Composite calcium sulfonate type railway wheel rail lubricating grease and preparation method thereof

A technology for compounding calcium sulfonate and synthesizing calcium sulfonate, applied in the field of lubricating grease, can solve the problems of frequent grease spraying, reducing the life of wheel rims and curved outer rails, wear of wheel-rail rims and curved rails, etc. delivery and jetting ability, extended effective lubrication time, and the effect of a wide operating temperature range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

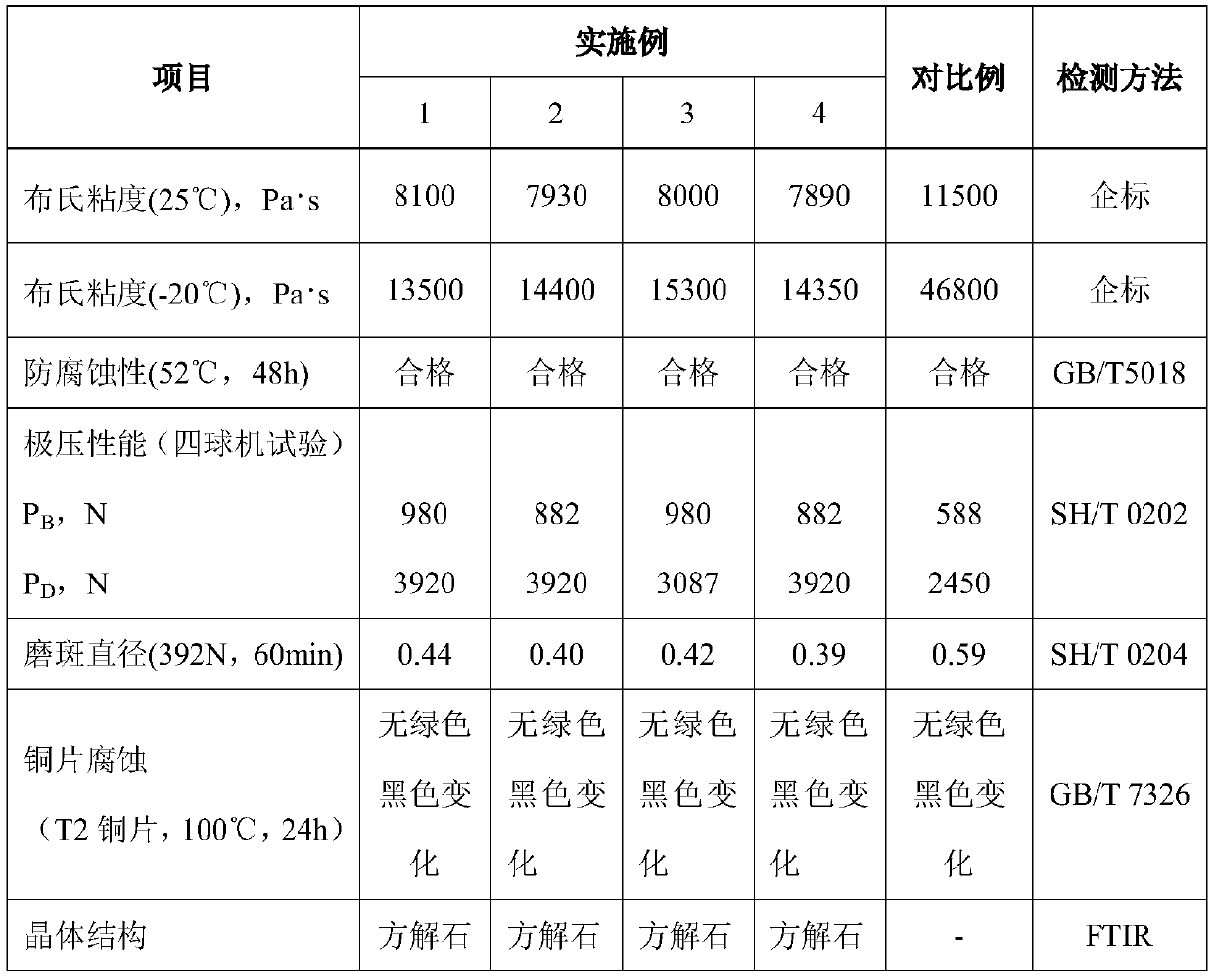

[0030] Embodiment 1: a kind of composite calcium sulfonate type railway wheel and rail lubricating grease comprises the following components: 40kg of high base value synthetic calcium sulfonate with a total base value of 400mgKOH / g, and a kinematic viscosity of 40°C is 82.01mm 2 / s, 200kg of 500N base oil with a pour point of -35°C, 0.40kg of water, 0.6kg of a mixture of n-butanol and ethylene glycol, 0.9kg of dodecylbenzenesulfonic acid, 0.40kg of calcium hydroxide, 0.53kg of boric acid, Dodecyl hydroxystearic acid 1.10kg, N-phenyl-α-naphthylamine 1.20kg, benzotriazole 0.72kg, polytetrafluoroethylene 2.40kg.

