Abrasion-resistant precision harmonic speed reducer

A harmonic reducer, wear-resistant technology, applied in the direction of components with teeth, hoisting devices, mechanical equipment, etc., can solve the problems of poor spheroidization, tooth chipping, tube wall thickness, etc., to achieve excellent wear resistance , the effect of high wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Attached below Figure 1-4 An embodiment of the present invention is described.

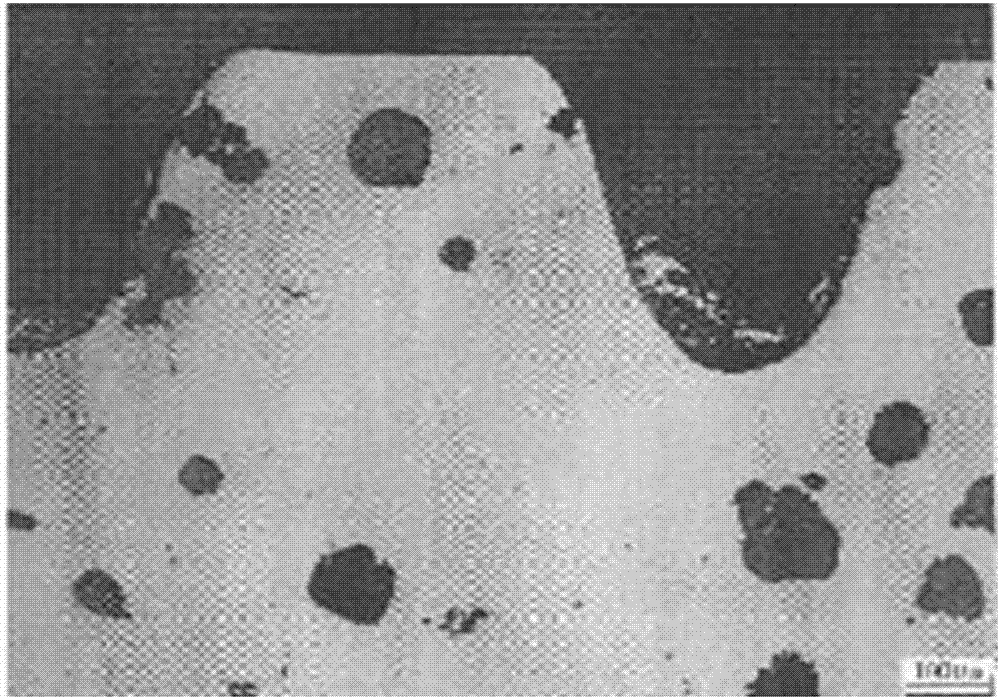

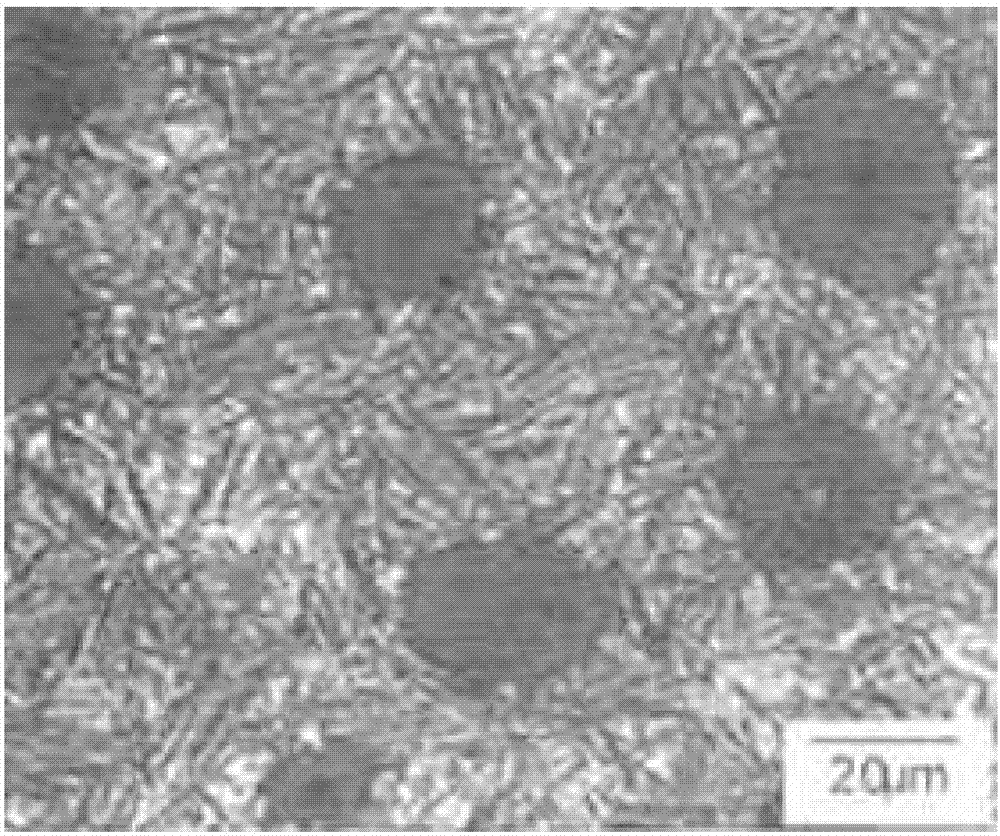

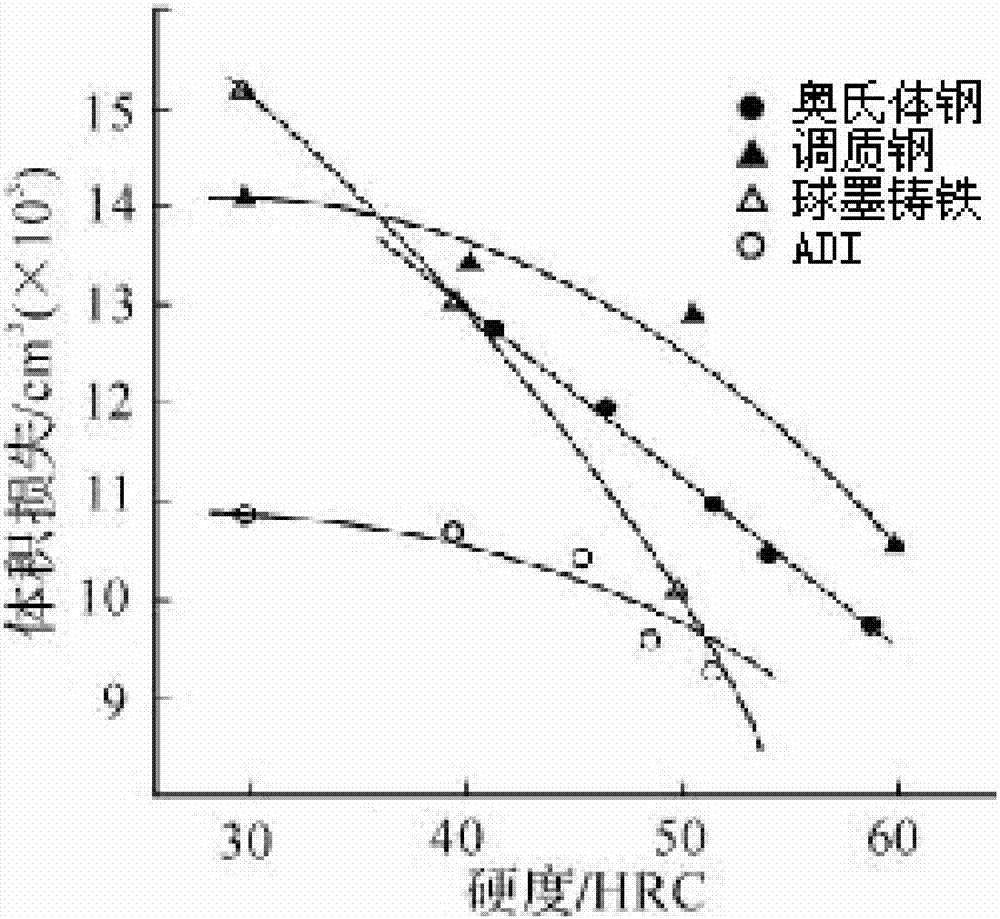

[0020] Wear-resistant precision harmonic reducer, with internal tooth steel wheel, flex spline and harmonic generator, the internal tooth steel wheel is made of nodular iron hollow section produced by vertical continuous casting method and after austempering treatment, The graphite spheroidization rate in the wall thickness inner surface structure of the ductile iron hollow profile reaches more than 90%, and the hardness reaches HRC28-32. The number of graphite nodules in the above-mentioned hollow cast iron pipe structure reaches 300 / mm 2 above; wherein the composition of the ductile iron hollow section is C: 3.0-3.4, Si: 2.5-3.0, Mn<0.2, S≤0.03, P≤0.03, Fe: balance; the austempering treatment is performed on the ductile iron hollow section Carry out after rough machining and before finish machining; the outer diameter of the ductile iron hollow section is 2-3mm larger than the outer di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| spheroidization rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com