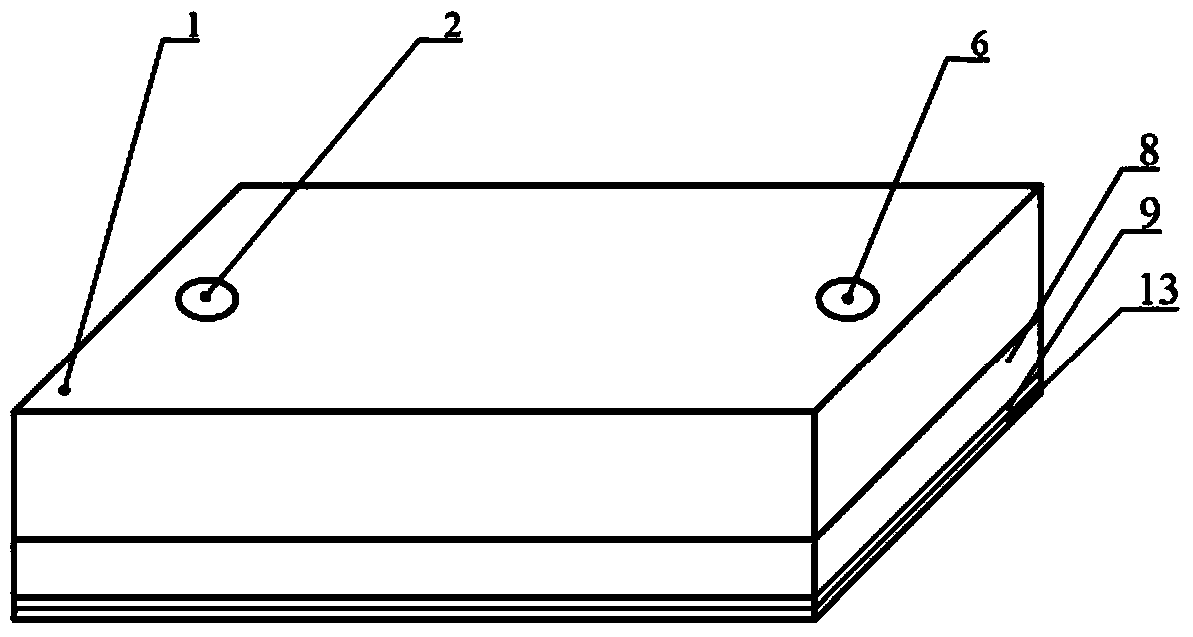

Steam-bubble-driven micro pump conducting heating through induction

A technology of induction heating and bubbles, which is applied to pumps, parts of pumping devices for elastic fluids, pump components, etc., can solve the problems of large pumping flow rate and difficult processing and production, and achieve large flow output and reduce Pollution sources and mechanical failures, the effect of achieving flow output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

