Three-freedom-degree parallel spindle head mechanism suitable for horizontal machining

A degree of freedom, spindle head technology, used in metal processing mechanical parts, metal processing equipment, manufacturing tools, etc., can solve the problems of high stiffness, low motion inertia, and poor dynamic isotropy, and achieve high stiffness and load capacity. Strong, low mass effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The structure, principle and specific implementation of the present invention will be further described below in conjunction with the accompanying drawings.

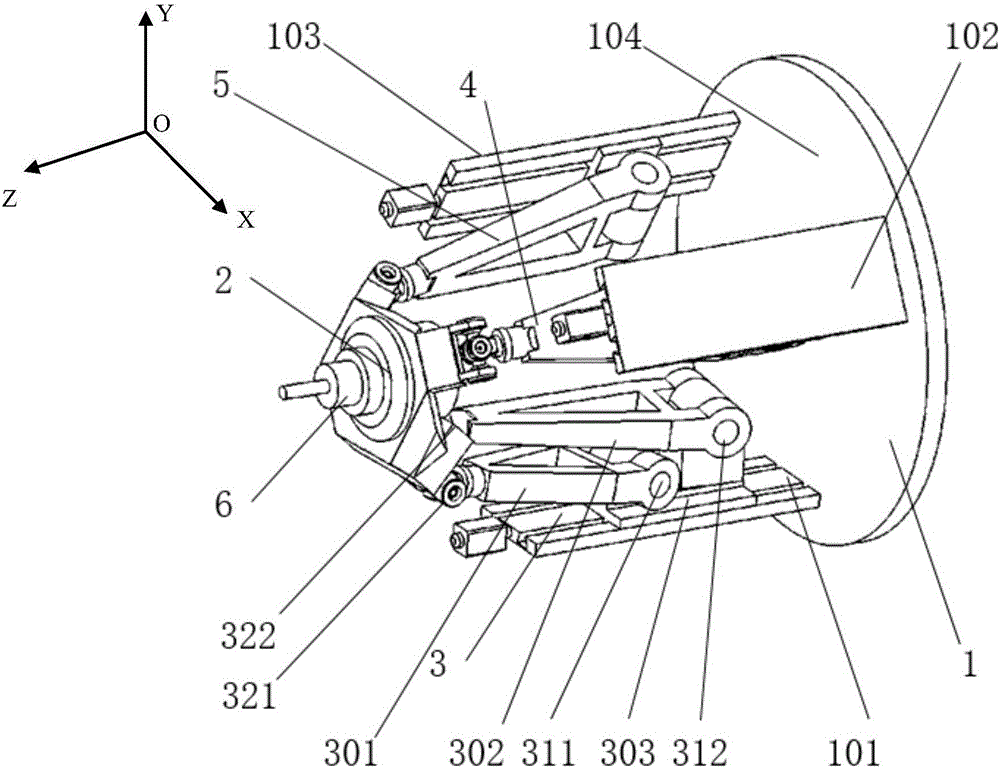

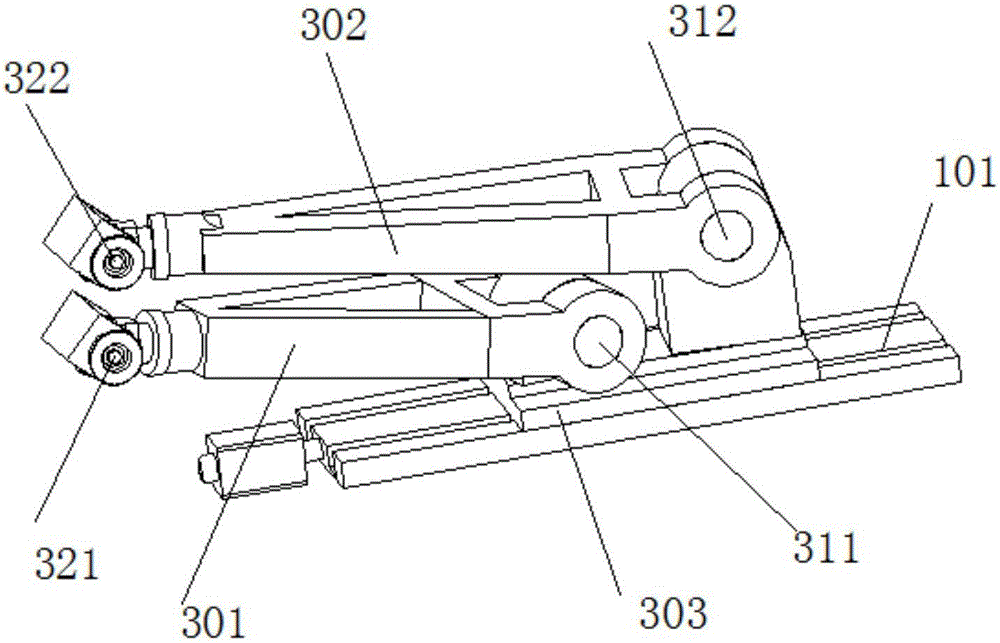

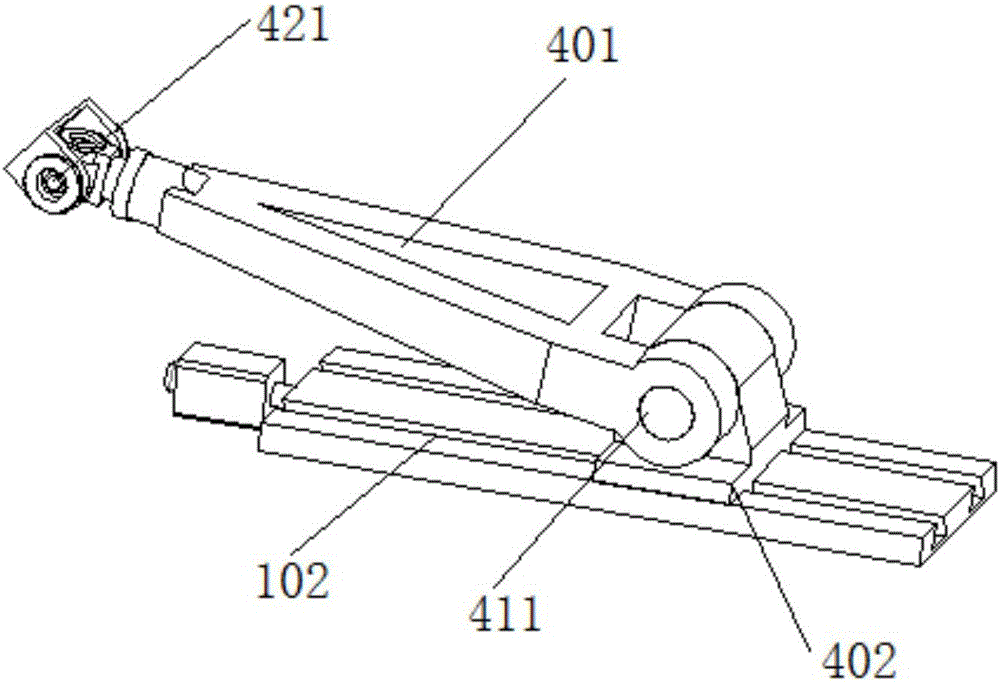

[0014] figure 1 The three-dimensional structural schematic diagram of the embodiment of the horizontal three-degree-of-freedom parallel spindle head mechanism provided by the present invention, the horizontal three-degree-of-freedom parallel spindle head mechanism structure includes a fixed platform 1, a moving platform 2, and a spindle 6, and is arranged on the The first branch 3 , the second branch 4 and the third branch 5 of the fixed platform 1 and the moving platform 2 constitute a parallel spindle head mechanism with three degrees of freedom in space. The fixed platform 1 includes a first frame 101, a second frame 102, a third frame 103 and a base 104, the first frame 101, the second frame 102 and the third frame 103 are fixed on the base 104 and The space is evenly distributed, and the first branch 3, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com