Patents

Literature

43results about How to "Extended lubrication time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

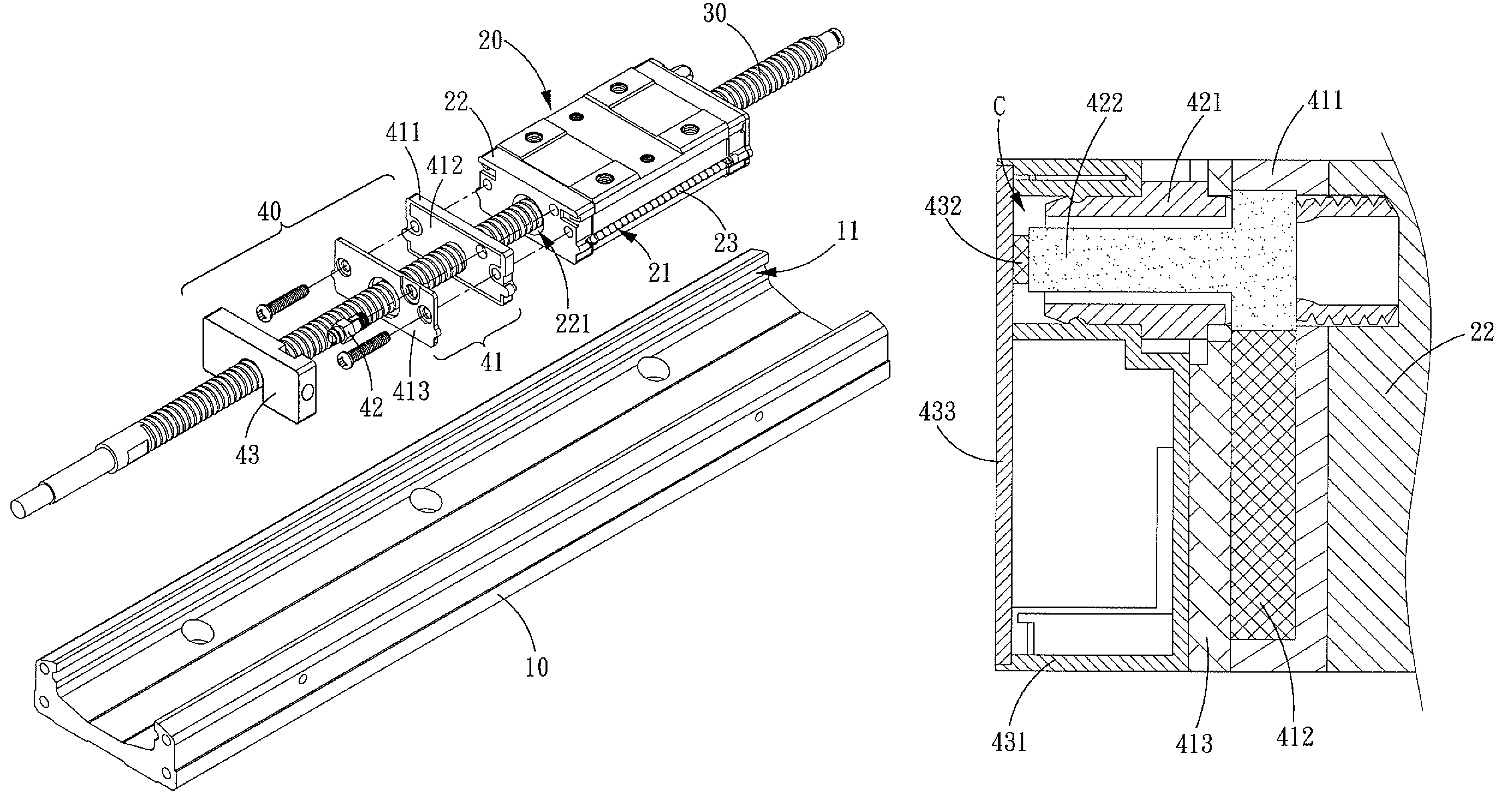

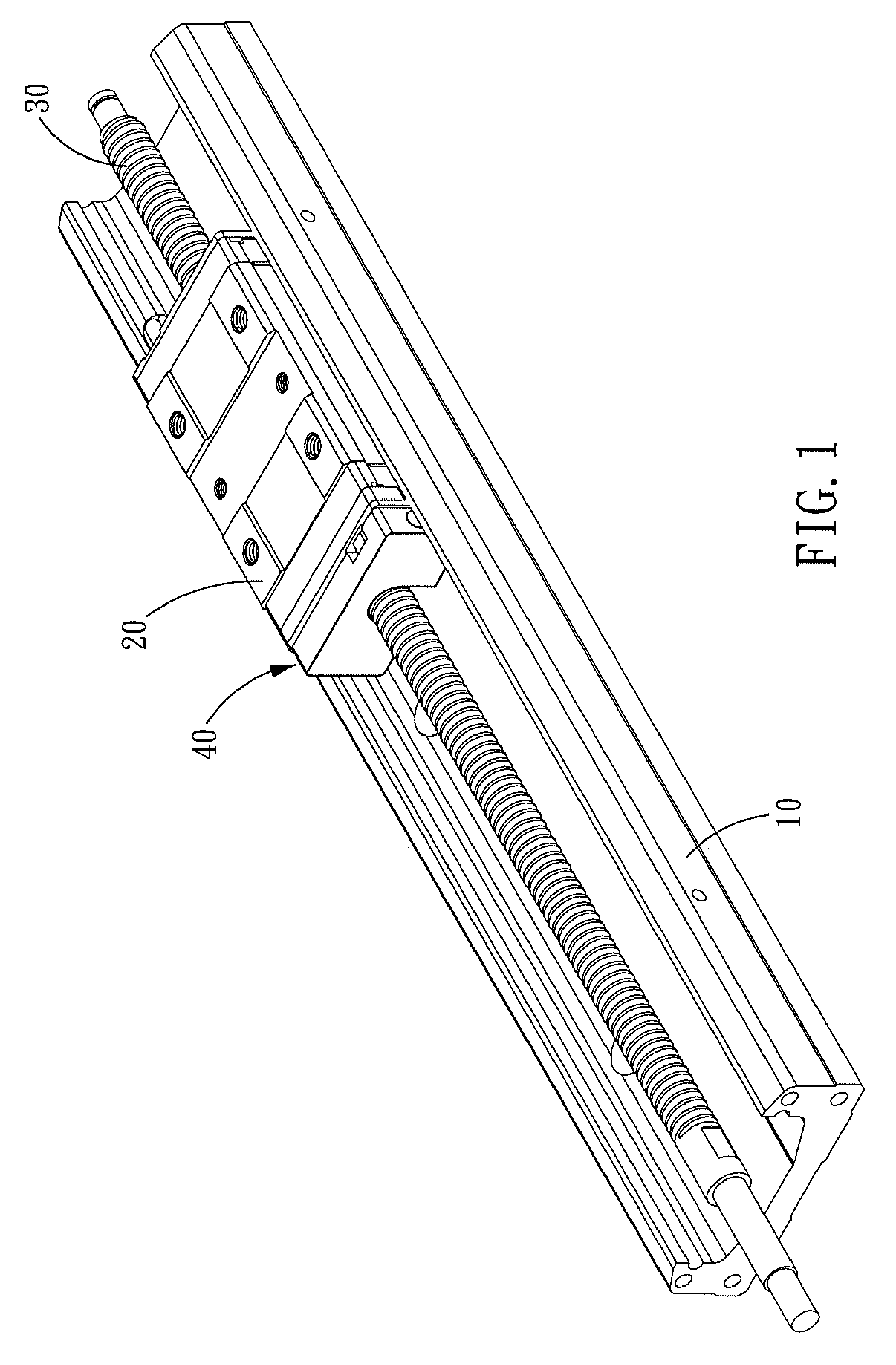

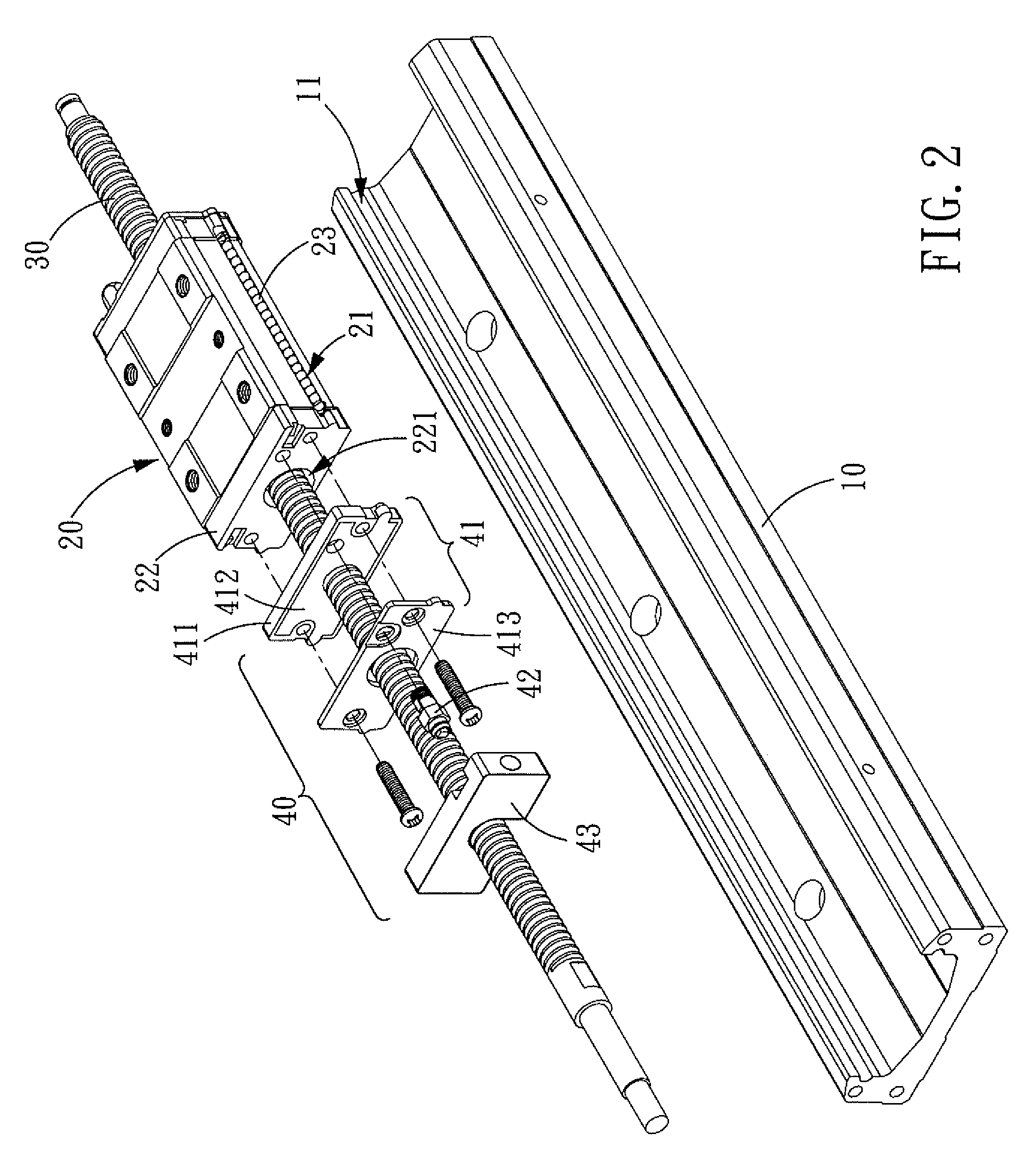

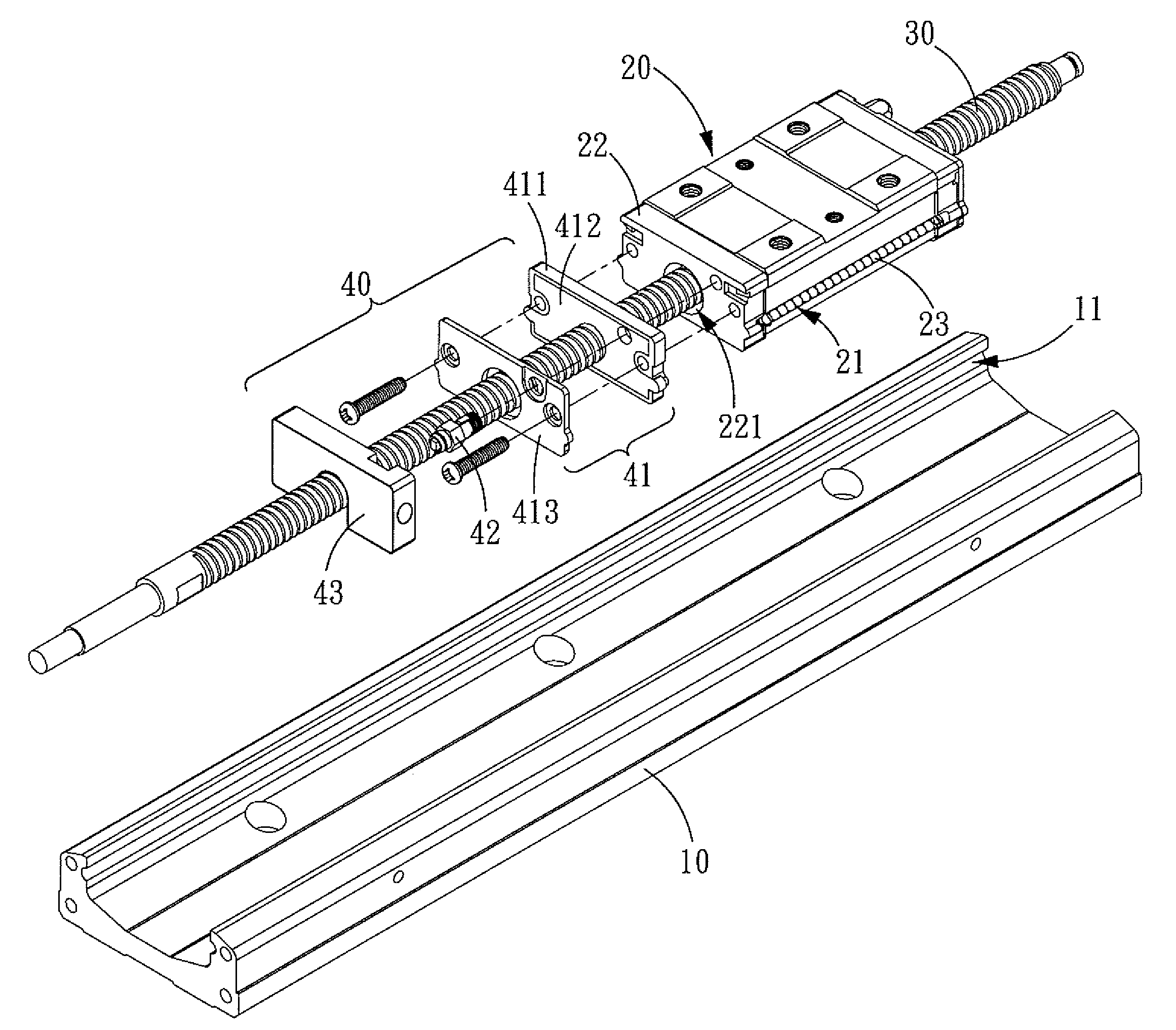

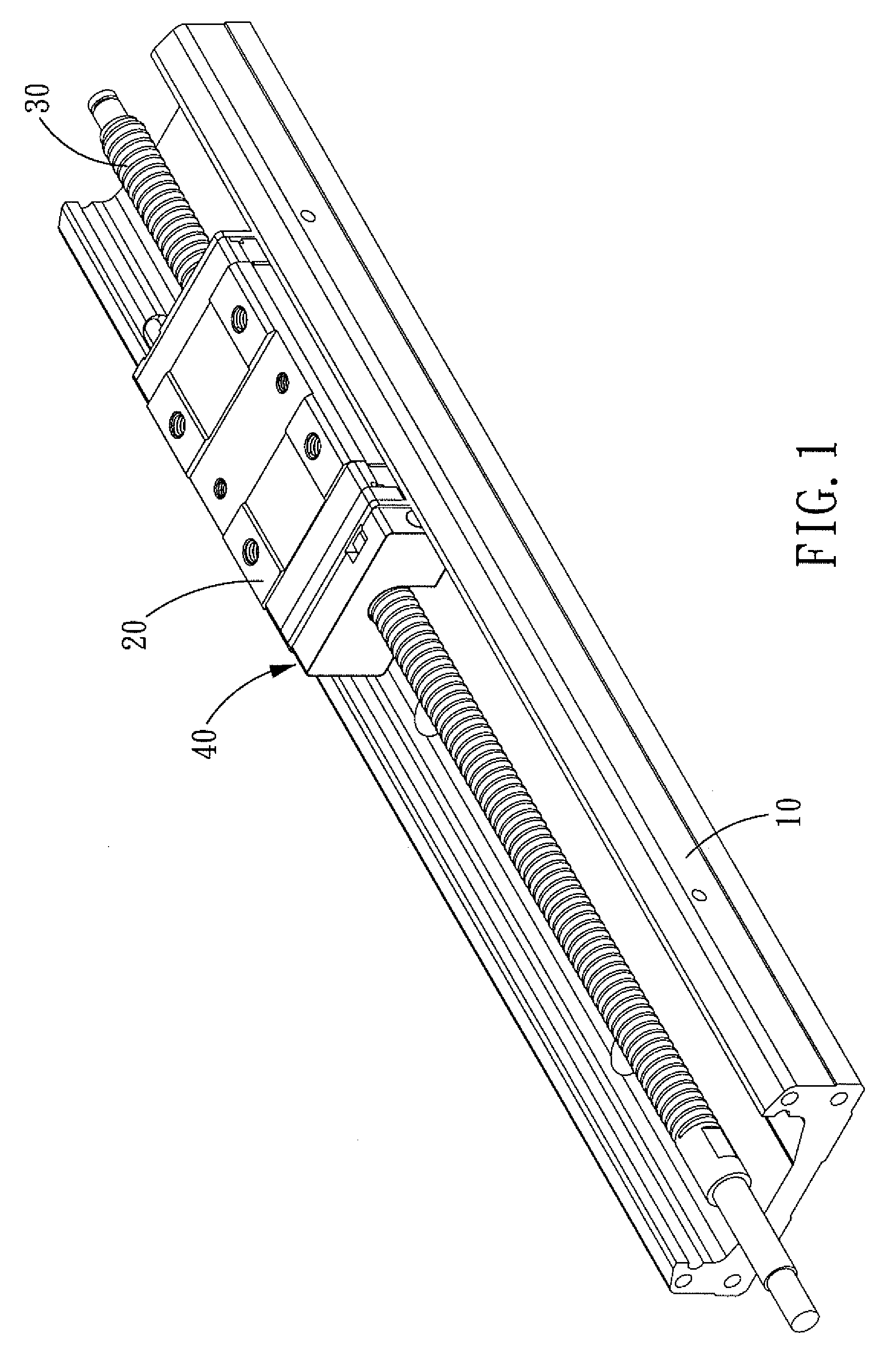

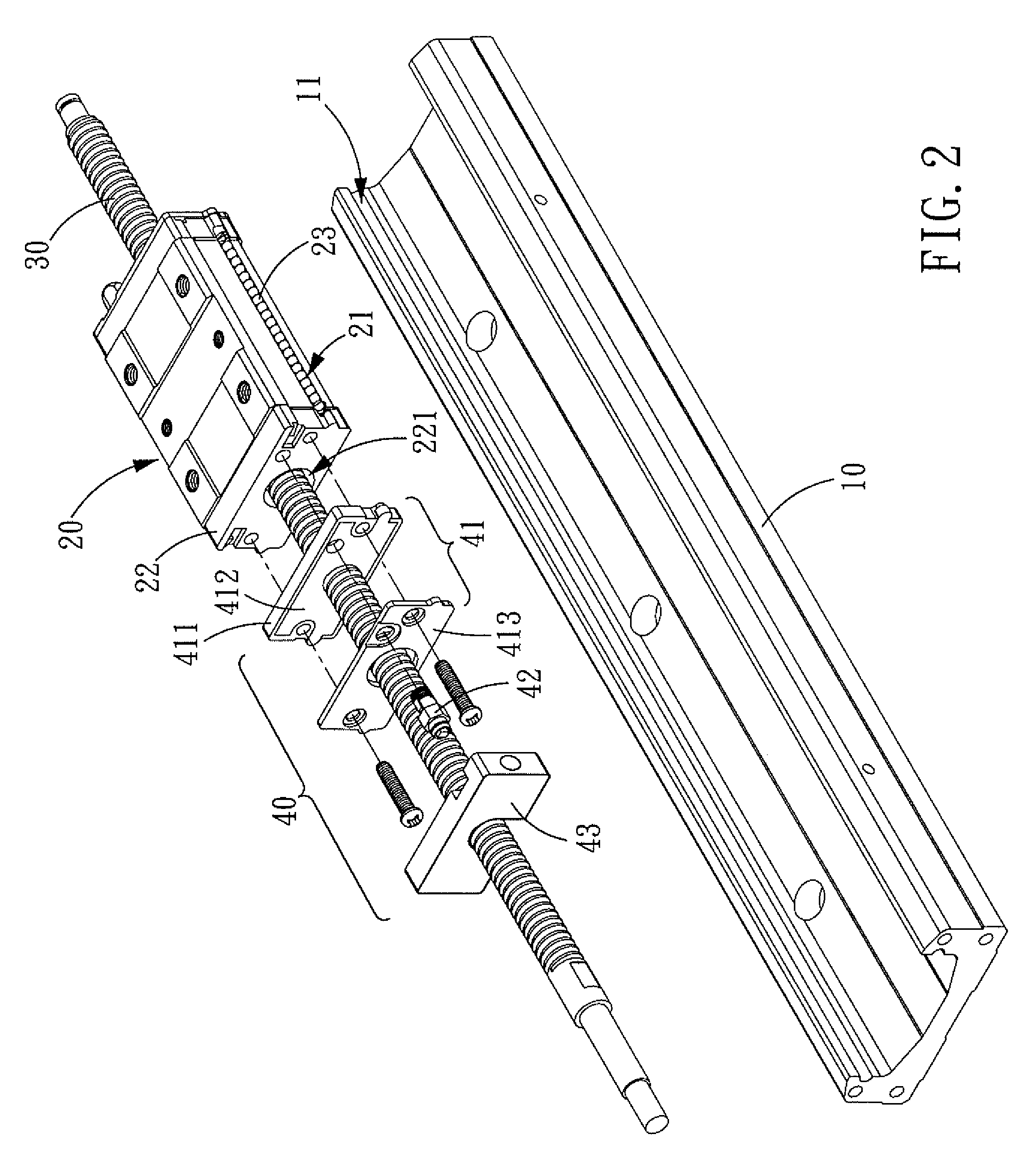

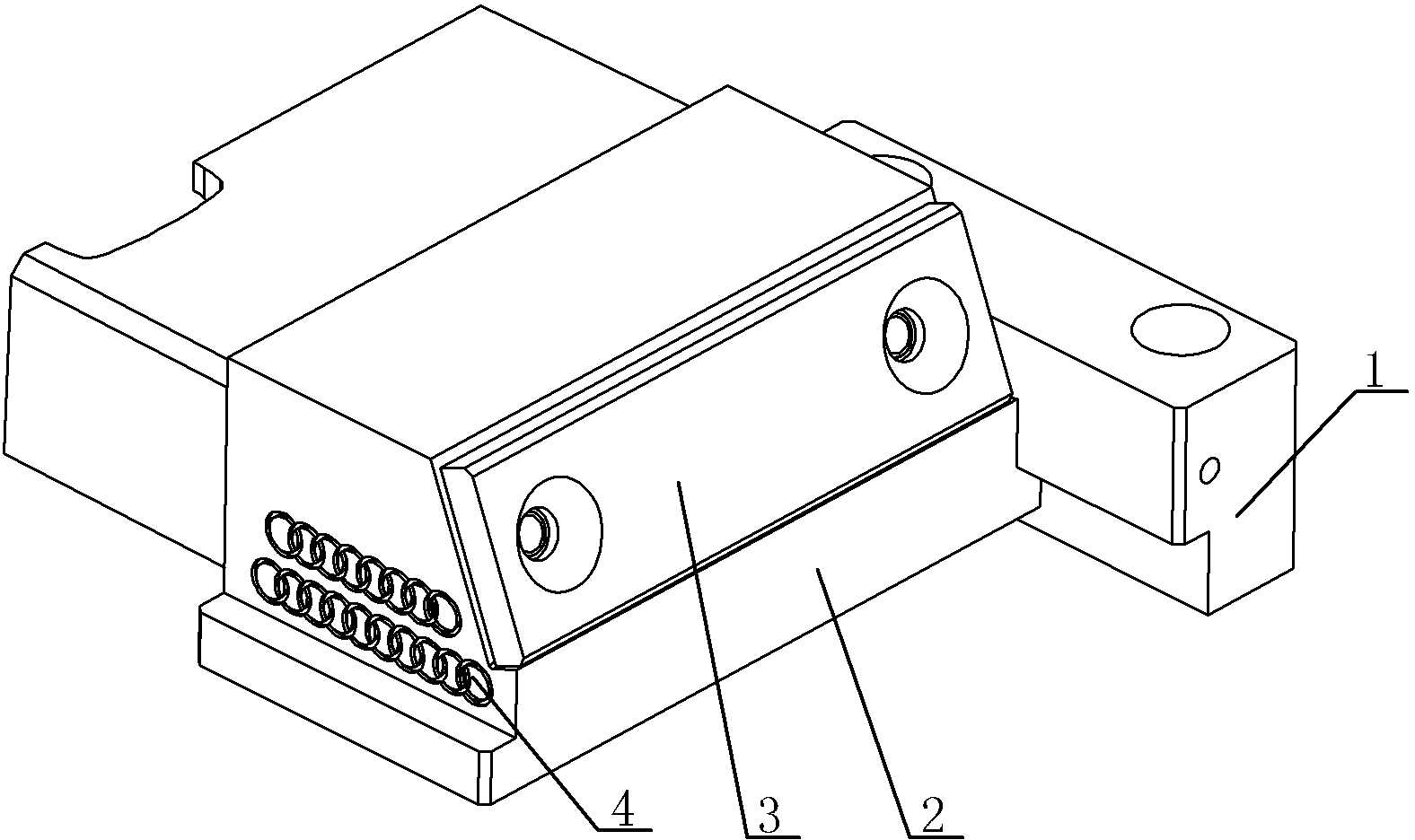

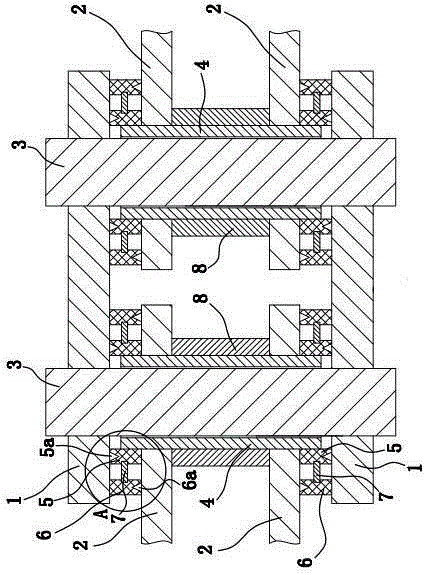

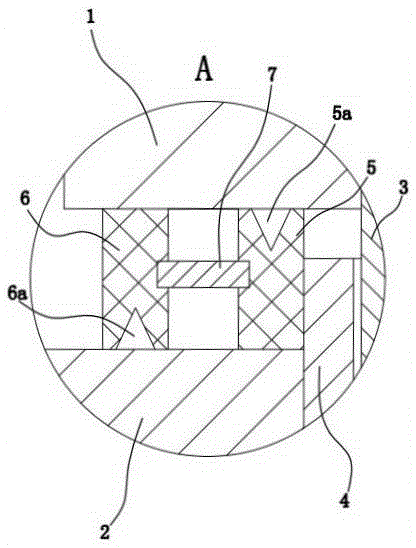

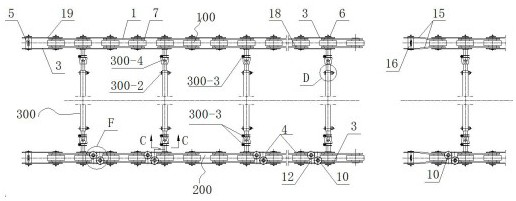

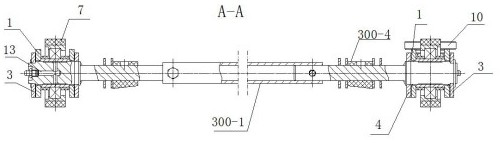

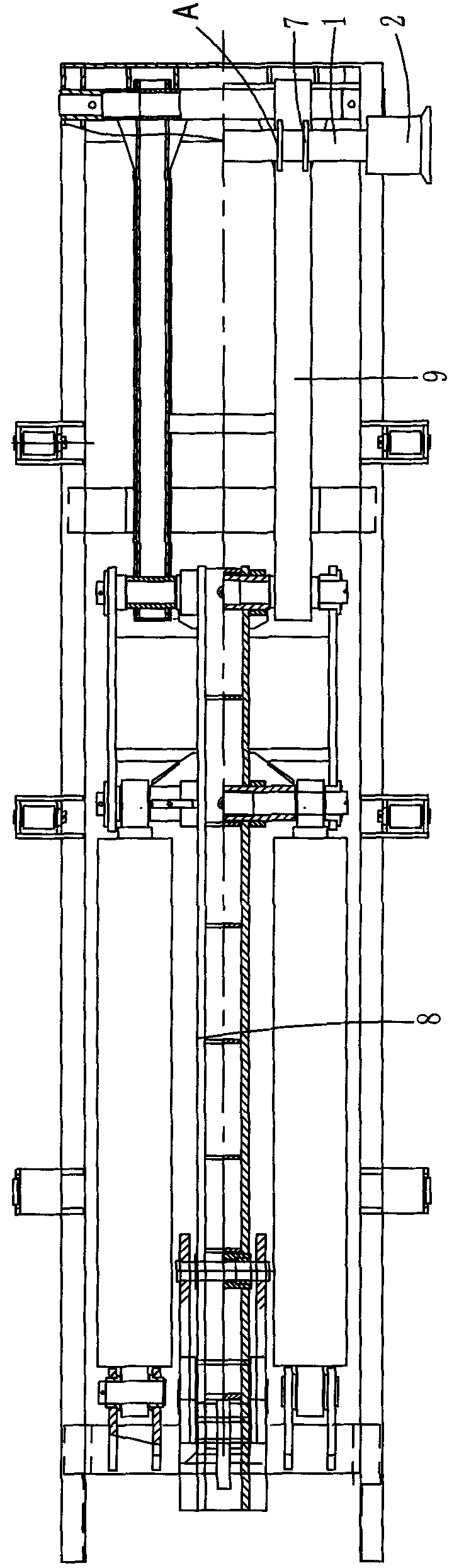

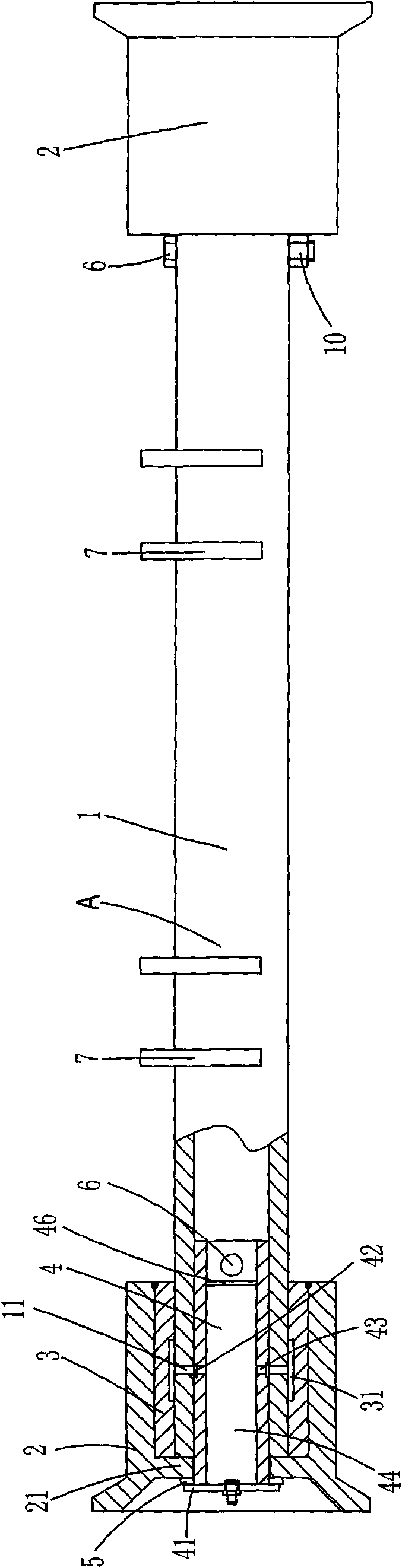

Linear driving device with a self-lubricating assembly

ActiveUS7614790B2Extended lubrication timeEasy to disassembleRotary combination bearingsLinear bearingsPetroleum engineeringLinear drive

A self-lubricating assembly for a linear driving device comprises an oil applying subassembly, an oil transmitting subassembly and an oil container. The oil transmitting subassembly transmits lubricating oil from the oil container to the oil applying subassembly, and the oil applying subassembly is driven by the linear driving device to perform lubricating action automatically. The oil container is provided for storing lubricating oil to prolong lubricating time of the linear driving device.

Owner:HIWIN TECH

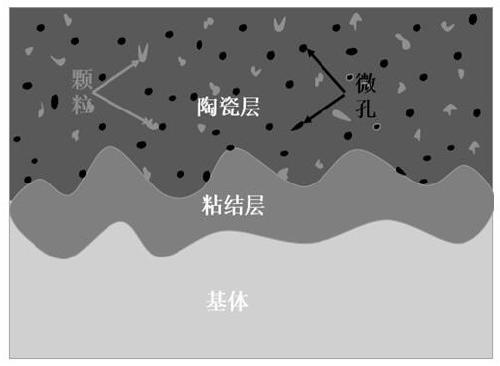

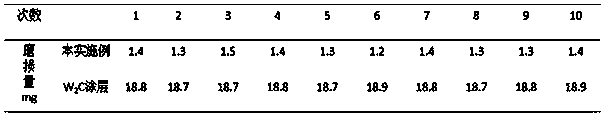

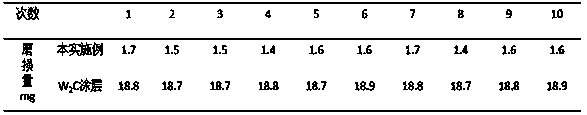

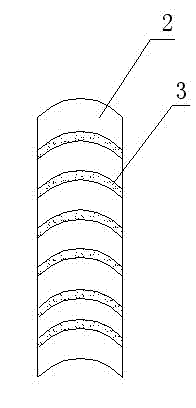

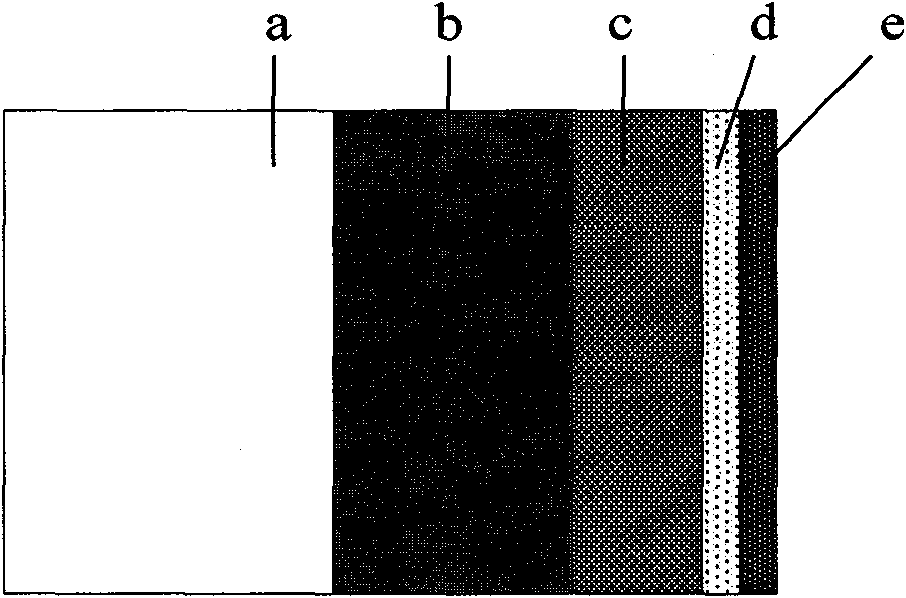

Preparation method of porous wear-resistant thermal spraying ceramic coating

