Flange, pump body assembly, rotary compressor and air conditioner

A flange and lower flange technology, applied to pump components, rotary piston type/swing piston type pump components, machines/engines, etc., can solve problems such as wall collapse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

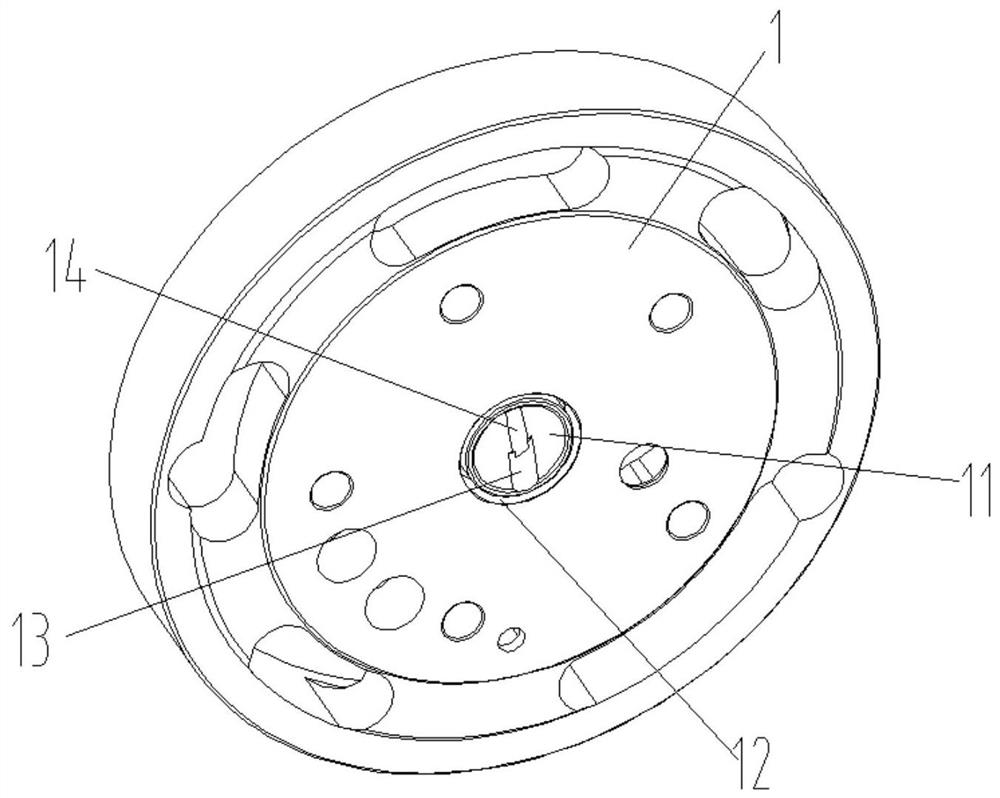

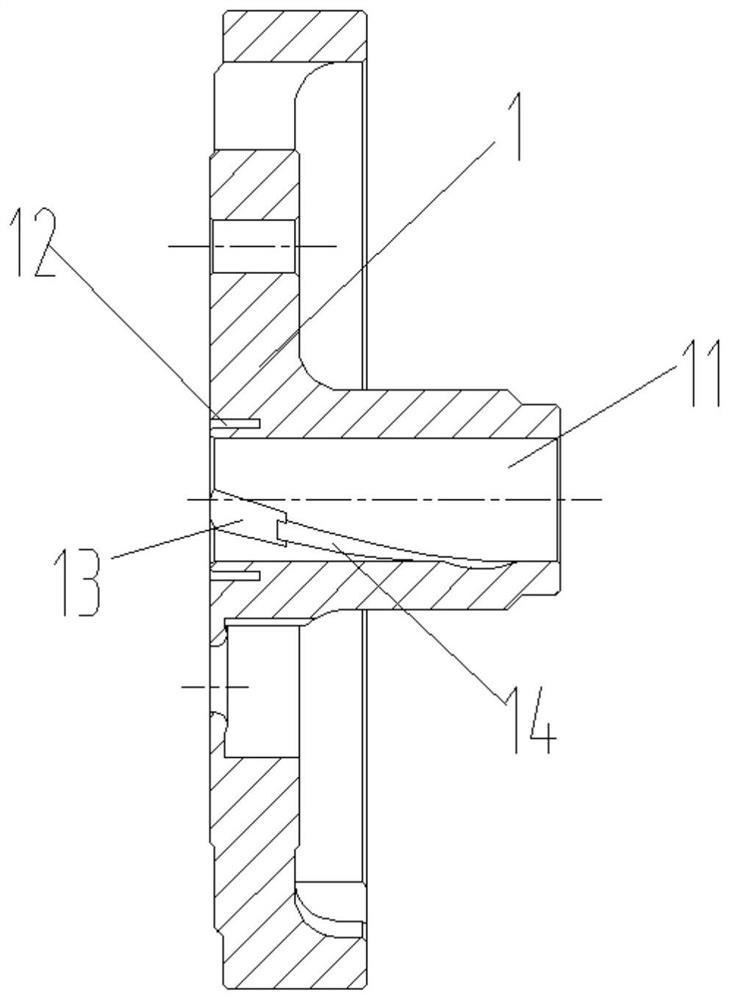

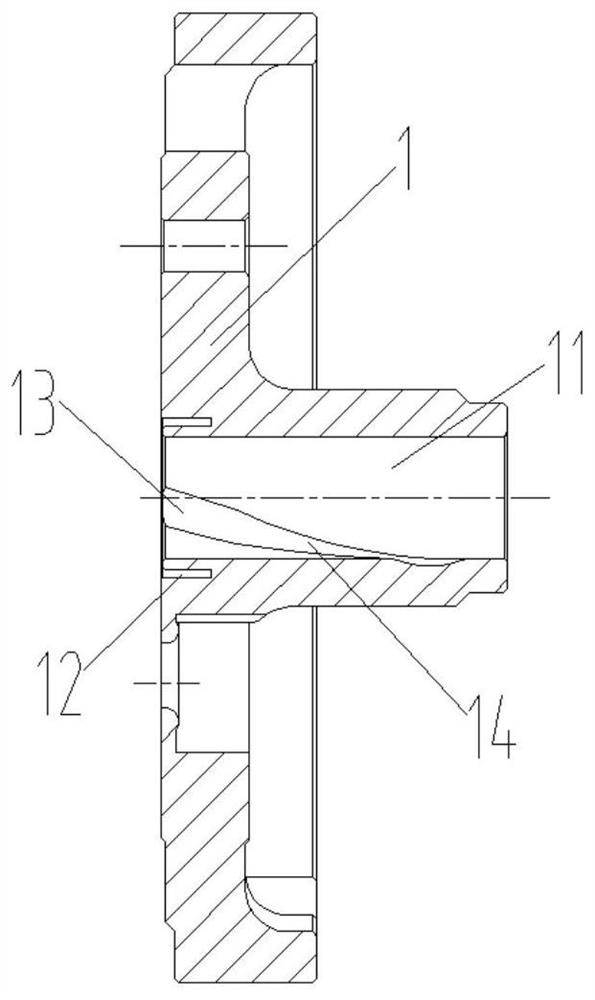

[0024] see in conjunction Figure 1 to Figure 5 As shown, according to an embodiment of the present invention, a flange is provided, including a flange body 1, and a bearing hole 11 for inserting a crankshaft 100 is configured on the flange body 1, and the bearing hole 11 is close to the crankshaft. 100 has a damping ring groove 12 configured on one side of the orifice wall of the eccentric part 101, and a spiral oil guide groove is configured on the hole wall of the bearing hole 11, and the spiral oil guide groove includes a second hole on the first hole section. A groove section 13 and a second groove section 14 on the second hole section, the maximum groove depth of the first groove section 13 is smaller than the minimum groove depth of the second groove section 14, wherein the first hole section is the hole wall section of the bearing hole 11 corresponding to the groove depth of the damping ring groove 12 (also called the flexible ring groove), and the second hole section ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com