Lifting platform

A technology of lifting platform and load-bearing platform, which is applied in the field of lifting platform, can solve the problems that the transition plate cannot be directly placed on the base surface of the warehouse, reduce the efficiency of loading and unloading goods, and cannot meet the requirements, etc., and achieve compact structure, high reliability, and convenience. The effect of control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

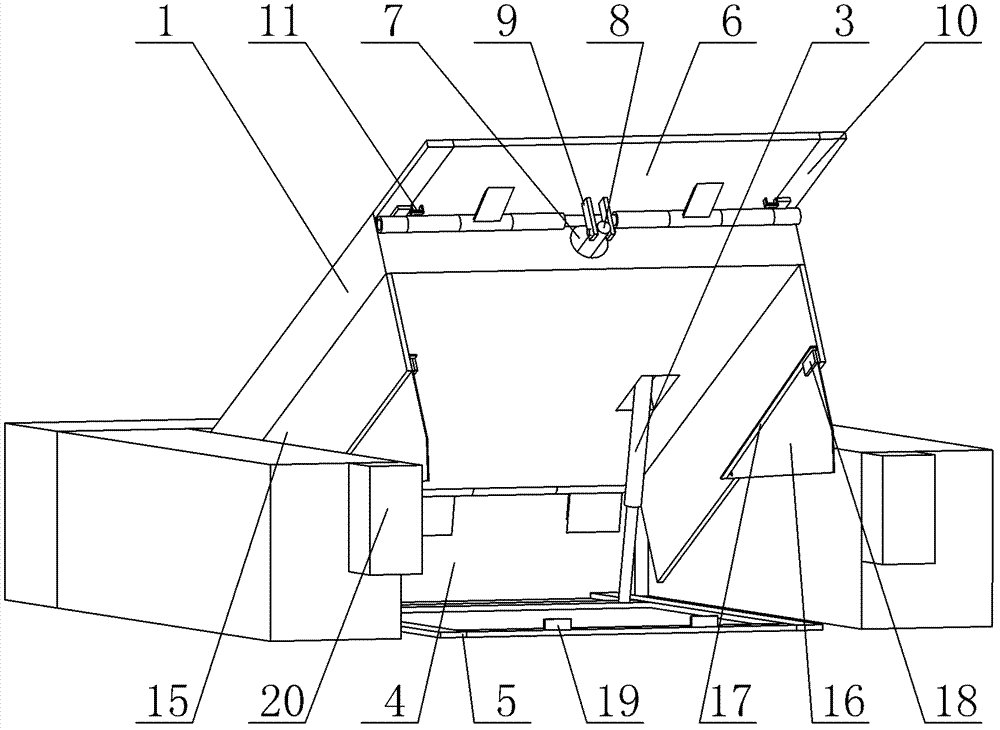

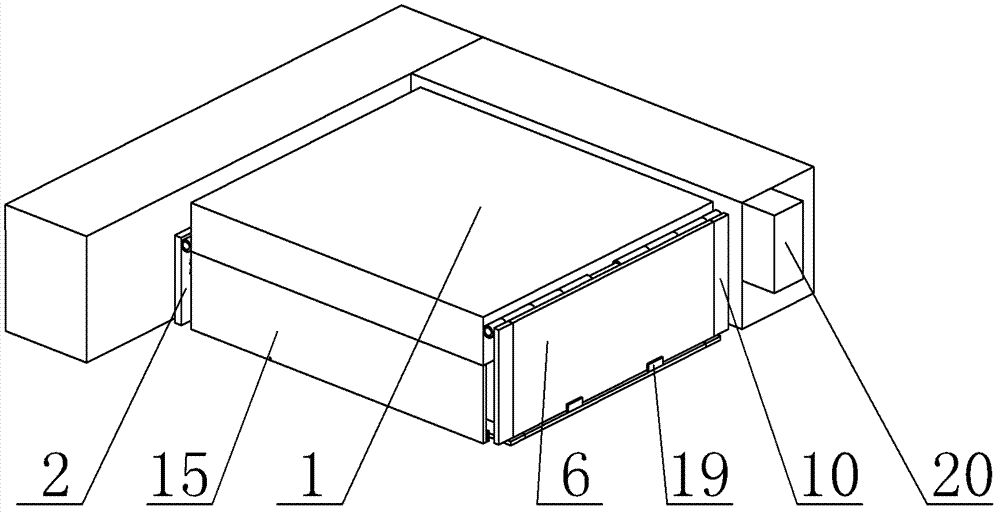

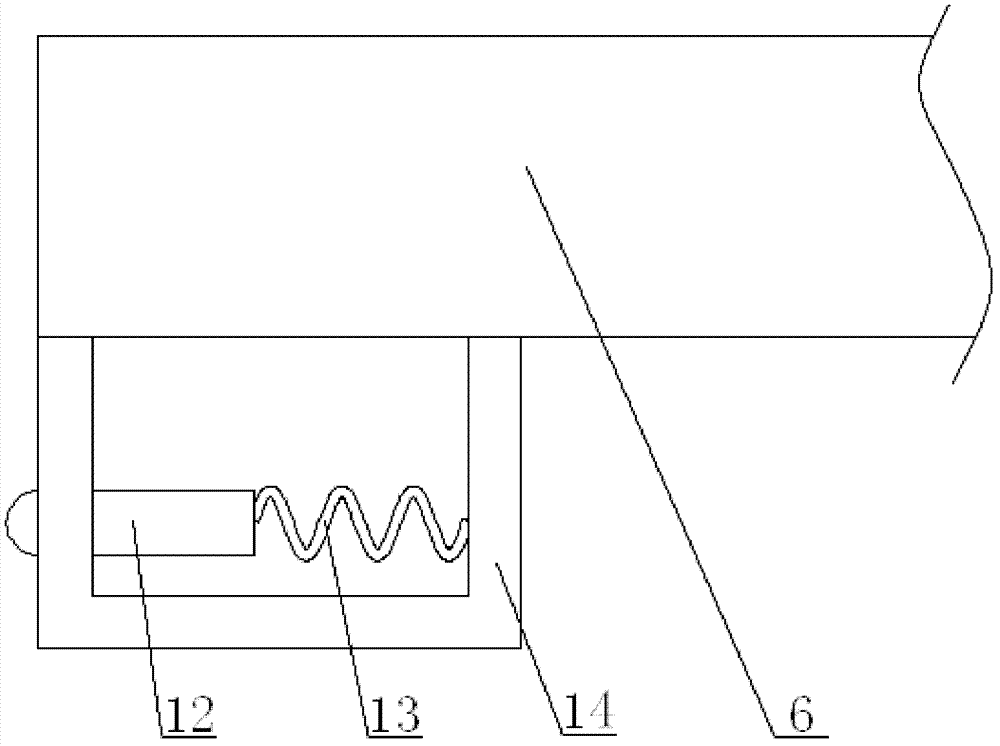

[0024] Embodiment 2 of the present invention: as figure 2 with Figure 4 As shown, the lift platform includes a load-bearing platform 1, a load-bearing platform support 2 and a lifting jack 3, and the load-bearing platform support 2 includes a rear wall 4 and a bottom frame 5. The load-bearing platform 1 is arranged above the load-bearing platform support 2 and rotates with the rear wall 4 Connection, one end of the lifting jack 3 is rotationally connected with the bottom frame 5, and the other end is rotationally connected with the load-bearing platform 1; the front part of the load-bearing platform 1 is provided with a board 6; It is arranged above the piston hole 7 and is connected to the load-bearing platform 1 in rotation. A piston 8 is arranged inside the piston hole 7. A connecting rod 9 is arranged on the lower side of the connecting plate 6. The connecting rod 9 is connected to one end of the piston 8 in rotation; The two sides of 6 are respectively provided with au...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com