Multifunctional all-terrain transportation robot

An all-terrain and robotic technology, applied in the field of transportation, can solve the problems of large internal space, poor ability to overcome obstacles, and inaccessibility, and achieve the effects of good maintenance, strong load capacity, and wide application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

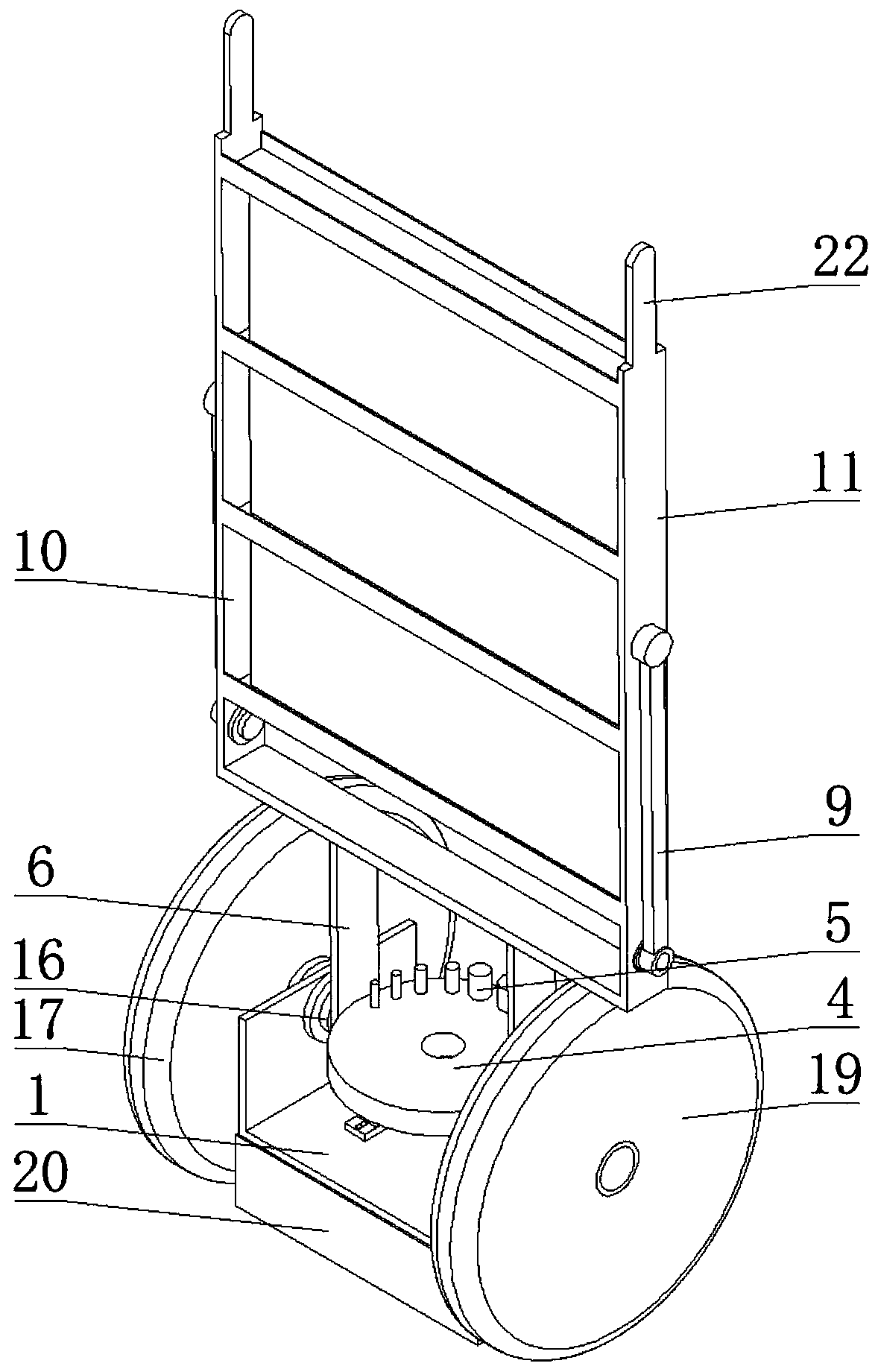

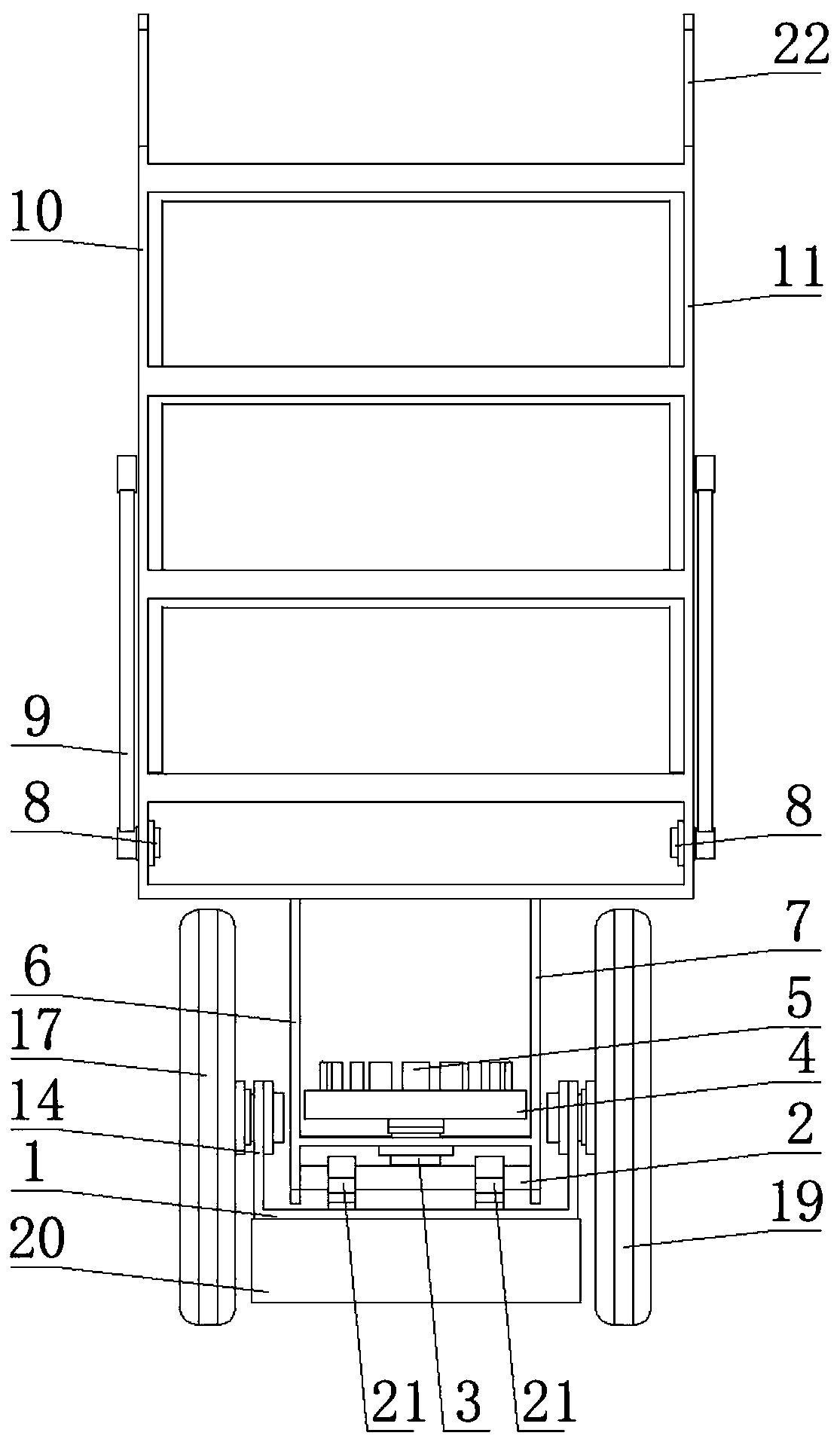

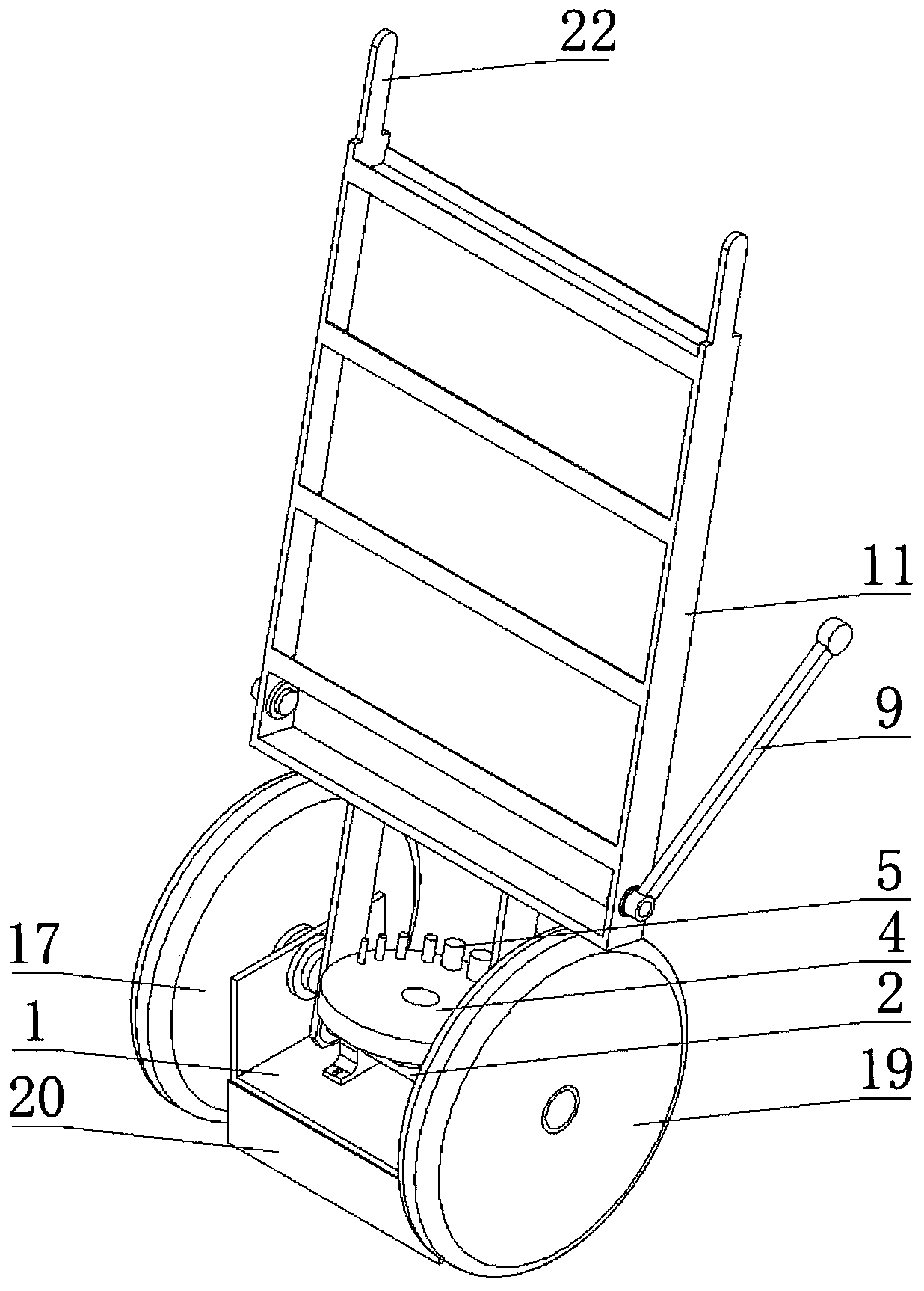

[0043] Such as figure 1 with Figure 5 The shown multifunctional all-terrain transport robot includes a chassis 1 and a wheel assembly. Such as figure 2 As shown, the left part of the chassis 1 is provided with a left mounting seat 14, and the right part of the chassis 1 is provided with a right mounting seat 15, and the wheel assembly includes a third motor 16 installed on the left mounting seat 14, a motor