Automatic lubricating device being suitable for nut-screw transmission mechanism

A screw drive, automatic lubrication technology, applied in the direction of transmission, mechanical equipment, belt/chain/gear, etc., can solve the problems of poor fluidity of grease, damage of screw, sticky grease, etc., and meet the requirements of processing accuracy. The effect of high machining accuracy requirements and few mechanism parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

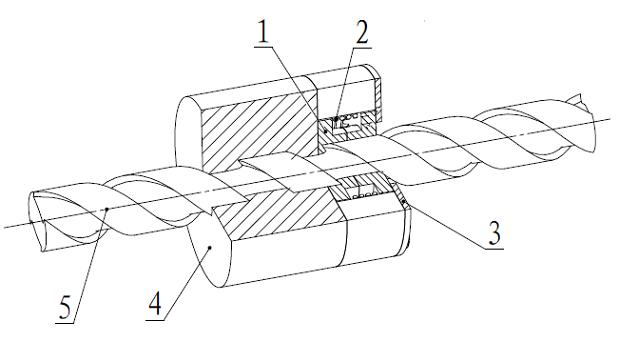

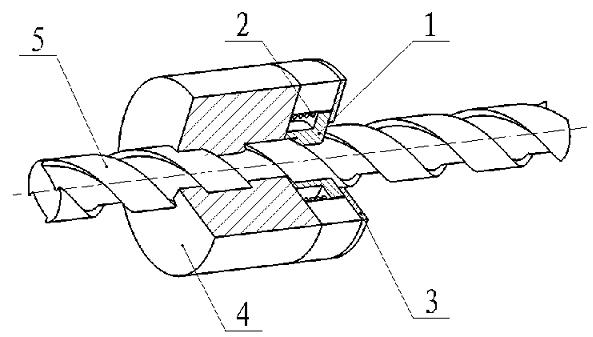

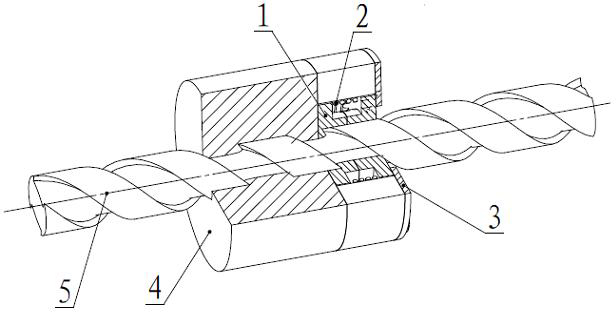

[0016] Embodiment 1: as figure 1 As shown, the present invention relates to an automatic lubricating device suitable for a nut screw drive mechanism, comprising a graphite nut 1, a torsion spring 2, a baffle plate 3, a drive nut 4 and a screw rod 5, wherein: the graphite nut 1 is set on the screw rod 1, so that the graphite nut 1 is in close contact with the screw rod 5, and the torsion spring 2 is installed on the graphite nut 1, so that the thread on the graphite nut 1 rotates in the opposite direction and sticks to both sides of the groove of the screw rod 5, thereby Lubricate the screw. In the present invention, the graphite nut 1 is arranged inside the transmission nut 4, and the baffle plate 3 is arranged outside the transmission nut, and the graphite nut 1 can also be arranged on the connecting plate provided between the baffle plate 3 and the transmission nut 4, and they They are all rigidly connected, so that the graphite nut 1 is sandwiched between the baffle plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com