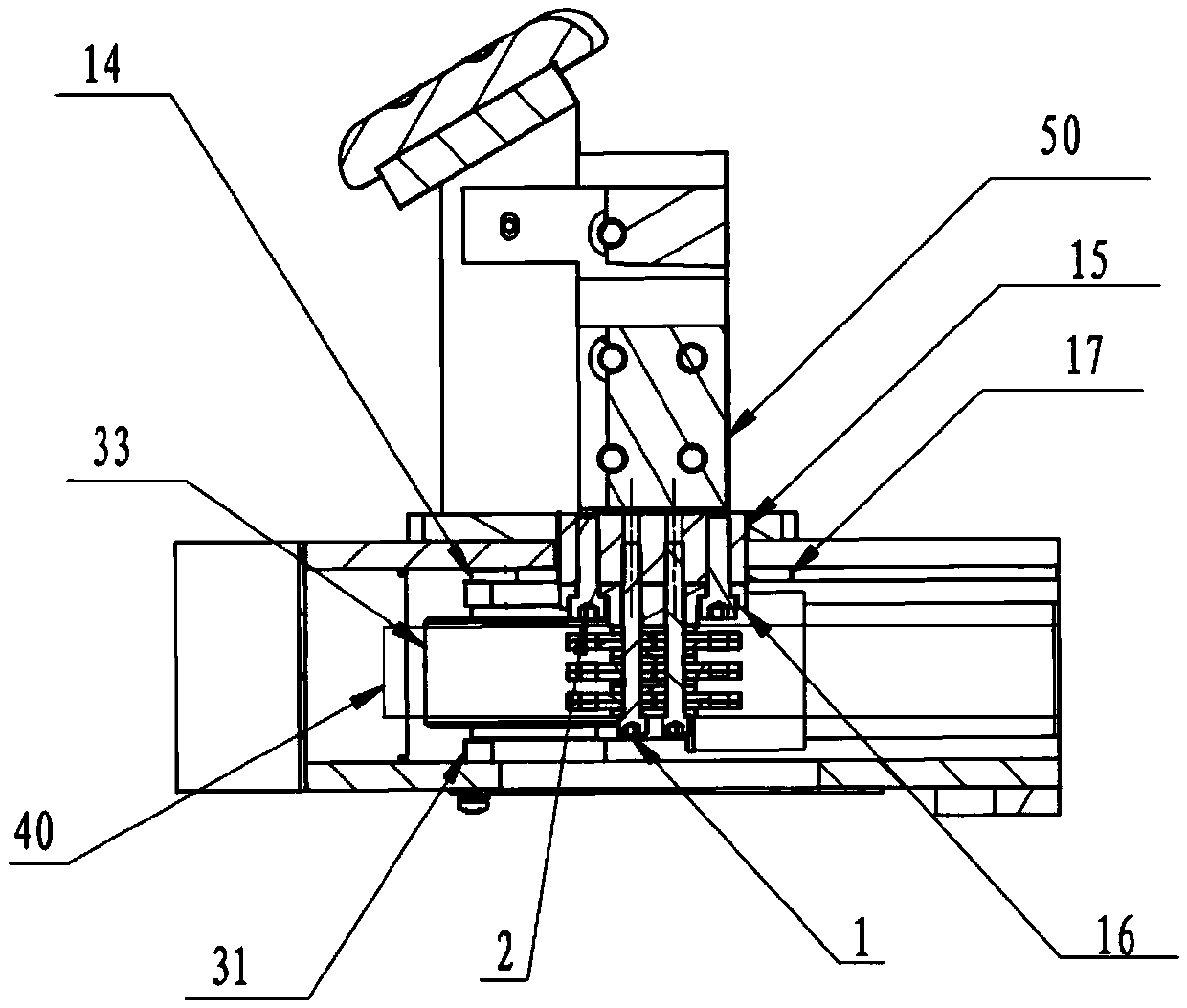

[0031] In order to realize the synchronous adjustment of the clamping jaws of the claw plate, the traditional solution is that each clamping jaw is equipped with a power mechanism, which can be adjusted one by one or simultaneously to meet the clamping requirements. However, the claw plate mechanism equipped with multiple powers is expensive and bulky. Moreover, during operation, a single adjustment of the clamping jaw takes time and effort, and the work efficiency is low, and due to the existence of errors, even if multiple power mechanisms are adjusted at the same time, the accuracy of the clamping jaw position cannot be guaranteed, and the accuracy is not high.