InactiveCN109440044AImprove wear resistanceImprove the lubrication effectMolten spray coatingThermal sprayingWear resistant

The invention discloses a preparation method of a porous wear-resistant thermal spraying ceramic coating, and belongs to the technical field of wear-resistant coating materials. The preparation methodcomprises the steps that a bonding layer Ni-Co-Cr-Al-Y alloy with the thickness of 70-100 microns is sprayed on a pretreated metal substrate by adopting a plasma spraying method, and then a plasma spraying method is adopted to spray a wear-resistant ceramic layer on the surface of the bonding layer Ni-Co-Cr-Al-Y alloy, wherein the bonding layer Ni-Co-Cr-Al-Y alloy comprises, by mass, 0.01-10% ofCo, 0.01-24% of Cr, 0.01-2% of Y, 7-12% of Al and the balance Ni. According to the preparation method, the microstructure of the coating is changed, and specially wear-resistant ceramic coating sheetsor blocks is converted into particles, and micro-holes are formed in the ceramic layer; and the abrasive resistance of the coating can be enhanced by the particles of the hard phase in the ceramic layer, the micro-holes facilities the storage of a lubricating liquid, the lubricating time of a workpiece is prolonged, moreover, a residual hole-forming lubricant in the granular ceramic layer can beself-lubricated, then the lubricating effect of the coating is enhanced, the lubricating and wear-resisting effects of the wear-resistant coating can be greatly enhanced, the comprehensive mechanicalproperty of the coating is improved, and the service life of the coating is prolonged.