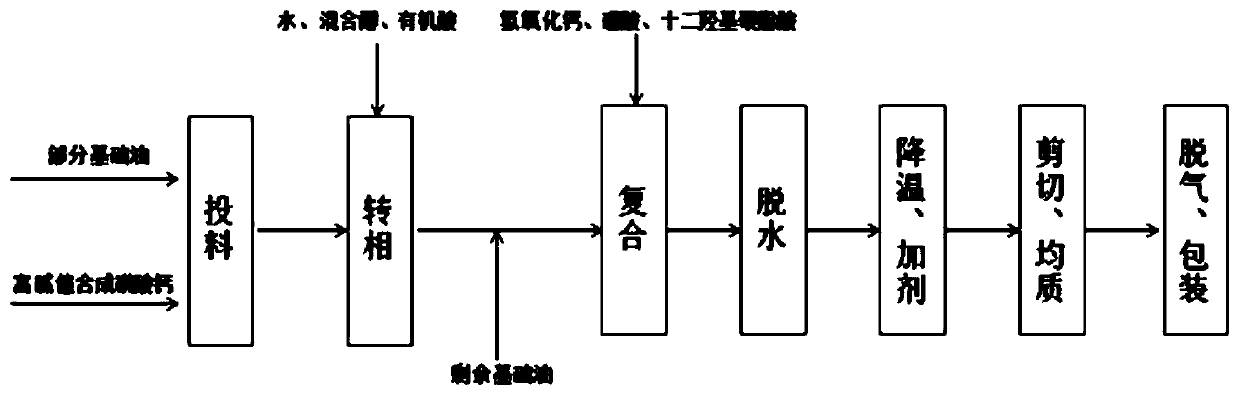

[0031] The preparation method of composite calcium sulfonate type railway wheel and rail grease comprises the following steps:

[0032] S1. Prepare an atmospheric pressure reactor with a volume of 300L, heating, cooling and triple stirring as a container, add 40kg of high alkali value synthetic calcium sulfonate with a total alkali value of 400mgKOH / g and a kinematic vi...

Embodiment 2

[0038] Embodiment 2: a kind of compound calcium sulfonate type railway wheel and rail lubricating grease, comprise following components: total base value is 380mgKOH / g synthetic calcium sulfonate 60kg, 40 ℃ kinematic viscosity is 82.01mm 2 / s 240kg of 500N base oil with a pour point of -35°C, 0.44kg of water, 0.6kg of a mixture of n-butanol and ethylene glycol, 0.90kg of dodecylbenzenesulfonic acid, 0.40kg of calcium hydroxide, 0.53kg of boric acid, ten 1.10 kg of dihydroxystearic acid, 1.20 kg of N-phenyl-α-naphthylamine, 0.72 kg of benzotriazole, and 2.40 kg of polytetrafluoroethylene were added.

[0039] The preparation method of composite calcium sulfonate type railway wheel and rail grease comprises the following steps:

[0040] S1. Prepare an atmospheric pressure reactor with a volume of 300L, heating, cooling and triple stirring as a container, put 60kg of high alkali value synthetic calcium sulfonate with a total base value of 380mgKOH / g into the reactor, and add kinem...

Embodiment 3

[0046] Embodiment 3: a kind of compound calcium sulfonate type railway wheel and rail lubricating grease, comprise following components: total base value is 400mgKOH / g synthetic calcium sulfonate 60kg, 40 ℃ kinematic viscosity is 82.01mm 2 / s 300kg of 500N base oil with a pour point of -35°C, 0.60kg of water, 0.47kg of a mixture of n-butanol and ethylene glycol, 2.13kg of dodecylbenzenesulfonic acid, 0.60kg of calcium hydroxide, 0.80kg of boric acid, ten Dihydroxystearic acid 1.45kg, N-phenyl-α-naphthylamine 1.87kg, benzotriazole 1.08kg, polytetrafluoroethylene 3.61kg.

[0047] The preparation method of composite calcium sulfonate type railway wheel and rail grease comprises the following steps:

[0048] S1. Prepare a normal-pressure reactor with a volume of 500 L, heating, cooling and triple stirring as a container, and put into the reactor 60 kg of high-basic synthetic calcium sulfonate with a total base value of 400 mgKOH / g. The kinematic viscosity at 40 ° C is 82.01mm 2 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pour point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com