All-dimension ground physical verification system and method for space manipulator load changing situation

A space manipulator, physical verification technology, applied in the field of space robot ground test verification, to achieve the effect of increasing applicability, wide adaptability, and strong load capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

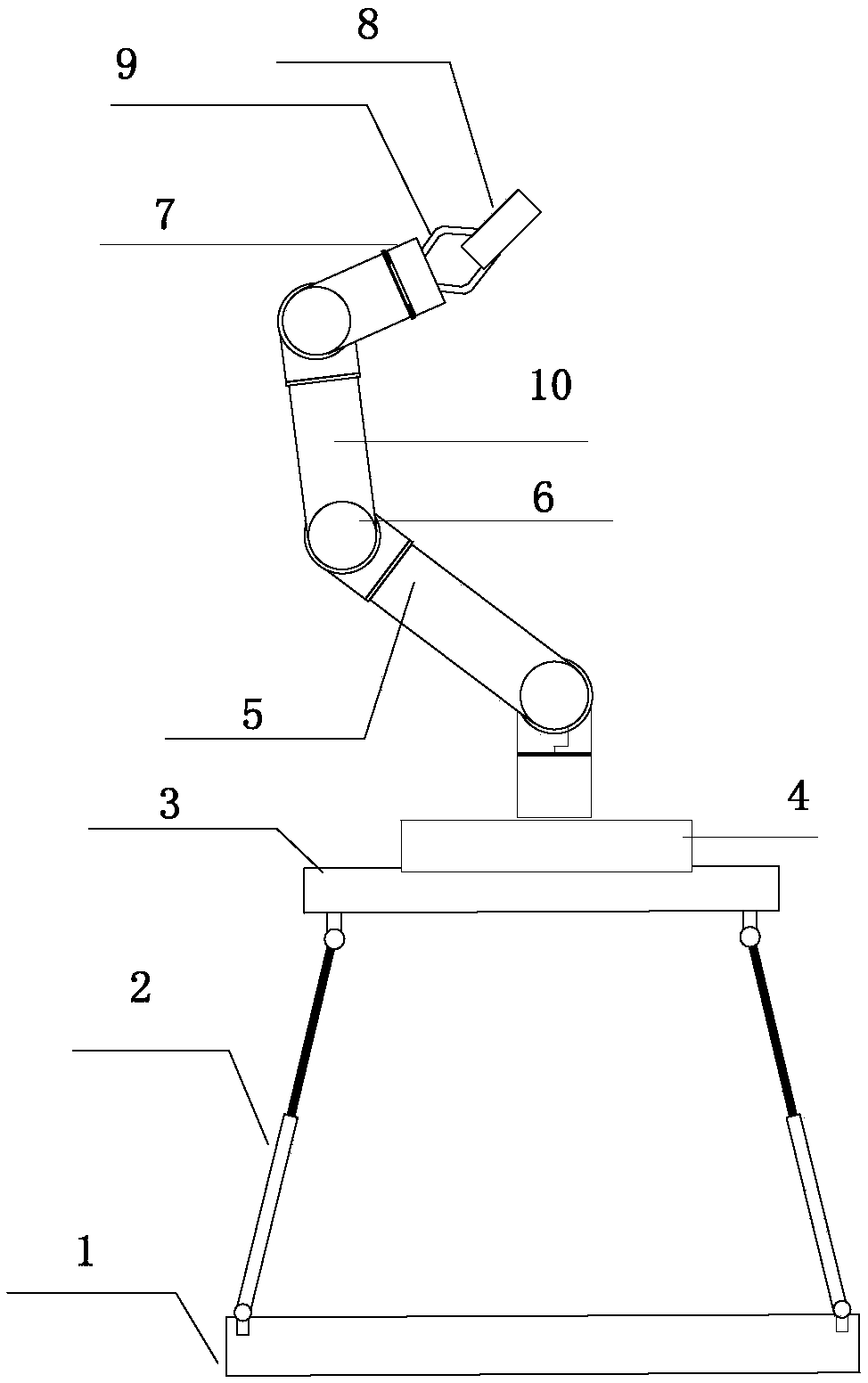

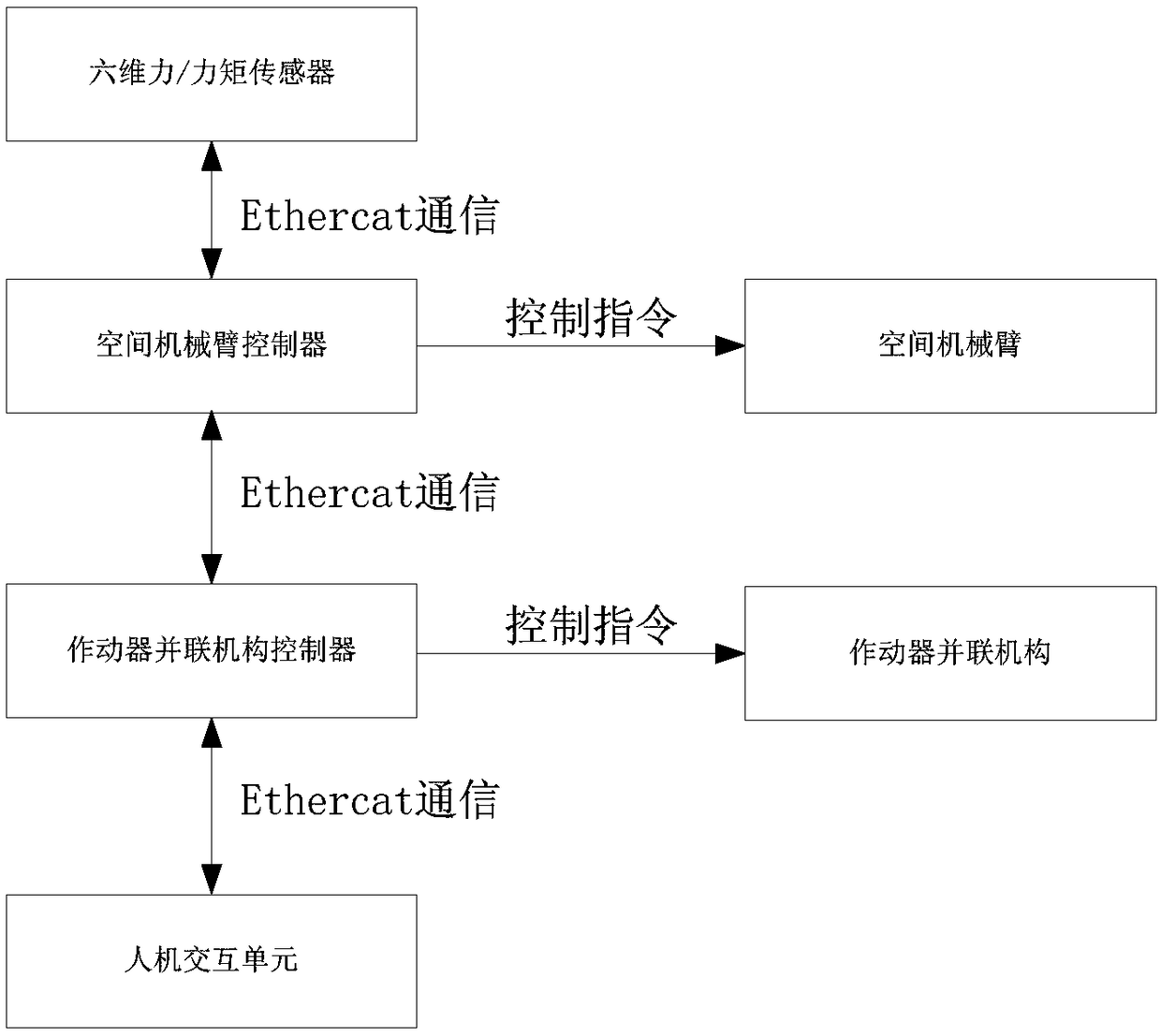

[0034] Such as figure 2 , the space robot ground physical verification system under variable load conditions includes a human-computer interaction unit, an actuator parallel mechanism 2, an actuator parallel mechanism controller, a six-dimensional force / torque sensor 7, a six-dimensional force / torque sensor signal processing module, and a six-dimensional force / torque sensor. Degree of freedom space manipulator 5, space manipulator controller, load clamping mechanism 9 and load.

[0035] Such as figure 1 , The actuator parallel mechanism is composed of upper platform 3, lower platform 1, six telescopic cylinders and Hooke hinge. One end of the telescopic cylinder is connected to the upper platform 3 through a Hooke hinge, and the other end is connected to the lower platform 1 through a Hooke hinge.

[0036] The signal processing module of the six-dimensional force / torque sensor 7 includes a force / torque signal filtering module and a communication module.

[0037] The space ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com