Owner:KUNMING UNIV OF SCI & TECH

Method for planting solid lubricating material in laser micropore template

InactiveCN107190304AImprove anti-wear performanceLubrication life improvementElectrophoretic coatingsMetallic material coating processesMicrowaveElectrophoresis

The invention relates to a method for planting a solid lubricating material in a laser microporous template, which belongs to the field of solid lubricating materials; the specific process is carried out according to the following steps: (1) The laser microporous template is made; Drill micropores on the surface of the cladding layer; (2) Before deposition, acid wash off the spatter on the surface of the template; (3) Plant a mixed lubricating material of molybdenum disulfide (MoS2) and polytetrafluoroethylene (PTFE) by electrophoretic deposition in micropores; (4) drying in an oven after deposition; (5) densification of the lubricating layer by microwave sintering. The lubricating layer obtained by the method of the invention stores the lubricating material through the micropores on the surface of the wear-resistant substrate, and slowly releases the lubricating material in the process of friction to play a continuous lubricating effect, thereby greatly improving the lubricating life.

Owner:杭州盛镭激光科技有限公司

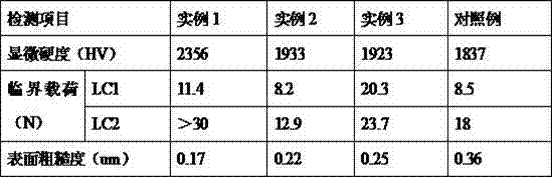

Hard thin film and preparation method thereof

InactiveCN107541710AImprove wear resistanceRelief of stressful situationsVacuum evaporation coatingSputtering coatingGas phaseCrystal orientation

The invention relates to a hard thin film and a preparation method thereof and belongs to the technical field of coating. By adoption of the physical vapor deposition technology and the ionic nitriding technology, a nitride layer and a W / Mo-doped multi-element compound CrTiAlN hard thin film are formed on the surface of a hard alloy, the surface of the thin film is smooth and flat, the thin film grows in a columnar crystal mode, the texture structure is compact, no obvious defect exists, the area, close to a substrate, of the fracture of the thin film is of an obvious fine crystal structure, the growth direction of the thin film is slightly oblique by means of nitriding treatment and shows predominant crystal orientation to a certain extent, and the abrasion resistance and the bonding strength with the substrate of the CrTiAlN thin film are improved; and meanwhile the thin film is more compact after nitriding is completed, as the element compositions of the thin film show gradient change, continuous transition of the physical and chemical performance and the texture structure of the film layer is achieved, the stress condition of an interface can be relieved, and the abrasion resistance is enhanced.

Owner:CHANGZHOU C PE PHOTO ELECTRICITY SCI & TECHN

Linear Driving Device with a Self-Lubricating Assembly

ActiveUS20080285898A1Extended lubrication timeEasy to disassembleRotary combination bearingsLinear bearingsPetroleum engineeringLinear drive

A self-lubricating assembly for a linear driving device comprises an oil applying subassembly, an oil transmitting subassembly and an oil container. The oil transmitting subassembly transmits lubricating oil from the oil container to the oil applying subassembly, and the oil applying subassembly is driven by the linear driving device to perform lubricating action automatically. The oil container is provided for storing lubricating oil to prolong lubricating time of the linear driving device.

Owner:HIWIN TECH

Sealing ring chain

InactiveCN106763501AFirmly connectedReduce volatilityChain linksDriving chainsEngineeringO-ring chain

The invention provides a sealing ring chain. By adoption of the sealing ring chain, the problem that existing sealing ring chains are short in service life is solved. The sealing ring chain is formed by sequentially combining a plurality of chain units. Each chain unit comprises two inner chain plates fixed through a shaft sleeve, wherein the outer sides of the two inner chain plates are each provided with an outer chain plate, and the two outer chain plates are fixed through a pin shaft which is sleeved with the shaft sleeve; and a sealing ring is arranged between each inner chain plate and the corresponding outer chain plate which are located on the same side and arranged on the shaft sleeve in a sleeving mode. The two end faces of the sealing rings are each a plane and are separately attached to the inner chain plates and the outer chain plates. The sealing rings are fixed to the inner chain plates through uneven connecting structures. At least two oil storage grooves and grooves which are each in an annular shape are formed in the end faces, making contact with the outer chain plates, of the sealing rings. All the oil storage grooves are concentrically distributed. Each groove is formed between every two corresponding adjacent oil storage grooves. The widths and the depths of the grooves are both larger than that of the oil storage grooves. The sealing ring chain has the advantage of long service life.

Owner:TIANJIN QIANGLI CHAIN

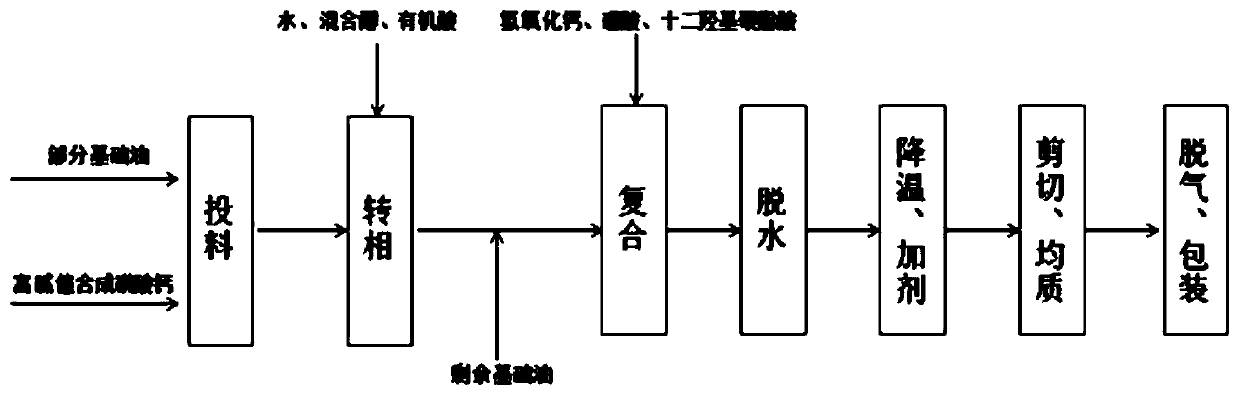

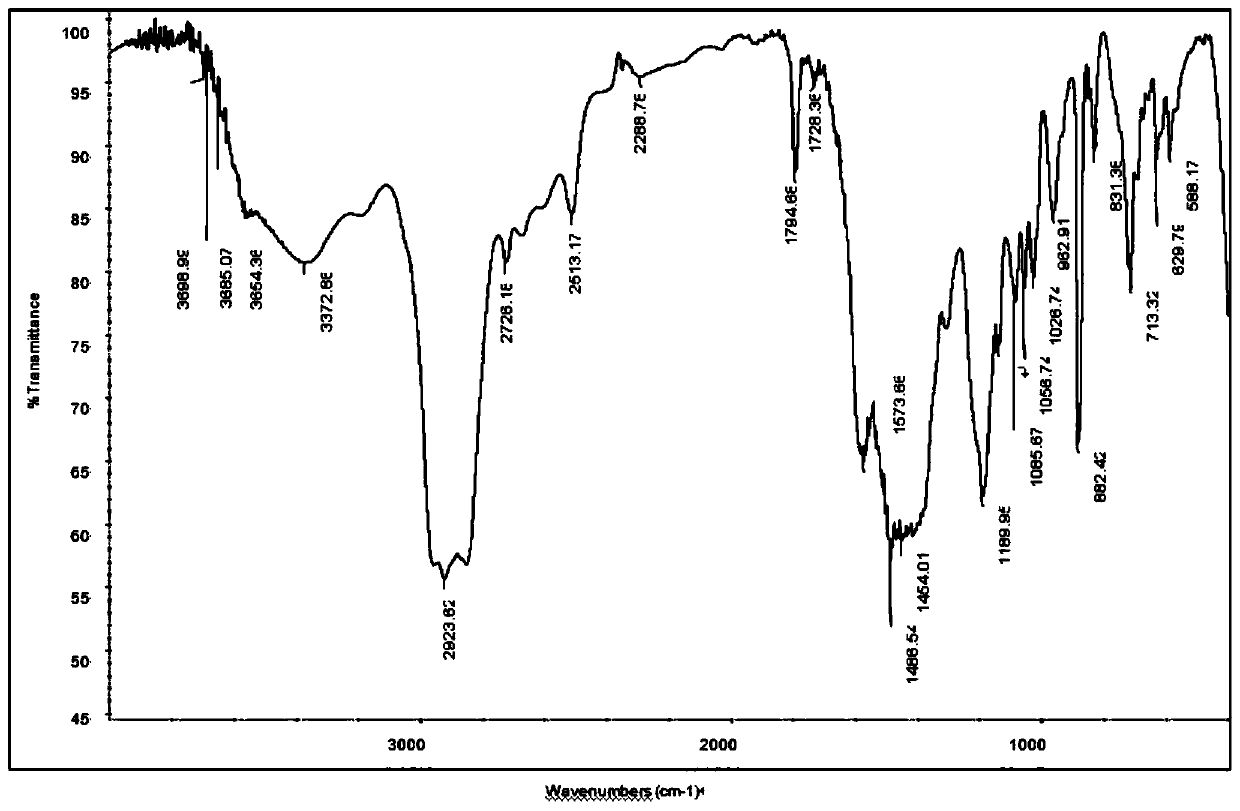

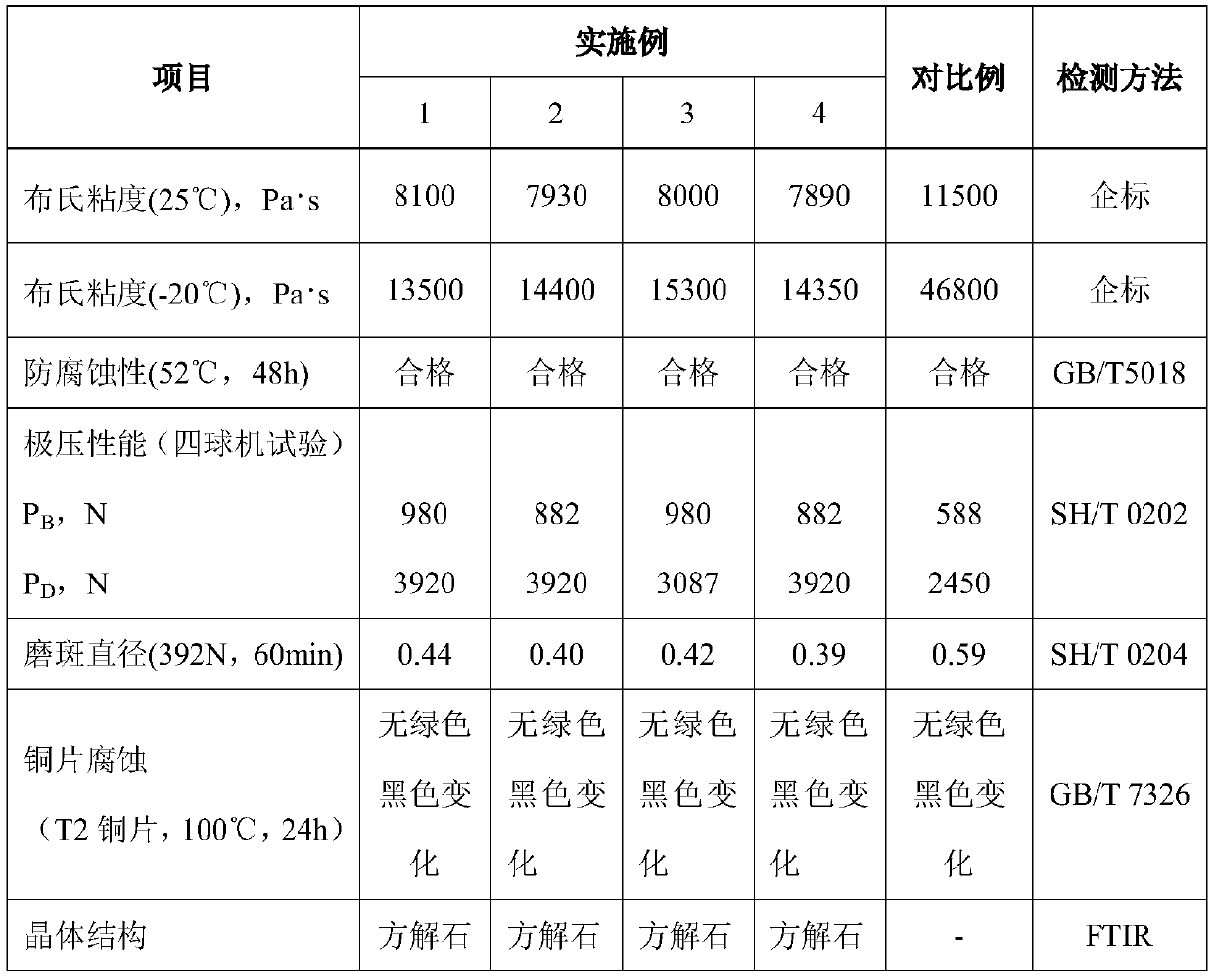

Composite calcium sulfonate type railway wheel rail lubricating grease and preparation method thereof

ActiveCN111500343AImprove featuresWide temperature rangeLubricant compositionAntioxidantHydroxystearic Acid

The invention relates to composite calcium sulfonate type railway wheel rail lubricating grease that comprises 10-30% of high-base-number calcium sulfonate, 65%-85% of base oil, 0.1%-0.6% of mixed alcohol, 0.2%-0.6% of organic acid, 0.2%-0.7% of 12-hydroxystearic acid, 0.1%-0.4% of boric acid, 0.1%-0.3% of calcium hydroxide, 0.3%-0.8% of antioxidant, 0.1%-0.4% of antirust agent and 0.8%-1.2% of solid additive. The percentage is the mass percentage of the total amount of the lubricating grease as a base number. The preparation method comprises the following steps: adding the high-base-number calcium sulfonate and the base oil into a reaction kettle, and fully stirring; adding water, alcohol and acid, heating to 80-89 DEG C, and keeping the constant temperature for 1-3 hours; adding calciumhydroxide, boric acid and 12-hydroxystearic acid, and compounding at 95-100 DEG C for 0.5-1 hour; raising the temperature to 130 to 150 DEG C and dehydrating; and cooling to 80-90 DEG C, adding an additive, shearing, homogenizing and degassing to obtain the product. According to the invention, the lubricating grease has excellent mechanical stability, extreme pressure antiwear property, water resistance, rust prevention and adhesion, is not hardened after long-term storage, can keep excellent pumpability and injection capacity, adapts to temperature change in south and north winter and summerin China, and can be used in all weathers.

