Composite abrasion-resisting corrosion-resisting self-lubricating film and preparation method thereof

A self-lubricating, film-layer technology, applied in the direction of coating, solid-state diffusion coating, metal material coating process, etc., can solve the problems of poor corrosion resistance, low hardness of sulfurized layer, unsatisfactory lubrication performance, etc., to improve the resistance Grinding, improving wear-resistant lubrication performance, good anti-friction lubrication performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

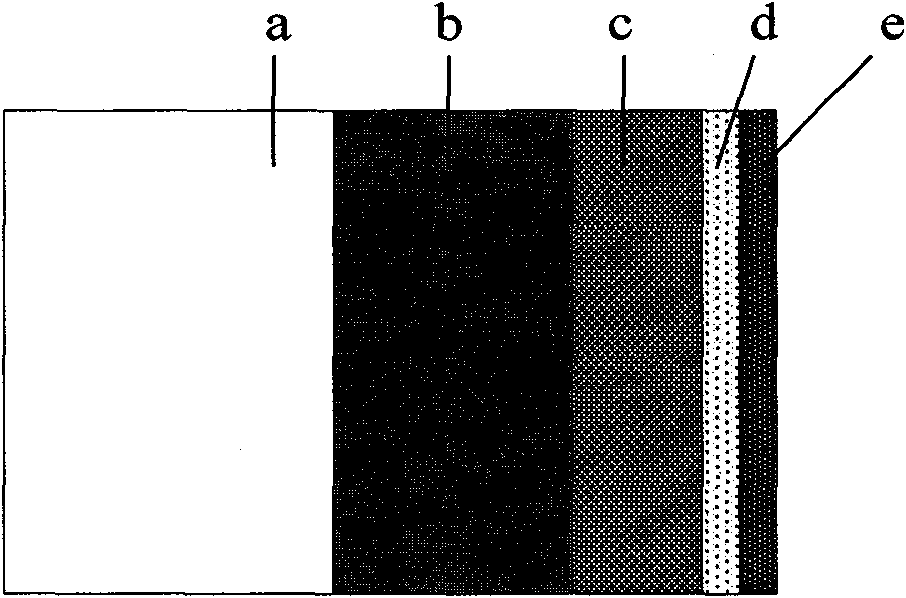

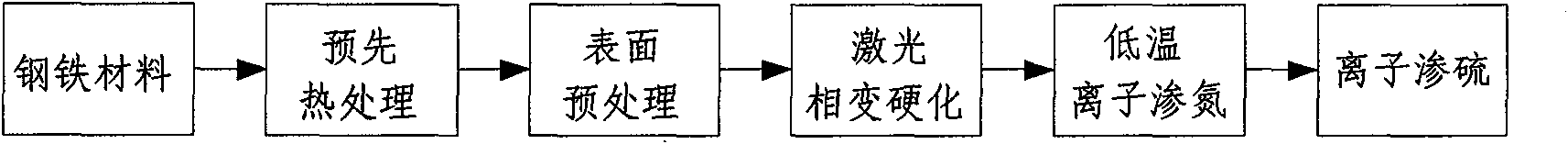

[0046] First, the 35CrMoA steel plate is subjected to quenching and tempering treatment. The specific process parameters of quenching and tempering treatment are: 850°C×20min oil quenching, 550°C×20min high temperature tempering, water cooling to obtain tempered sorbite structure, surface hardness is HRC30; surface finish Grinding and polishing, the roughness is 0.8μm.

[0047] Then clean the surface with acetone, and spray the self-made light-absorbing paint on the surface of the workpiece with a Japanese Iwata W-77 spray gun. The thickness of the light-absorbing paint sprayed layer is about 0.05mm. The workpiece is subjected to laser phase transformation hardening treatment. The specific steps and process parameters are: using 5kW cross-flow CO 2 Laser processing system, rectangular spot 10mm×1mm, power 2kW, scanning on the workpiece surface at a speed of 2000mm / min. During the scanning process, the high-energy laser beam irradiates the surface of the workpiece, and the li...

Embodiment 2

[0055] First, the trusses on the inner wall of the quenched and tempered 45# steel oil pump barrel were rubbed to a roughness of 0.8 μm. Clean the surface with acetone, and spray the self-made light-absorbing paint evenly on the inner wall of the pump barrel with a self-made slender tube inner wall light-absorbing paint spraying device. The thickness of the light-absorbing paint sprayed layer is about 0.05mm.

[0056]Laser phase transformation hardening treatment is carried out on the inner wall of the pump barrel (oil pipe) of the oil well pump by using the laser inner hole wall processing device. The specific steps and process parameters are: use a high-power laser processing system inner hole wall processing device, circular spot φ3mm, power 1000W, scan the inner wall of the pump cylinder with a spiral trajectory at a speed of 3500mm / min. During the scanning process, the high-energy laser beam irradiates the inner wall of the pump cylinder, and the light energy absorbed by ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com