Preparation method of paving asphalt modified at normal temperature

A road asphalt and modification technology, which is applied to building insulation materials, building components, buildings, etc., can solve problems such as high production costs, high energy consumption, and health effects, and achieve shortened production cycles, energy savings, and protection environmental effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

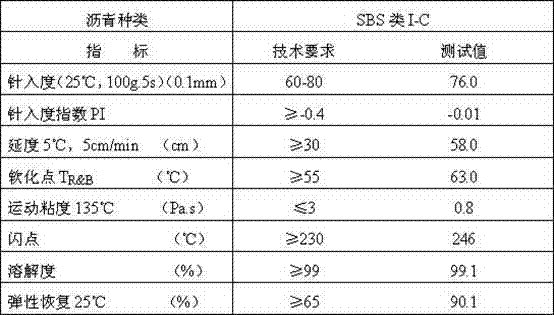

Examples

Embodiment 1

[0027] Put 150 kg of pine tar, 30 kg of heat stabilizer, and 2,700 kg of waste rubber powder into the horizontal rotary cracker, and stop heating after raising the temperature to 345°C; after the temperature in the horizontal rotary cracker drops to 320°C, keep the temperature constant for 2 hours , and then cooled naturally, and the evaporated gas is passed into the decompression bag for decompression separation, wherein the gas part enters the condensing system upwards to obtain condensate, and the water and polymer in the condensate are separated, and the obtained high The polymer is used as a diluent; add 3% of its own weight of dispersant W33 and 1.5% of accelerator CBS to the heavy component obtained by decompression separation, and stir evenly to obtain a polymer resin modifier.

[0028] Put 24,000 kg of 130-150°C base asphalt into the esterification reactor, then add 120 kg of polymer resin modifier and 1,320 kg of No. 10 asphalt, and stir for 30 minutes. When the temp...

Embodiment 2

[0030] Put 210 kg of pine tar, 60 kg of heat stabilizer, and 3,000 kg of waste rubber powder into the horizontal rotary cracker, and stop heating after raising the temperature to 355°C; after the temperature in the horizontal rotary cracker drops to 320°C, keep the temperature constant for 2 hours , and then cooled naturally, and the evaporated gas is passed into the decompression bag for decompression separation, wherein the gas part enters the condensing system upwards to obtain condensate, and the water and polymer in the condensate are separated, and the obtained high The polymer is used as a diluent; add 3% of its own weight of dispersant W33 and 1.5% of accelerator CBS to the heavy component obtained by decompression separation, and stir evenly to obtain a polymer resin modifier.

[0031] Put 10,000 kg of base asphalt at 130-150°C into the esterification reaction kettle, then add 50 kg of polymer resin modifier and 550 kg of No. 10 asphalt, and stir for 30 minutes. When ...

Embodiment 3

[0033] Put 180 kg of pine tar, 45 kg of heat stabilizer, and 2,760 kg of waste rubber powder into the horizontal rotary cracker, and stop heating after raising the temperature to 365°C; after the temperature in the horizontal rotary cracker drops to 320°C, keep the temperature constant for 2 hours , and then cooled naturally, and the evaporated gas is passed into the decompression bag for decompression separation, wherein the gas part enters the condensing system upwards to obtain condensate, and the water and polymer in the condensate are separated, and the obtained high The polymer is used as a diluent; add 3% of its own weight of dispersant W33 and 1.5% of accelerator CBS to the heavy component obtained by decompression separation, and stir evenly to obtain a polymer resin modifier.

[0034] Put 10,000 kg of base asphalt at 130-150°C into the esterification reaction kettle, then add 50 kg of polymer resin modifier and 550 kg of No. 10 asphalt, and stir for 30 minutes. When ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com