Owner:无锡中石油润滑脂有限责任公司

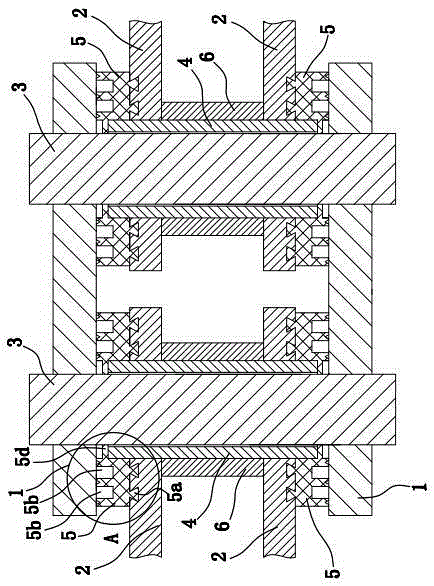

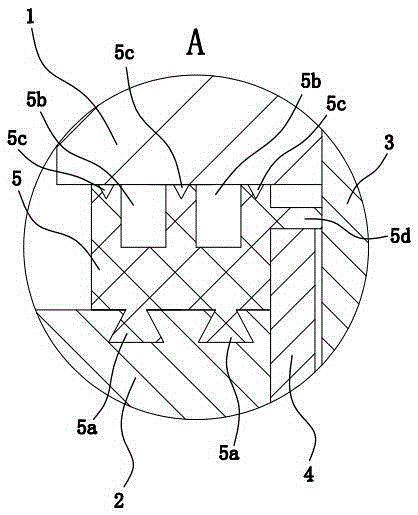

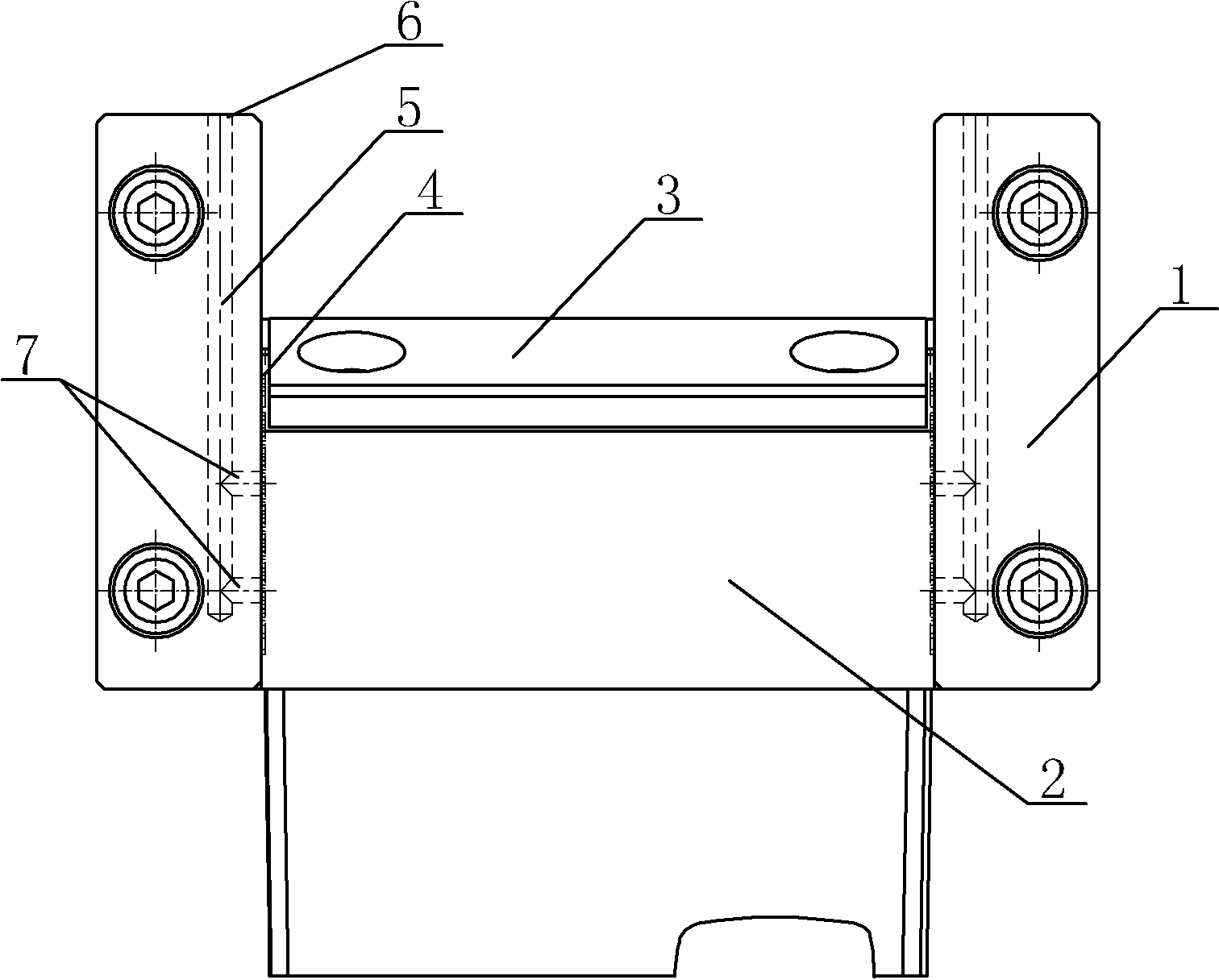

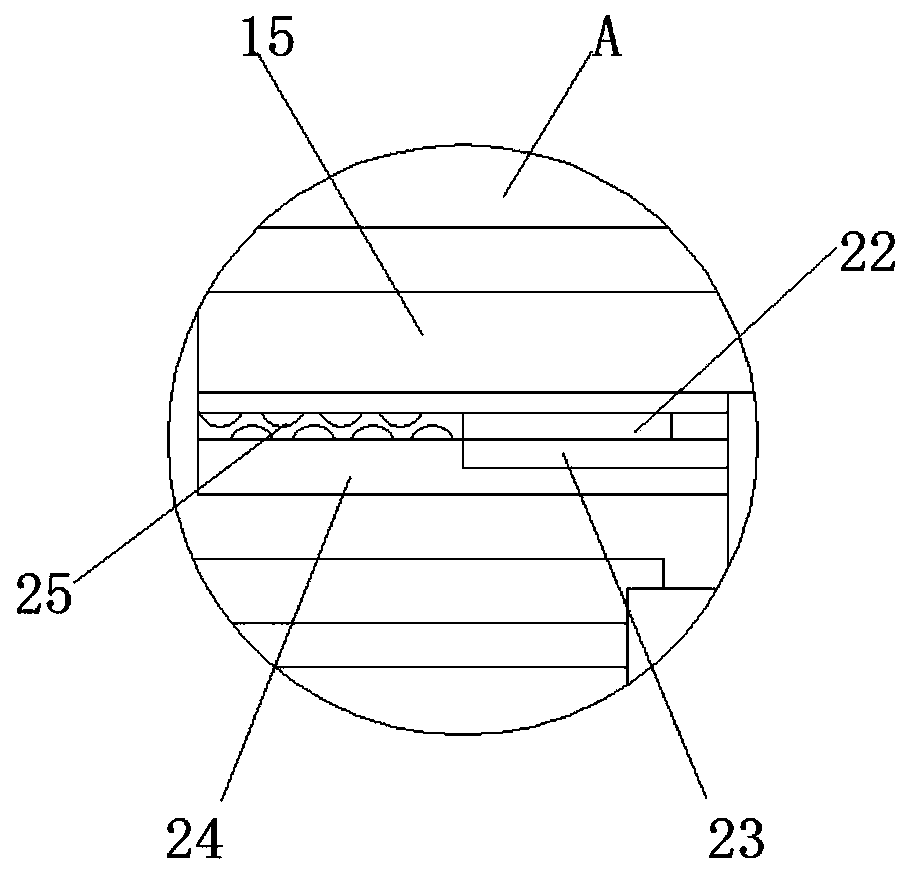

Self-lubricating line guide rail structure

The invention provides a self-lubricating line guide rail structure, which enables lubricating oil to be added under the condition of not detaching a mould, ensures the use time of the mould and reduces the labor cost. The self-lubricating line guide rail structure comprises line straight-line guide rails, a line base and a line insert; the line insert is tightly fixed at one end of the line base; the two sides of the line base are clamped on the line straight-line guide rails at the two sides; the self-lubricating line guide rail structure is characterized in that the regions of the two sides of the line base, which are stuck with the line straight-line guide rails, are provided with annular oil grooves; the annular oil grooves are distributed along the line straight-line guide rails in a straight-line manner; lubricating agent oil paths are arranged inside the line straight-line guide rails; oil inlets of the lubricating agent oil paths are located on the tail end faces of the line straight-line guide rails; oil outlets of the lubricating agent oil paths are over against the annular oil grooves; and the oil inlets are provided with oil feeding nozzles with check valves.

Owner:VANGUARD TECH WUXI

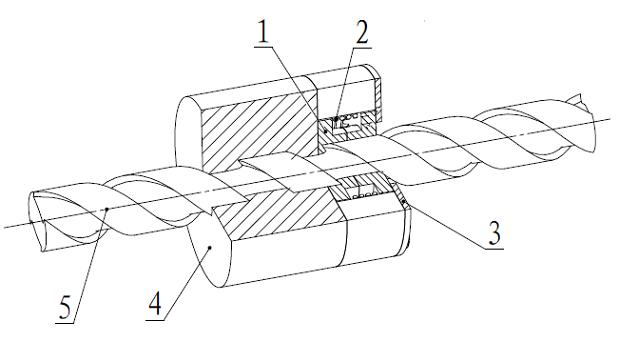

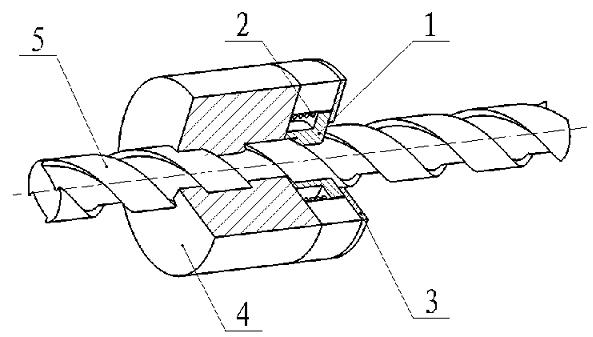

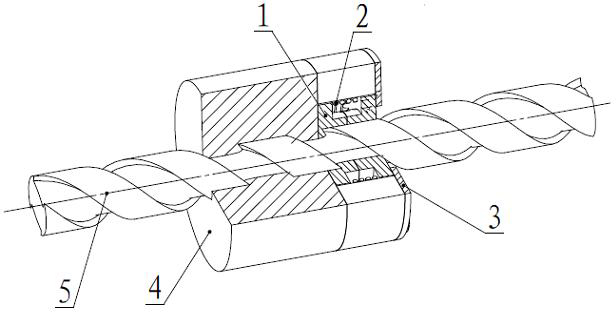

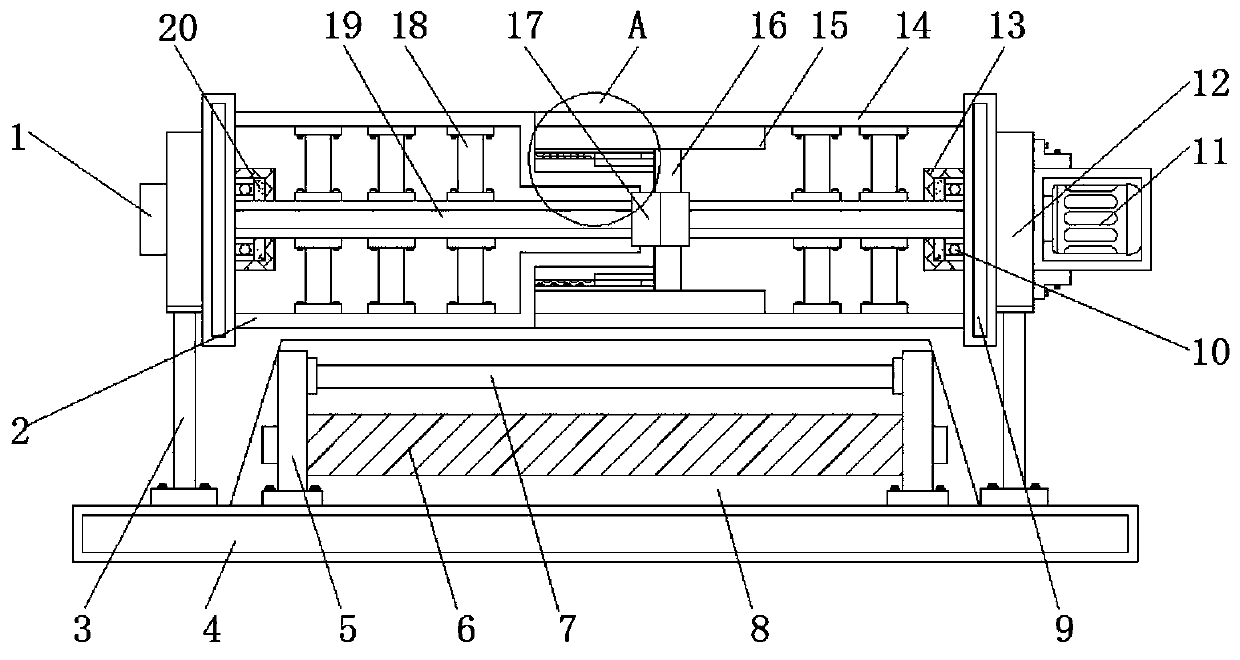

Automatic lubricating device being suitable for nut-screw transmission mechanism

The invention discloses an automatic lubricating device being suitable for a nut-screw transmission mechanism. The automatic lubricating device comprises at least one graphite nut, a baffle, a driving nut and a lead screw, wherein the graphite nut is sleeved on the lead screw, and the baffle and the driving nut are in rigid connection to clamp the graphite nut between the baffle and the driving nut, so that the graphite nut and the driving nut can synchronously move; the graphite nut is arranged in the driving nut, the lubricating device also comprises a torsion spring which is arranged on the graphite nut, and the thread of the graphite nut anticlockwise rotates to be clung to the two sides of the groove of the lead screw; and the cross section of the graphite nut is annular or semi-annual. According to the automatic lubricating device provided by the invention, solid is used for lubrication, the lubrication time is long, the volume is small, the lubrication action is realized by virtue of self motion of the nut-screw transmission mechanism only without maintenance, the structure is simple, the mechanism part is less, the working accuracy requirement is not high, and the maintenance is convenient.

Owner:NANJING KANGNI

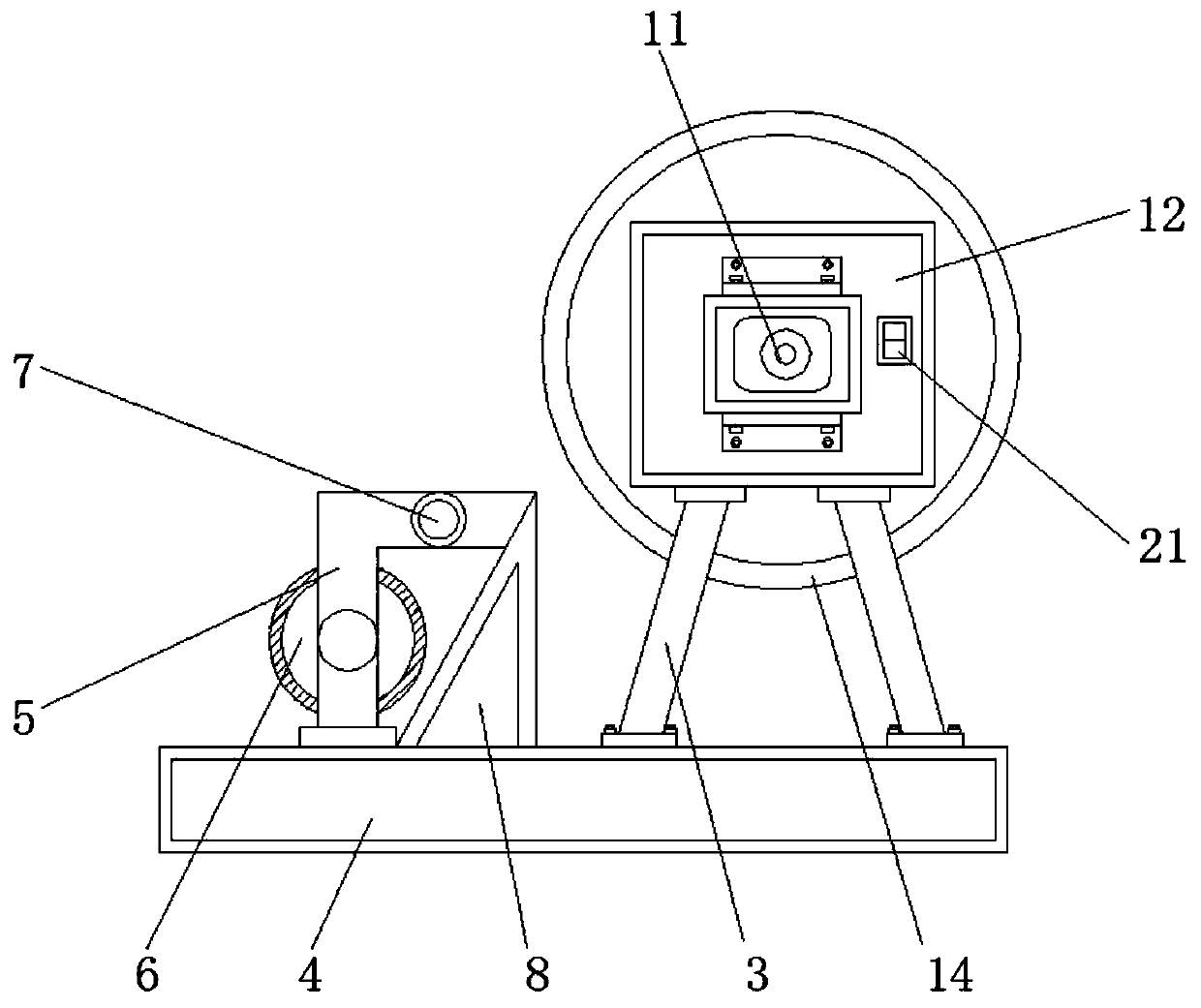

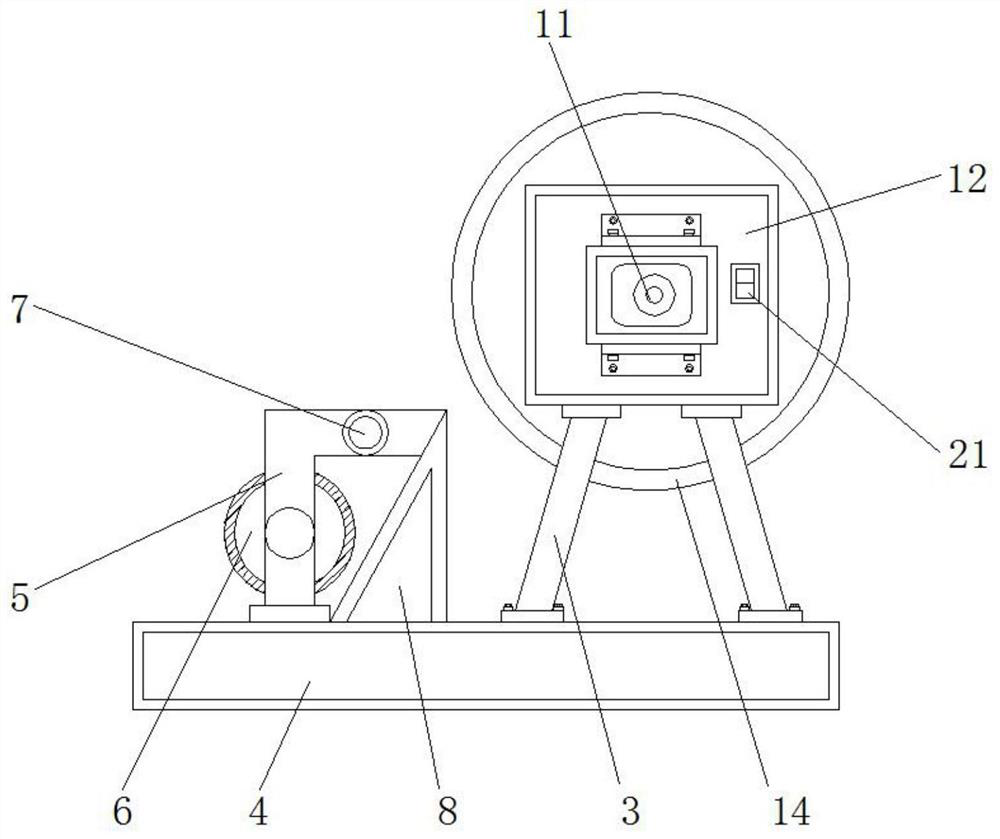

Lubricating device for elevator lifting and operating rolling wheels

The invention provides a lubricating device for elevator lifting and operating rolling wheels and relates to the technical field of elevator accessories. The lubricating device comprises a supporting frame, a lubricating wheel, a lubricating oil tank and a flow guide pipeline. The lubricating wheel is arranged in front of the supporting frame. A bearing is arranged between the lubricating wheel and the supporting frame. The lubricating oil tank is arranged at the top end of the supporting frame. The lubricating oil tank is transparent. The flow guide pipeline is arranged at the bottom of the lubricating oil tank and is fixed to the supporting frame through a fixing plate. A pipe orifice at the tail end of the flow guide pipeline is arranged over the lubricating wheel in an extending mode. The lubricating device for the elevator lifting and operating rolling wheels is convenient to use, reasonable in structural design, lasting and effective in lubrication, convenient to replace and maintain at any time and beneficial for improving the lubricating efficiency and prolonging the lubricating time.

Owner:含山县众力铸造有限公司

Wire-drawing nanometer graphite lubricant of single crystal copper bonding wire and preparation method of lubricant

The invention discloses a wire-drawing nanometer graphite lubricant of a single crystal copper bonding wire. The wire-drawing nanometer graphite lubricant is prepared by adding 100ppm-150ppm of nanometer graphite to a common lubricant through ultrasonic stirring. The nanometer graphite in the lubricant can enter a lubricating gap, so that the lubricant is not extruded out under high pressure; the preparation method has the advantages that the lubricating time is long, the lubricating effect is good, and a wire-drawing mould is difficult to damage; and besides, service life of the mould is remarkably prolonged, the energy consumption and the cost are remarkably reduced, and the economic value and the social value are remarkable.

Owner:NEIJIANG HAIDE TECH

Novel sealing chain

InactiveCN106763496AIncrease the difficultyImprove connection tightnessChain linksEngineeringOil storage

The invention provides a novel sealing chain which solves the problem that the existing sealing chain is short in life. The novel sealing chain is formed by combining a plurality of chain units sequentially; each chain unit comprises two inner chain plates that are fixed by a shaft sleeve; two outer chain plates are arranged on the outer sides of the two inner chain plates of each chain unit, and are fixed by a pin shaft correspondingly; the shaft sleeves are arranged on the pin shafts in a sleeving manner; a first sealing ring and a second sealing ring are arranged between one inner chain plate and one outer chain plate that are arranged on the same side correspondingly; the first sealing rings are arranged on the shaft sleeves in a sleeving manner; the second sealing rings are arranged on the first sealing rings in a sleeving manner; the two end faces of each first sealing ring and the two end faces of each second sealing ring are planes; the two end faces of one first sealing ring and the two end faces of one second sealing ring abut against one inner chain plate and one outer chain plate correspondingly; the first sealing rings are fixedly connected with the inner chain plates; the second sealing rings are fixedly connected with the outer chain plates; an annular first oil storage groove is formed in the end face, contacted with one outer chain plate, of one first sealing ring correspondingly; and an annular second oil storage groove is formed in the end face, contacted with one inner chain plate, of one second sealing ring correspondingly. The novel sealing chain has the advantage of long service life.

