Mechanical butt joint device

A docking device and mechanical technology, used in workpiece clamping devices, assembling machines, metal processing equipment, etc., can solve problems such as poor adaptability, inability to apply to railless workshops, and difficulty in meeting the requirements of rapid product response, to ensure reliable manufacturing. The effect of moving and improving the safety of docking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

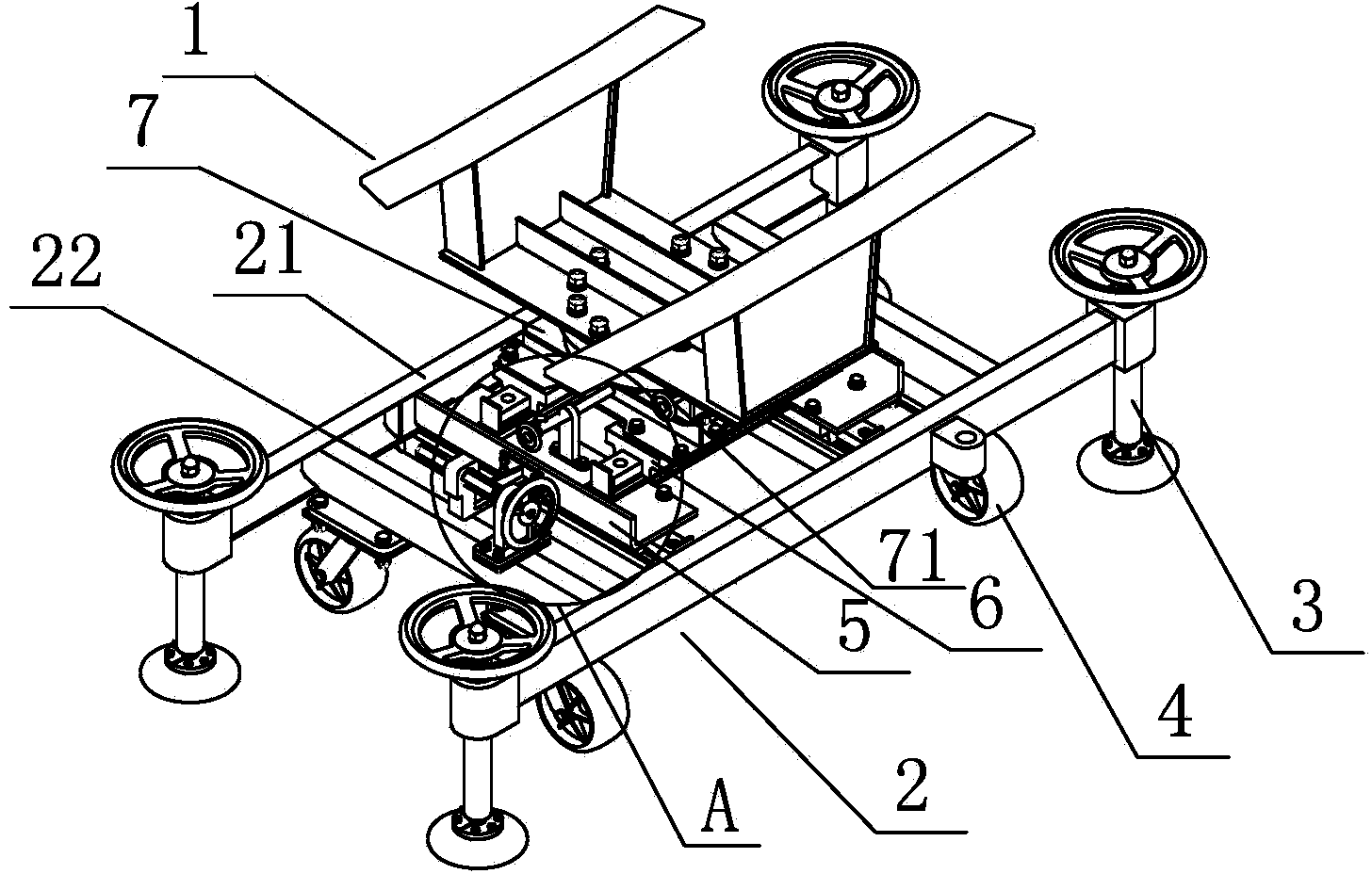

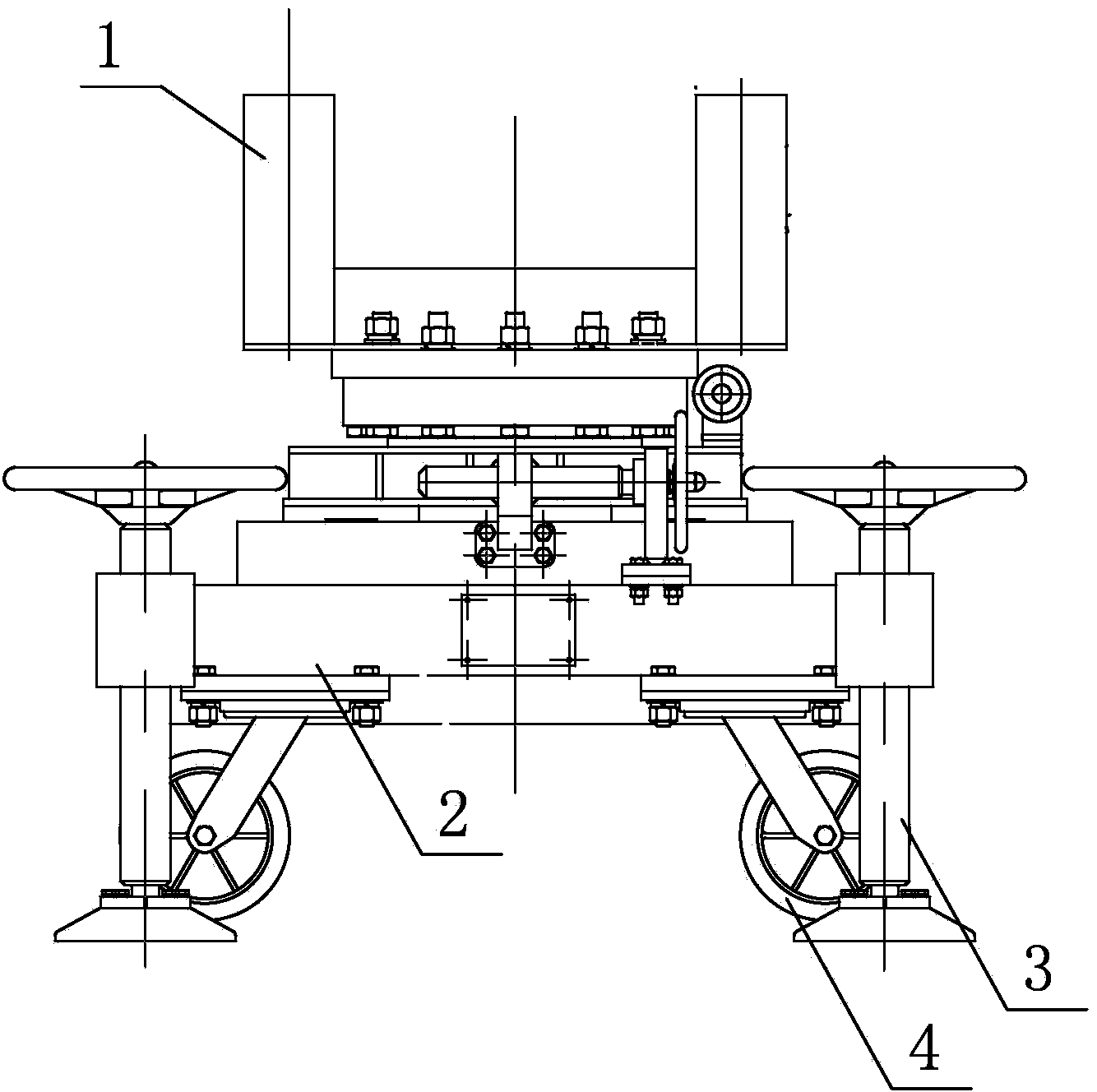

[0026] Such as Figure 1-3 As shown, the mechanical docking device of this embodiment includes a supporting plate 1 for clamping the docking parts, an underframe 2 carrying the supporting plate 1, a supporting leg 3 supporting the underframe 2 and a bottom frame installed at the bottom of the underframe 2. The universal wheel 4 and the chassis 2 include two longitudinal beams 21 parallel to each other. Two parallel beams 22 are arranged in the middle of the longitudinal beams 21. The cross beams 22 are perpendicular to the longitudinal beams 21. The ends of the longitudinal beams 21 are provided with supporting legs 3. , the support leg 3 is a screw lifting mechanism, and the docking device also includes an adjustment device for adjusting the docking angle of the support plate 1, and the adjustment device includes:

