Processing method for sintering bimetallic lining

A processing method and bi-metal technology, applied in metal processing equipment, abrasives, manufacturing tools, etc., can solve the problems of waste of non-ferrous metal resources, high labor intensity, and high product cost, so as to improve labor production efficiency, reduce labor intensity, and simplify The effect of the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

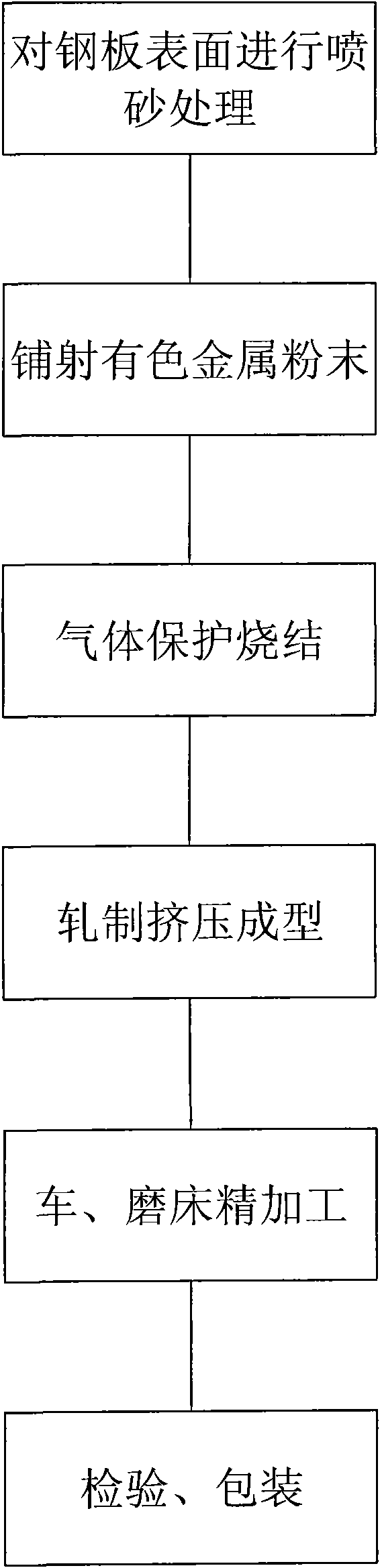

Image

Examples

Embodiment 1

[0018] First of all, surface treatment is carried out on the cold-rolled and hot-rolled sheet, and the surface of the sheet is treated with 180-200 mesh quartz sand using a sandblasting machine; then, the surface of the sheet is evenly paved with Babbitt alloy colored Metal powder material, the babbitt alloy non-ferrous metal powder material is 160 order irregular spherical powder containing 85% bronze and 15% pure tin; then by connecting liquid ammonia decomposition equipment, liquid ammonia is decomposed into 73% hydrogen and 27% nitrogen, and then mix the two gases to obtain a hydrogen-nitrogen mixed gas, then introduce the decomposed hydrogen-nitrogen mixed gas into the sintering furnace tube for combustion, and perform gas-protected sintering on the sheet metal lined with metal powder to obtain a bimetal sheet; Roll the sintered bimetal sheet through a precision rolling mill to make its surface roughness reach Ra3.2μm~Ra0.8μm (that is, the smoothness reaches 6~8 grades), a...

Embodiment 2

[0020] First of all, surface treatment is carried out on the cold-rolled and hot-rolled sheet, and the surface of the sheet is treated with 180-200 mesh quartz sand using a sandblasting machine; then, the surface of the sheet is evenly lined with a ternary alloy non-ferrous metal by a powder spreading device Powder material, the ternary alloy non-ferrous metal powder material is a 160 mesh irregular ball powder containing 70% bronze, 20% zinc, and 10% lead; then by connecting liquid ammonia decomposition equipment, the liquid ammonia is decomposed into 73 % hydrogen and 27% nitrogen, and then mix the two gases to obtain a hydrogen-nitrogen mixed gas, and then introduce the decomposed hydrogen-nitrogen mixed gas into the sintering furnace tube for combustion, and perform gas-protected sintering on the sheet metal lined with metal powder to obtain a bimetallic Sheet material: Roll the sintered bimetallic sheet material through a precision rolling mill to make its surface roughnes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com