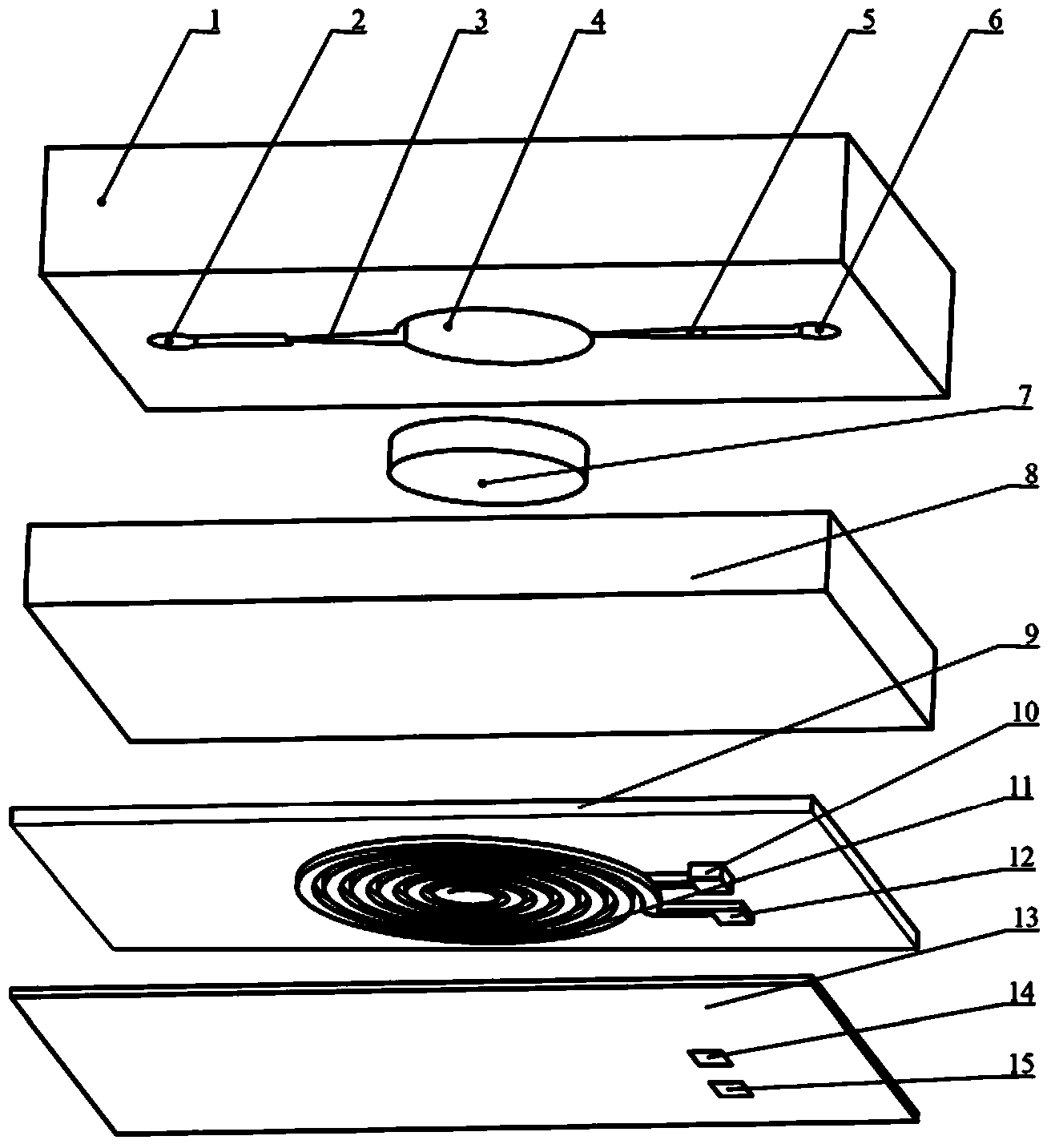

[0060] specific implementation plan

[0061] Micropump processing technology of the present invention is made, embodiment one