mounted on the third motor 16 The left wheel 17 on the rotating shaft, the fourth motor 18 installed on the right mount 15 and the right wheel 19 located on the rotating shaft of the fourth motor 18, the left wheel 17 and the right wheel 19 are symmetrical and coaxially arranged, through the left The difference of wheel 17 and right wheel 19 rotating speeds can realize the steering of robot. The chassis 1 is provided with a lower electrical box 20 fixed on the chassis 1, the lowest height of the electrical box 20 is higher than the lowest height of the left wheel 17 or...

Embodiment 2

[0066] The structural principle of this embodiment is basically the same as that of Embodiment 1, the difference is that, as Figure 4 As shown, the central axis of the first motor 3 is parallel to the tilting axis 2 . Such as Figure 4 As shown, a vertical bar 24 is arranged between the cross bar 23 and the shelf, and the first motor 3 is fixed on the vertical bar 24 . When the shelf is tilted forward, the first motor 3 drives the center of gravity of the counterweight to rotate behind the tilting axis 2, thereby changing the center of gravity of the upper part of the robot, so that the center of gravity of the upper part of the robot is located directly above the tilting axis 2, maintaining the upper part of the robot balance. When the shelf is tilted backward, the first motor 3 drives the center of gravity of the counterweight to rotate to the front of the tilting axis 2, thereby changing the center of gravity of the upper part of the robot, so that the center of gravity ...

Embodiment 3

[0068] The structural principle of this embodiment is basically the same as that of the first embodiment, except that the gravity center adjustment component is a gyroscope.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com