Owner:TIANJIN QIANGLI CHAIN

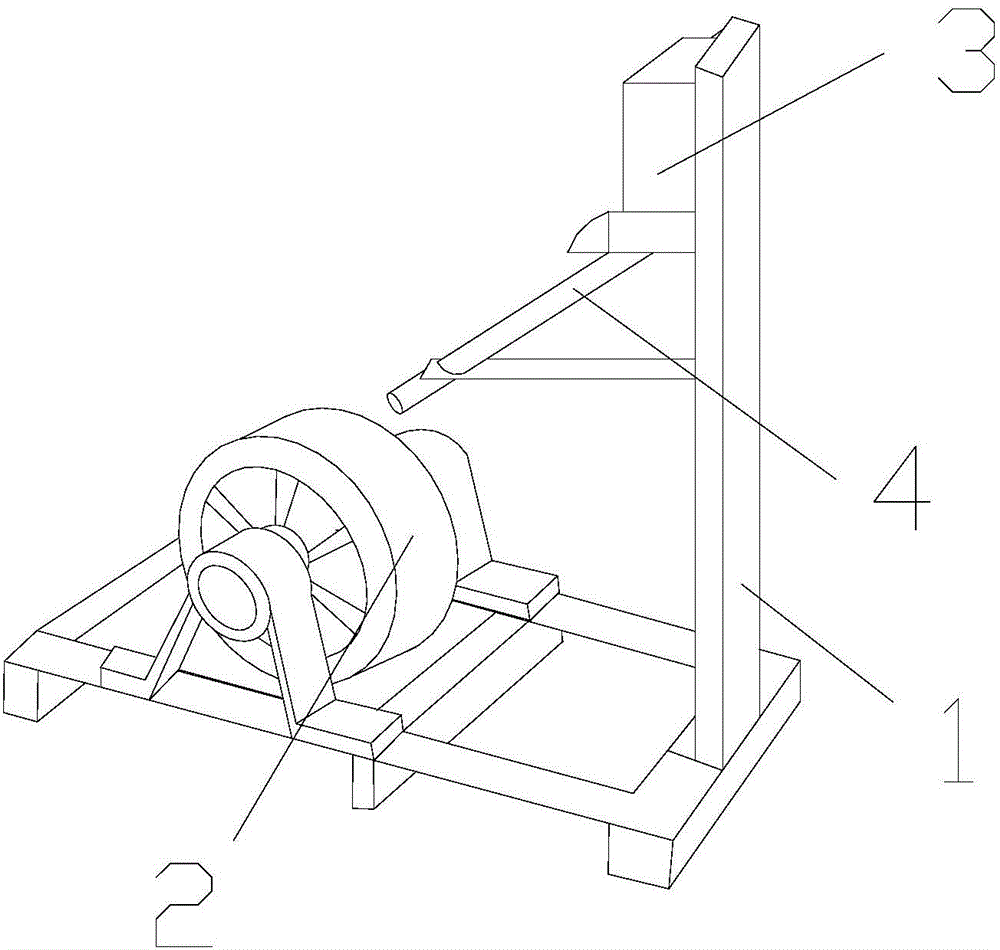

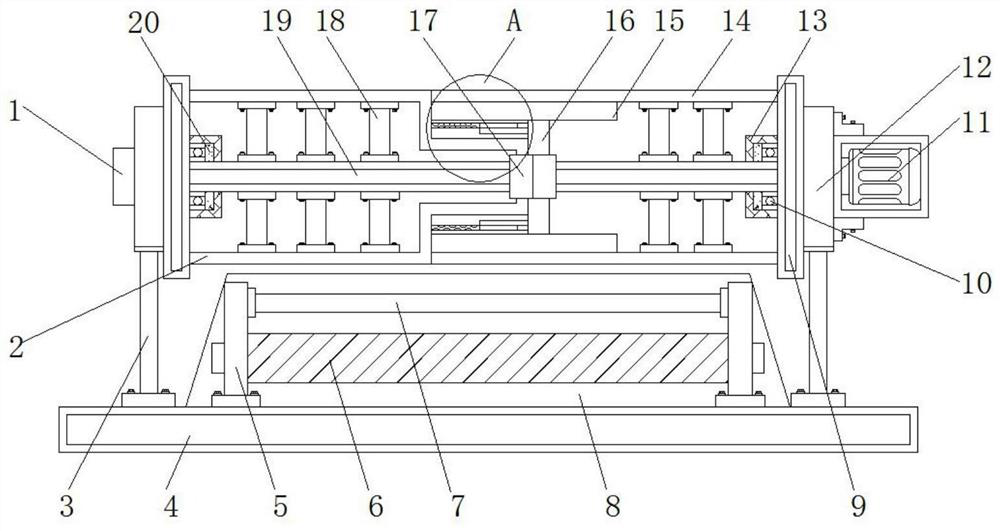

Detachable expanding and contracting coiling drum

ActiveCN110681721APrevent leakageAvoid frictional damageBearing componentsElectric machineryEngineering

The invention discloses a detachable expanding and contracting coiling drum. The detachable expansion and retraction coiling drum comprises a base, a controller and a motor, wherein second supports are arranged at the top end of the base, a rotating drum is arranged between one sides of the second supports, a second drum shell is arranged on the other side above the base through first supports, sleeve rings are arranged on one side of the second drum shell and one side of a first drum shell correspondingly, a rotating rod is arranged between the inner wall of one side of the first drum shell and the inner wall of one side of the second drum shell, and bearing blocks are correspondingly arranged on the outer walls of the two sides of the rotating rod, one side of the interior of the seconddrum shell and one side of the interior of the first drum shell. According to the detachable expanding and contracting coiling drum, second connecting rods are uniformly arranged between the outer walls, on the inner wall of the first drum shell, of the rotating rod and between the outer walls, on the inner wall of the second drum shell, of the rotating rod, and a connecting block is arranged at the middle position of the rotating rod, so that the strength of the expanding and contracting coiling drum is strengthened through the structure, and the service life of the expanding and contractingcoiling drum is effectively prolonged.

Owner:镇江市宏业科技有限公司

Planet carrier lubricating structure of wind power gear box

PendingCN110185779AExtended lubrication timeImprove the lubrication effectGear lubrication/coolingElectricityPlanet

The invention discloses a planet carrier lubricating structure of a wind power gear box. The structure comprises a box body, a planet carrier, a planet carrier bearing, a pin shaft, a planet wheel anda planet wheel bearing; the planet carrier is mounted on the box body through the planet carrier bearing, the pin shaft is arranged on the planet carrier, the planet wheel is mounted on the pin shaftthrough the planet wheel bearing, the pin shaft forms an oil storage groove and an oil way, and the oil way is used for guiding oil in the oil storage groove to the planet wheel bearing for lubricating the planet wheel bearing, the oil way communicates with the oil storage groove, the planet carrier is provided with an oil inlet allowing oil to enter the oil storage groove, the oil storage grooveand the oil inlet are aligned, the hole opening area of the oil storage groove is smaller than the hole opening area of the oil inlet, and the planet carrier lubricating structure of the wind power gear box further comprises an oil spraying structure for spraying oil into the oil inlet when being aligned with the oil inlet. The structure has the beneficial effects that compared with a traditionallubricating manner, the structure is simple, and machining cost is low.

Owner:NANJING HIGH SPEED GEAR MFG

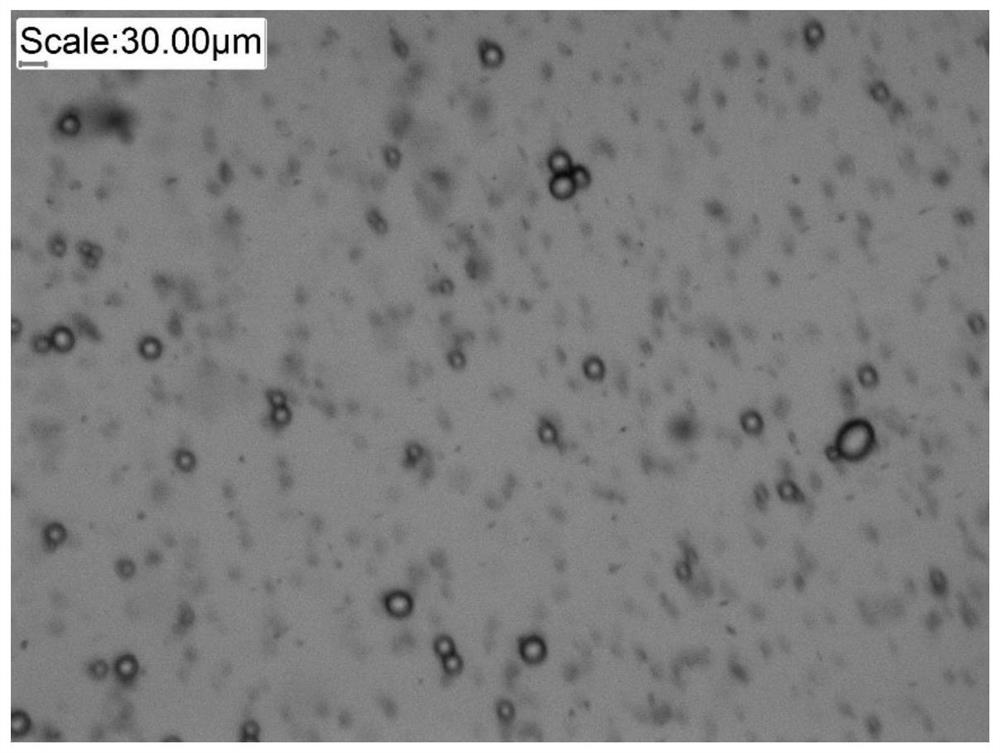

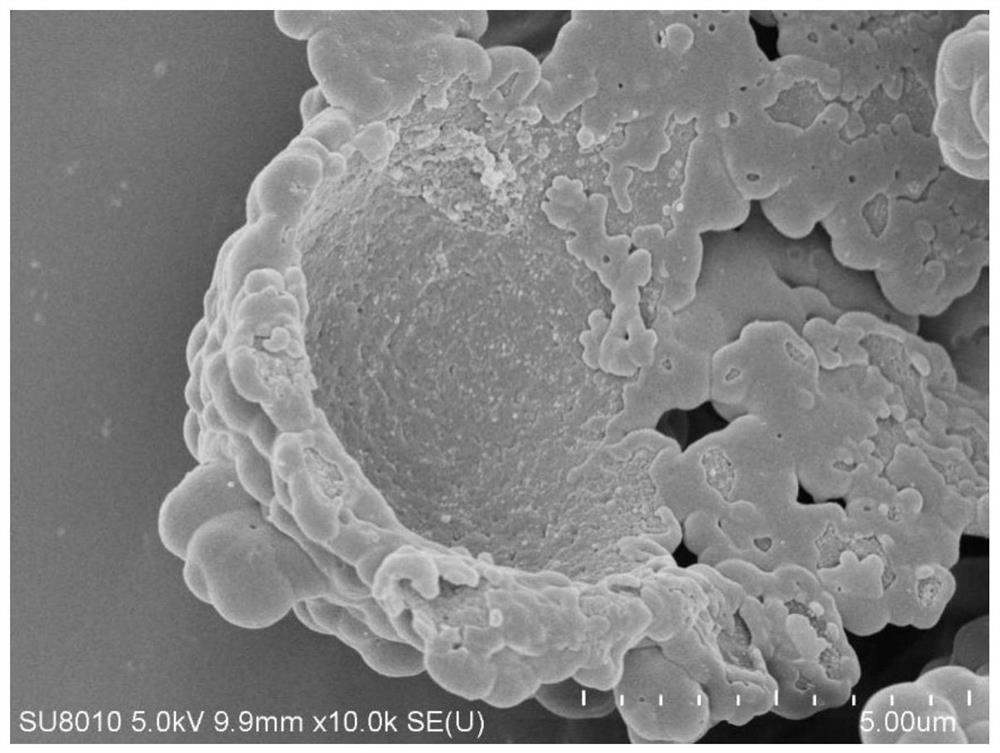

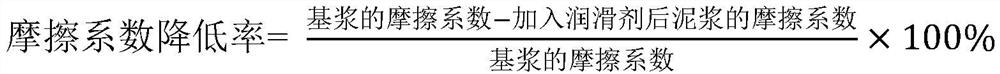

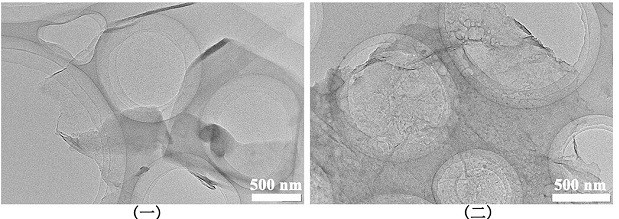

High-temperature-resistant microcapsule lubricant, preparation method and application thereof, and water-based drilling fluid

ActiveCN113549433AImprove temperature resistanceImprove the lubrication effectDrilling compositionMicroballoon preparationEmulsionMicrosphere

The invention relates to the field of oilfield chemistry, and discloses a preparation method of a high-temperature-resistant microcapsule lubricant, which comprises the following steps: (1) mixing a prepolymer solution prepared from formaldehyde and urea with carbon microspheres to obtain a wall material mixed solution; (2) using an emulsifier, an ionic liquid, lubricating oil, an anti-wear reagent at extreme pressure and water to prepare a compound emulsion; and (3) in the presence of a curing agent, carrying out a reaction on the wall material mixed solution and the compound emulsion under an acidic condition, and standing, filtering and drying the product to obtain the high-temperature-resistant microcapsule lubricant. The elastic modulus of the microcapsule lubricant at normal temperature is not lower than 1550 MPa, and the microcapsule lubricant has excellent temperature resistance and can resist the temperature of 150 DEG C; 3% w / v of the microcapsule lubricant is added into water-based drilling fluid base slurry, and the friction coefficient reduction rate of the slurry is greater than 80% after the slurry is subjected to hot rolling at 150 DEG C for 16 hours; and after the microcapsule lubricant is subjected to hot rolling in a high-temperature water phase at 150 DEG C for 16 hours, the mass retention rate is greater than 80%.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

