Planetary transmission swinging mechanism

A technology of slewing mechanism and planetary transmission, which is applied in the direction of transmission box, transmission device, transmission device parts, etc., can solve the problems of large volume, heavy weight, small torsion transmission capacity, etc., and achieve uniform load, compact axial size, radial small size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

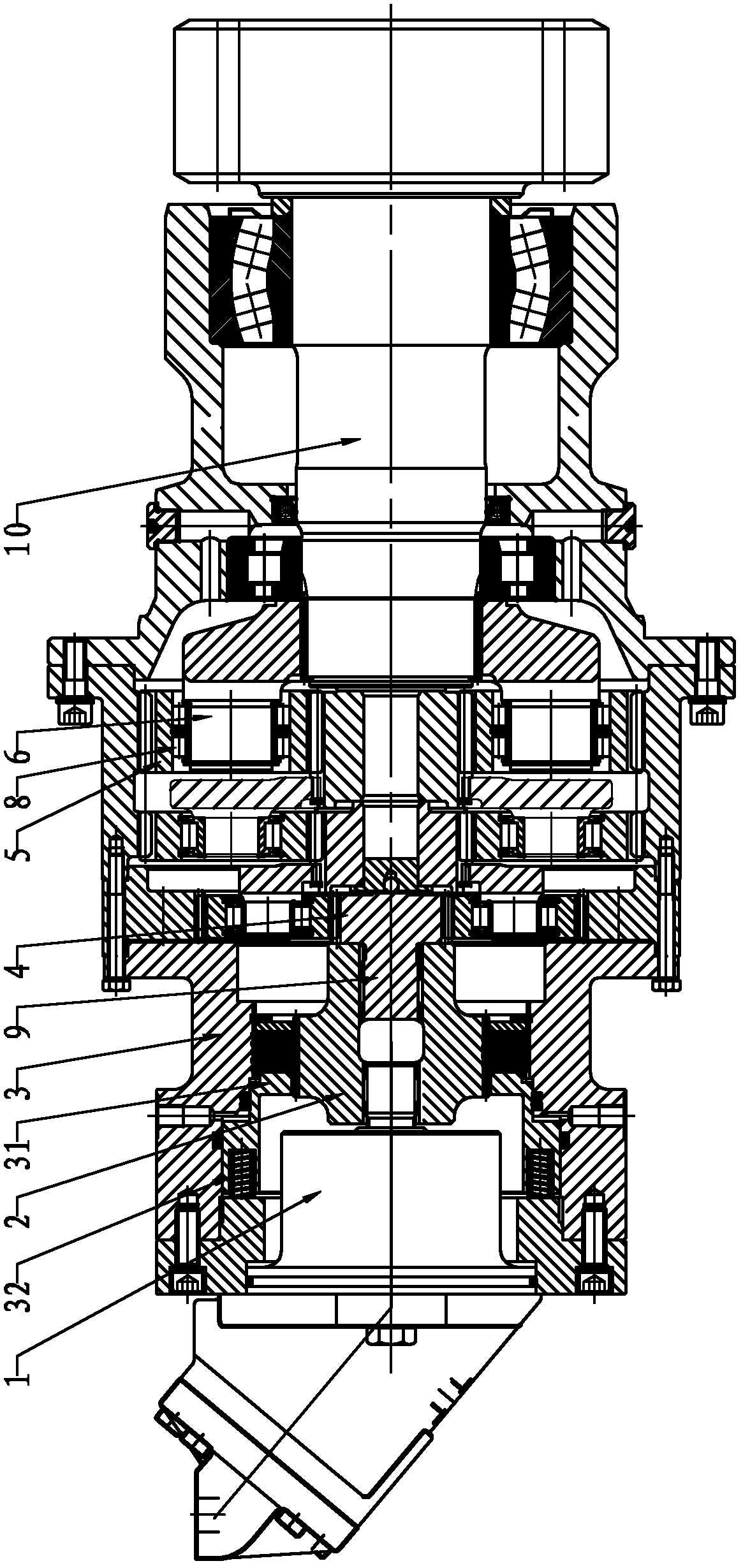

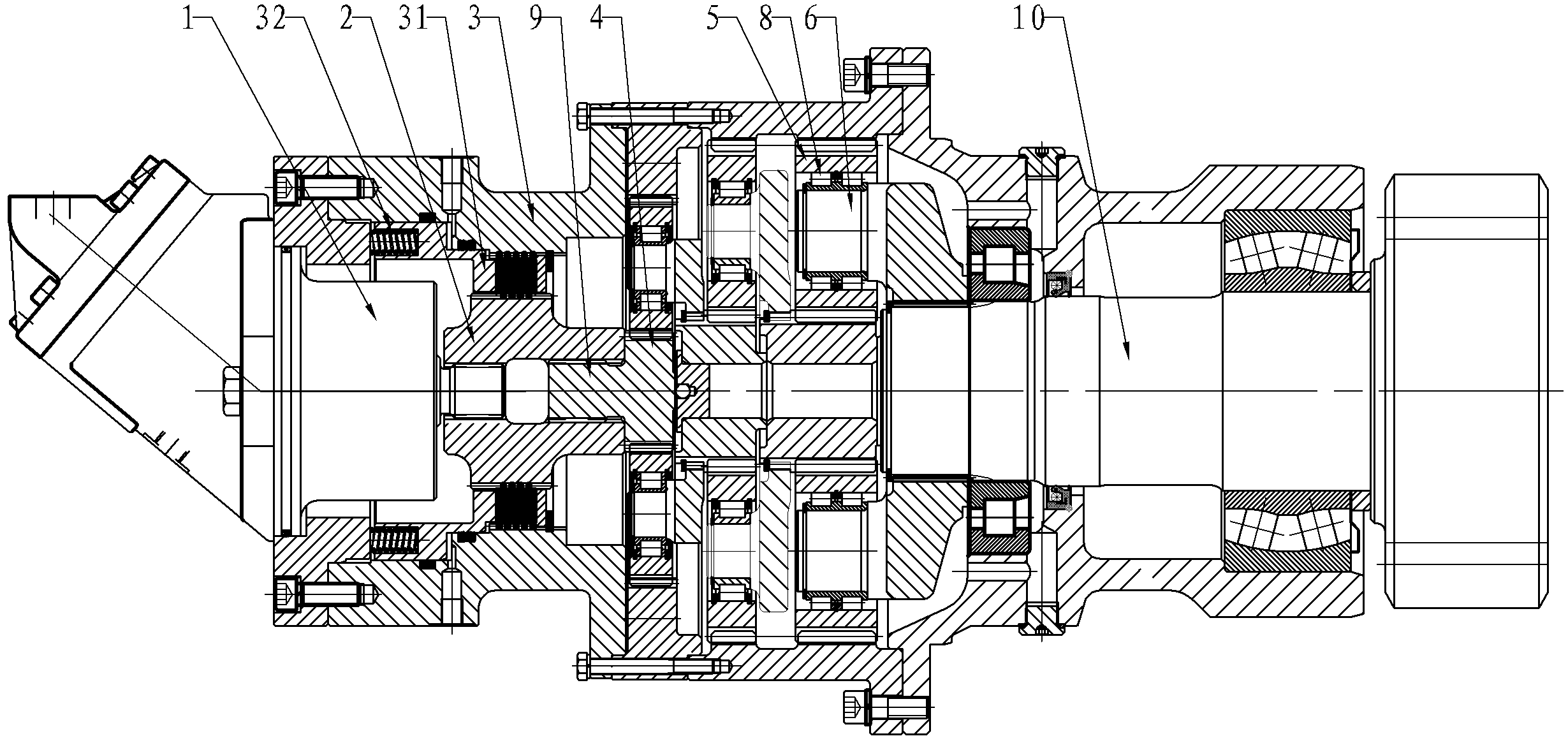

[0013] Such as figure 1 As shown, the planetary transmission slewing mechanism includes a motor 1, and also includes a coupling 2, a multi-plate friction brake 3, a multi-stage planetary reduction mechanism, and an output gear shaft 10. The motor 1 is connected to a main shaft 9 through the coupling 2 , the multi-plate friction brake 3 is assembled on the coupling 2; the sun gear 4 of the multi-stage planetary reduction mechanism is set on the main shaft 9, and the output end of the multi-stage planetary reduction mechanism is the planet carrier 6; the planet carrier 6 is connected by a spline An output gear shaft 10; the planet carrier in the multi-stage planetary reduction mechanism is provided with a cantilever, and the cantilever installs the planetary gear 5 through the bearing 8 without outer ring.

[0014] The pressure oil acts on the piston 31 of the multi-plate friction brake to open the multi-plate friction brake 3. When the motor 1 transmits the power to the couplin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com