Reverse towing system and wind generating set

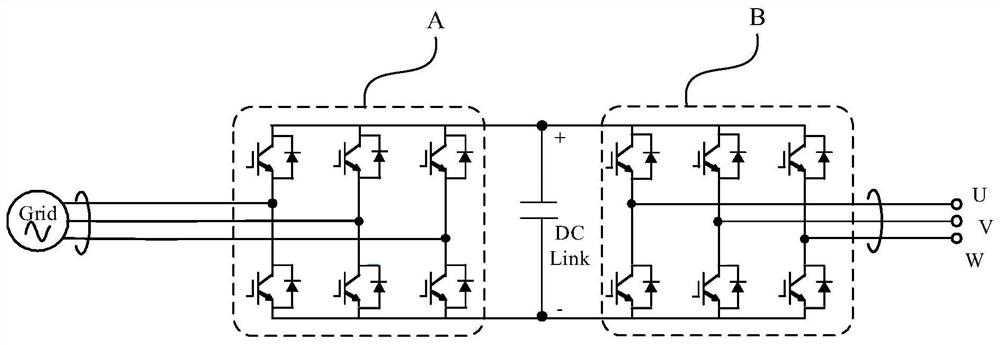

A wind turbine and electrical connection technology, applied in the field of converters, can solve problems such as weak load capacity, increased cost, current mismatch, etc., and achieve the effects of strong load capacity, reduced use, and stable output performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

