Epicyclic dynamic and static vacuum mixer

A technology for vacuum mixers and static mixers, which is applied to mixers, mixers with rotating stirring devices, and dissolution. It can solve the problems of long mixing time, low manufacturing cost, and poor mixing effect of solid-liquid mixtures. Mixing efficiency, good mixing effect, high mixing efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

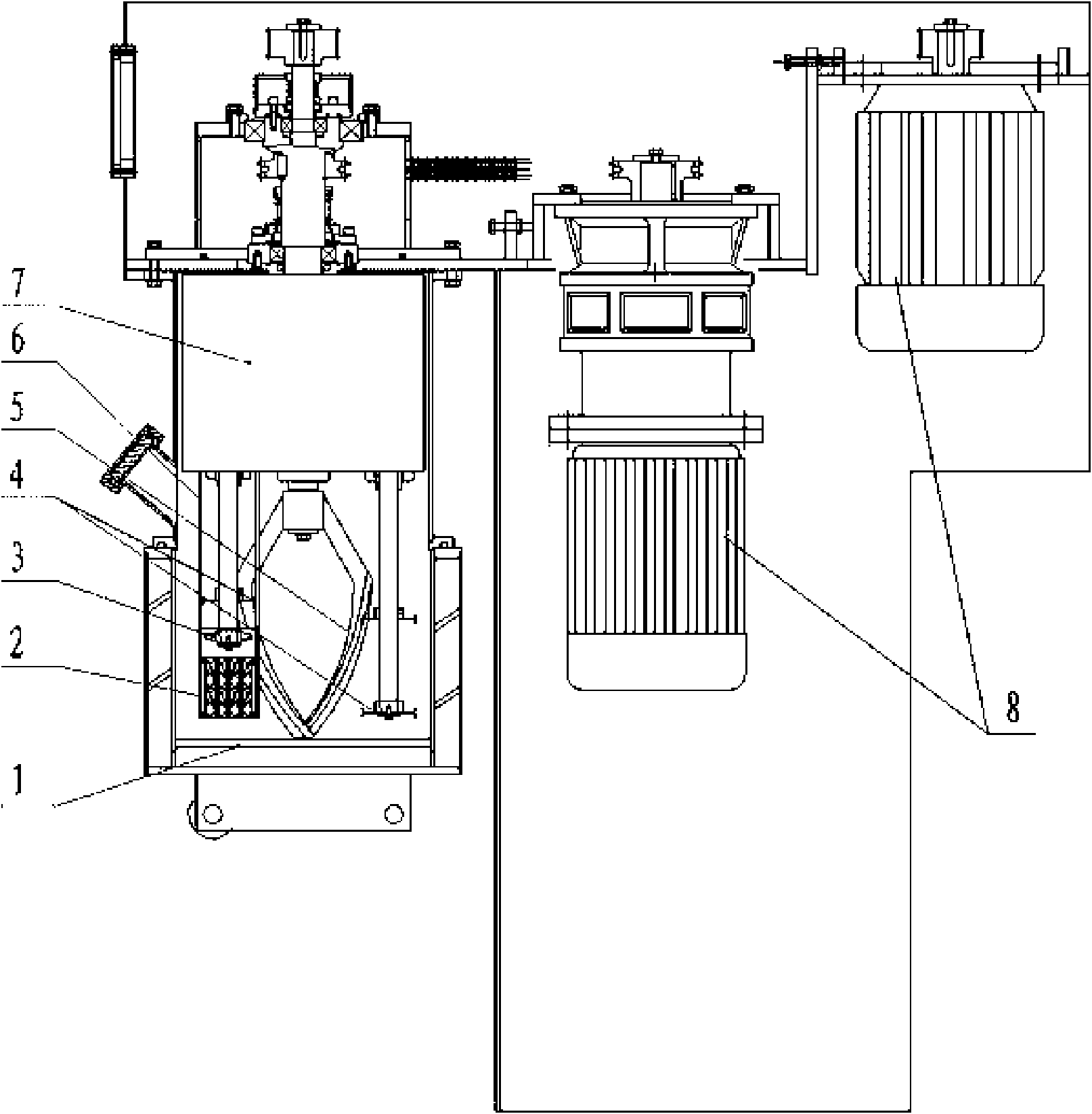

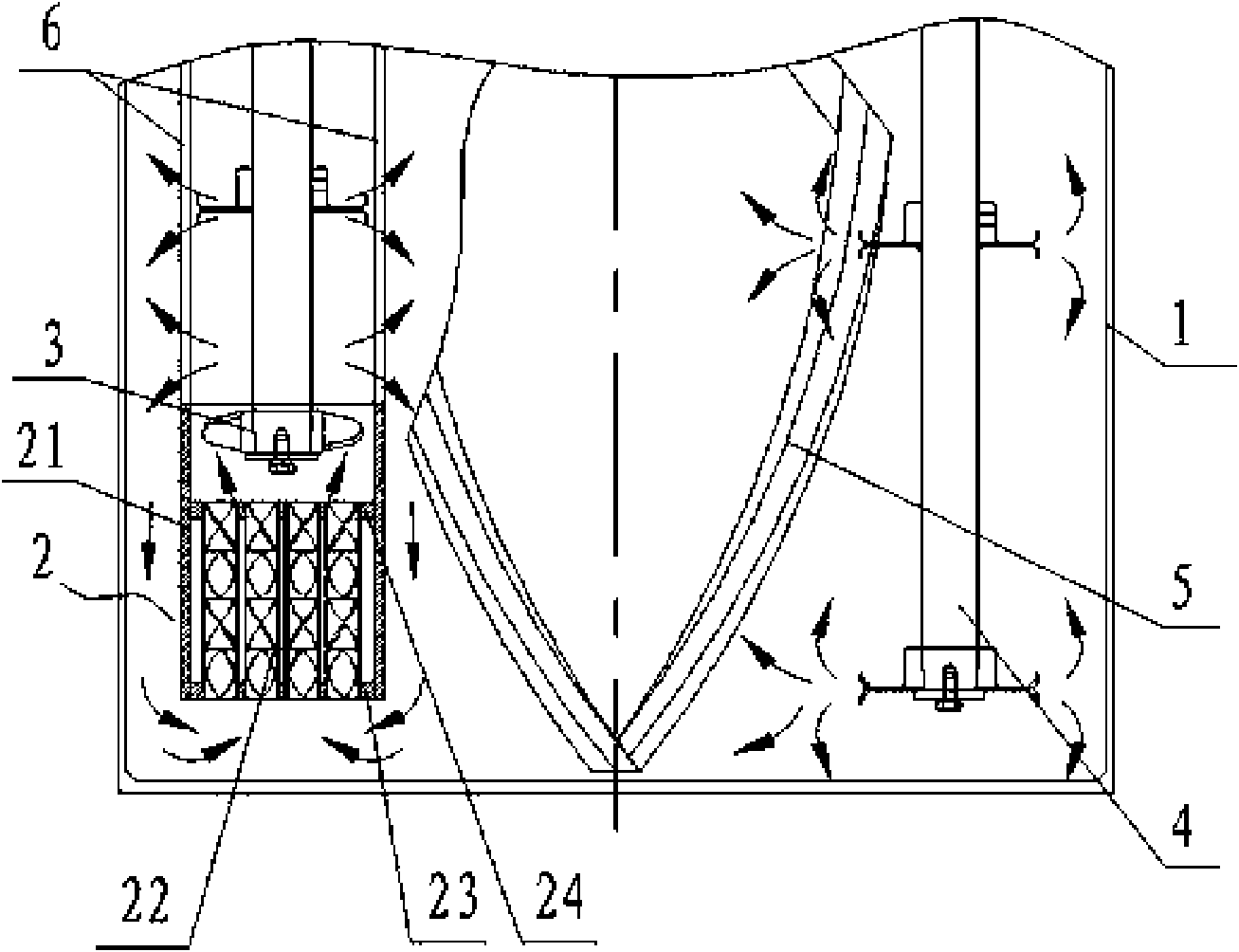

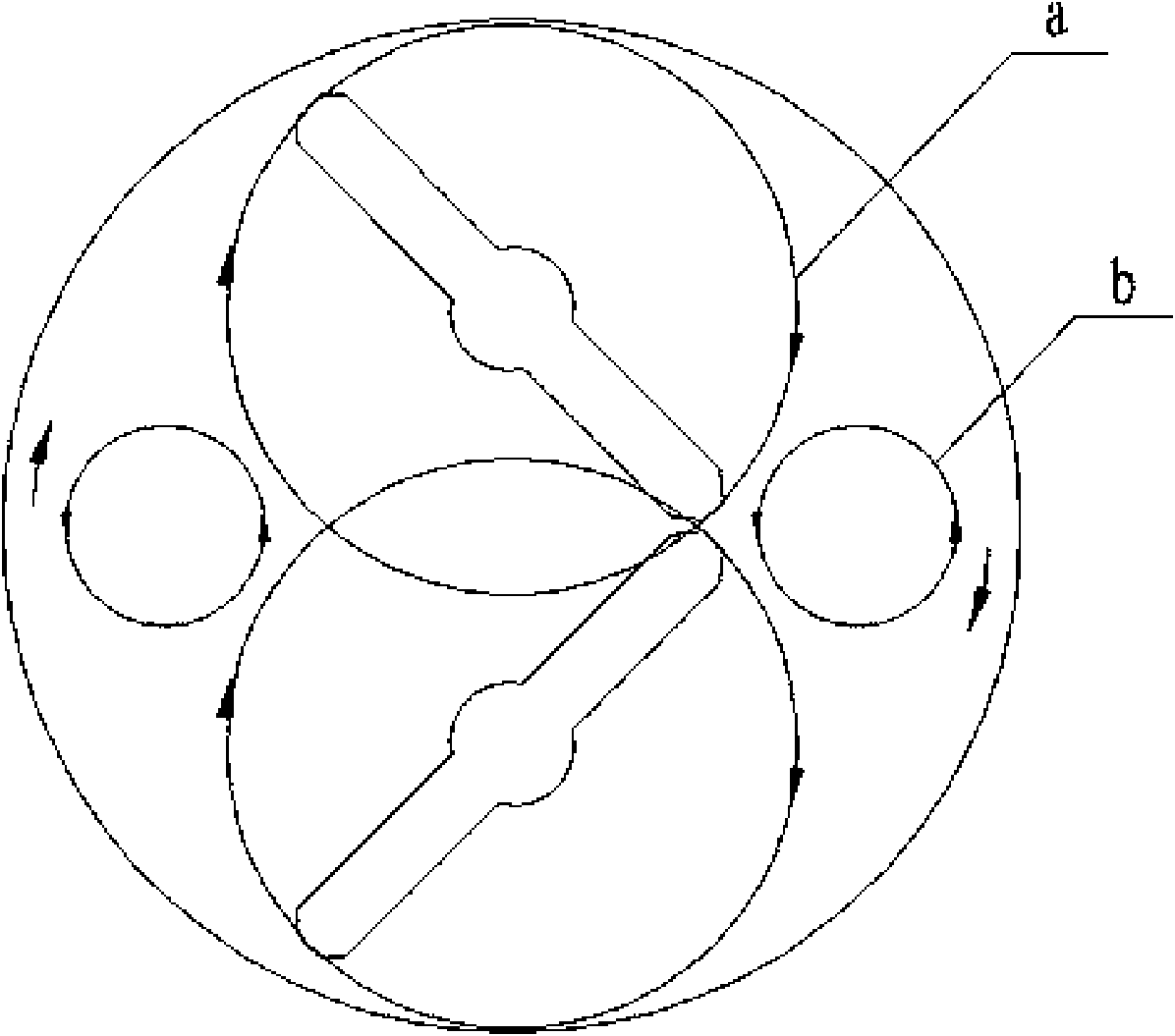

[0035] A planetary dynamic-static vacuum mixer (see Figure 1-Figure 3 ), including two sets of power units 8, planetary gear assembly 7, mixing barrel 1, transmission shaft, two sets of high-speed dispersing components 4 and two sets of low-speed agitating components 5, the high-speed dispersing components 4 and low-speed agitating