Nickel-based bearing retainer material and preparation method thereof

A bearing cage, nickel-based technology, applied in the field of materials, to achieve significant social and economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

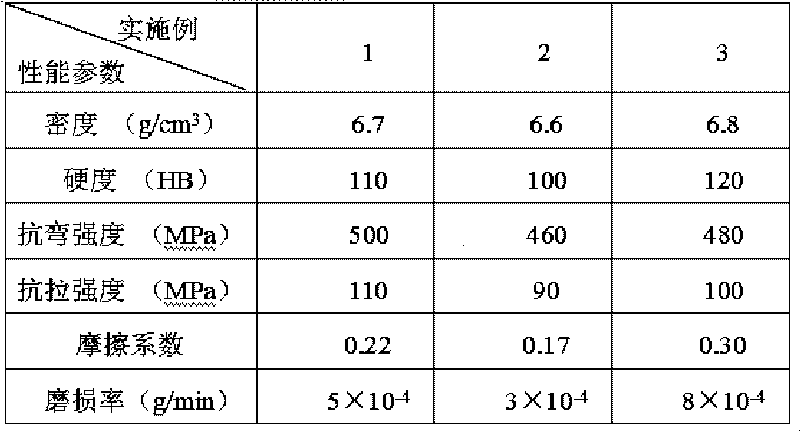

Embodiment 1

[0012] The composition of the nickel-based bearing cage material by weight percentage is: 67% nickel, 9% chromium, 5% silver, and 19% molybdenum disulfide.

[0013] The preparation method of the bearing cage material, the specific steps are: accurately weigh nickel powder, chromium powder, silver powder and molybdenum disulfide powder according to the weight percentage, put them into a drum type ball mill, the ball-to-material ratio is 2:1, mix 20 hours; after mixing, press and form with a hydraulic press to make a billet with a density of 6g / cm 3 The finished blank is then put into a vacuum carbon tube furnace and vacuum sintered at a sintering temperature of 1030° C. for 1.5 hours to obtain a bearing cage material.

Embodiment 2

[0015] The composition of the nickel-based bearing cage material by weight percentage is: 65% nickel, 5% chromium, 8% silver, and 22% molybdenum disulfide.

[0016] The preparation method of the bearing cage material, the specific steps are: accurately weigh nickel powder, chromium powder, silver powder and molybdenum disulfide powder according to the weight percentage, put them into a drum type ball mill, the ball-to-material ratio is 2:1, mix 30 hours; after mixing, press and form with a hydraulic press to make a billet with a density of 5.5g / cm 3 The finished blank is then put into a vacuum carbon tube furnace and vacuum sintered at a sintering temperature of 1050° C. for 2 hours to obtain a bearing cage material.

Embodiment 3

[0018] The composition of the nickel-based bearing cage material by weight percentage is: 70% nickel, 12% chromium, 2% silver, and 16% molybdenum disulfide.

[0019] The preparation method of the bearing cage material, the specific steps are: accurately weigh nickel powder, chromium powder, silver powder and molybdenum disulfide powder according to the weight percentage, put them into a drum type ball mill, the ball-to-material ratio is 2:1, mix 40 hours; after mixing, press and form with a hydraulic press to make a billet with a density of 6.5g / cm 3 The finished billet is then put into a vacuum carbon tube furnace and vacuum sintered at a sintering temperature of 1000° C. for 1 hour to obtain a bearing cage material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com