Automatic grain metering device

An automatic measurement and grain technology, applied in the agricultural field, can solve the problems of low efficiency, high labor intensity, intermittent weighing, etc., and achieve the effect of low production cost, simple and ingenious structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The implementation of the present invention will be illustrated by specific specific examples below, and those skilled in the art can easily understand other advantages and effects of the present invention from the contents disclosed in this specification.

[0020] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

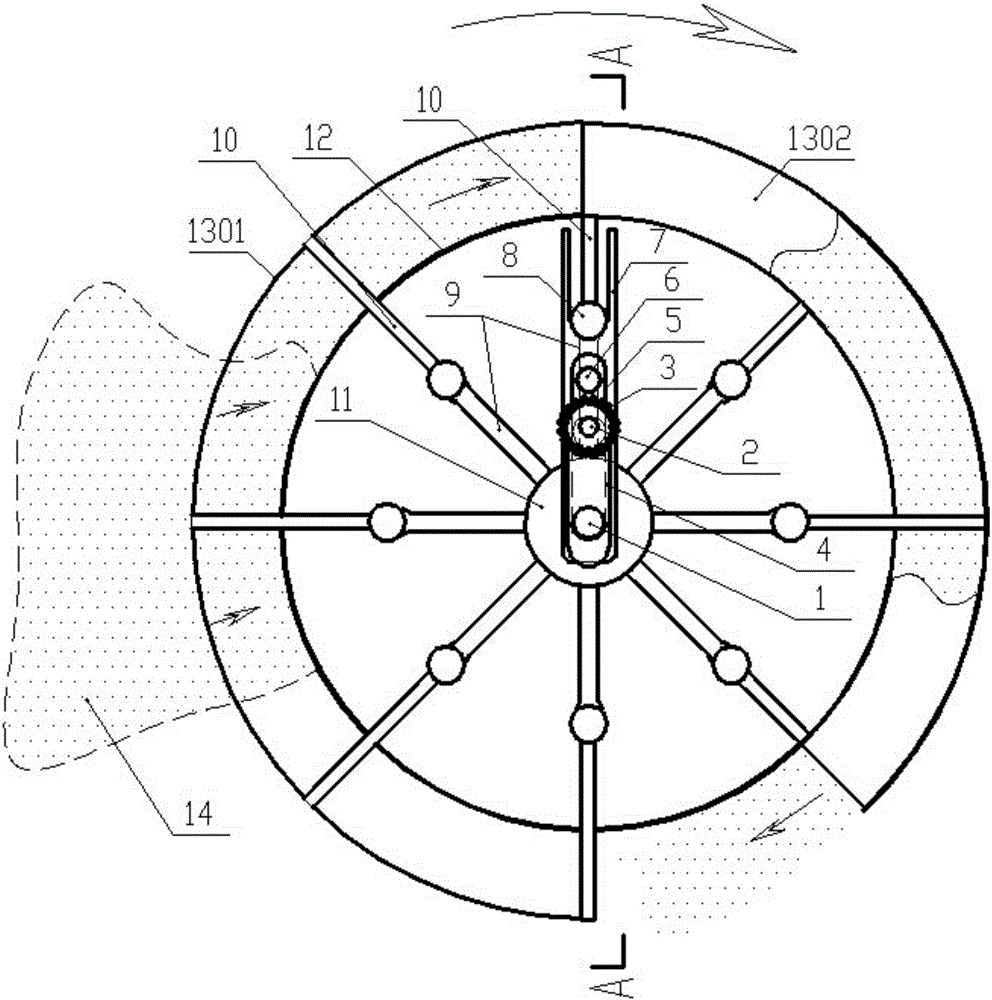

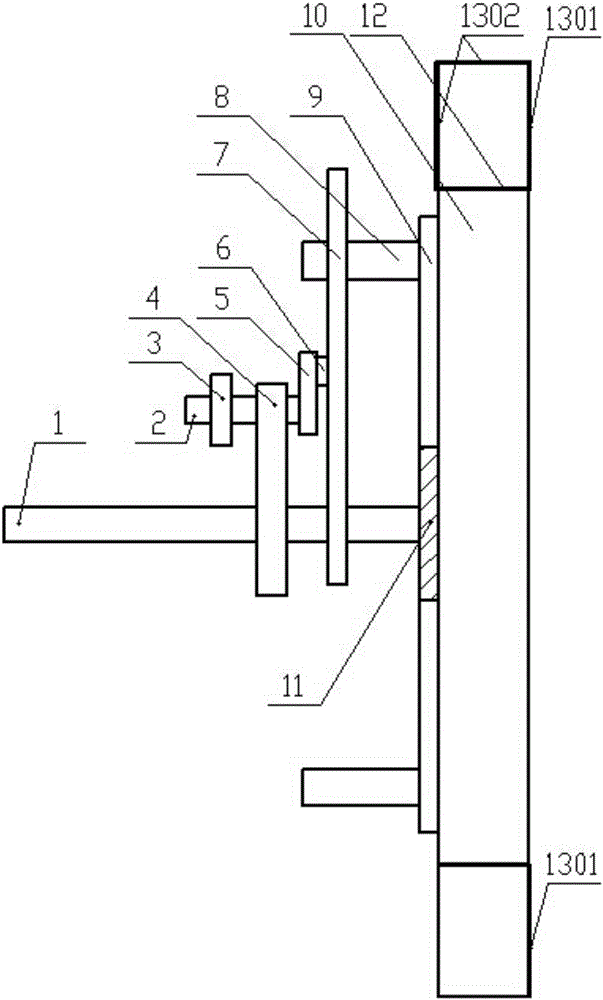

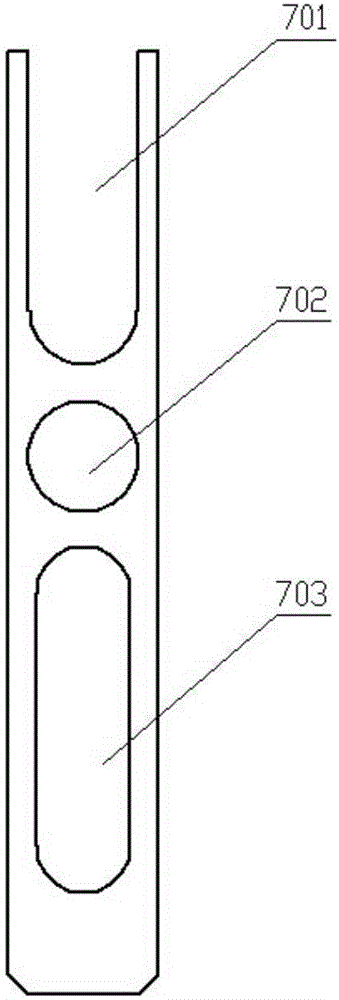

[0021] Such as Figure 1-6 As shown, a grain automatic metering device includes a casing 13 and a rotor assembly disposed in the casing 13, and the rotor assembly can freely sweep in the casing 13. Wherein, the shell 13 includes a section of arc bottom plate 1301, and a section of angle steel 1302 bent into an arc shape on the arc bottom plate 1301, the arc bottom plate 1301 is a section of arc plate cut from a thin steel plate . Angle steel 1302 can be formed by welding two thin steel plates perpendicularly to each other. During production, firstly bend the two thin steel plates into an arc shap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com