components 5 are respectively powered by two groups The device is driven by a transmission shaft and a planetary gear train assembly, and the planetary gear train assembly includes a planetary gear train 71, a planetary box 73 and a planetary shield 72, wherein a set of static mixers 2 is installed under a set of high-speed dispersion components 4, the described The static mixer group 2 is mainly composed of a hollow cylinder 21 and n SK-type static mixers 22. The hollow cylinder 21 is provided with a top plate 24 and a bottom plate 23. The top plate and the bottom plate are respectively provided with through holes. The n SK Type static mixer 22 is...

Embodiment 2

[0037] A planetary dynamic-static vacuum mixer (see Figure 4-Figure 5), including two sets of power units 8, planetary gear assembly 7, mixing barrel 1, transmission shaft, three sets of high-speed dispersing assemblies 4 and one set of low-speed agitating assemblies 5, the high-speed dispersing assemblies 4 and low-speed agitating assemblies 5 are respectively powered by two groups The device is driven by a transmission shaft and a planetary gear train assembly. The planetary gear train assembly includes a planetary gear train 71, a planetary box 73 and a planetary shield 72. A set of static mixer groups 2 are respectively installed under the two sets of high-speed dispersion assemblies 4. The static mixer group 2 described above is mainly composed of a hollow cylinder 21 and n SK-type static mixers 22. The hollow cylinder 21 is provided with a top plate 24 and a bottom plate 23, and the top plate and the bottom plate have corresponding through holes up and down, n Two SK-ty...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com