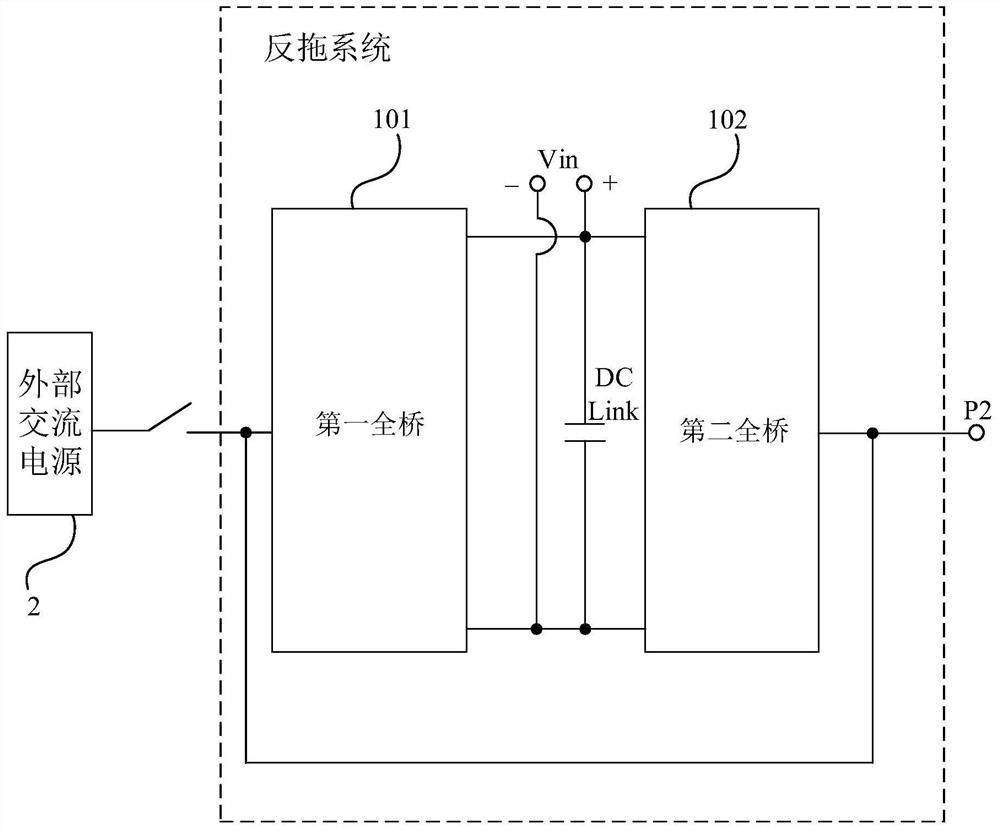

[0042] This embodiment provides an anti-drag system, and the anti-drag system includes a converter. refer to figure 2 , the converter includes a first full bridge 101, a second full bridge 102, and a DC bus DC Link. The first full bridge 101 and the second full bridge 102 are electrically connected back to back through a DC bus, that is, the DC port of the first full bridge 101 is electrically connected to the DC port of the second full bridge 102 . The AC port of the first full bridge 101 is disconnected from the external AC power supply 2; the AC port of the first full bridge 101 is electrically connected to the AC port of the second full bridge 102; the DC bus DC Link is used to electrically connect to an external DC power supply Vin ; The AC port of the second full bridge 102 is used as the output terminal P2 of the anti-drag system.

[0043] When the AC port of the first full bridge 101 is electrically connected to the external AC power supply 2, the AC port of the fir...

Embodiment 2

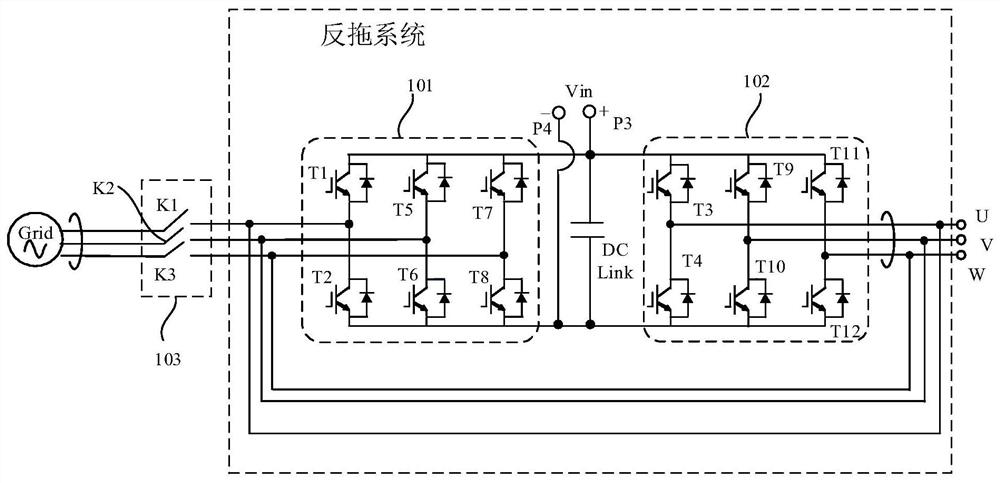

[0046] On the basis of Embodiment 1, this embodiment provides an anti-drag system. refer to image 3 , in the converter of the anti-drag system, both the first full bridge and the second full bridge are three-phase full bridges. In other optional implementation manners, both the first full bridge and the second full bridge are single-phase full bridges, multi-phase full bridges, multi-level full bridges, and the like.

[0047] The converter of the reverse drag system is disconnected from the external AC power supply through the second switch module 103 . The second switch module 103 includes a first switch K1, a second switch K2, and a third switch K3.

[0048] The first full bridge 101 includes a first phase AC terminal, a second phase AC terminal, and a third phase AC terminal; the second full bridge 102 includes a first phase AC terminal, a second phase AC terminal, and a third phase AC terminal. The first phase AC terminal, the second phase AC terminal, and the third ph...

Embodiment 3

[0055] On the basis of Embodiment 2, this embodiment provides an anti-drag system. refer to Figure 4 , the anti-drag system further includes a first switch module 104 . The AC port of the first full bridge is electrically connected to the AC port of the second full bridge through the first switch module.

[0056] As an optional implementation manner, the anti-drag system further includes a second switch module 103 ; the AC port of the first full bridge is disconnected from the external AC power supply through the second switch module 103 .

[0057] The second switch module 103 includes a first switch K1, a second switch K2, and a third switch K3; the first switch module 104 includes a fourth switch K4, a fifth switch K5, and a sixth switch K6.

[0058] The output terminals of the anti-drag system include a first phase output terminal U, a second phase output terminal V, and a third phase output terminal W. The external AC power supply includes a first phase terminal, a sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com