Integral composite material self-lubricating plain bearing and method for the production thereof

A technology of composite materials and sliding bearings, which is applied in the direction of bearing cooling, manufacturing tools, bearing components, etc., can solve the problems of bearing bush fracture or falling off, lack of self-lubrication of bearings, and short service life, so as to improve bearing capacity and accurate bearing size , enhance the effect of wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] 1) Take each component by weight % as follows:

[0029] Glass fiber (thickness 0.1mm grid cloth and long fiber each 1 / 2) 65

[0030] Carbon fiber (thickness 0.4mm fiber unidirectional cloth) 3

[0031] Lubricant (molybdenum disulfide, graphite 1 / 2 each) 2

[0032] Thermosetting resin (epoxy resin: phenolic resin = 2:1) 30

[0033] 2) Preparation of fiber resin impregnation:

[0034] a) First, mix ethanol and toluene in a ratio of 1:2 by volume to prepare a solvent, then dissolve the epoxy resin, phenolic resin mixture and solvent in a ratio of 10:3 by weight, add a lubricant, and prepare Form a resin impregnating solution, then impregnate glass fibers and carbon fibers in the resin impregnating solution respectively, and finally dry at a temperature range of 120°C to 180°C to 120°C for 30 minutes to obtain a fiber resin impregnated product.

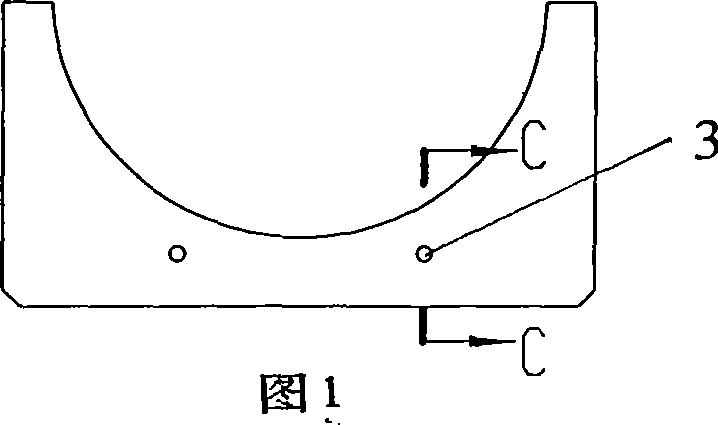

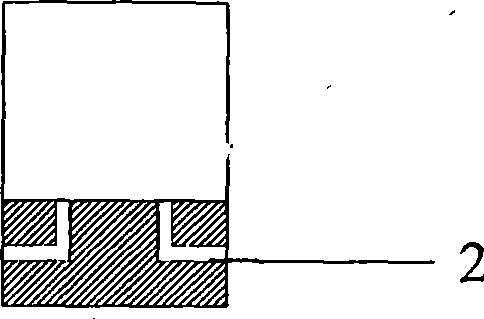

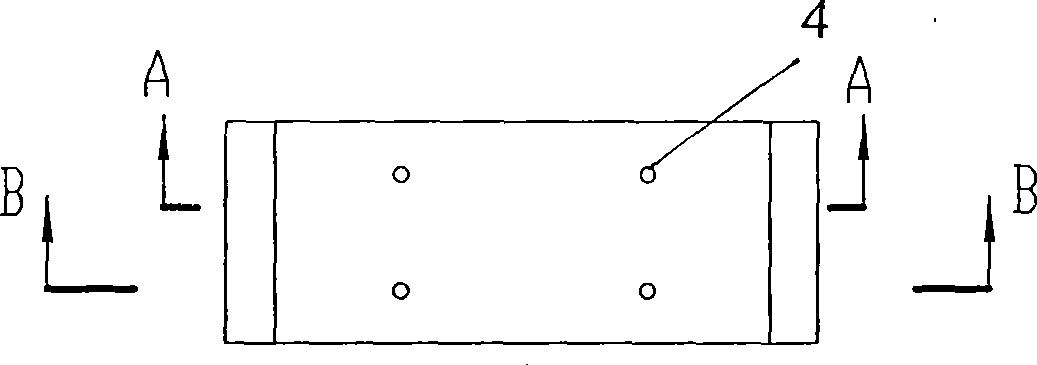

[0035] 3) Bearing molding:

[0036] a) First, the resin impregnated product obtained in step 2) is cut according to the dire...

Embodiment 2

[0040] 1) Take each component by weight % as follows:

[0041] Glass fiber (thickness 0.4mm grid cloth) 45

[0042] Carbon fiber (1 / 2 each of long fiber and 0.1mm thick unidirectional cloth) 10

[0043] Lubricants (1 / 2 each of molybdenum disulfide and zinc stearate) 10

[0044] Thermosetting resin (diaminodiphenyl sulfone modified epoxy resin) 35

[0045] 2) Preparation of fiber resin impregnation:

[0046] a) First, mix the resin and toluene at a ratio of 10:1 by volume, and add a lubricant at the same time to prepare a resin impregnating solution, then impregnate glass fibers and carbon fibers in the resin impregnating solution, and finally, at 120 ° C ~ Dry at a temperature range of 180° C. to 120° C. for 20 minutes to obtain a fiber resin impregnated product.

[0047] 3) Bearing molding:

[0048] a) First, cut the resin impregnated product obtained in step 2) according to the directional arrangement of the fibers to make a sheet consistent with the cavity of the mold,...

Embodiment 3

[0052] 1) Take each component by weight % as follows:

[0053] Glass fiber (thickness 0.1mm grid cloth) 45

[0054]Carbon fiber (thickness 0.4mm fiber unidirectional cloth) 3

[0055] Lubricant (molybdenum disulfide) 7

[0056] Thermosetting resin (isophthalic unsaturated polyester resin) 45

[0057] 2) Fiber resin impregnation and preparation:

[0058] b) Respectively impregnating glass fiber and carbon fiber in isophthalic unsaturated polyester resin to obtain a fiber resin impregnated product.

[0059] 3) Bearing molding:

[0060] a) First, the resin impregnated product obtained in step 2) is cut according to the directional arrangement of the fibers to make a sheet consistent with the mold cavity, and then the sheet is laminated into a glass fiber laminate with a thickness of 4mm and a thickness of 2mm carbon fiber composite.

[0061] b) Put the laminated fiber into the mold in the direction perpendicular to the axis of the bearing shaft, press for 6 hours at a tempe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com