Mixing conveying vehicle

A technology for mixing transport vehicles and mixing drums, which is applied in the direction of concrete transportation, cement mixing devices, clay preparation devices, etc., which can solve the problems of poor adaptability and achieve the effects of strong obstacle-crossing ability, simplified structure, and good trafficability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

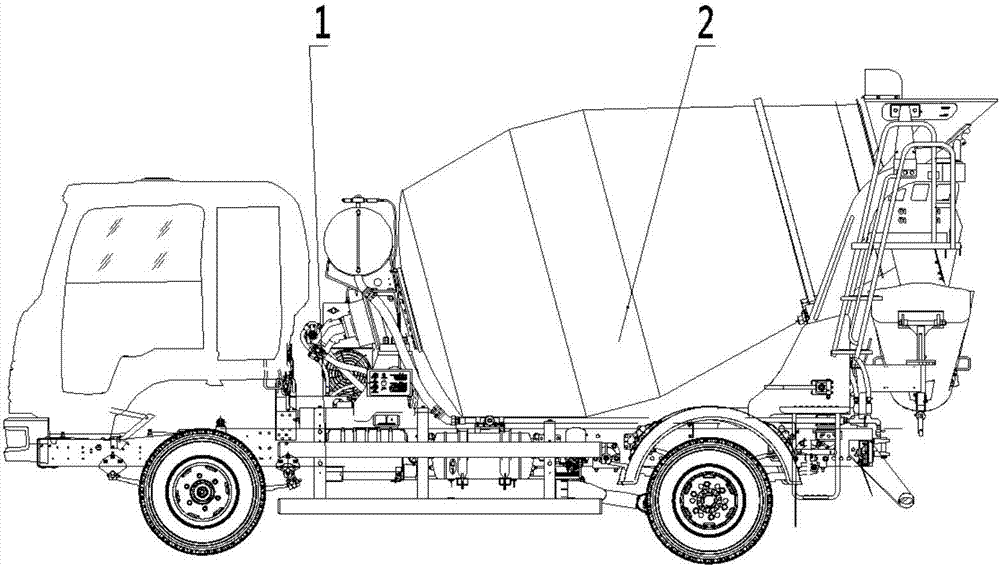

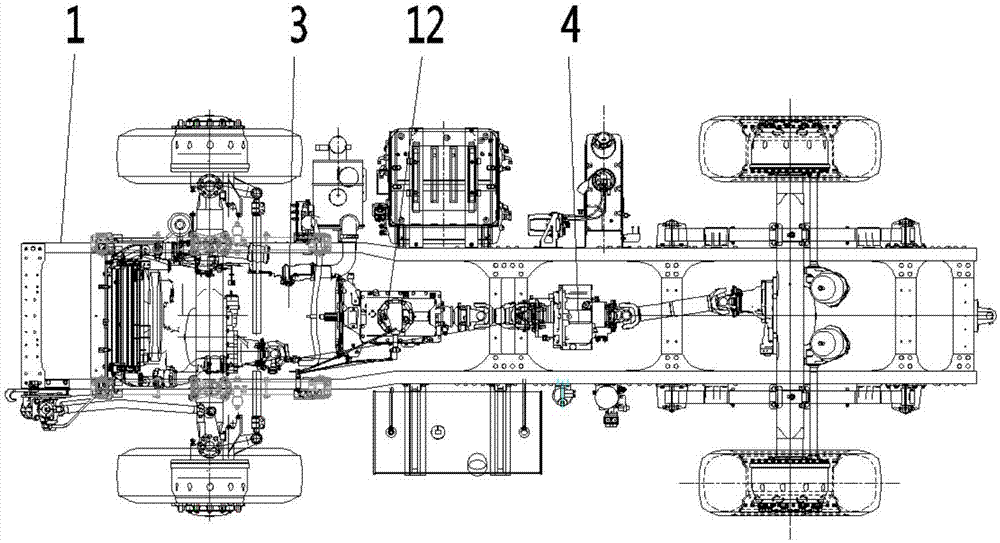

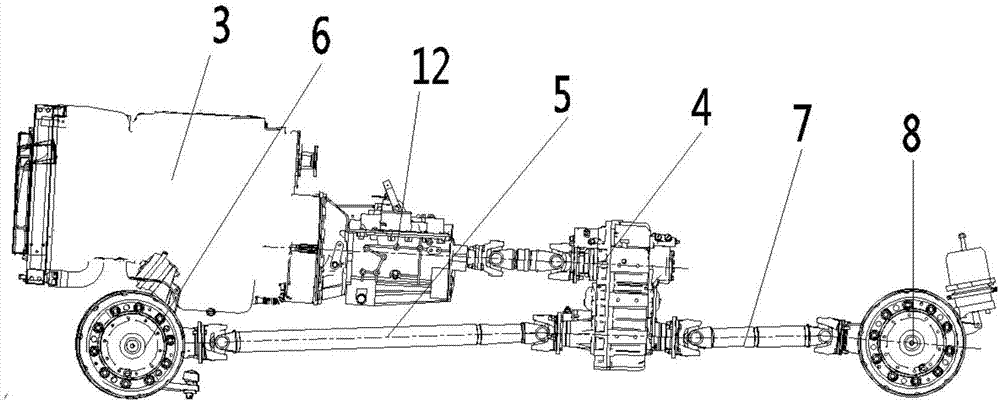

[0034] Figure 1 to Figure 3 Shown a specific embodiment of the present invention, a kind of agitator truck, comprises chassis 1, and the mixing drum 2 that is arranged on chassis 1, is provided with power unit 3, transfer case 4, front drive shaft 5 on chassis 1, The front drive axle 6, the rear drive shaft 7, and the rear drive axle 8, the power part 3 is connected to the input shaft 9 of the transfer case 4, and the front output shaft 10 of the transfer case 4 is connected to the front drive axle 6 through the front drive shaft 5 , the rear output shaft 11 of the transfer case 4 is connected to the rear drive axle 8 through the rear transmission shaft 7 .

[0035] It should be noted that the mixer truck includes two parts, the bodywork and the chassis 1, wherein the bodywork includes the mixing drum 2, s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com