Cut deal high-order steel tapping machines

A tapping machine and high-level technology, applied in furnaces, heat treatment equipment, heat treatment furnaces, etc., can solve the problems of shortening the roller table and buffer device, large impact and noise of the roller table, unmatched heating furnace structure, etc., so as to improve the service life , avoid collisions, and brake reliably

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

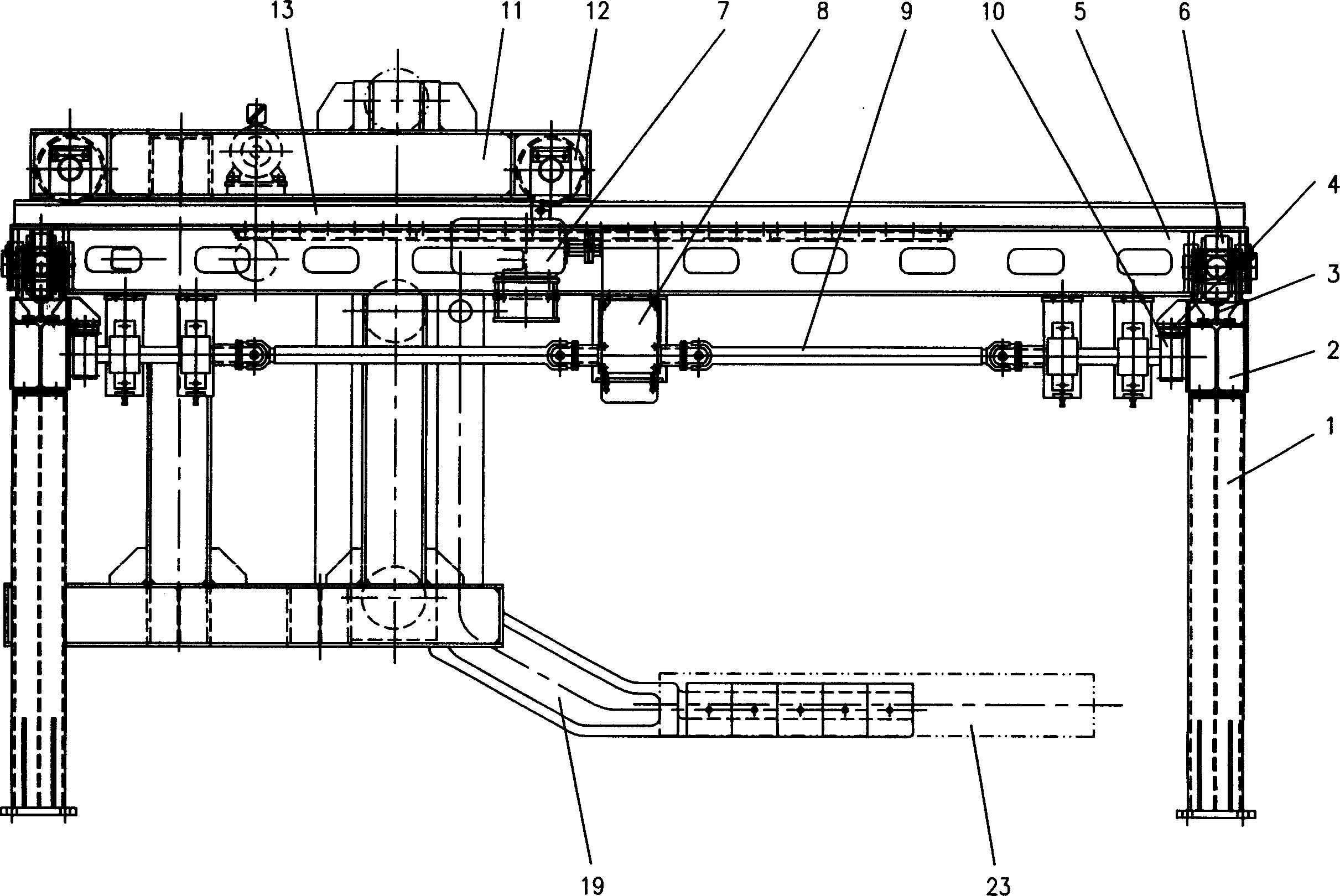

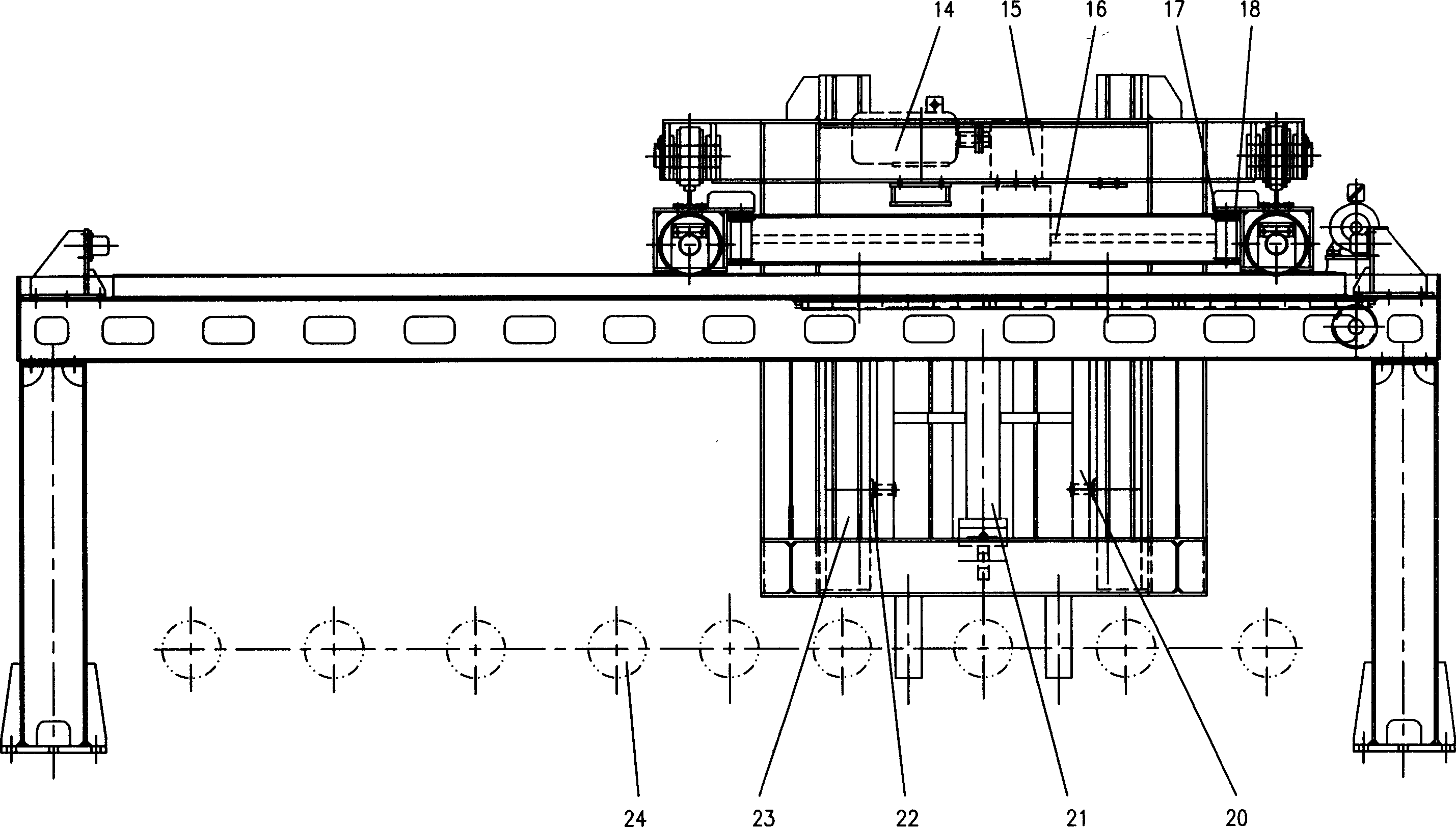

[0014] A high-position steel tapping machine for medium and thick plates, which is composed of a traveling beam, a cart, a trolley, and a lifting mechanism. The traveling beam consists of a column 1, a crossbeam 2, a cart running track 3 and a rack 4 inside the crossbeam (the teeth face downward) constitute. The cart is supported by a glyph-shaped beam body 5, and the glyph-shaped beam body is supported on the cart running track 3 by four passive wheels 6 at four corners. The cart transmission system consists of a motor 7, a reducer 8, and a universal joint shaft 9 , Gear 10 constitutes. When the motor 7 rotates, it drives the reducer 8, the universal joint shaft 9 and the gear 10 to rotate, and the gear 10 meshes with the rack 4 (tooth down) on the inside of the beam to drive the cart to walk.

[0015] Dolly is also supported on the cart track 13 by four driven wheels 12 on the four corners by the zigzag beam body 11, the zigzag beam body. The trolley transmission system is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com