Sealing ring chain

A sealing ring and chain technology, applied in the field of chains, can solve the problems of poor wear resistance of sealing rings, accelerated wear speed, failure to meet the life requirements of high-strength sealing chains, etc., and achieve the effect of increasing sealing, reducing friction and increasing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

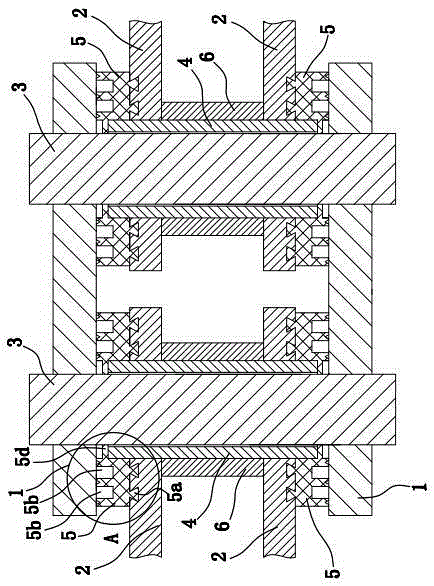

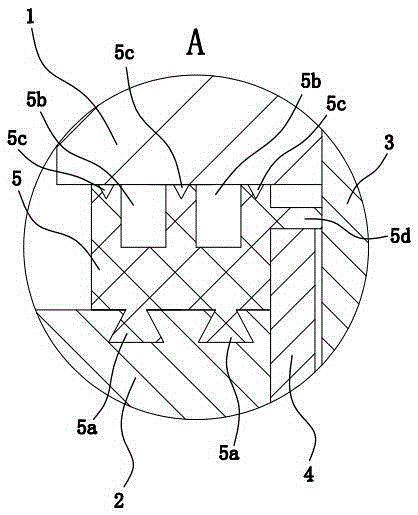

[0027] as shown in the picture 1 As shown, the sealing ring chain is composed of several chain units sequentially. Among them, each chain unit is composed of an outer chain plate 1 , inner chain plate 2 , pin 3 , bushing 4 , sealing ring 5 ,Roller 6 composition.

[0028] Specifically, the inner chain 2 There are two pieces, and two inner chain plates 2 Right on set. Bushing 4 Vertically installed on the two inner chain plates 2 between, and the shaft sleeve 4 The two ends of the two inner chain plates are connected respectively 2 phase fixed. Two inner chain plates 2 Outer chain plates are provided on the outside 1 , and two outer chain plates 1 Right on set. pin 3 inserted in the bushing 4 inner pin 3 Both ends protrude from the bushing 4 , and the pin 3 The two ends of the two outer chain plates are connected respectively 1 phase fixed. Roller 6 Cylindrical and set on the shaft sleeve 4 superior. ...

Embodiment 2

[0034] The structure and principle of the second embodiment are basically the same as that of the first embodiment, the difference is that the concave-convex connection structure includes 2 Connecting holes and sealing rings on the outer wall 5 Connecting posts matching the connecting holes on the top, the connecting holes have at least 2 indivual and along the sealing ring 5 Evenly distributed in the circumferential direction, the connecting hole is tapered and the diameter of the connecting hole gradually increases inwardly, the number of connecting posts is the same as that of the connecting holes and the positions correspond to each other, and the connecting posts are embedded in the connecting holes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com