Controllable-degradation PBAT/PLA (poly(butyleneadipate-co-terephthalate)/polylactic acid) composite film and preparation method thereof

A composite membrane, calcium carbonate technology, applied in the field of PBAT/PLA blending and compatibilization, can solve the problems of easy penetration of low molecular substances, poor material stability, unsatisfactory and other problems, and achieve good light stability and antibacterial properties, phase The effect of improved capacitance and enhanced binding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

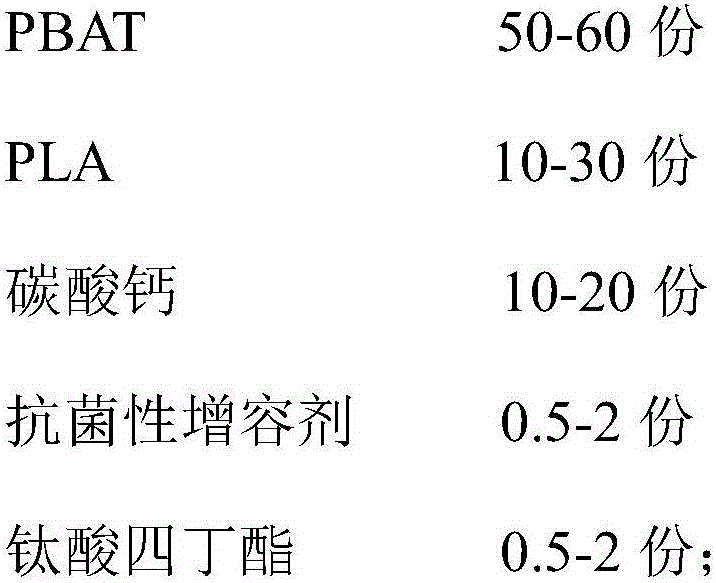

[0052] A PBAT / PLA composite film with controllable degradation, comprising the following components and parts by weight:

[0053]

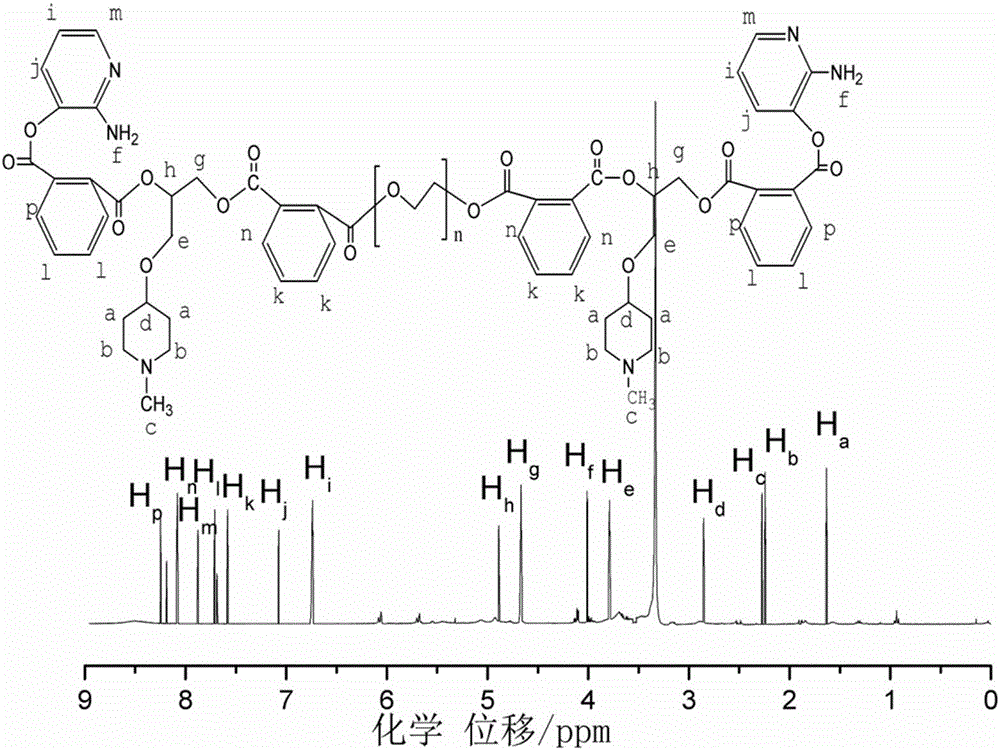

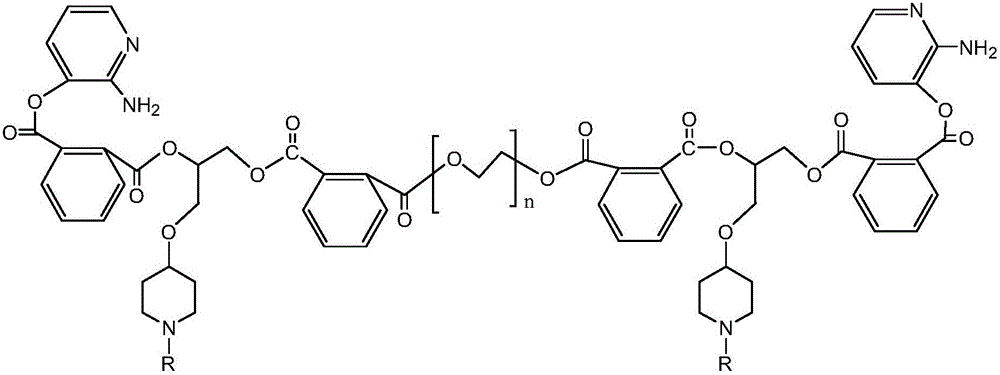

[0054] Wherein the antibacterial compatibilizer is:

[0055]

[0056] Among them, R is -CH 3 or -CH 2 CH 3 .

[0057] A method for preparing a degradation-controllable PBAT / PLA composite film, comprising the steps of:

[0058] (1) Weigh the raw materials according to the parts by weight of the above components, and dry the PLA particles and PBAT particles in a vacuum drying oven at 70°C for 3-5h;

[0059] (2) Mix the dried PLA granules, PBAT granules, antibacterial compatibilizer, tetrabutyl titanate and calcium carbonate in proportion and add them to a twin-screw extruder for extrusion granulation. Set the extruder The temperature in each zone is between 170-185°C;

[0060] (3) Add the PBAT / PLA blended particles obtained in step (2) into a plastic blown film machine to blow film to form a PBAT / PLA composite film, wherein the temperatu...

Embodiment 2-6

[0061] Embodiment 2-6, comparative example 1-4 are the same as embodiment 1, and difference is in table 1:

[0062] Table 1:

[0063]

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com