Self-lubricating insulating rubber for limiting block of auxiliary frame for vehicle and processing technology of self-lubricating insulating rubber

A technology of insulating rubber and processing technology, which is applied in the field of self-lubricating insulating rubber and its processing technology for the limit block of the sub-frame of the vehicle. The effect of avoiding abnormal noise and improving the rust prevention ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

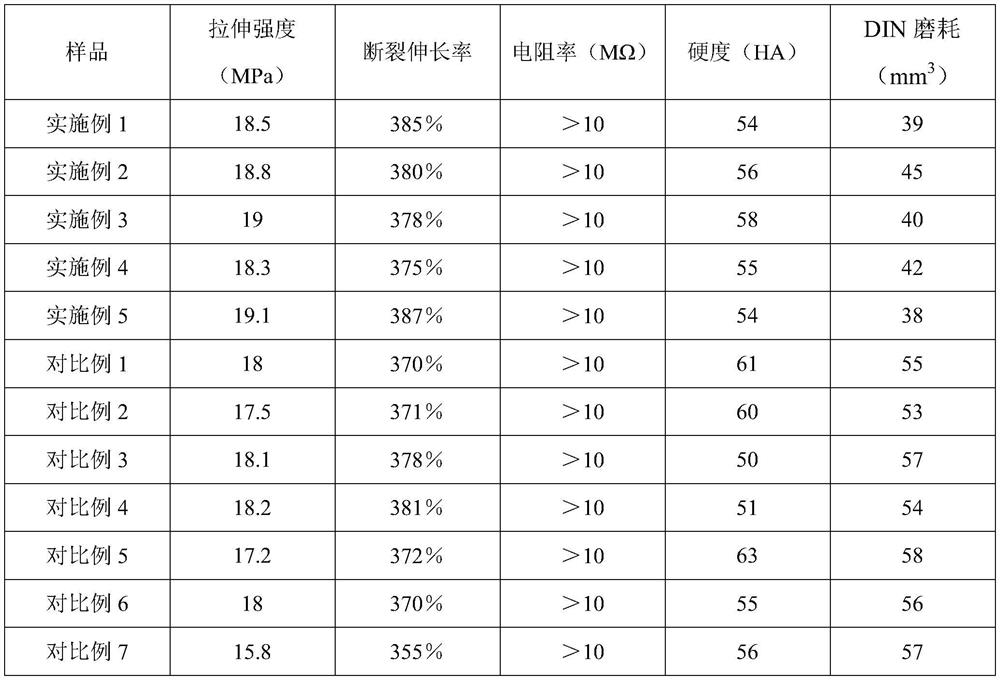

Examples

Embodiment 1

[0029] The self-lubricating insulating rubber of the vehicle auxiliary frame stopper of the present embodiment comprises the following raw materials: 60kg of natural rubber, 5kg of eucommia rubber, 8kg of thermoplastic vulcanizate rubber, 10kg of quick extruded carbon black, 20kg of semi-reinforced carbon black, white carbon black 10. Paraffin oil 5kg, zinc oxide 5kg, stearic acid 1kg, paraffin wax 3kg, silane coupling agent 2kg, antioxidant 3kg, polytetrafluoroethylene 5kg, lubricant 3kg, sulfur 2kg, accelerator 2kg.

[0030] The thermoplastic vulcanizate TPV is in powder form, and the particle size of the thermoplastic vulcanizate TPV is 100 μm; the model of the thermoplastic vulcanizate TPV is 121-50M100, and the hardness is HA54.

[0031] The particle size of polytetrafluoroethylene is 50 μm.

[0032] The lubricant is oleamide.

[0033] Antiaging agent is antiaging agent RD.

[0034] The white carbon black is the precipitation method white carbon black is 175GR white car...

Embodiment 2

[0043] The self-lubricating insulating rubber of the vehicle sub-frame limit block of the present embodiment includes the following raw materials: 70kg of natural rubber, 10kg of Eucommia rubber, 10kg of thermoplastic vulcanizate TPV, 15kg of fast extruded carbon black, 25kg of semi-reinforced carbon black, white carbon black 15kg, paraffin oil 10kg, zinc oxide 5kg, stearic acid 1kg, paraffin 4kg, silane coupling agent 3kg, antioxidant 4kg, polytetrafluoroethylene 4kg, lubricant 2kg, sulfur 3kg, accelerator 1kg.

[0044] The thermoplastic vulcanizate TPV is in powder form, and the particle size of the thermoplastic vulcanizate TPV is 110 μm; the model of the thermoplastic vulcanizate TPV is 281-55MED, and the hardness is HA59.

[0045] The particle size of polytetrafluoroethylene is 80 μm.

[0046] The lubricant is oleamide.

[0047] Anti-aging agent is anti-aging agent 4010NA.

[0048] The white carbon black is the precipitation method white carbon black is 175GR white carb...

Embodiment 3

[0057] The self-lubricating insulating rubber of the vehicle sub-frame limit block of the present embodiment includes the following raw materials: 80kg of natural rubber, 8kg of Eucommia rubber, 5kg of thermoplastic vulcanized rubber TPV, 20kg of fast extruded carbon black, 30kg of semi-reinforced carbon black, white carbon black 20. Paraffin oil 15kg, zinc oxide 8kg, stearic acid 2kg, paraffin wax 5kg, silane coupling agent 2kg, antioxidant 5kg, polytetrafluoroethylene 8kg, lubricant 2kg, sulfur 2kg, accelerator 2kg.

[0058] The thermoplastic vulcanizate TPV is in powder form, and the particle size of the thermoplastic vulcanizate TPV is 120 μm; the model of the thermoplastic vulcanizate TPV is 191-55PA, and the hardness is HA55.

[0059] The particle size of polytetrafluoroethylene is 60 μm.

[0060] The lubricant is erucamide.

[0061] Anti-aging agent is anti-aging agent 4010NA.

[0062] The white carbon black is the precipitation method white carbon black is 175GR whit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com