Cleaning dishcloth easy to remove oil and making method thereof

A cleaning and rag technology, applied in the field of easy-to-oil cleaning rags and their production, can solve the problems of large amount of use, unsanitary, difficult to clean and recycle for secondary use, etc., and achieves the effect of strong load force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] An easy-to-grease cleaning cloth includes a base cloth, and the base cloth is added with a cleaning formula as shown in Table 1; wherein, the base cloth is made of polyester-viscose woven fabric.

[0050] Table 1 Cleaning Recipe

[0051] components

Content (i.e., the value of the total mass of the cleaning formula)

Organosilicon quaternary ammonium salt antibacterial agent (such as known antibacterial agents)

0.2%

Sodium linear dedecylbenzene sulfonate

3%

Dimethicone

5%

Isomer Heptaol Ether

2%

Deionized water

Remaining content (ie 89.8%)

[0052] For the above-mentioned easy-to-grease cleaning rag, its specific production steps are as follows:

[0053]1) According to the formula in Table 1, add organic silicon quaternary ammonium salt antibacterial agent, linear sodium dodecylbenzene sulfonate, dimethyl siloxane, and isomeric heptaol ether into deionized water, and stir evenly to obtain a cleaning fo...

Embodiment 2

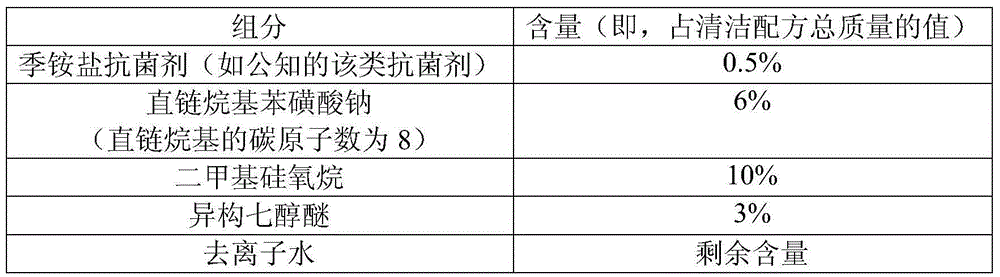

[0064] An easy-to-grease cleaning rag, comprising a base cloth, and the base cloth is added with a cleaning formula as shown in Table 3; wherein, the base cloth is made of polyester-cotton woven fabric.

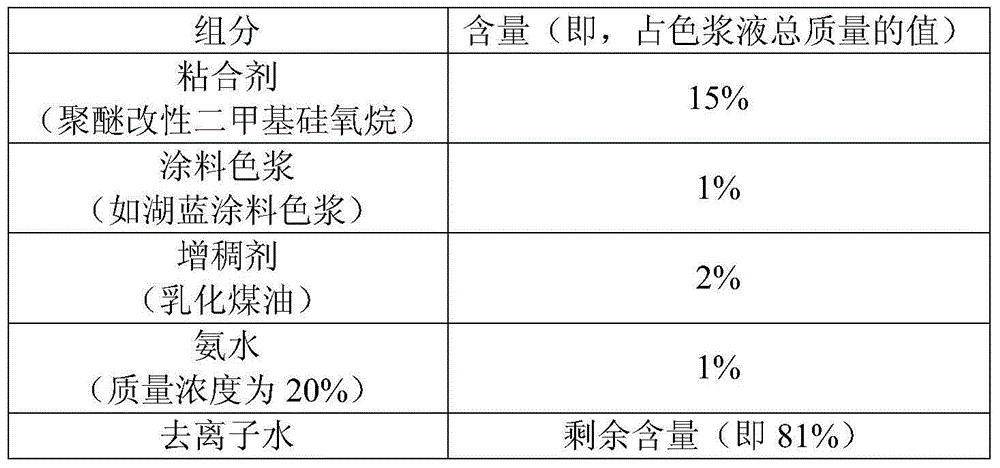

[0065] Table 3 Cleaning Recipe

[0066]

[0067] For the above-mentioned easy-to-grease cleaning rag, its specific production steps are as follows:

[0068] 1) According to the formula in Table 3, add the quaternary ammonium salt antibacterial agent, sodium linear alkylbenzene sulfonate, dimethyl siloxane, and isomeric heptaol ether into deionized water, and stir evenly to obtain the original solution of the cleaning formula;

[0069] 2) Dyeing by immersing the above-mentioned base cloth in the color paste liquid prepared from the formula shown in Table 4;

[0070] The formula of table 4 color slurry

[0071]

[0072] Wherein, the preparation method of emulsified kerosene in Table 4 is: after mixing kerosene, emulsifier (such as isomerized tridecyl alcohol polyoxyethy...

Embodiment 3

[0080] An easy-to-grease cleaning cloth includes a base cloth, and the base cloth is added with a cleaning formula as shown in Table 5; wherein, the base cloth is a hemp woven cloth prepared from hemp fiber according to a conventional process.

[0081] Table 5 Cleaning Recipe

[0082]

[0083] For the above-mentioned easy-to-grease cleaning rag, its specific production steps are as follows:

[0084] 1) According to the formula in Table 5, add the quaternary ammonium salt antibacterial agent, sodium linear alkylbenzene sulfonate, dimethyl siloxane, and isomeric heptaol ether into deionized water, and stir evenly to obtain the cleaning formula stock solution;

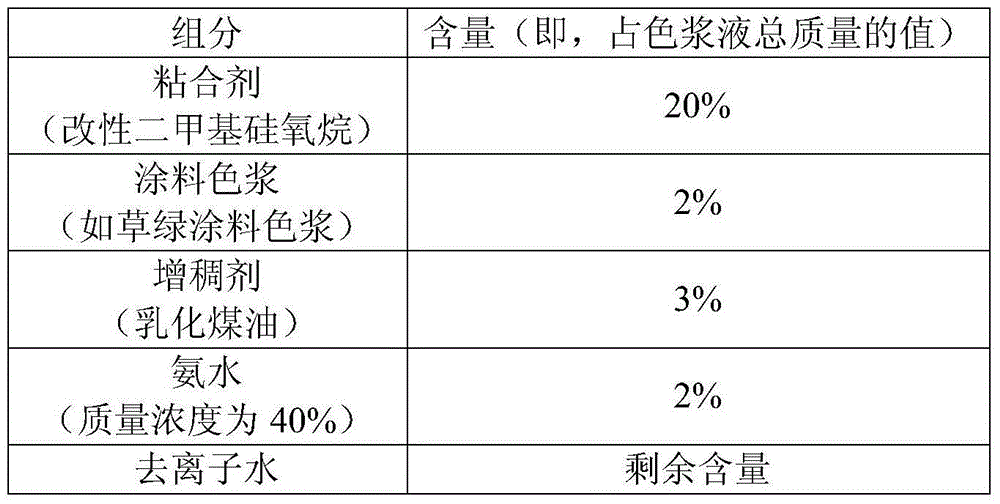

[0085] 2) Dyeing by immersing the above-mentioned base cloth in the colorant solution prepared from the formula shown in Table 6;

[0086] The formula of table 6 color slurry

[0087]

[0088] Wherein, the preparation method of emulsified kerosene in Table 6 is: after mixing kerosene, emulsifier (such as isomerize...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com