Pipeline crawling welding robot

A welding robot and welding mechanism technology, applied in welding equipment, tubular objects, arc welding equipment, etc., can solve the problems of pipeline bends and slopes, high requirements, and failure to meet welding requirements, etc., and achieve the effect of strong load capacity and balanced operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

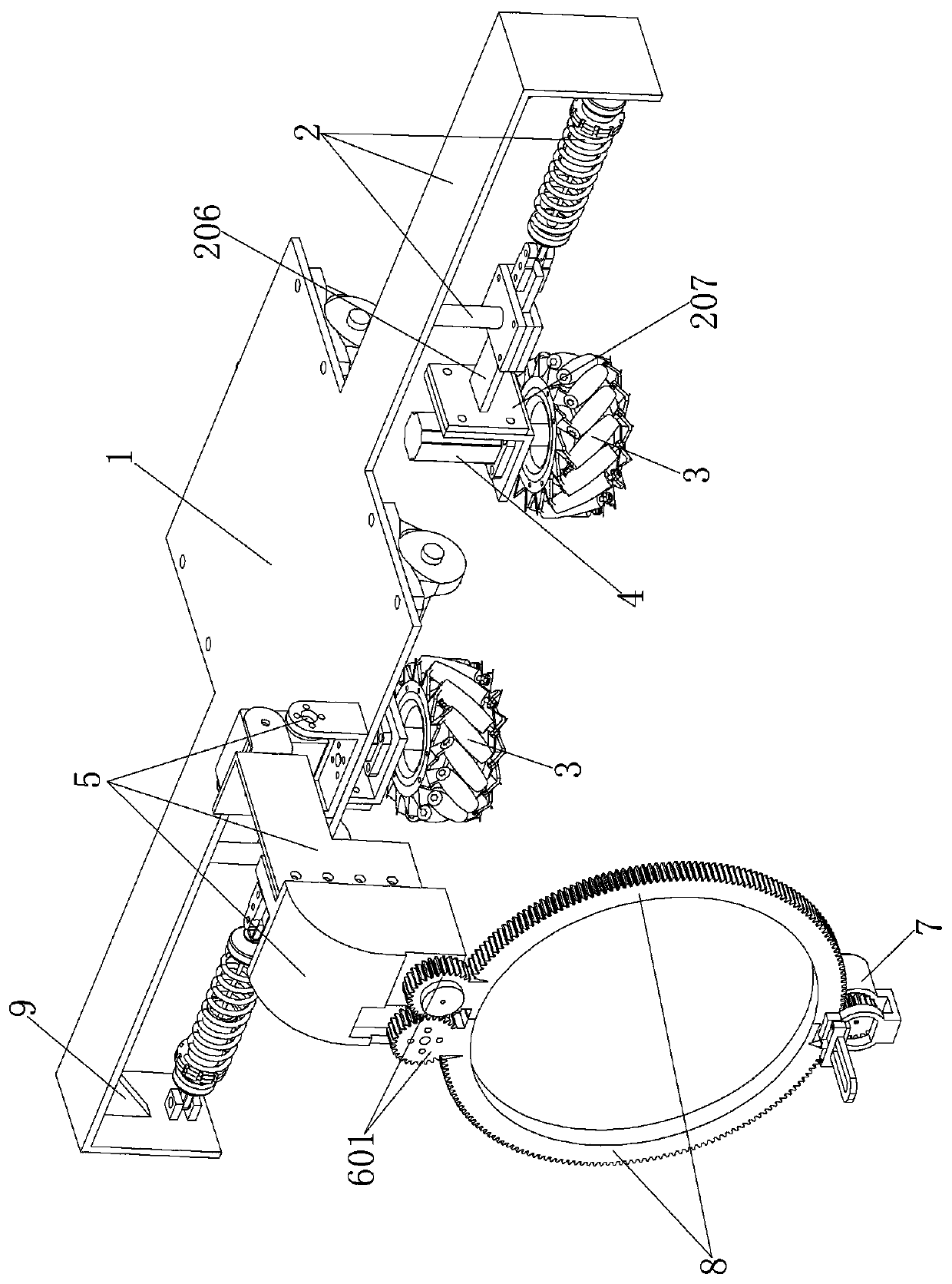

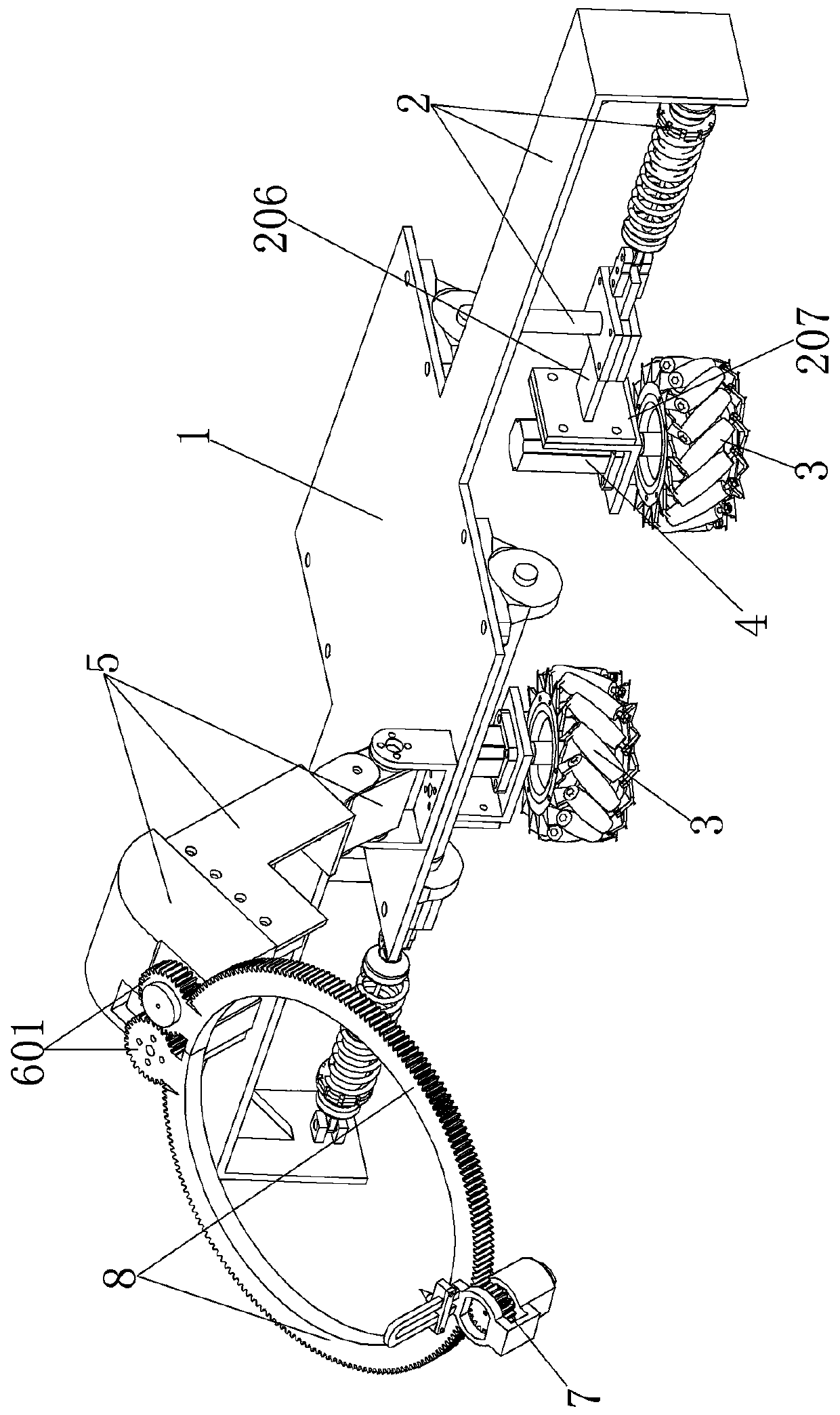

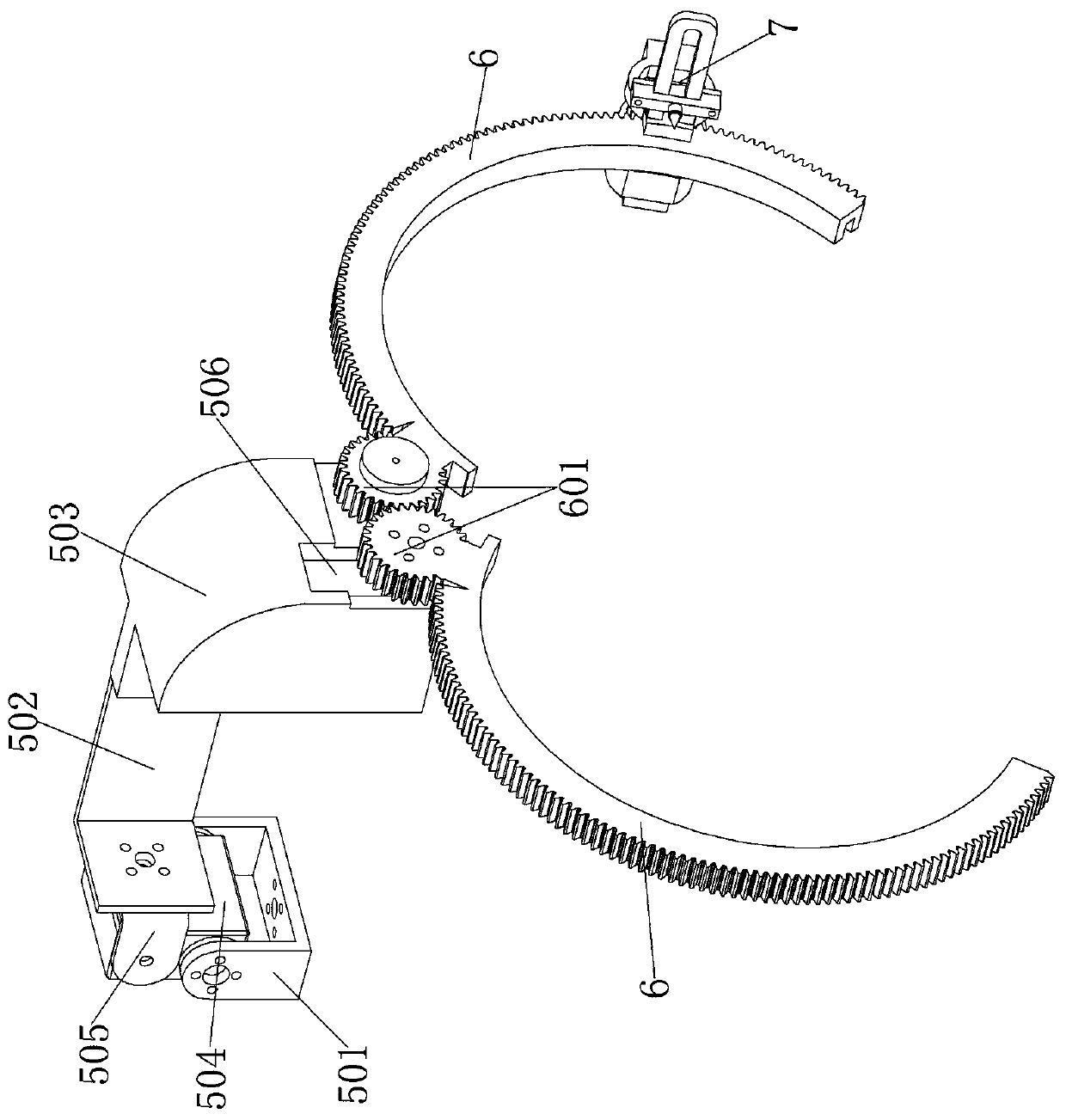

[0032]Embodiment 1, refer to the accompanying drawings (1-9) of the specification, a pipeline crawling welding robot, including a walking mechanism and a welding mechanism, the walking mechanism is used to drive the robot to move, and the welding mechanism is used to weld the pipeline. It is characterized in that: The walking mechanism described above includes a square plate-shaped walking platform, two symmetrically installed suspension devices at the lower ends of both sides of the walking platform, and two Mecanum wheels, and two symmetrical bearings are arranged on both sides of the front end of the bottom surface of the walking platform. seat, the two sides of the rear end of the bottom surface of the walking platform are also provided with two symmetrical bearing seats, and long rollers are installed between the symmetrical bearing seats, and the long rollers are pressed on the top of the pipeline to roll; the suspension device includes a suspension bracket, Suspension sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com