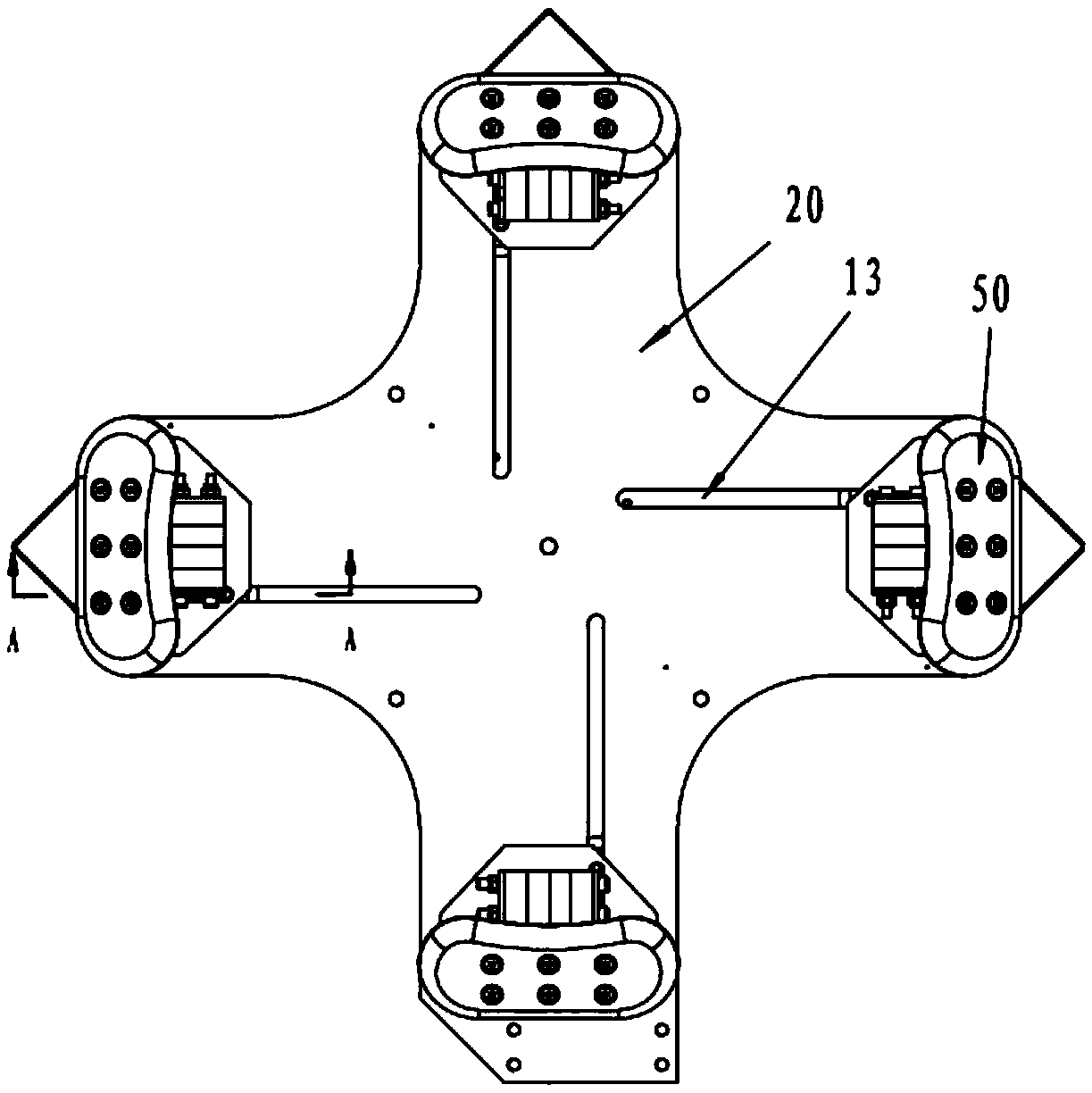

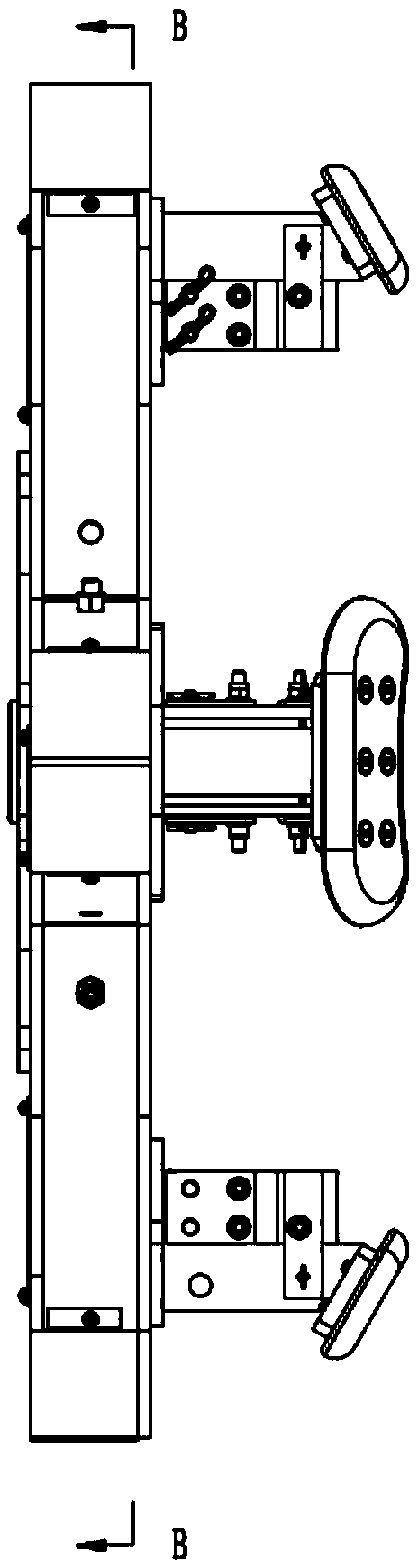

[0032] In view of the shortcomings in the prior art, the present invention provides a clamping linkage mechanism and a claw plate, so that the whole mechanism only needs a single power to drive a single clamping claw, and the linkage mechanism inside the claw plate realizes the multiple clamping claws. Synchronous adj...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com