Self-balancing tractor

An automatic balancing and tractor technology, which is applied in the field of agricultural machinery and tools, can solve the problems of inability to adjust the left and right driving wheels, weak chain drive traction, and inability to pull and transport materials, etc., and achieve the effect of wide application range, large load capacity and reliable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

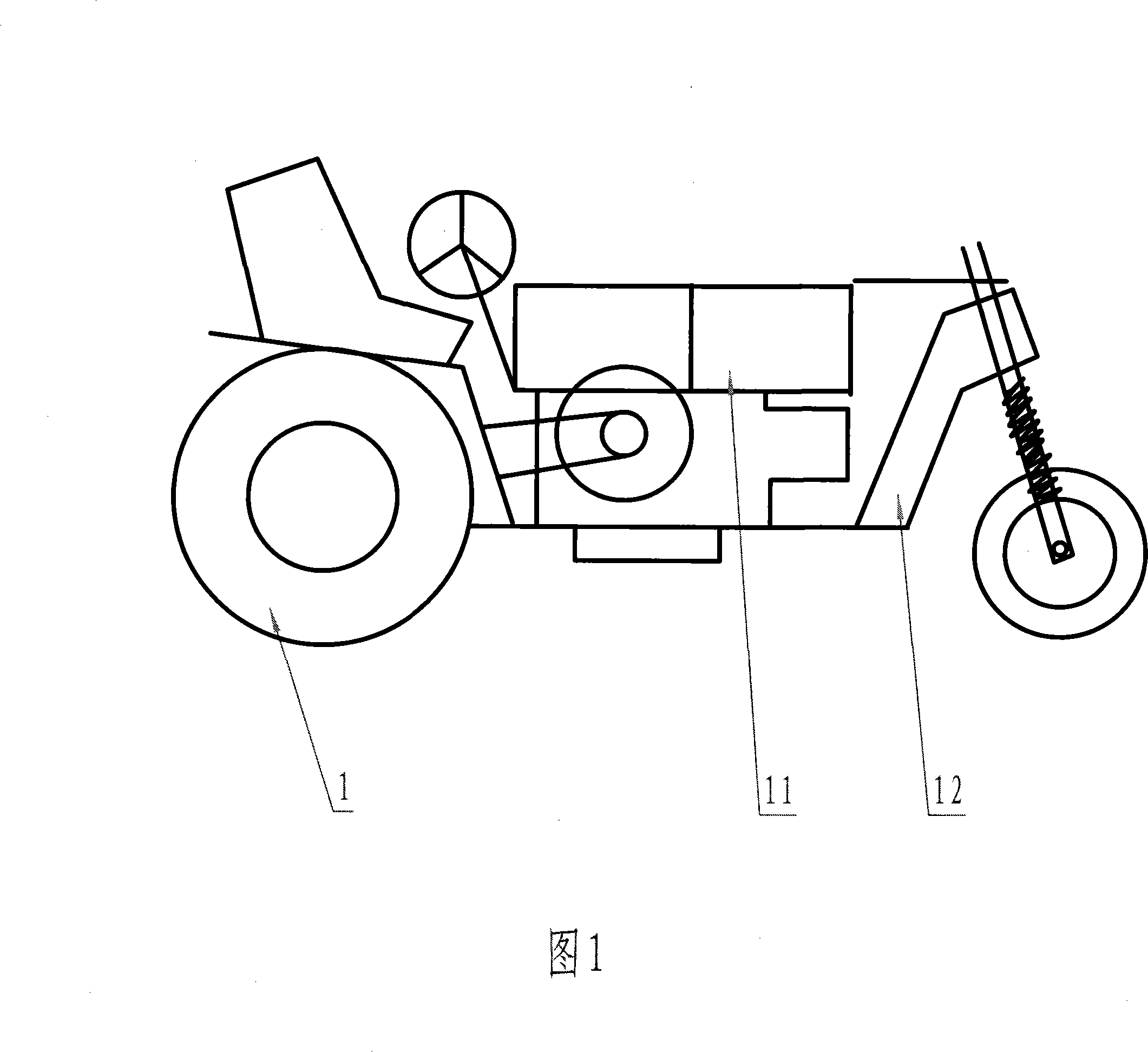

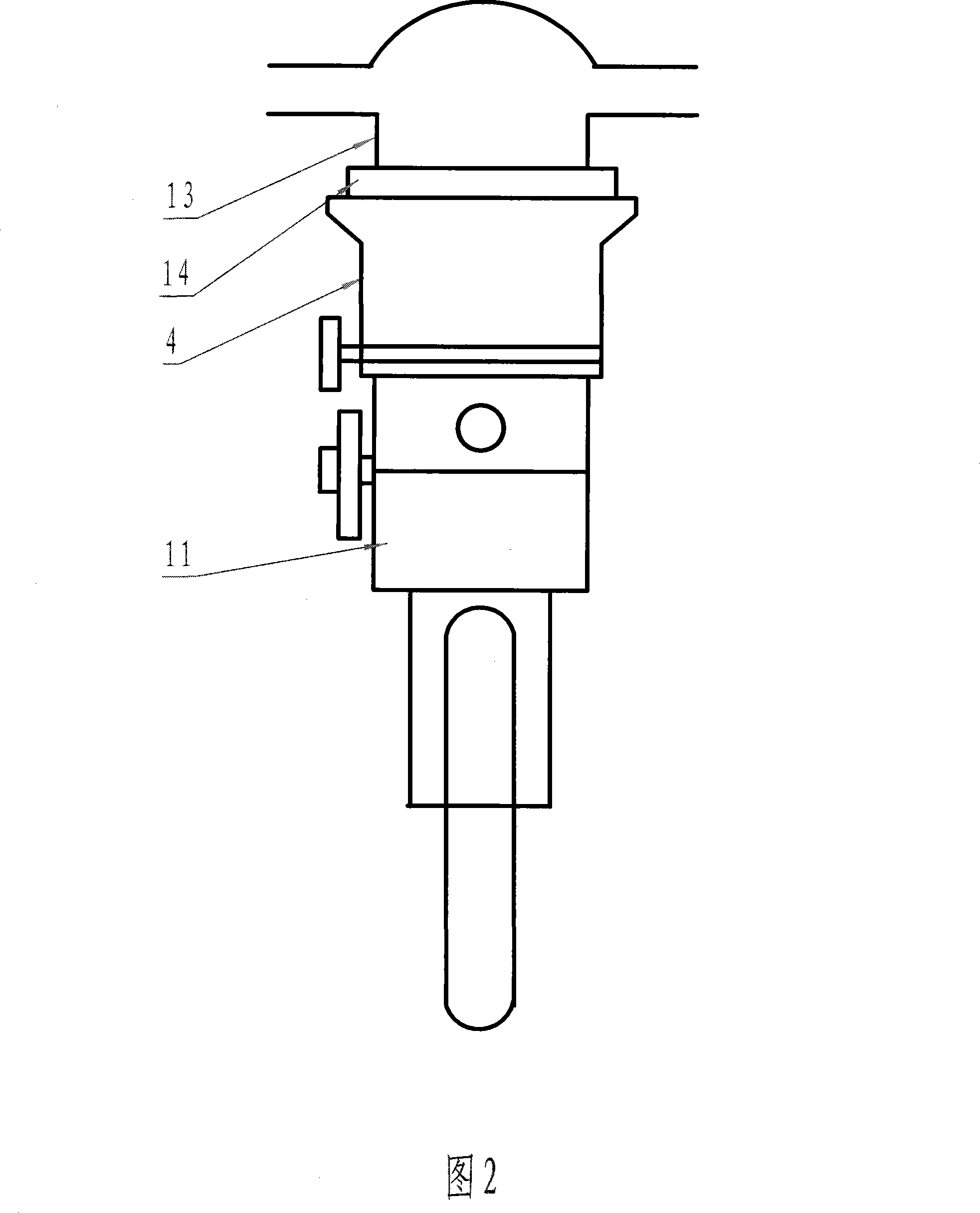

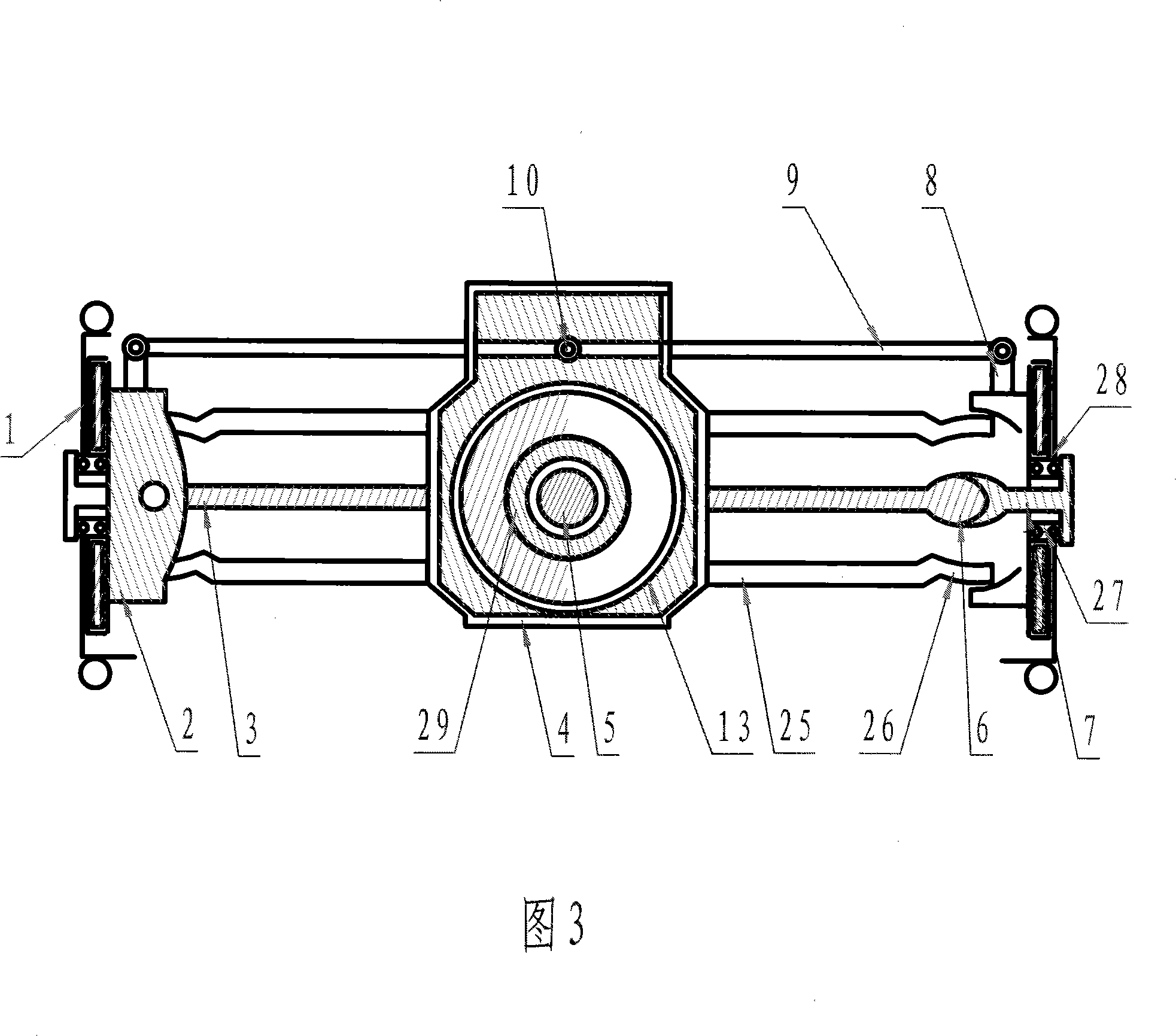

[0015] The front wheel steering assembly seat 12 of the present invention is fixed on the frame of the engine 11, and the frame of the engine 11 is fixed on the gearbox 4, and the final reducer housing 13 is connected with the gearbox 4 by the pressure ring 14 with bolts, and the final reducer The shell 13 is integrated with the spherical support seat 26 through the inner half shaft tube 