High-temperature resistant sector conductor cable

A fan-shaped wire and high-temperature-resistant technology, applied in the direction of insulated cables, cables, circuits, etc., can solve the problems of insufficient creep resistance and wear resistance, and achieve improved high-temperature resistance and mechanical properties, ingenious structural improvements, and excellent chemical properties. The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

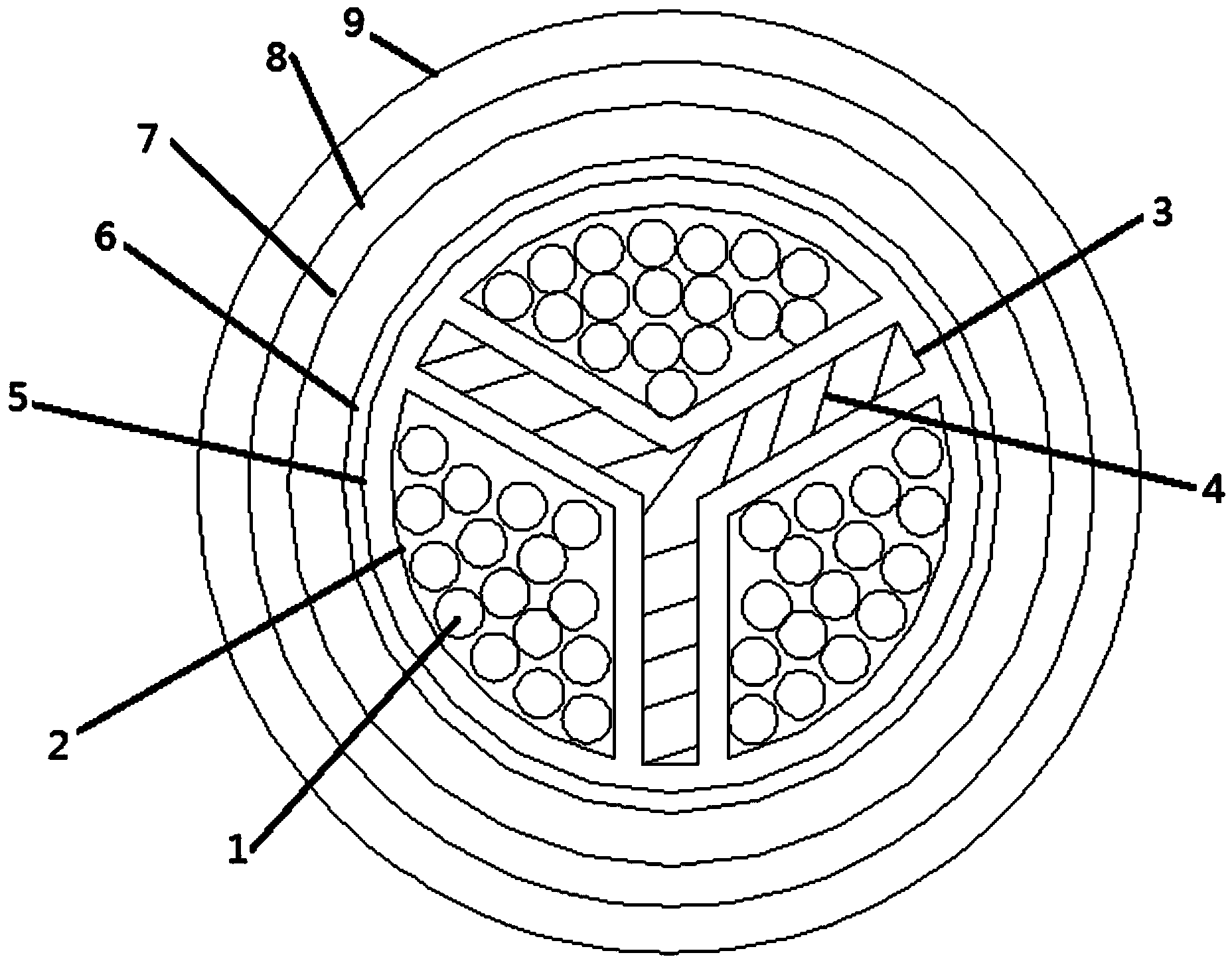

[0015] see figure 1 , a high-temperature-resistant fan-shaped core cable, including a plurality of tinned copper wires 1, the plurality of tinned copper wires 1 are respectively twisted to form three fan-shaped wire cores 2, and the three fan-shaped wire cores 2 are in the form of a ring The Y-shaped nylon frame 3 is arranged between the three wire cores 2, and the outer surface of the Y-shaped nylon frame 3 is covered with overlapping and wrapped high-temperature-resistant fiber filaments 4. The three fan-shaped The wire core 2 is covered with an insulating layer 5, and the insulating layer 5 is covered with a high flame-retardant fiber tape isolation layer 6, an alkali-free glass fiber cloth tape layer 7, a metal shielding layer 8 and a sheath layer in sequence. 9.