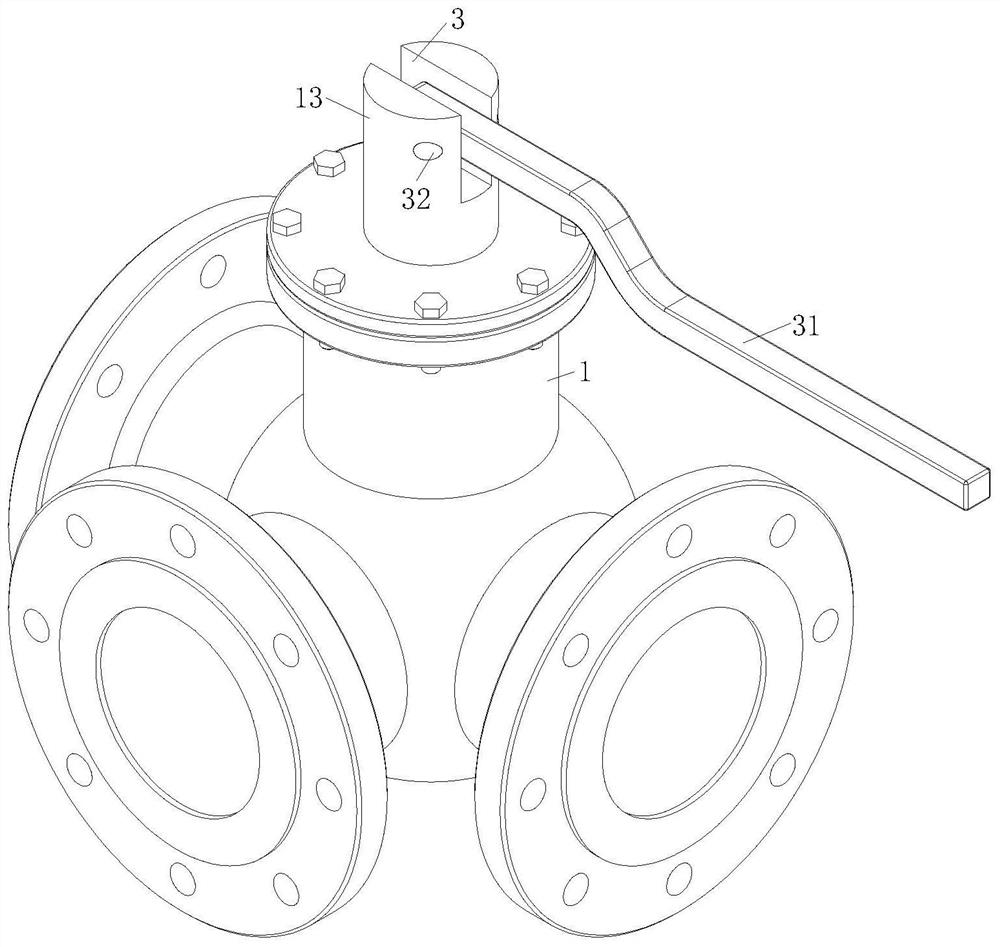

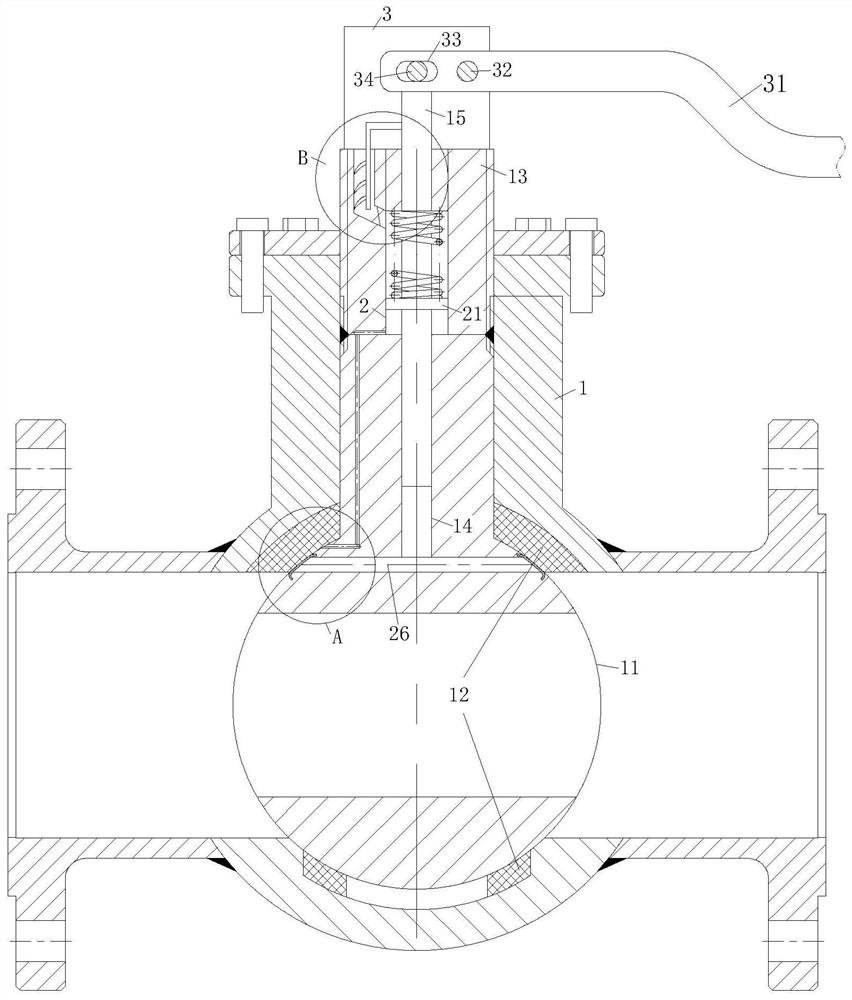

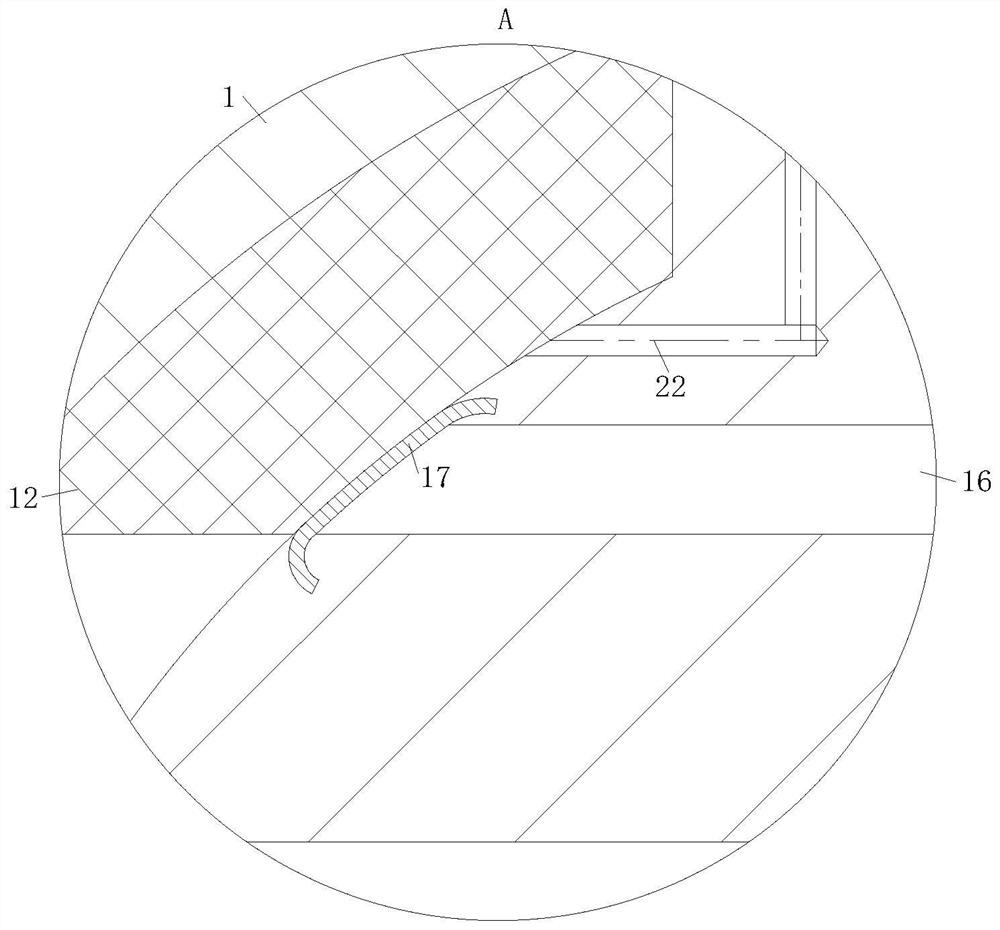

A three-way ball valve

ActiveCN111609174BImprove opening efficiencyReduce air pressurePlug valvesMultiple way valvesEngineeringValve stem

The invention belongs to the technical field of valves, and is specifically a three-way ball valve, including a valve body; a valve ball is rotatably connected to the valve body, and a valve seat is provided at the sliding connection part between the valve body and the valve ball; a valve stem is fixedly connected to the top of the valve ball , the No. 1 hole opened in the valve stem is slidingly connected with a spool; the valve ball is provided with a No. 2 hole corresponding to the valve seat, and the No. 2 hole is connected with the No. 1 hole; the two ends of the No. 2 hole are sealed and connected with arc-shaped shrapnel; No. 1 hole is provided with a chute near the top, a limit ring is provided at the corresponding position of the spool and the chute, and a spring is set on the spool above the limit ring; a through groove is opened on the top of the valve stem; There is a handle, the middle part of the handle is rotationally connected with the through groove through the revolving pin, and the revolving pin deviates from the center of the valve stem; the handle is provided with a round hole near the center of the valve stem, and a round rod is slidingly connected in the round hole, and the round rod and the sliding column The top is fixed; the invention reduces the friction between the shrapnel and the valve seat by pressing down the handle, and increases the opening efficiency of the ball valve.

Owner:CAMBRIDGE VALVE IND GRP CO LTD

Waterproof step chain with special structure

InactiveCN112173935AEasy to fill oilFill oil in timeDriving chainsEscalatorsForeign matterChain link

The invention relates to a waterproof step chain with a special structure. According to the technical scheme, the waterproof step chain of the special structure comprises a chain A and a chain B whichare formed by connecting a plurality of chain links in sequence, each chain link comprises an inner chain plate and a sleeve, an outer chain plate and a shaft chain plate are arranged at two sides ofadjacent ends of every two adjacent chain links, the connected ends of the adjacent chain links penetrate through the corresponding inner chain plates, the sleeves, the outer chain plates and the shaft chain plates through retaining ring pins, the other ends penetrate through the corresponding inner chain plates, the sleeves, the outer chain plates and the shaft chain plates through D-shaped pins, felt sealing rings and filler sealing rings are arranged between the inner chain plates and the outer chain plates and between the inner chain plates and the shaft chain plates, and a guide wheel assembly is arranged at one side of each step shaft. The waterproof step chain is advantageous in that a good protection effect is achieved on external dust, water, foreign matters and the like, injected grease can be reserved in gaps between the pins and the sleeves for a long time, the lubricating time between the pins and the sleeves is prolonged, the abrasion between parts when a hinge rotates is reduced, and the service lifetime is prolonged.

Owner:UNIVERSAL CHUANDONG TAIZHOU

Design method of shaft sleeve used for rocker arm of coal mining machine

InactiveCN102518669AImprove uniformityIncrease filling volumeSlitting machinesBearing componentsDrive shaftControl engineering

For increasing the timing length of lubrication between a shaft sleeve and a transmission shaft, minimizing the frequency of the maintenance, and raising the operation speed and workload, the present invention provides a design method of the shaft sleeve used for a rocker arm of a coal mining machine, the design is characterized by comprising an external wall and an internal wall, a groove used for storing a lubricant is provided on the external wall. The design that the groove used for storing the lubricant (like a solid lubricant) which is provided on the internal wall of the shaft sleeve is capable of increasing the filling amount of the lubricant, prolonging the lubrication timing length, raising the uniformity of the lubrication, reducing the maintenance frequency, and raising the operation speed and workload.

Owner:西安奥奈特固体润滑工程学研究有限公司

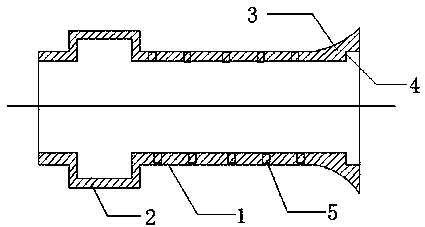

Pump shaft sleeve for double suction pump

InactiveCN107701490AExtended service lifeReduce adverse effectsPump componentsRadial flow pumpsImpellerCavitation

The invention discloses a pump shaft sleeve for a double suction pump. The pump shaft sleeve comprises a shaft sleeve body. A cylindrical cavity structure is arranged in the shaft sleeve body. An annular groove is formed in the inner wall of the left side of the shaft sleeve body. An arc structure smoothly connected with the shaft sleeve body is arranged on the outer side of the right end of the shaft sleeve body. An annular step is arranged at the position, corresponding to the arc structure, of the inner wall of the shaft sleeve body. Multiple through holes are evenly formed in the peripheryof the shaft sleeve body. Compared with the prior art, the pump shaft sleeve has the following beneficial effects that the annular groove of the shaft sleeve cooperates with a pump shaft to form a closed oil cavity, the lubricating time of the shaft and a bearing can be effectively increased, and the service life of the shaft can be prolonged; the through holes are formed in the shaft sleeve body, and therefore concentration of bubbles on the surface of the shaft sleeve can be reduced, and the bad influence generated by cavitation on the shaft sleeve is avoided; and a part matched with the step formed by an impeller and the pump shaft is arranged at the right end of the shaft sleeve, the axial locating function can be achieved on the impeller, the outer side of the shaft sleeve and the impeller are in smooth transition, resistance to water flow is reduced, and the work efficiency of the double suction pump is improved.

Owner:ANHUI TENGLONG PUMP VALVE MFG CO LTD

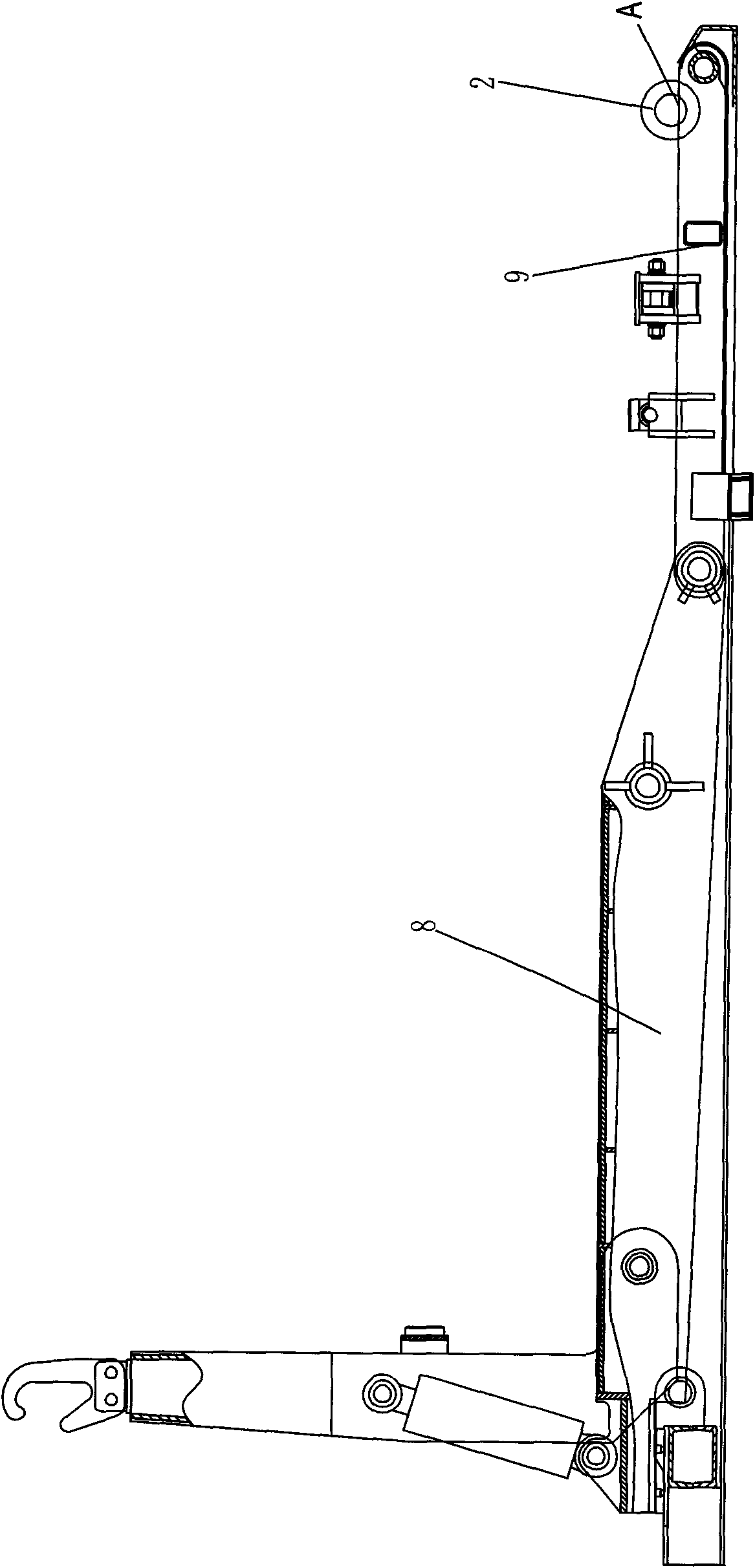

Box loading wheel mechanism of box pulling device

InactiveCN102069985BReasonable designEven by forceRefuse vehiclesStructural reliabilityWear resistant

The invention discloses a box loading wheel mechanism of a box pulling device. The mechanism comprises a run-through shaft and a roller, wherein the run-through shaft is fixedly connected with the upper end on the rear side of a turning frame of the box pulling device; a wear-resistant ring is tightly arranged on the inner side in the middle cavity of the roller; the inner wall of the wear-resistant ring is sleeved on external circles of the two ends of the run-through shaft and is in running fit with the external circles; an inward convex baffle ring body is arranged outside the middle cavity of the roller; the inner surface of the baffle ring body is contacted with the outer end face of the run-through shaft; a connecting pin is penetrated in the middle of the two ends of the run-through shaft; the rear end head of the connecting pin is provided with a convex ring; a spacer ring is arranged between the inner surface of the convex ring and the outer surface of the baffle ring body; the front end head of the connecting pin is provided with a bolt member; and the bolt member is also inserted into the two sides of the run-through shaft. Due to adoption of the overall structure, long-span rigid connection is realized on the two sides during box loading, so the structure has high reliability; the wear-resistant ring structure is lined in the roller, so the flexibility of the roller during running is improved and the service life of the entire member is prolonged; the axial relative moment of the roller is limited by using the connecting pin and the bolt member, so the structure of the mechanism is simple; and an oil storage ring is internally arranged to prolong the service life of the mechanism.

Owner:阮志华

Fixed-point automatic oiling device of marine pump shaft seat

InactiveCN109340545ASimple structureEasy to usePositive displacement pump componentsLiquid fuel engine componentsButt jointWorkload

The invention discloses a fixed-point automatic oiling device of a marine pump shaft seat. The fixed-point automatic oiling device comprises an oil storage tank, an oil guiding pipe, a bearing and a shaft seat shell; the shaft seat shell is a shell with the D-shaped cross section, the bearing is placed in an inner cavity of the shell, lubricating oil is reserved in the inner cavity of the shell, aventilating screw plug is arranged on the top layer of the shell, and a discharging screw plug is arranged on the bottom layer of the shell; the oil guiding pipe is a lying L-shaped pipe, the longerend of the oil guiding pipe is transversely connected with a through hole in the bottom of the side face of the shaft seat shell, a pipe opening of the shorter end of the oil guiding pipe is bent upwards, and the vertical oil storage tank is hinged to one side edge of the pipe opening; and the oil storage tank is a cylindrical thin-walled container, the middle of the downward end of the vertical storage tank is provided with an oiling pipe penetrating through the interior and the exterior, and the downward oiling pipe is in butt joint with the upwards-bent pipe opening of the oil guiding pipeto constitute an oiling channel communicating with the oil storage tank and the shaft seat shell. The configured oil storage tank can store much more lubricating oil than the shaft seat shell, thus byconfiguring the fixed-point automatic oiling device, long-term fixed-point automatic oiling can be achieved, and the maintenance frequency and workload can be significantly decreased.

Owner:江苏振华海科装备科技股份有限公司

A kind of ferric oxide/tungsten disulfide nanocomposite lubricant and preparation method thereof

InactiveCN105802699BReasonable compositionExtended lubrication timeAdditivesSodium acetateCentrifugation

The invention discloses a ferroferric oxide / tungsten disulfide nano-composite lubricating agent.The mole ratio of ferroferric oxide to tungsten disulfide is (0.1-0.):(1-2).The invention further discloses a preparation method of the ferroferric oxide / tungsten disulfide nano-composite lubricating agent.The preparation method comprises the following steps that the tungsten disulfide is subjected to ball milling and then added into glycerinum for ultrasonic dispersion, and tungsten disulfide nanosheet glycerinum dispersion liquid is obtained through centrifugation; sodium oxalate, ferric chloride hexahydrate and sodium acetate are sequentially added into the tungsten disulfide nanosheet glycerinum dispersion liquid, a hydrothermal reaction is carried out after ultrasonic dispersion, drying is performed after cleaning, and the ferroferric oxide / tungsten disulfide nano-composite lubricating agent is obtained.The lubricating agent has the excellent lubricating performance, the effective lubricating time can be significantly prolonged, in addition, technology is simple, convenient and safe, the yield is high, the cost is low, and large-scale production is easy.