25, and the left and right spherical support seats 26 are connected with the left and right steering knuckle shells 2 through the kingpin perforation, and the left and right steering knuckle shells 2 are integrated with the left and right steering knuckle journals 27. The moving plate is fixed to the left and right knuckle shells 2, the left and right knuckle journals 27 are connected to the left and right hubs 28 through bearings, the left and right hubs 28 are fixed to the left and right drive wheels 1, the left and right knuckle shells 2 are fixed to the left and right knuckle arms 8, and the...

Embodiment 2

[0017] When the utility model is used in hydraulic transmission, a hydraulic oil cylinder is installed between the main reducer housing 13 and the gearbox 4, and the upper and lower ends of the hydraulic oil cylinder are equipped with hydraulic pull arms, and the upper and lower ends of the hydraulic pull arms are connected with the main drive respectively. The reducer housing 13 is fixed to the gearbox 4, the output of the hydraulic pump passes through the hydraulic valve handle, and the hydraulic valve handle is activated to make the hydraulic oil cylinder rise and fall, and the main reducer housing 13 drives the drive wheel to move up and down through the balance drive axle.

Embodiment 3

[0019] When the utility model is used in a walking tractor, the front wheel steering assembly seat (12) is removed, and only the control handle is fixedly connected with the gearbox 4, and the two ends of the main reducer 16 are respectively connected with the jaw-type clutch, and the jaw-type The clutch is connected with the left and right inner half shafts 3 . The left and right steering pulls the clutch through the fork, the clutch is separated, and the left and right steering drives the driving wheel 1 to travel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com