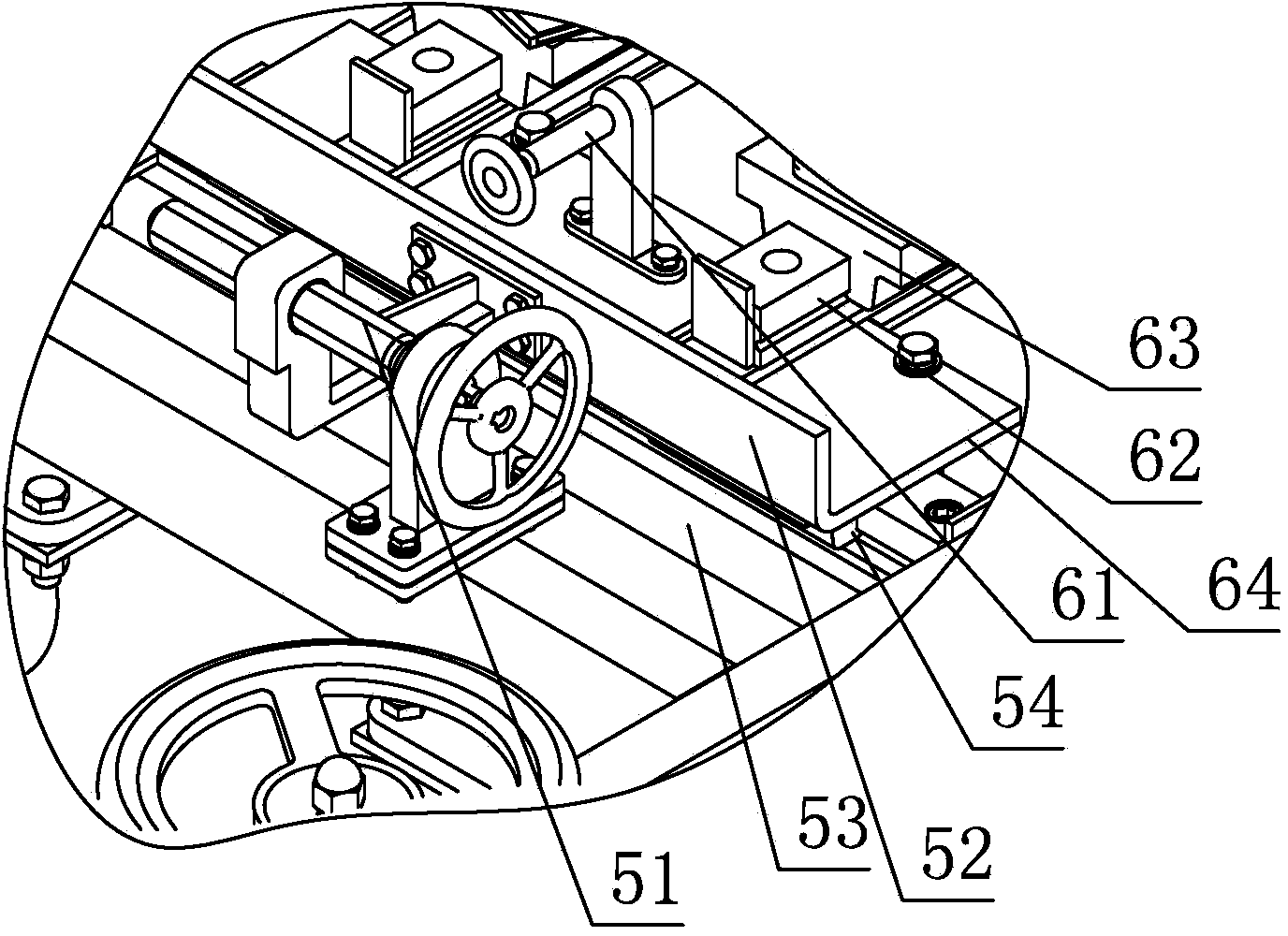

[0027] Lateral adjustment device 5

[0028] The horizontal adjustment device 5 installed on the chassis 2, the horizontal adjustment device 5 includes two horizo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com