Bionic soft robot

A robot and software technology, applied in the field of robots, to achieve the effects of excellent load capacity, expanded application fields, and flexible design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The present invention will be further described below with reference to the drawings and embodiments.

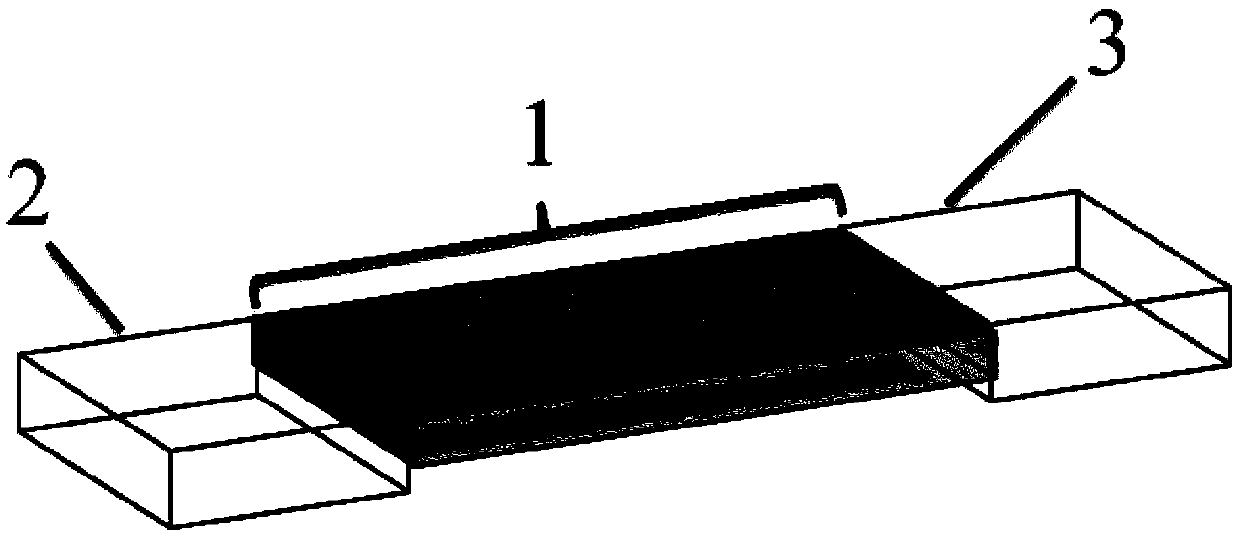

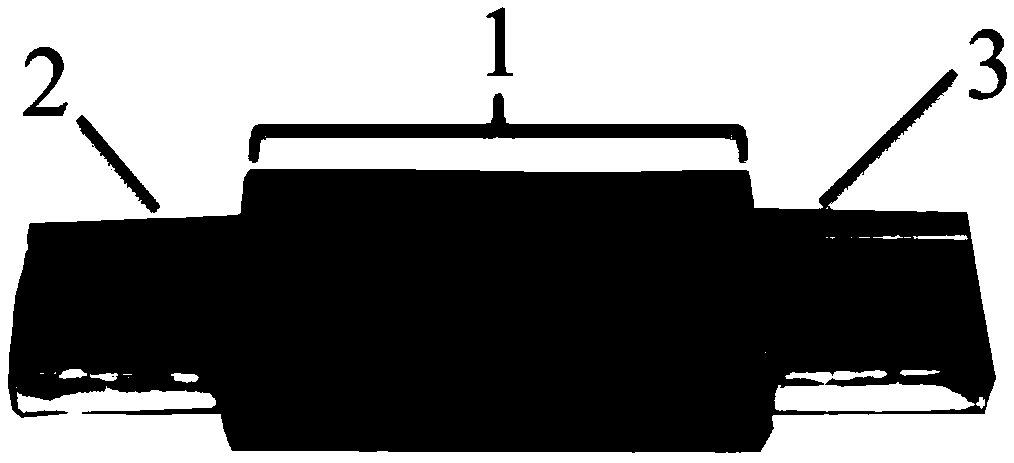

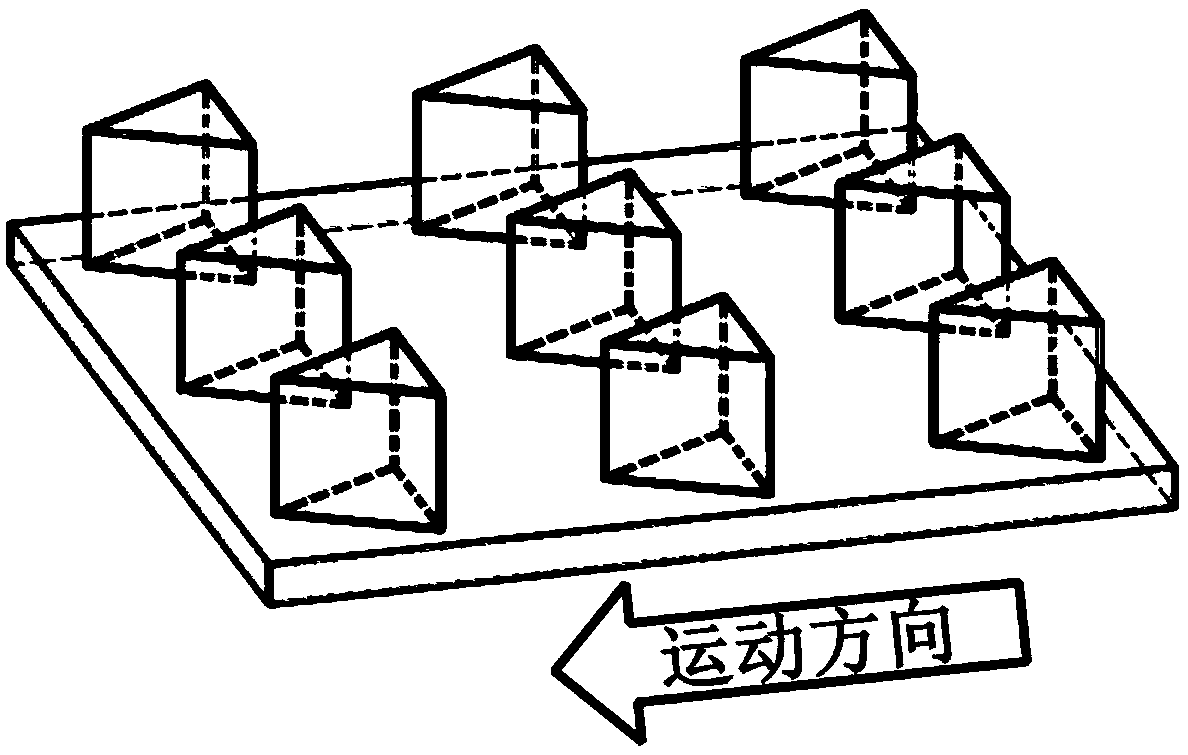

[0030] Such as figure 1 , 2 , A bionic soft robot, including a rectangular parallelepiped torso, forefoot and hindfoot, and energy supply modules. The dimensions of the robot’s torso, forefoot and hindfoot are between centimeters and millimeters. The surface of the forefoot and hindfoot bottom is microscopic The array structure is micron level; the forefoot and hindfoot are made of silicone rubber material polydimethylsiloxane, fixedly connected to the ends of the trunk, and the lower surface has a triangular prism array structure with the same structure, oriented along the direction of movement and the orientation is consistent ( Such as image 3 ), when the robot is walking, the ends of the triangular prism array at the bottom of the forefoot and hindfoot are in contact with the base as the walking surface; the trunk is made of graphene-polydimethylsiloxane composite ma...

Embodiment 2

[0040] Based on a biomimetic soft robot of Example 1, the rest of the structure remains unchanged. The body material can be replaced with ionic metal composites (IPMCs) with sulfonated polystyrene as the base. The front and rear ends of the robot are connected to an external power source through wires. The DC voltage is 3 to 5 volts, and the voltage cycle for the robot to complete a single forward movement is: the loading time is 60 seconds, and the unloading time is 60 seconds.

example 3

[0042] Based on a biomimetic soft robot of Example 1, the rest of the structure remains unchanged. The material of the trunk part can be replaced with a photodeformable liquid crystal elastomer (LCE) containing the long conjugated group of azobisphenylacetylene. The driving energy of the trunk is light. Yes, the energy supply module is a 365-nanometer wavelength ultraviolet light emitter. The light intensity of the light emitter is between 250 and 400 milliwatts per square centimeter. The light cycle for the robot to complete a single forward movement is: continuous light for 15 seconds, remove light 15 seconds.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com