Rapid mounting structure for curtain wall glass

A technology for installing structures and glass, applied in the direction of walls, building components, building structures, etc., can solve the problems of poor versatility, poor stability, waste of labor, etc., and achieve the effect of convenient installation, good passability, and labor reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

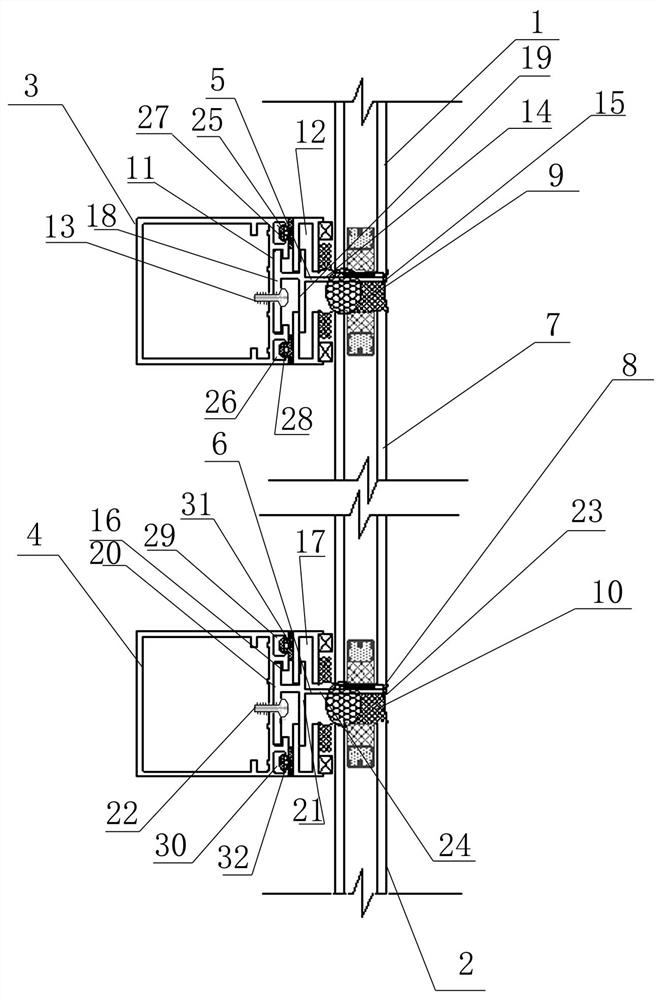

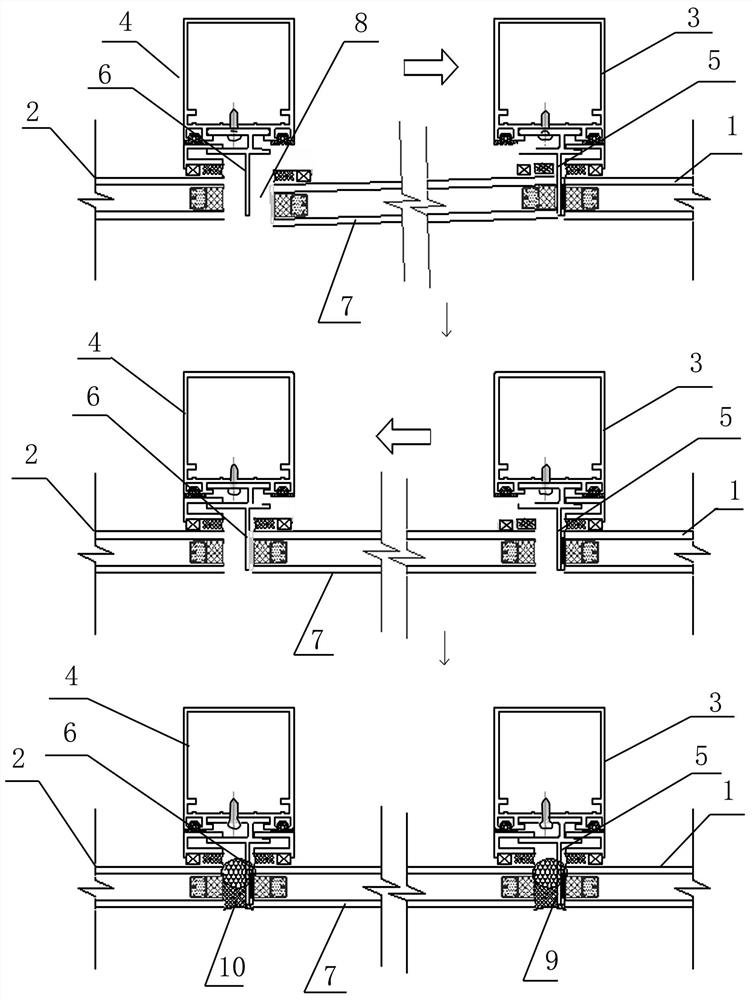

[0009] exist figure 1 Among them, the present invention provides a curtain wall glass rapid installation structure, which mainly includes an upper outer frame 1 and a lower outer frame 2, the upper outer frame 1 and the lower outer frame 2 are arranged symmetrically, and an upper The inner support profile 3 is provided with a lower inner support profile 4 on the inner side of the upper part of the lower outer frame 2, and an upper hidden frame glass support frame 5 is provided between the lower part of the upper outer frame 1 and the upper inner support profile 3. A lower hidden frame glass support frame 6 is arranged between the upper part and the lower inner support profile 4, and the vertical gap between the upper hidden frame glass support frame 5 and the lower hidden frame glass support frame 6 is set as a curtain wall glass installation area 8, and the curtain wall The height of the glass installation area 8 is greater than the height of the curtain wall glass 7, the cur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com