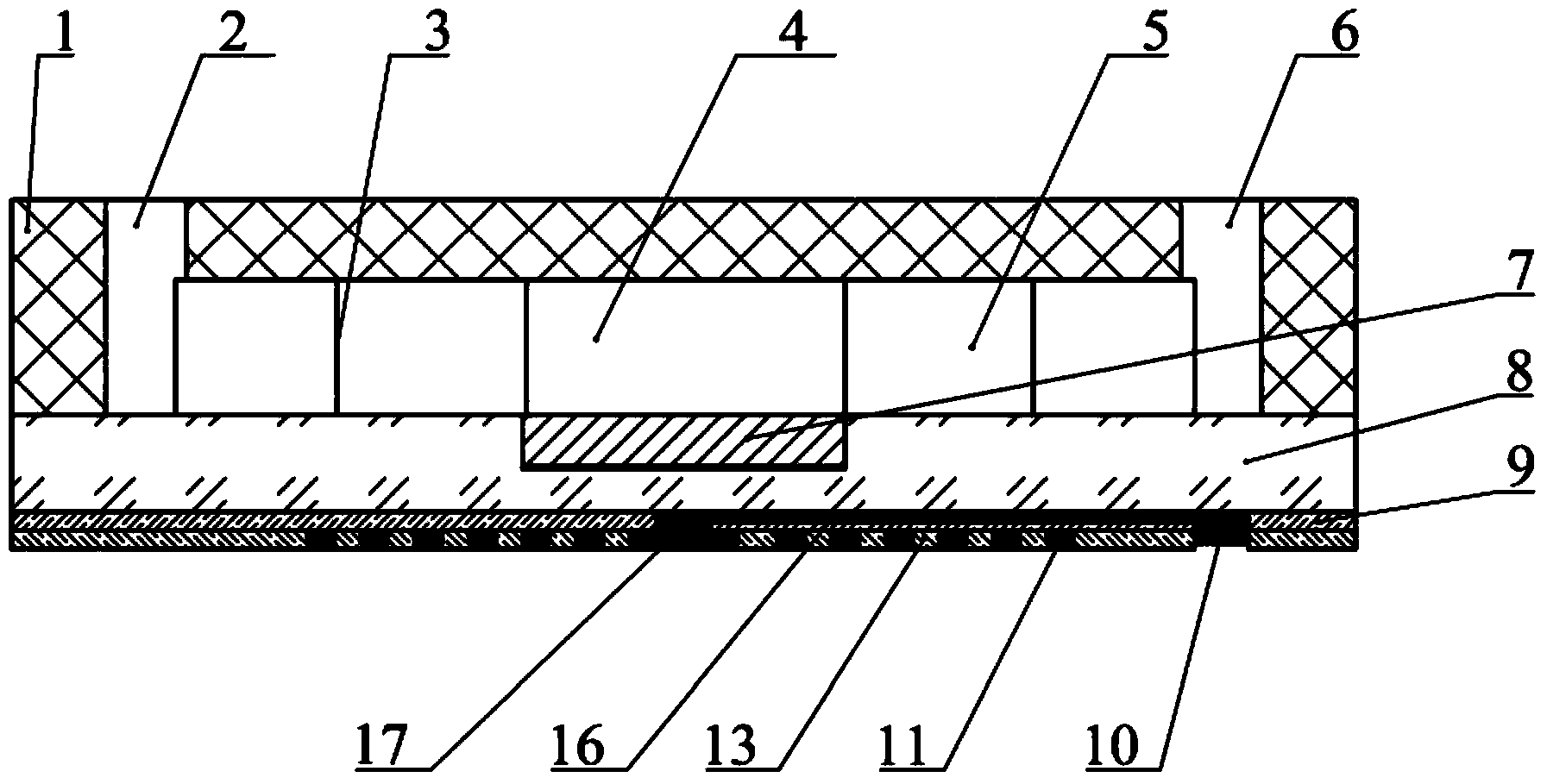

[0062] The microfluidic upper chip 1 in the present invention adopts SU-8 negative photoresist to make a positive mold, and polydimethylsiloxane (PDMS) injection molding process is used for manufacturing. The specific process flow is as follows:

[0063] (a) with Figure 14 , select silicon substrate I20 as the substrate, wash it with deionized water, and dry it on a rubber drying table at a temperature of 110°C;

[0064] (b) with Figure 15 , Spin coat a layer of SU-8 glue 21 on the silicon substrate I20, the thickness of the glue layer is 50μm-250μm, use a hot plate for pre-baking, first dry at a temperature of 65°C for 35min, and then bake at a temperature of 95°C The drying time is 30-90 minutes (related to the thickness of the adhesive layer, the greater the thickness, the longer the drying time), and then naturally cool to solidify the SU-8 a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com