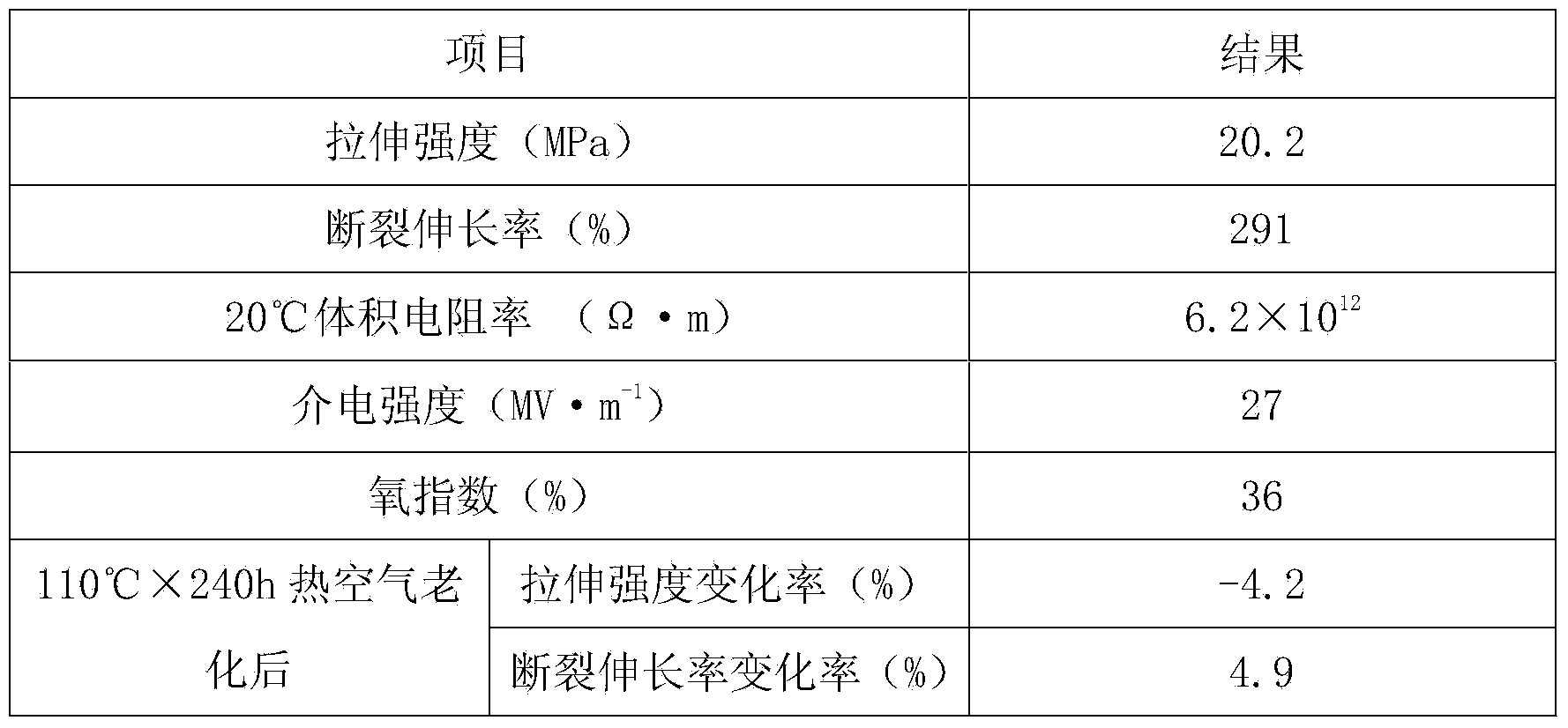

[0016] The material of the sheath layer 9 is made of the following raw materials in parts by weight: polyphenylene ether 50, polyether ether ketone 50, microcrystalline paraffin 4, cumene diphenyl phosphate 15,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com