Owner:HEFEI NORMAL UNIV

Composite abrasion-resisting corrosion-resisting self-lubricating film and preparation method thereof

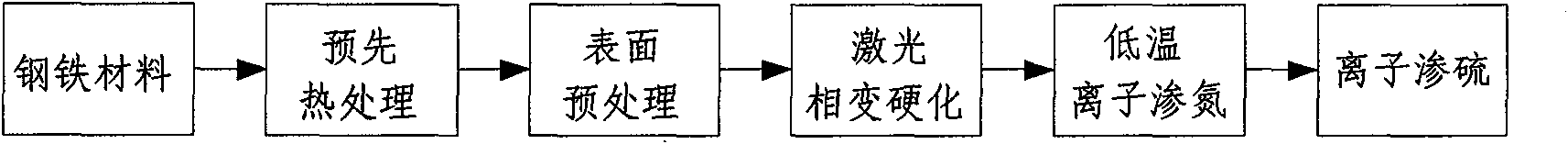

ActiveCN102560505BGood self-lubricating performanceSelf-lubricating comprehensive performance hasSolid state diffusion coatingTransformation hardeningLubrication

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

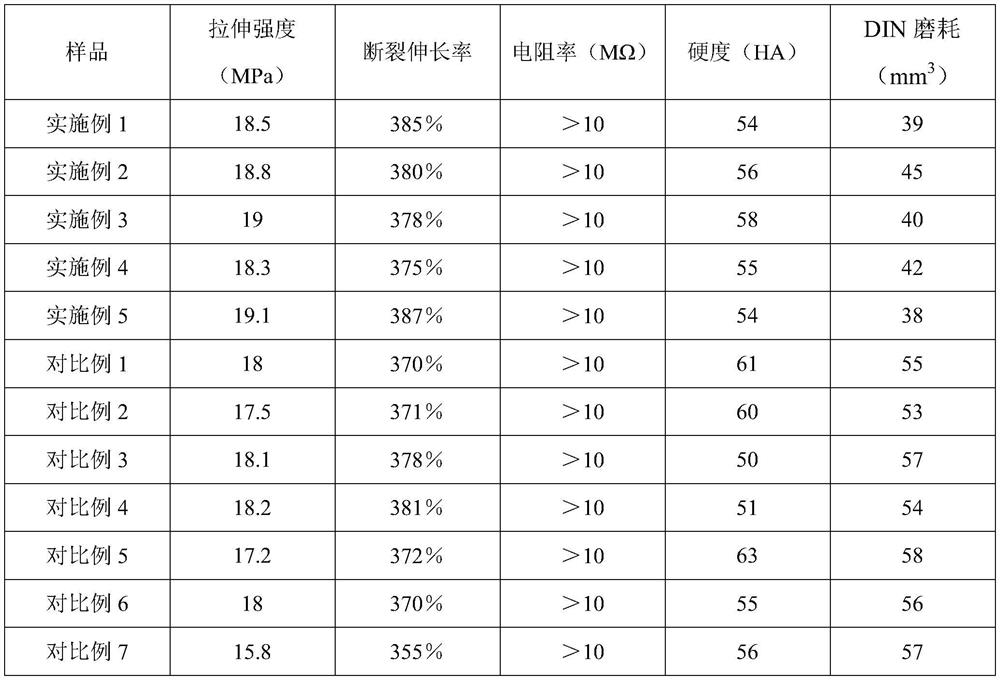

Self-lubricating insulating rubber for limiting block of auxiliary frame for vehicle and processing technology of self-lubricating insulating rubber

ActiveCN114276589AIncrease elasticityImprove wear resistanceRolling resistance optimizationVehicle frameParaffin oils

The invention relates to self-lubricating insulating rubber for a vehicle auxiliary frame limiting block and a processing technology of the self-lubricating insulating rubber. The rubber comprises the following raw materials in parts by weight: 60-80 parts of natural rubber, 5-10 parts of eucommia ulmoides rubber, 5-10 parts of thermoplastic vulcanized rubber TPV, 10-20 parts of fast extruding furnace black, 20-30 parts of semi-reinforcing carbon black, 10-20 parts of white carbon black, 5-15 parts of paraffin oil, 5-8 parts of zinc oxide, 1-2 parts of stearic acid, 3-5 parts of paraffin, 2-3 parts of a silane coupling agent, 3-5 parts of an anti-aging agent, 4-8 parts of polytetrafluoroethylene, 2-3 parts of a lubricant, 2-3 parts of sulfur and 1-2 parts of an accelerant. A layer of uniform enveloping film with low friction coefficient is arranged between the rubber and the metal piece, the friction force between the rubber and the metal piece is small, and the abrasion of the rubber and the friction noise between the rubber and the metal piece are reduced.

Owner:HENAN HENGFA RUBBER & PLASTIC +1

A detachable expansion and contraction reel

ActiveCN110681721BPrevent leakageAvoid frictional damageBearing componentsElectric machineryEngineering

The invention discloses a detachable expansion and contraction reel, which comprises a base, a controller and a motor. A second bracket is arranged on the top of the base, and a rotating drum is arranged between one side of the second bracket. The base The other side above is provided with a second shell through the first bracket, and one side of the first shell on one side of the second shell is provided with a collar, and the inner wall of the second shell on one side of the first shell is A rotating rod is arranged between the inner walls on one side, and a bearing seat is arranged on the inner side of the second cylindrical shell on the side of the outer wall on both sides of the rotating rod and on the inner side of the first cylindrical shell. In the present invention, second connecting rods are evenly arranged between the outer walls of the inner wall of the first shell and the inner wall of the second shell, and the outer walls of the rotating rods, and a connecting block is arranged at the middle position of the rotating rods. This structure strengthens the expansion and contraction of the reel. Strength, effectively prolonging the service life of the expansion and contraction reel.

