Box loading wheel mechanism of box pulling device

A technology of box wheels and rollers, which is applied in the field of detachable sanitation vehicles, can solve the problems of imperfect structure, no effective self-control force, complicated rear structure of the sub-frame, etc., to achieve convenient filling and improve lubrication Effect, fast disassembly and assembly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

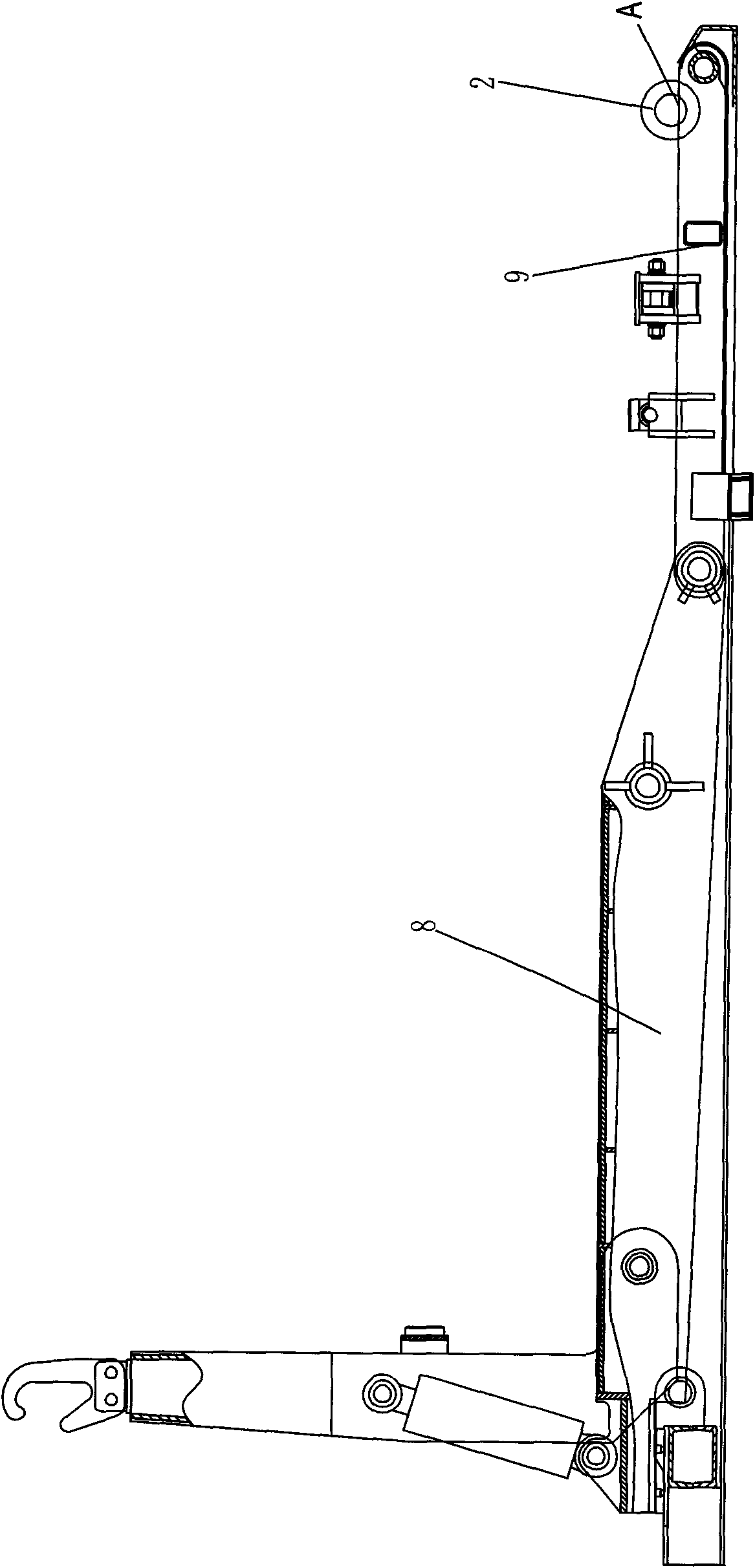

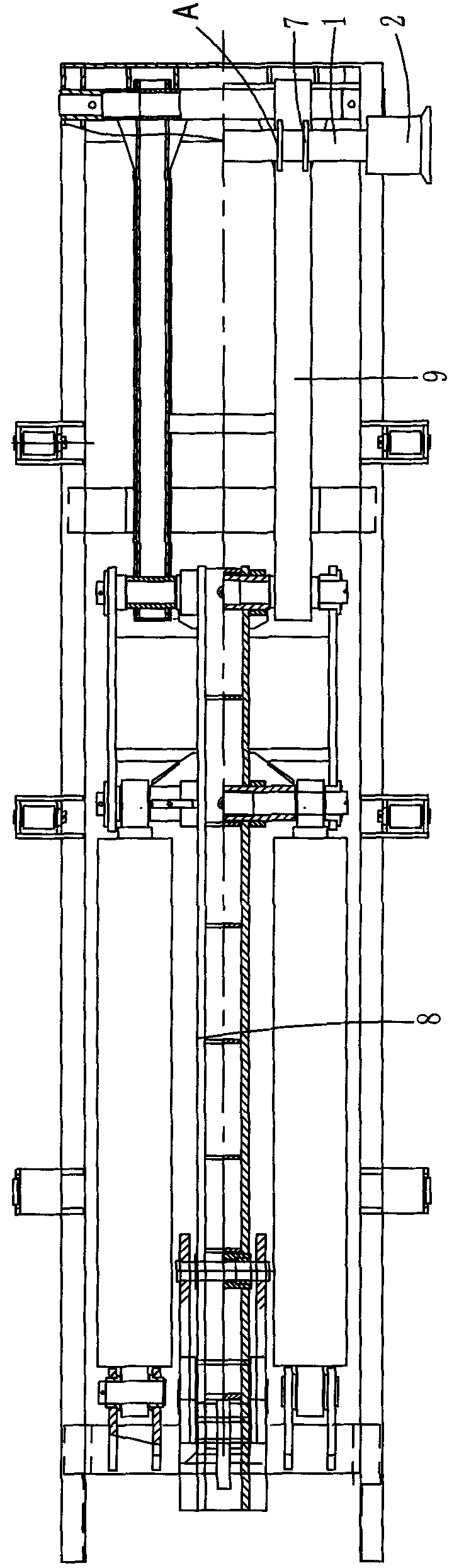

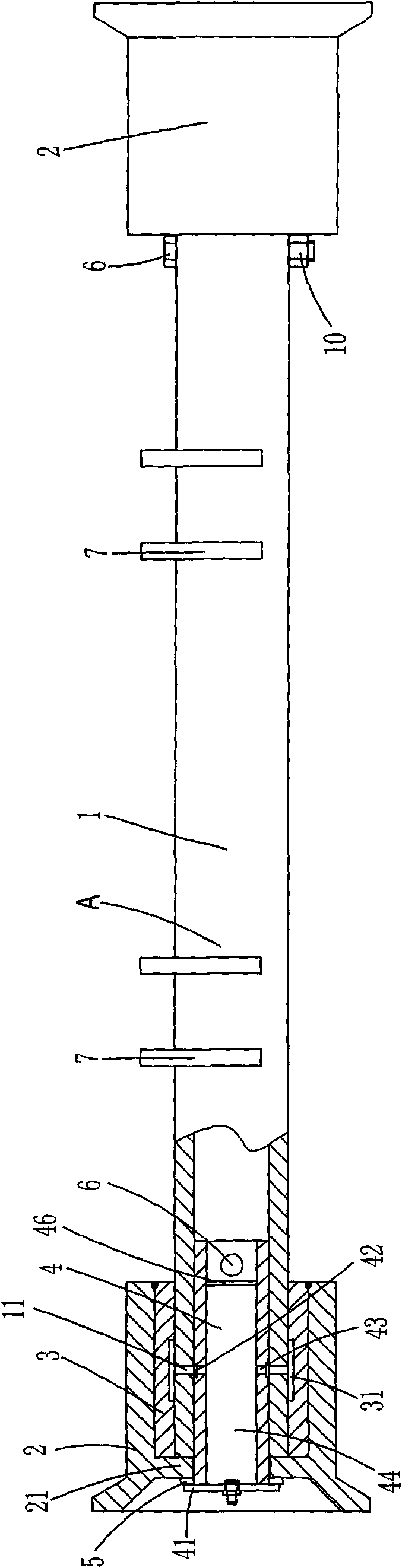

[0028] Such as Figure 1 to Figure 11 As shown, the description of the icon number: through shaft 1, oil hole 11, shaft connection hole 12, roller 2, retaining ring body 21, ring taking hole 22, circular surface 23, positioning italic body 24, wear ring 3, oil storage Ring 31, connecting pin 4, protruding ring 41, oil passing ring groove 42, auxiliary oil hole 43, middle cavity 44, pin connecting hole 45, sealing plate 46, spacer ring 5, plug piece 6, reinforcement piece 7, pull Box device 8, overturn frame 9, nut body 10, upper box wheel mechanism A.

[0029] In the embodiment of the present invention, the upper box wheel mechanism of the box pulling device, the upper box wheel mechanism A includes a through shaft 1 and a roller 2, the through shaft 1 is fixedly connected to the rear upper end of the turning frame 9 of the box pulling device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com