Owner:镇江市宏业科技有限公司

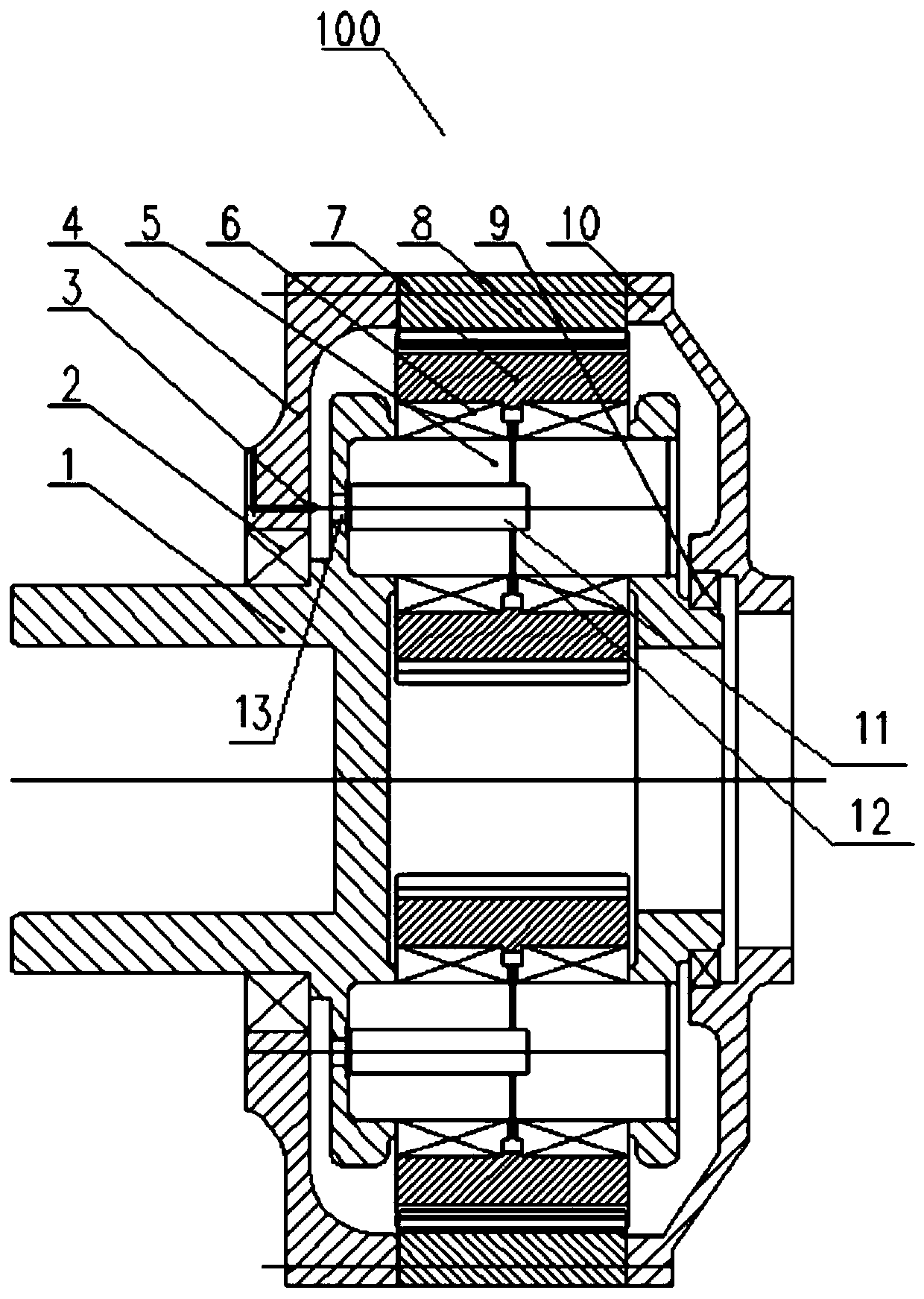

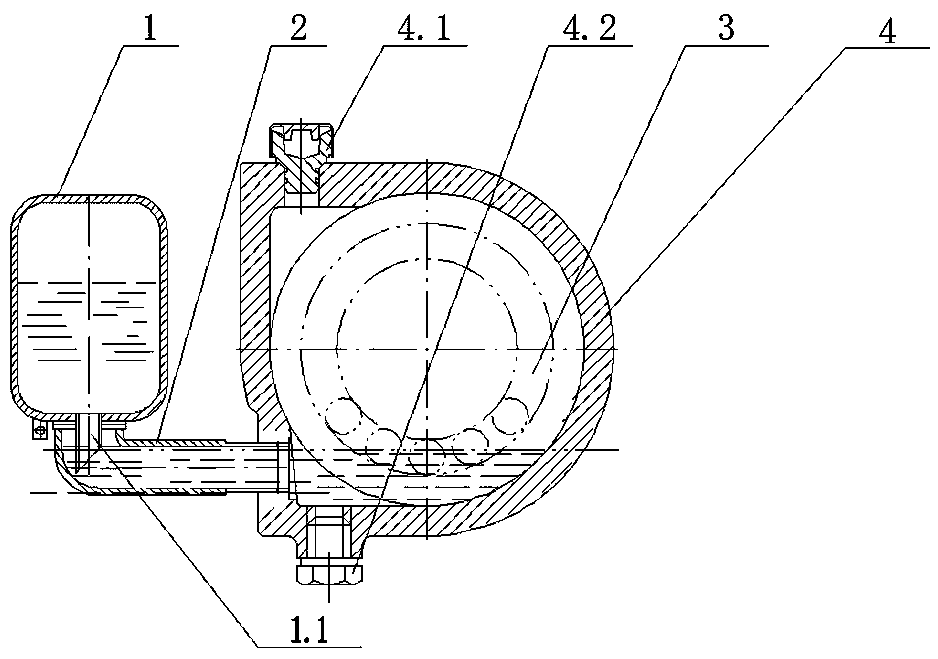

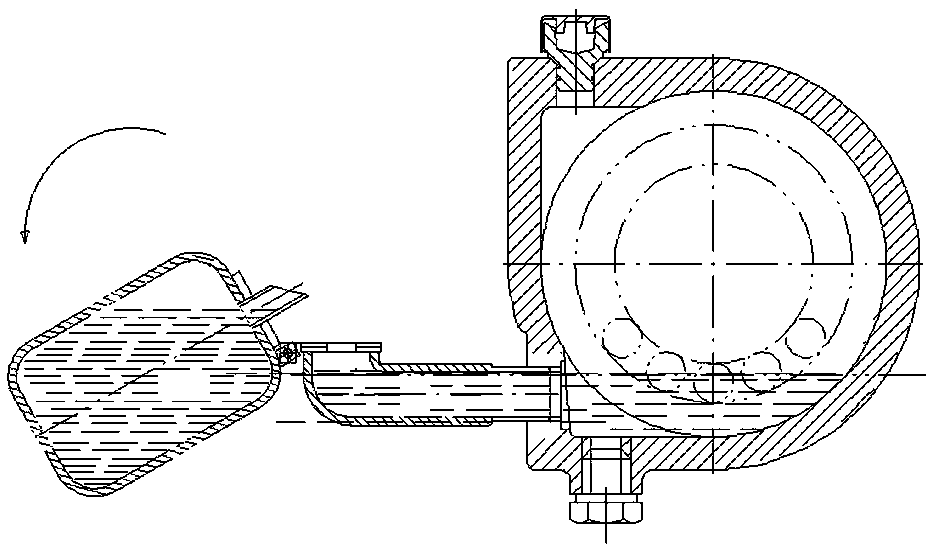

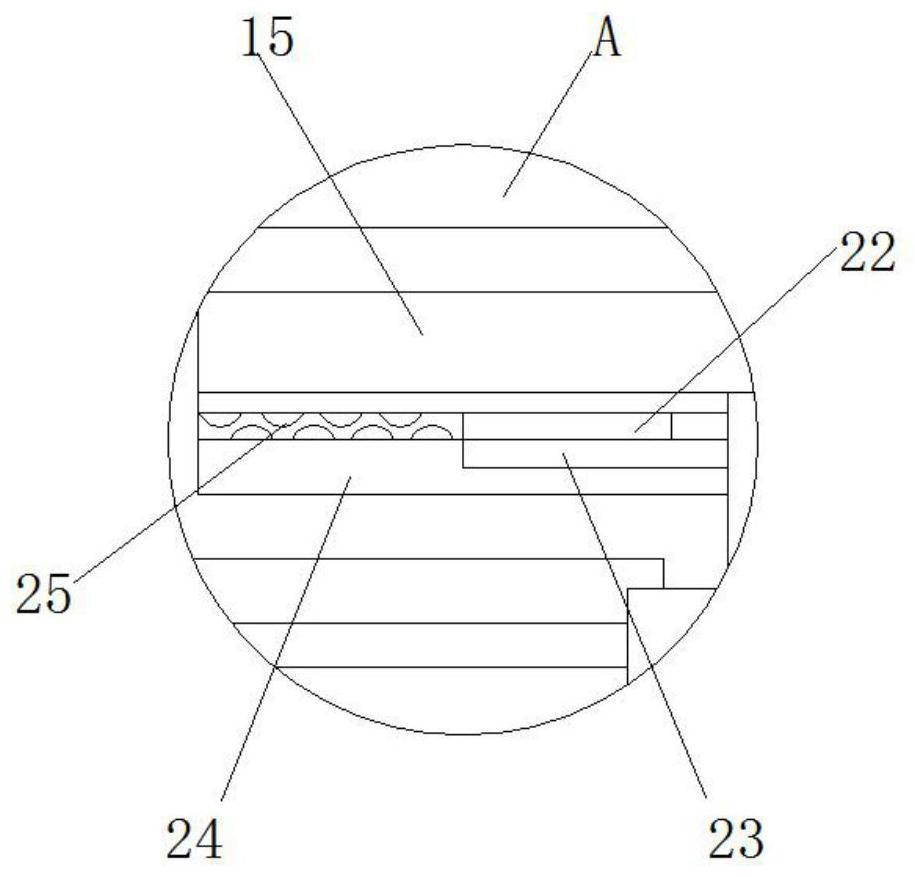

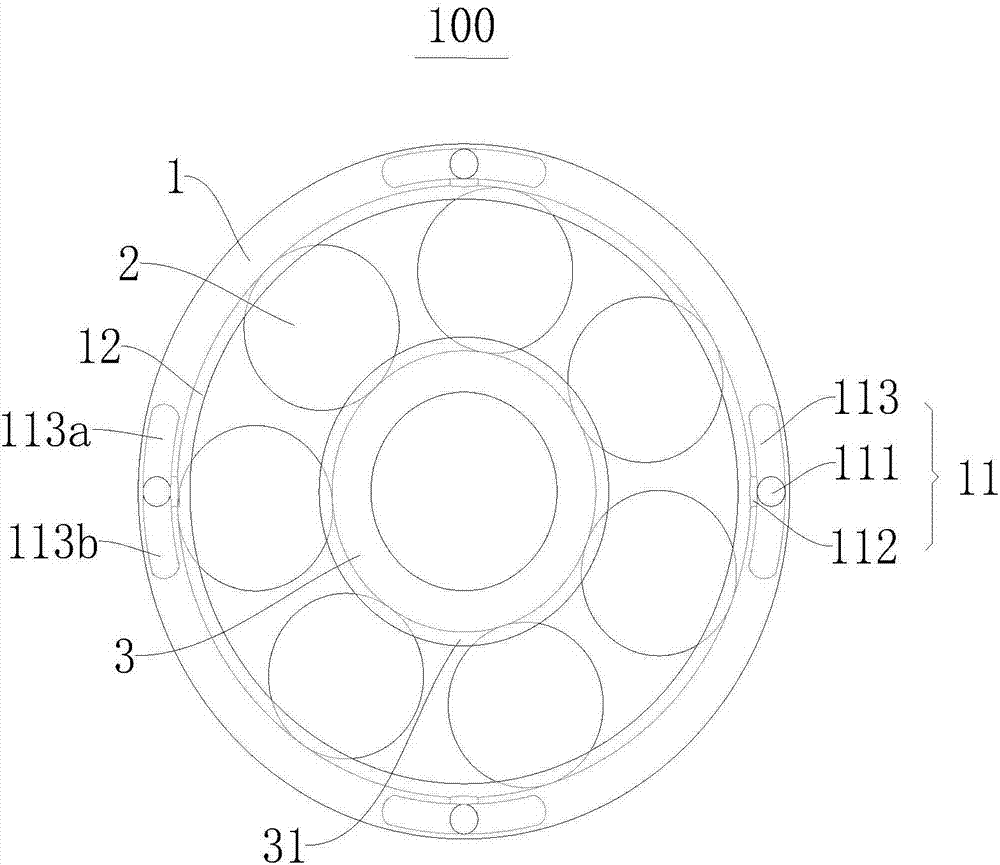

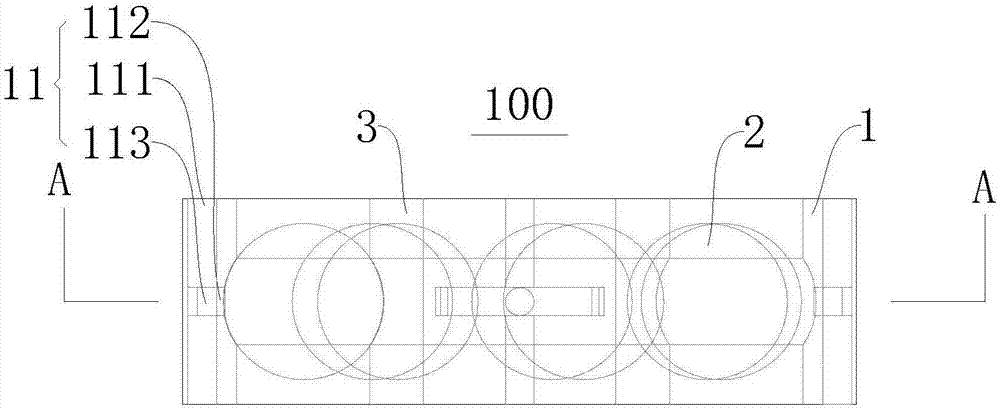

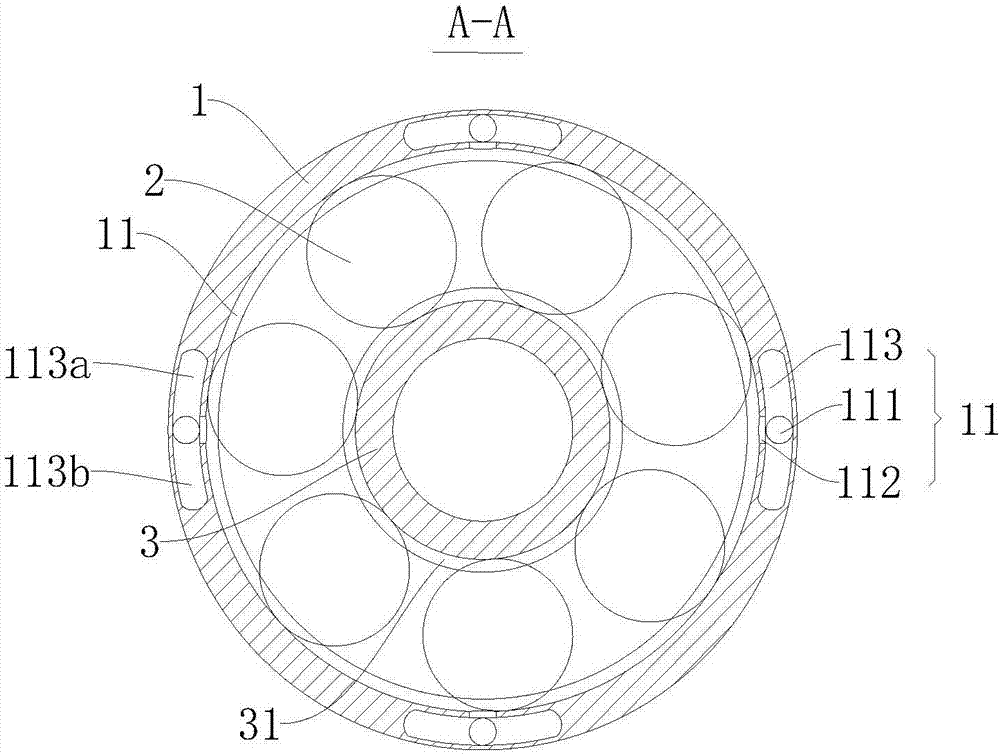

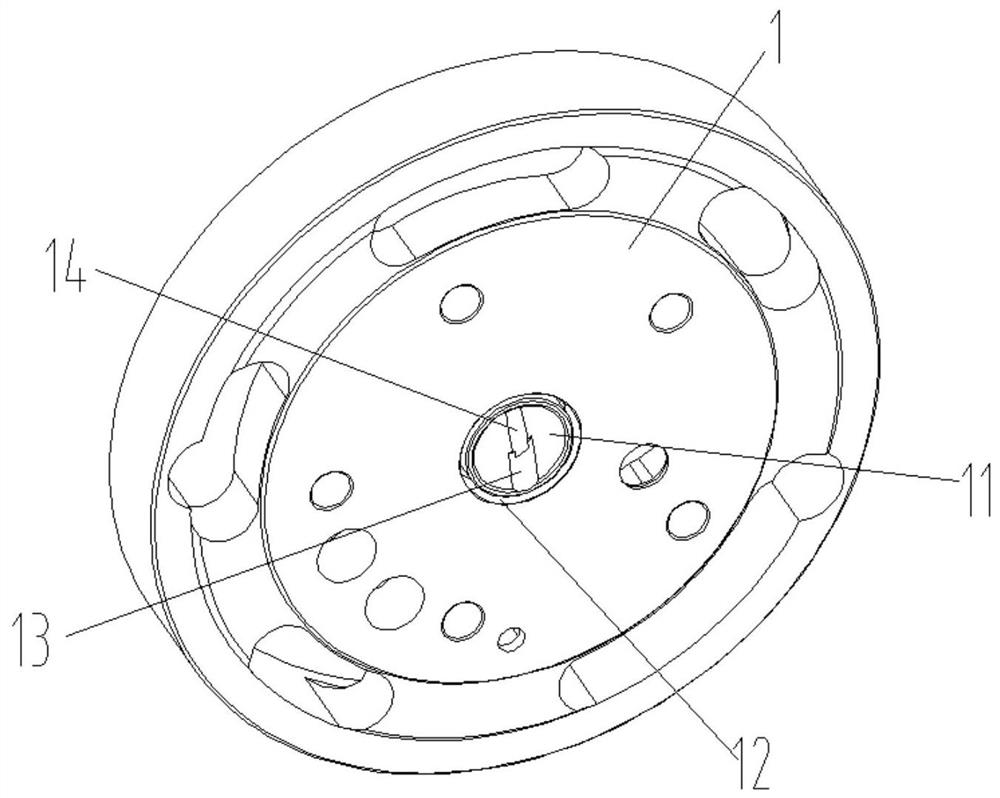

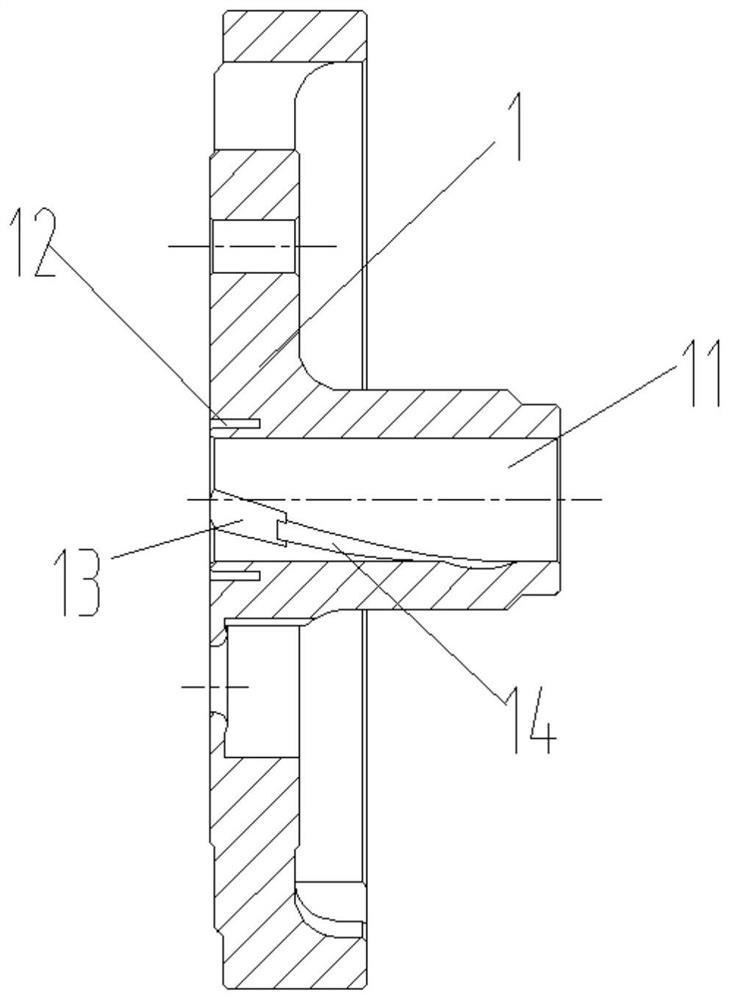

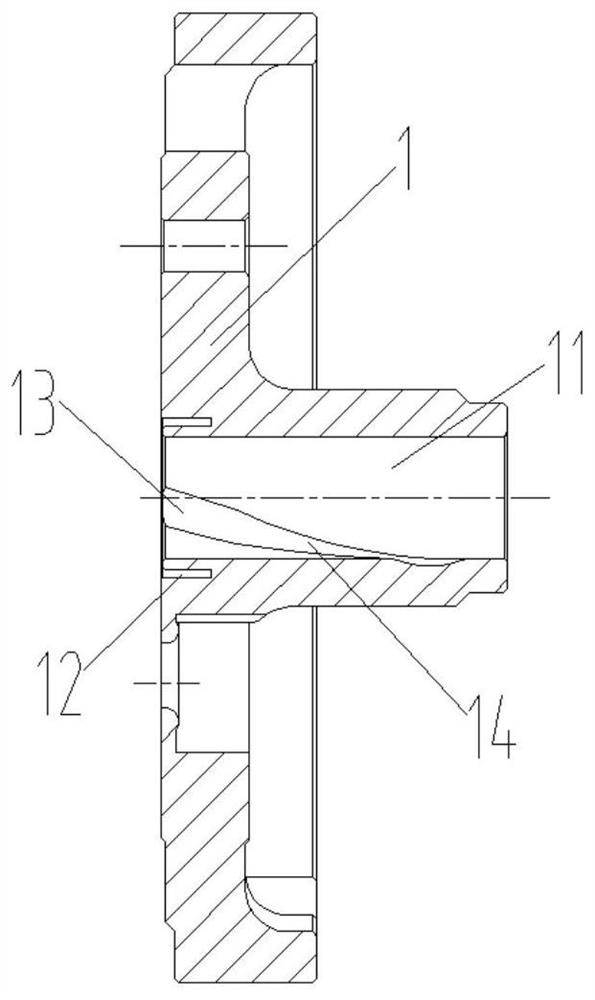

Self-lubricating rolling bearing

PendingCN107314030AExtended lubrication timeExtended service lifeBall bearingsBearing componentsRolling-element bearingStructural engineering

The invention discloses a self-lubricating rolling bearing. The self-lubricating rolling bearing comprises a bearing inner ring (3), a bearing outer ring (1) and a rolling body (2); the bearing inner ring (3) is arranged in the bearing outer ring (1); the rolling body (2) is arranged between the bearing inner ring (3) and the bearing outer ring (1); a hole assembly (11) comprises a guide hole (111) and a through hole (112); the guide hole (111) is formed in the side wall of the bearing outer ring (1); the through hole (112) is formed along the radial direction of the bearing outer ring (1); and the through hole (112) is connected with the area of the guide hole (111), the bearing inner ring (3) and the bearing outer ring (1). The self-lubricating rolling bearing can prolong the lubricating time and enhance the flowability of lubricating oil so as to prolong the service life of a bearing.

Owner:徐州博丰轴承有限公司

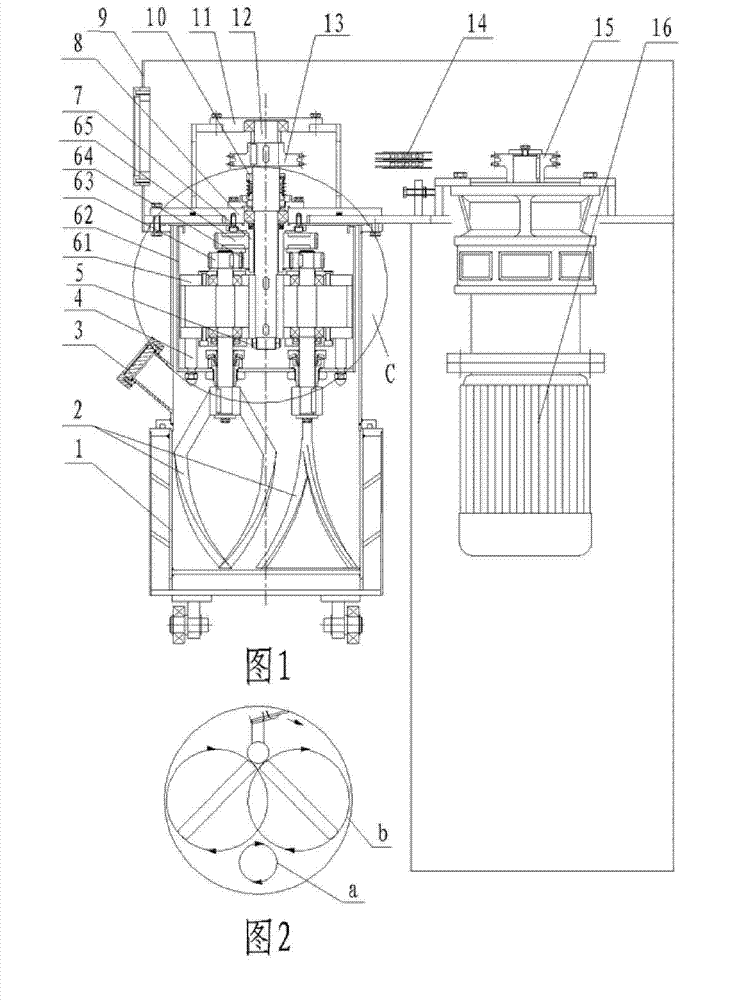

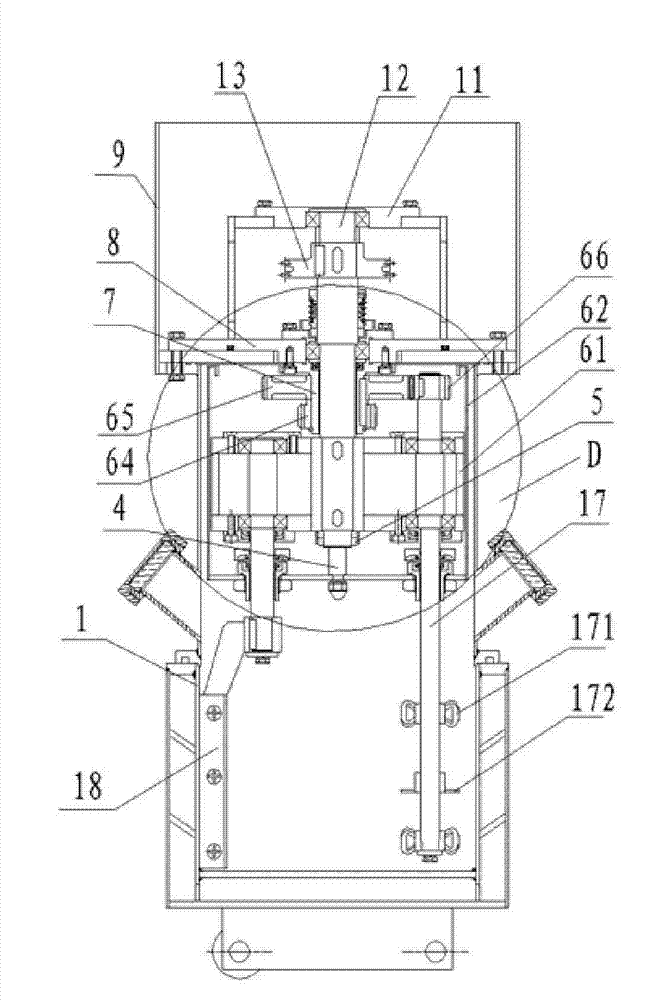

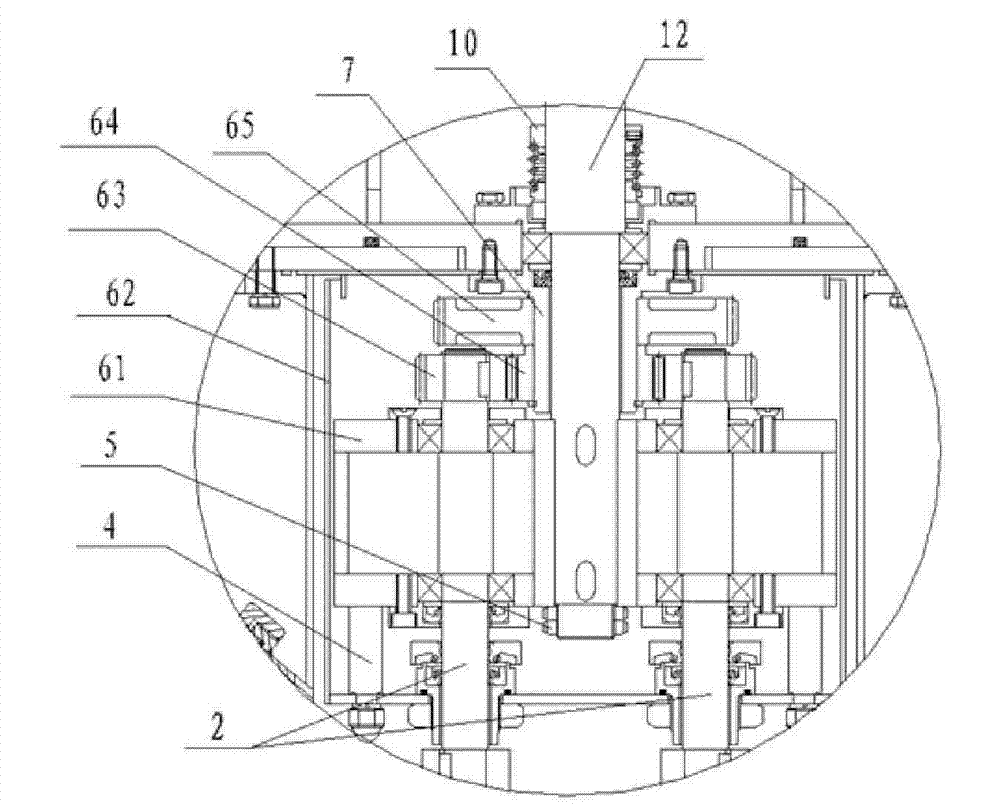

Novel high-efficiency energy-saving planetary vacuum stirrer

InactiveCN101927136BPlay the role of dispersing and breakingImprove mixing efficiencyRotary stirring mixersChemical industryLow noise

The invention relates to mixing and stirring equipment for chemical industry, in particular to a novel high-efficiency energy-saving planetary vacuum stirrer. The stirrer is only provided with a transmission shaft, wherein a planetary gear train component mainly consists of two groups of planetary gear trains, a planetary box and a planetary shield; solar gears I and II of the planetary gear train are fixedly arranged on a bearing seat which is loosely sleeved on the transmission shaft; the planetary box is arranged on the transmission shaft and fixed by a nut; a high-speed dispersing component and a low-speed stirring component are arranged on the planetary box; a planetary gear I engaged with the solar gear I is connected with the high-speed dispersing component; the planetary gear II engaged with the solar gear II is connected with the low-speed stirring component; and the diameter of the solar gear I is greater than that of the solar gear II. The stirrer has the advantages of improving high work reliability, reducing the manufacturing cost and the maintenance cost, showing the high stirring efficiency, reducing the size of the entire machine and reducing the weight, along withhigh mixing efficiency, low gap, low noise and the like.

Owner:LIUZHOU HUT CHEM MACHINERY

A kind of drug-loaded synovial fluid additive and its preparation method and application

ActiveCN111053912BImprove friction and wear resistanceImprove lipophilicityOrganic active ingredientsAntipyreticJoint synovialJoints inflammation

Owner:QUFU NORMAL UNIV

Bearing bush with surface microporous structure and processing method thereof

ActiveCN102537066BIncreasing the thicknessImprove the extrusion effectBearing componentsMicrometerAlloy

The invention provides a bearing bush with surface microporous structures and a processing method. The bearing bush includes a bearing bush body, and the body comprises a metal bearing bush back and an antifriction alloy layer, wherein the antifriction alloy layer is a friction layer between the bearing bush and a journal. The bearing bush is characterized in that microporous structures are formed on the inner surface of the antifriction alloy layer through machining. The microporous structures are micropores formed by adopting the laser micromachining technique for machining, the micro-pores are arranged regularly, the diameters range from 150 micrometers to 200 micrometers, and the depths range from 35 micrometers to 50 micrometers. The bearing bush is provided with the microporous structures on the inner surface, can effectively improve the oil film bearing capability, and remarkably improves the lubrication effect.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

Flange, pump body assembly, rotary compressor and air conditioner

PendingCN112814909AImprove volumetric efficiencyImprove reliabilityRotary/oscillating piston pump componentsLiquid fuel engine componentsGroove widthEngineering

The invention provides a flange, a pump body assembly, a rotary compressor and an air conditioner. The flange comprises a flange body, a bearing hole used for inserting a crankshaft is formed in the flange body, a vibration reduction ring groove is formed in the hole opening wall of the side, close to an eccentric part of the crankshaft, of the bearing hole, and a spiral oil guide groove is formed in the hole wall of the bearing hole; and the spiral oil guide groove comprises a first groove section located on a first hole section and a second groove section located on a second hole section, and the maximum groove width of the second groove section and the maximum groove depth of the first groove section are smaller than the minimum groove depth of the second groove section. According to the flange, the spiral oil guide groove on the first hole section, namely the first groove section, is designed into the shallow groove structure, so that the outer ring groove wall of the vibration reduction ring groove can be closer to the bearing hole, the sealing distance of the end part of the flange body and the matching position of a roller is increased, and the volume efficiency of a pump body structure is improved; and meanwhile, the phenomenon of opening collapse caused by too small wall thickness of the wall body between the vibration reduction ring groove and the bearing hole can be prevented.

Owner:ZHUHAI GREE REFRIGERATION TECH CENT OF ENERGY SAVING & ENVIRONMENTAL PROTECTION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com